Mahogany Wood Density Kg/M3: Uncover the Heft!

Mahogany wood has a density ranging from 600 to 900 kg/m³. This variation depends on the specific species and moisture content.

Mahogany is a highly prized hardwood known for its rich color and durability. Originating primarily from Central and South America, it has been a favorite in furniture making and cabinetry for centuries. Its fine grain and natural luster make it aesthetically appealing for both traditional and modern designs.

Beyond its beauty, mahogany is resistant to decay and insects, making it a practical choice for long-lasting projects. Understanding the density of mahogany wood is crucial for builders and craftsmen, as it affects workability, strength, and overall performance in various applications. This guide will delve deeper into the characteristics and uses of mahogany wood.

Mahogany Wood Basics

Mahogany wood is prized for its beauty and durability. Known for its rich color, this wood is a favorite in furniture making. Understanding the basics of mahogany helps appreciate its value.

Species And Characteristics

Several species contribute to the mahogany family. Each species has unique traits.

- Swietenia macrophylla – Commonly known as Honduras mahogany.

- Swietenia mahagoni – Known as the Caribbean mahogany.

- Swietenia humilis – Often called the small-leaved mahogany.

Key characteristics of mahogany wood include:

| Characteristic | Description |

|---|---|

| Color | Rich reddish-brown that deepens over time. |

| Grain | Straight with a fine, even texture. |

| Durability | Highly resistant to decay and insects. |

| Density | Averages around 600-900 kg/m³. |

Global Distribution

Mahogany trees grow in tropical regions. Their primary habitats include:

- Central America

- South America

- Parts of the Caribbean

These areas provide ideal conditions for mahogany growth. The wood’s popularity has led to extensive logging. Efforts are ongoing to promote sustainable practices.

Conservation efforts help ensure future availability. Understanding global distribution aids in responsible sourcing.

Physical Properties Of Mahogany

Mahogany wood is known for its unique physical properties. Its stunning appearance and durability make it a popular choice. Understanding these properties helps in choosing the right applications for this beautiful wood.

Color And Texture

Mahogany wood displays a rich, warm color. The shades range from light brown to deep reddish-brown. This color deepens over time, adding to its charm.

The texture of mahogany is smooth. It has a fine, even grain that enhances its aesthetic appeal. This wood polishes beautifully, making it ideal for furniture and cabinetry.

Here’s a quick overview of its color and texture:

| Property | Description |

|---|---|

| Color | Light brown to deep reddish-brown |

| Texture | Fine, even grain; smooth finish |

Durability Factors

Mahogany is highly durable. It resists moisture and decay, making it suitable for various environments. This wood is also resistant to insect attacks.

Key durability factors include:

- Resistance to Rot: Ideal for outdoor furniture.

- Insect Resistance: Keeps pests away.

- Stability: Less prone to warping.

- Longevity: Lasts for many years.

In summary, mahogany’s physical properties make it an excellent choice for furniture, cabinetry, and more.

Measuring Wood Density

Measuring wood density is essential for understanding wood properties. Density affects strength, durability, and workability. For mahogany wood, density significantly influences its popularity in furniture making.

Importance Of Density

Density defines how heavy a material is for its size. Higher density means stronger and more durable wood. Here are key reasons why density matters:

- Strength: Denser wood can withstand more pressure.

- Durability: Higher density wood lasts longer.

- Workability: Density affects how easy it is to cut and shape wood.

- Cost: Denser woods often have higher market value.

Units And Conversion

Wood density is usually measured in kilograms per cubic meter (Kg/m³). Understanding how to convert between units is important. Here’s a simple conversion guide:

| Measurement Type | Value in Kg/m³ |

|---|---|

| Lightweight Wood | 200 – 400 Kg/m³ |

| Medium Density Wood | 400 – 800 Kg/m³ |

| Heavyweight Wood | 800 – 1200 Kg/m³ |

To convert between units, use this formula:

Density (Kg/m³) = Mass (Kg) / Volume (m³)

Understanding density helps in selecting the right wood for your project.

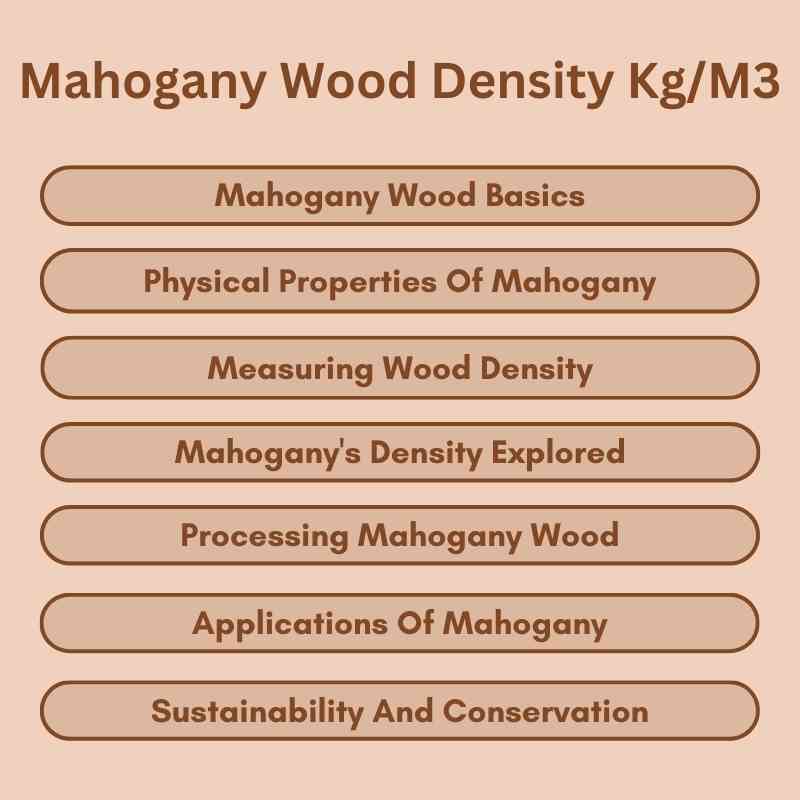

Mahogany’s Density Explored

Mahogany wood is famous for its beauty and strength. Understanding its density is crucial for various applications. This section dives into the density of mahogany, measured in kg/m³, and its significance.

Comparative Analysis

The density of mahogany typically ranges from 600 to 900 kg/m³. Here’s a comparison with other popular woods:

| Wood Type | Density (kg/m³) |

|---|---|

| Mahogany | 600 – 900 |

| Oak | 700 – 900 |

| Pine | 350 – 650 |

| Maple | 600 – 750 |

Mahogany’s density makes it heavier than some woods. This quality contributes to its durability. Lighter woods, like pine, are easier to handle. However, they may lack the strength of mahogany.

Impact On Woodworking

Understanding mahogany’s density affects woodworking projects. Here are some key points:

- Stability: Mahogany resists warping and shrinking.

- Finishing: Its density allows for a smooth finish.

- Tools: Requires sharp tools for precise cuts.

- Weight: Heavier pieces may need additional support.

Woodworkers appreciate mahogany for its workability. It holds screws and nails well. The wood can be sanded to a fine finish. This makes it ideal for furniture and cabinetry.

In summary, mahogany’s density plays a vital role in its characteristics. Understanding this helps in selecting the right wood for your projects.

Factors Affecting Mahogany’s Density

Mahogany wood is valued for its rich color and durability. Its density varies widely based on several factors. Understanding these factors helps in selecting the right wood for projects.

Growth Conditions

Mahogany thrives in specific environmental conditions. These conditions significantly influence its density.

- Soil Type: Rich, well-drained soils lead to denser wood.

- Climate: Warm, humid climates promote faster growth.

- Water Availability: Adequate rainfall enhances wood density.

Different regions produce mahogany with varying densities. Forests in Central America yield denser wood than those in Asia.

Age And Maturity

The age of the mahogany tree affects its density. Older trees typically have denser wood.

- Young Trees: Less dense, softer wood.

- Mature Trees: Denser, harder wood.

Harvesting mahogany at the right age is crucial. It ensures the best quality and density.

| Tree Age (Years) | Density (Kg/m³) |

|---|---|

| 5 | 450 |

| 10 | 650 |

| 20 | 850 |

Choosing mahogany with the right density ensures strong and beautiful results.

Processing Mahogany Wood

Processing Mahogany wood requires careful attention. This wood is known for its beauty and strength. Understanding its properties helps in effective usage.

Drying And Its Effects

Drying Mahogany wood is crucial for quality. Proper drying prevents warping and cracking. Here are some key points:

- Air Drying: Slower but maintains natural color.

- Kiln Drying: Faster and reduces moisture content.

- Target Moisture Content: Aim for 6-8% for best results.

Improper drying can lead to:

- Increased susceptibility to pests.

- Loss of natural luster.

- Dimensional instability.

Choosing the right drying method is essential. It ensures the wood remains durable and visually appealing.

Machining Challenges

Machining Mahogany wood can be tricky. Its density affects cutting tools and techniques. Key challenges include:

- Tool Wear: Tools may dull quickly.

- Splintering: Can occur if not handled carefully.

- Dust Production: Generates fine dust that can irritate.

To overcome these challenges:

- Use sharp tools.

- Apply lubrication during cutting.

- Wear protective gear.

Effective machining leads to better finishes. It showcases the rich color and grain patterns of Mahogany wood.

Applications Of Mahogany

Mahogany wood is well-known for its beauty and strength. Its density, around 600-800 kg/m³, makes it perfect for various applications. This wood is highly valued in both furniture making and musical instrument production.

Furniture And Cabinetry

Mahogany is a popular choice for furniture and cabinetry. Its rich color and fine grain add elegance to any space. Many people prefer it for:

- Tables

- Chairs

- Cabinets

- Desks

- Dressers

Furniture made from mahogany is durable and resistant to damage. This wood can withstand wear and tear over time. Its natural luster enhances the aesthetic appeal of any room.

Musical Instruments

Mahogany is also used in crafting musical instruments. Its acoustic properties contribute to rich sound quality. Common instruments made from mahogany include:

- Guitars

- Pianos

- Drum shells

- Violins

The density of mahogany provides excellent resonance. Musicians appreciate its warm tones and rich sound. This wood helps create beautiful music.

Sustainability And Conservation

Mahogany wood is prized for its beauty and durability. Its popularity raises concerns about sustainability. Responsible practices ensure the preservation of mahogany forests for future generations. Understanding these practices is key to protecting our environment.

Logging Practices

Logging practices greatly impact mahogany wood sustainability. Here are some important points:

- Selective Logging: This method removes only mature trees. It protects young trees and biodiversity.

- Reduced Impact Logging: This practice minimizes damage to the surrounding area. It helps maintain forest health.

- Illegal Logging: This poses a major threat to mahogany forests. It leads to habitat destruction and loss of biodiversity.

Certification And Management

Certification programs help ensure sustainable mahogany sourcing. They promote responsible forest management. Some key certifications include:

| Certification | Purpose |

|---|---|

| FSC (Forest Stewardship Council) | Promotes responsible forest management. |

| PEFC (Programme for the Endorsement of Forest Certification) | Supports sustainable forest practices globally. |

These certifications ensure mahogany wood comes from well-managed forests. They protect wildlife and plant species. Consumers can make informed choices by looking for these labels.

Frequently Asked Questions

What Is The Density Of Mahogany Wood?

The density of mahogany wood typically ranges from 600 to 900 kg/m³. This variation depends on the specific species and growing conditions. Generally, denser mahogany offers better durability and resistance to wear, making it ideal for furniture and cabinetry.

Why Is Mahogany Wood So Popular?

Mahogany wood is popular for its beauty, durability, and workability. Its rich color and fine grain enhance the aesthetics of furniture. Additionally, mahogany is resistant to warping and pests, which adds to its appeal in high-quality woodworking projects.

How Does Mahogany Compare To Other Woods?

Mahogany is denser and more durable than many softwoods, like pine. It also has a unique, warm color that sets it apart from other hardwoods. While it is more expensive than some alternatives, its longevity and visual appeal often justify the investment.

Can Mahogany Wood Be Used Outdoors?

While mahogany can withstand outdoor conditions, proper treatment is essential. Applying a protective finish helps prevent moisture damage and UV fading. For outdoor furniture, consider using specific mahogany species that are more resistant to weather elements.

Conclusion

Understanding mahogany wood density is crucial for various applications. Its impressive weight and durability make it a favorite among craftsmen and builders. Choosing the right density can enhance your project’s quality and longevity. By considering these factors, you can make informed decisions when selecting mahogany wood for your needs.