MDF Vs Birch Plywood: The Ultimate Smart Decision

For a smooth, paintable surface at a low cost, choose MDF—it’s perfect for cabinet doors and decorative trim in dry areas. For projects needing superior strength, screw-holding power, and the beauty of real wood grain, choose Birch Plywood. It excels for cabinet boxes, shelves, and furniture that need to last.

Walking down the lumber aisle can feel overwhelming. You see big sheets of wood, but they all look a little different. Two of the most common choices you’ll face are MDF and Birch Plywood. You might wonder, which one is right for my project? It’s a question every single woodworker asks at the beginning.

Choosing the wrong material can lead to wobbly shelves, peeling paint, or a project that just doesn’t hold up over time. It can be frustrating. But don’t worry, you’re in the right place. I’m here to walk you through the differences in plain, simple terms. Together, we’ll figure out exactly which board is best for your specific needs, so you can build with confidence. Let’s get started!

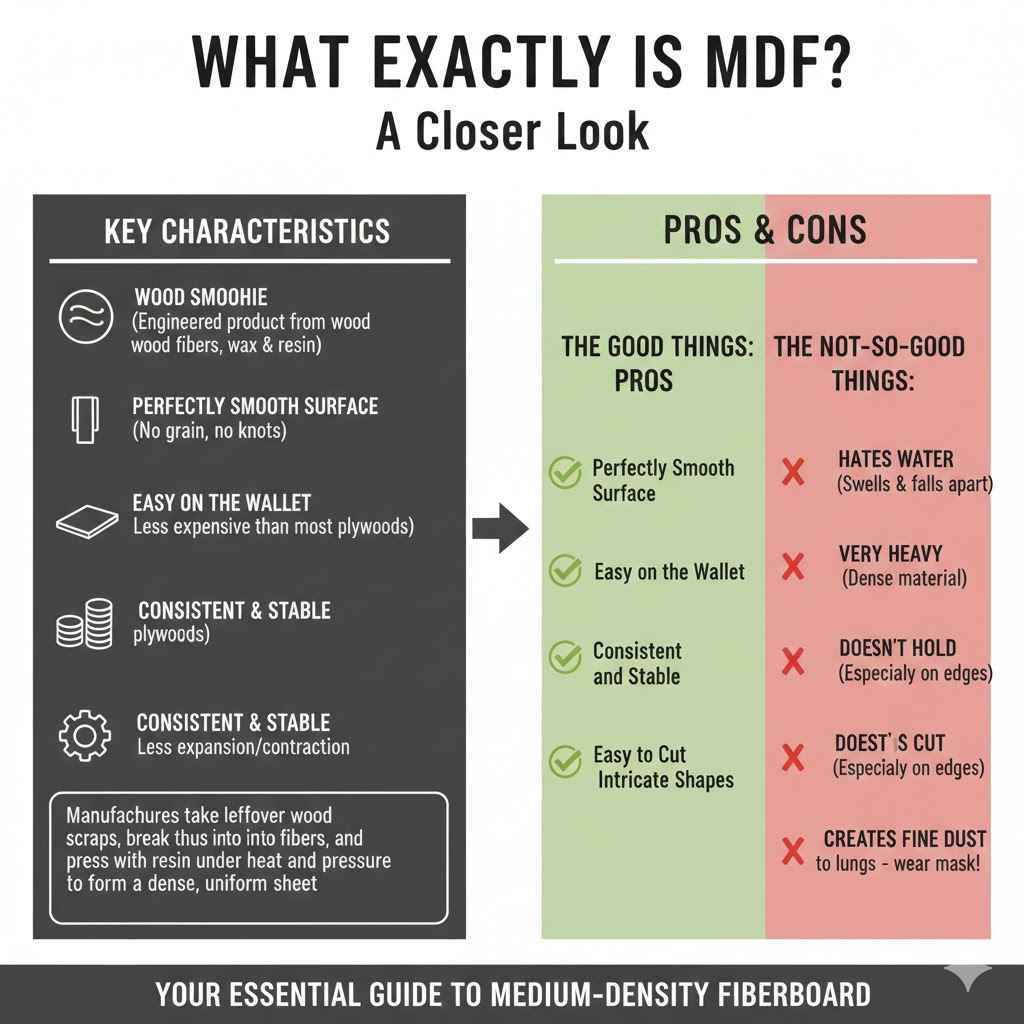

What Exactly Is MDF? A Closer Look

Let’s demystify one of the most common materials in the workshop: Medium-Density Fiberboard, or MDF. Thinking of it as a “wood smoothie” is a great way to start. It’s not a traditional board cut from a log. Instead, it’s an engineered product.

Manufacturers take leftover wood scraps—like sawdust and shavings—and break them down into tiny wood fibers. They then mix these fibers with wax and a strong resin binder. This mixture is pressed together under high heat and pressure to form a dense, uniform, and very flat sheet. There is no wood grain, no knots, and no imperfections. It’s a completely consistent material from edge to edge.

The Good Things: Pros of Using MDF

MDF has become popular for good reasons, especially for certain types of projects. Here’s why many woodworkers keep a few sheets on hand.

Perfectly Smooth Surface: The number one advantage of MDF is its flawless surface. It’s completely flat and free of any wood grain or knots. This makes it an ideal canvas for paint. You can achieve a glass-smooth finish that’s difficult to get on regular wood.

Easy on the Wallet: Generally, MDF is less expensive than most plywoods, including birch. When you have a large project or are working on a tight budget, these savings can really add up.

Consistent and Stable: Because it’s an engineered product, MDF is very stable. It doesn’t expand and contract with changes in humidity and temperature as much as solid wood does. It’s also free of voids or knots you might find in plywood.

Easy to Cut Intricate Shapes: MDF cuts very smoothly. You can use a router to create detailed edges or a jigsaw to cut curves without worrying about the material splintering or tearing out, which can happen with plywood.

The Not-So-Good Things: Cons of Using MDF

Of course, no material is perfect. MDF has some significant weaknesses you must consider before starting your project.

Hates Water: This is MDF’s biggest downfall. If it gets wet, it will soak up water like a sponge, swell up, and fall apart. Once it suffers water damage, it cannot be repaired. It must be replaced. This makes it a poor choice for bathrooms, kitchens, or any area with high moisture.

It’s Very Heavy: MDF is incredibly dense, which makes it much heavier than plywood of the same size. A full sheet can be very difficult to handle by yourself, and it can put a lot of strain on shelf brackets or cabinet hardware.

Doesn’t Hold Screws Well: The fine-particle structure of MDF doesn’t provide much grip for screw threads. Screws can strip out easily, especially if over-tightened. It’s even worse when screwing into the edge of a board.

Creates Fine Dust: Cutting or sanding MDF produces a cloud of very fine dust. This dust can be harmful to your lungs, so wearing a high-quality dust mask is not just recommended—it’s essential for your safety.

Cannot Be Stained: Since MDF has no wood grain, it cannot be stained. It’s a material meant to be painted or covered with a veneer.

Understanding Birch Plywood: The Strong Contender

Now, let’s turn our attention to Birch Plywood. If MDF is a “wood smoothie,” think of plywood as a “wood layer cake.” It’s also an engineered product, but it’s made in a very different way and from different components.

Birch Plywood is constructed by gluing together multiple thin layers of birch wood, called veneers. Each layer’s grain is turned 90 degrees to the one below it. This cross-graining technique is what gives plywood its incredible strength and stability. It resists bending and warping far better than a solid piece of wood of the same thickness. Baltic Birch is a particularly high-quality version of this, known for having more layers (plies) and fewer voids inside.

The Strengths: Pros of Using Birch Plywood

Birch Plywood is a favorite among cabinetmakers and furniture builders for many compelling reasons. It combines the beauty of real wood with enhanced structural integrity.

Excellent Strength and Durability: The cross-grain construction makes plywood incredibly strong for its weight. It can handle heavy loads without sagging, making it perfect for shelves, cabinet boxes, and furniture frames.

Holds Screws Tightly: The wood layers provide excellent grip for screws. You can confidently drive screws into the face and edges of plywood, and they will hold firm. This is crucial for building strong, long-lasting joints.

Beautiful Wood Grain: High-quality birch plywood has a smooth, attractive wood grain. It can be stained to a beautiful finish, showcasing the natural beauty of the wood, or painted if you prefer. The exposed edges with their visible layers can even be a desirable design feature.

More Lightweight Than MDF: A sheet of birch plywood is noticeably lighter than a sheet of MDF of the same thickness, making it easier to carry, lift, and install.

Good Moisture Resistance: While not waterproof, plywood stands up to moisture much better than MDF. It is less likely to swell or fall apart when exposed to some humidity, making it a safer choice for kitchens and bathrooms (when properly sealed).

The Weaknesses: Cons of Using Birch Plywood

Despite its many strengths, Birch Plywood has a few characteristics you should be aware of.

Higher Cost: Birch Plywood is almost always more expensive than MDF. The higher price reflects the cost of the real wood veneers and the more complex manufacturing process.

Can Have Voids: Lower grades of plywood can have hidden gaps or voids between the layers. If you drive a screw into one of these voids, it won’t hold. This is less of an issue with high-quality Baltic Birch.

Potential for Splintering: The top wood veneer can sometimes splinter or tear when you cut it, especially with a dull blade. This is called “tear-out” and can leave a messy-looking edge if you’re not careful.

Edges Need Finishing: The raw, layered edges of plywood are not as smooth as the face. To get a professional look, you often need to hide the edges with solid wood trim or cover them with edge banding.

MDF vs. Birch Plywood: The Head-to-Head Comparison

Okay, we’ve met the two contenders. Now, let’s put them side-by-side to see how they stack up in the areas that matter most for your projects.

1. Durability and Strength

This is where Birch Plywood really shines. Its layered construction gives it superior structural strength. It can bear heavy loads over long spans, which is why it’s the go-to material for things like kitchen cabinet carcasses and long bookshelves. MDF, being made of fine particles, is more prone to sagging under its own weight over time. If strength is your top priority, plywood is the clear winner.

2. Cost and Value

For budget-conscious builders, MDF is almost always the cheaper option. You can buy more material for less money. However, value is about more than just the sticker price. A project built with Birch Plywood will likely last longer and withstand more abuse, potentially offering better long-term value. For a quick, paint-grade project like a decorative wall panel, MDF offers great value. For a family heirloom piece of furniture, plywood is the better investment.

3. Workability and Finishing

This category is a bit of a tie, as each material excels in different ways. MDF is a dream to cut with a router, producing crisp, clean profiles and curves with no splinters. Its super-smooth surface makes painting incredibly easy. Birch Plywood, on the other hand, is much more forgiving when it comes to joinery. It holds screws, dowels, and other fasteners far more securely. While you need a sharp blade to prevent tear-out when cutting plywood, it can be stained to a beautiful finish—something you can’t do with MDF.

4. Moisture Resistance

There is no contest here. Birch Plywood wins by a landslide. MDF acts like a sponge when it encounters water. Even a small leak can cause it to swell and crumble, completely ruining your project. Plywood, while not fully waterproof, tolerates humidity and occasional moisture far better. For any project in a kitchen, bathroom, laundry room, or basement, plywood is the only safe and reliable choice.

5. Weight and Handling

MDF is dense and heavy. A single 4×8 sheet of 3/4-inch MDF can weigh nearly 100 pounds. This can make it very challenging to move around your workshop and lift into place, especially if you’re working alone. Birch Plywood of the same size is significantly lighter, usually around 60-70 pounds. This difference matters a lot when you’re building large cabinets or furniture.

6. Health and Safety

Both materials create dust when cut, and you should always wear a mask. However, the dust from MDF is a more serious concern. It’s composed of very fine particles and the urea-formaldehyde resins used as a binder. According to the U.S. Environmental Protection Agency (EPA), formaldehyde can cause irritation and is considered a probable human carcinogen. Always work in a well-ventilated area and wear a NIOSH-approved respirator when cutting MDF. Plywood dust is more like regular wood dust, though the glues can still be irritating. Good dust collection and personal protective equipment are always a smart idea.

Quick Comparison Table: MDF vs. Birch Plywood

| Feature | MDF (Medium-Density Fiberboard) | Birch Plywood |

|---|---|---|

| Core Strength | Low; prone to sagging under weight. | Very High; strong and rigid due to cross-grain layers. |

| Best For Painting | Excellent; perfectly smooth surface. | Good; may show some wood grain texture. |

| Best For Staining | Not possible; no wood grain. | Excellent; beautiful, natural wood grain finish. |

| Screw Holding | Poor; screws can strip out easily, especially on edges. | Excellent; layers provide a strong grip for fasteners. |

| Moisture Resistance | Very Poor; swells and disintegrates when wet. | Good; much more resistant to humidity and water damage. |

| Weight | Very Heavy and dense. | Lighter and easier to handle. |

| Cost | Lower; more budget-friendly. | Higher; a more premium material. |

| Cutting & Machining | Cuts smoothly without splintering; ideal for routing. | Can splinter (“tear-out”) without a sharp blade. |

| Safety Concern | Fine dust contains formaldehyde; requires good ventilation and a respirator. | Wood dust can be an irritant; a mask is still recommended. |

Making the Right Choice: When to Use MDF

Based on its strengths and weaknesses, MDF is the perfect choice for specific applications where its smooth surface and low cost are the most important factors.

Painted Cabinet Doors: Especially for Shaker-style doors, where the center panel needs to be perfectly flat and stable.

Bookshelves for Light Items: For paperbacks or decorative objects, MDF works well. For heavy books, you’ll need to add extra support to prevent sagging.

Jigs and Templates: In the workshop, MDF is fantastic for creating jigs and routing templates because it’s stable and easy to shape.

Decorative Trim and Wainscoting: Its smooth surface takes paint beautifully, making it ideal for non-structural decorative elements in dry rooms.

Speaker Boxes: The density of MDF is great for acoustics as it deadens vibration.

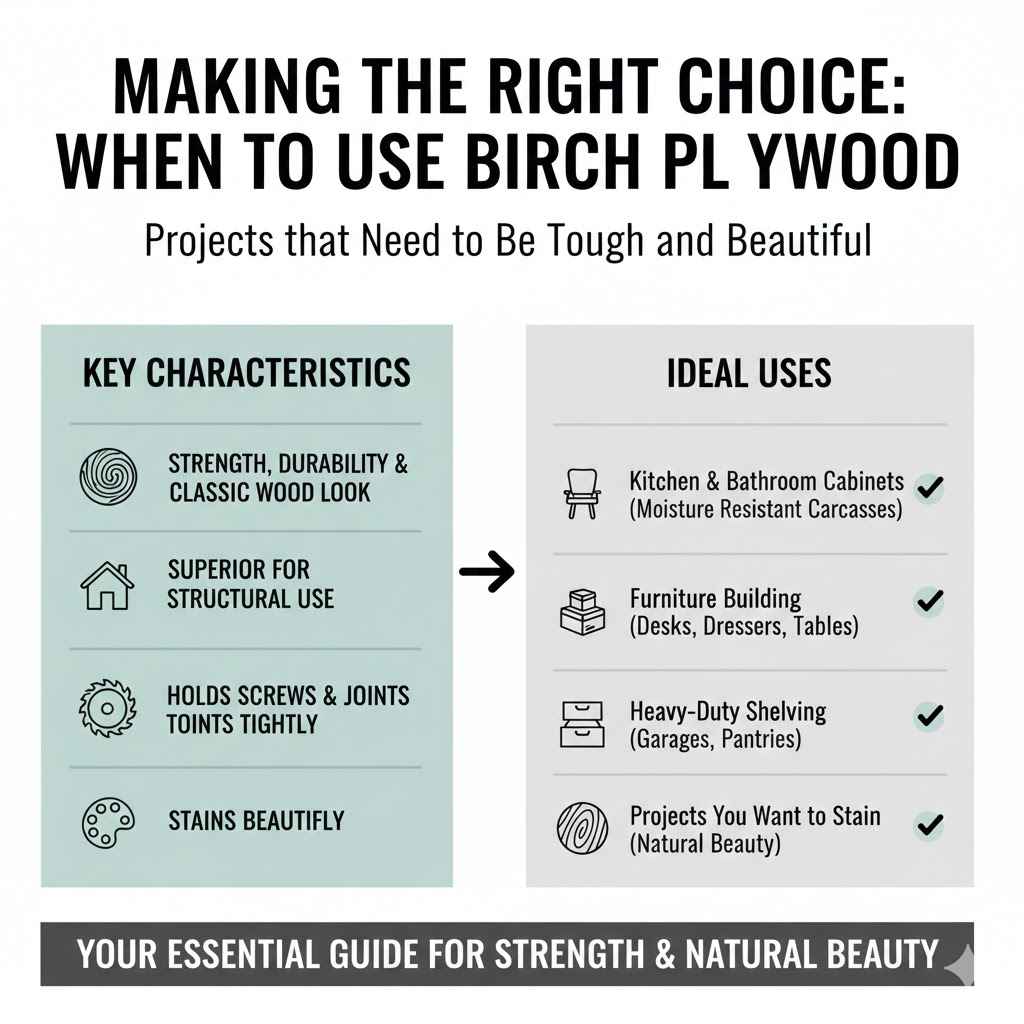

Making the Right Choice: When to Use Birch Plywood

Birch Plywood’s strength, durability, and classic wood look make it the superior choice for projects that need to be tough and beautiful.

Kitchen and Bathroom Cabinets: Plywood is the industry standard for cabinet boxes (carcasses) because of its strength and better moisture resistance.

Furniture Building: For desks, dressers, tables, and bed frames that need to withstand daily use and hold strong joints.

Heavy-Duty Shelving: Ideal for garage shelves, pantry shelves, or bookshelves that will hold a lot of weight.

Drawer Boxes: Its strength and ability to hold joints together make it perfect for building drawers that will open and close thousands of times.

Projects You Want to Stain: Anytime you want the natural beauty of wood grain to be the star of the show.

Frequently Asked Questions (FAQ)

1. Which material is better for building shelves?

It depends on the weight the shelves will hold. For light decorative items, MDF is fine if properly supported. For heavy items like books, tools, or kitchenware, Birch Plywood is a much better choice because it is stronger and far less likely to sag over time.

2. Is birch plywood real wood?

Yes! Birch plywood is made of thin layers of real birch wood veneer glued together. While it’s an “engineered wood product,” its core components are 100% real wood, which is why it has a natural wood grain and can be stained.

3. Can I use MDF in a bathroom or kitchen?

It’s highly discouraged. MDF absorbs moisture very easily and will swell and fall apart. Even “moisture-resistant” MDF is not waterproof. For rooms with any humidity or risk of water exposure, Birch Plywood is the much safer and more durable option.

4. Do I need a special saw blade to cut these materials?

For both MDF and plywood, a blade with a high tooth count (60-80 teeth for a circular saw) will give you the cleanest cut. For plywood, you can also put painter’s tape along your cut line to help reduce splintering on the top surface. A sharp blade is always your best friend!

5. Why is my plywood splintering when I cut it?

This is called “tear-out.” It happens when the saw blade’s teeth exit the wood and tear the top fibers instead of cutting them cleanly. To prevent this, use a sharp, high-tooth-count blade, place painter’s tape on the cut line, or use a “zero-clearance insert” on your table saw.

6. Is MDF toxic?

The dust from cutting MDF can be harmful because it contains formaldehyde from the resin binders. It’s very important to wear a quality respirator (not just a paper mask) and work in a space with good ventilation or dust collection to protect your lungs.

7. Which one is easier for a beginner to paint?

MDF is generally easier to get a perfectly smooth, glass-like painted finish. Its surface has no texture. Plywood can be painted beautifully, but you will often need to use a good primer first, and some of the subtle wood grain texture may still show through, which can also be a desirable look.

Your Final Decision

As you can see, the debate of MDF vs. Birch Plywood isn’t about which material is “better” overall, but which is the smarter choice for the specific project you have in front of you. They are both incredibly useful materials that have a place in every workshop.

If your project calls for a smooth, painted finish, will be kept in a dry environment, and needs to be budget-friendly, MDF is an excellent choice. If you need strength, durability, screw-holding power, and the classic look of real wood grain, Birch Plywood is absolutely the way to go.

Don’t be afraid to use both! A common and very smart approach in cabinet making is to use sturdy Birch Plywood for the cabinet boxes and smooth, paintable MDF for the doors. By understanding the unique strengths of each material, you can make informed decisions that save you time, and money, and lead to beautiful, long-lasting projects you can be proud of. Now, go build something amazing!