MDF vs OSB Board: Which Should You Use?

Choosing the right board for your project can feel tricky, especially when you’re just starting out. You might be wondering about MDF vs OSB board: which should you use? Both are popular choices, but they’re good for different things.

Don’t worry, figuring this out is easier than you think! We’ll break down what each board is made of and when to pick one over the other, step by step. Get ready to learn what makes them different so you can make the best choice for your DIY or professional work.

Understanding MDF vs OSB Board Which Should You Use

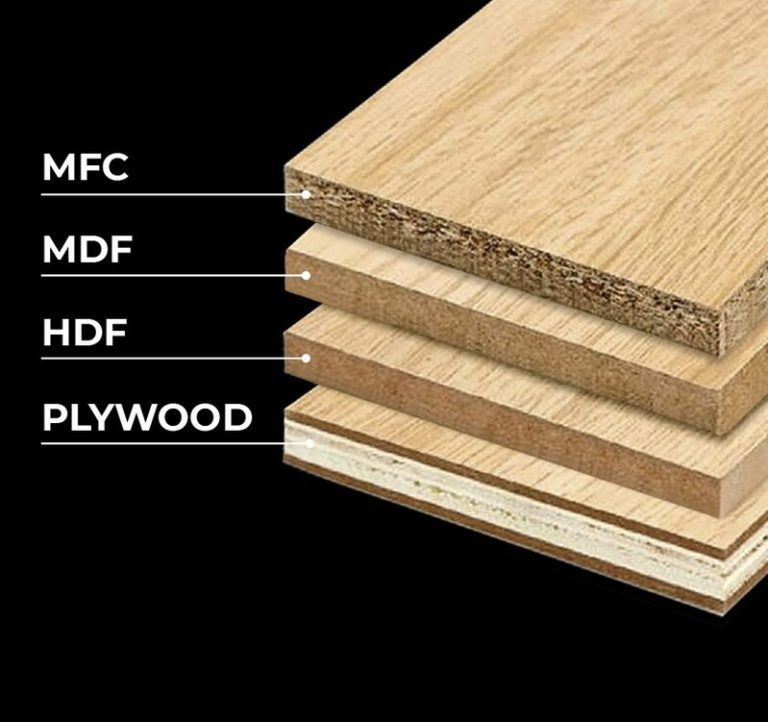

Selecting the correct type of engineered wood panel is a key decision in many building and crafting projects. For beginners and even experienced DIYers, the distinction between Medium-Density Fiberboard (MDF) and Oriented Strand Board (OSB) can be a source of confusion. Both are composite wood products, but their manufacturing processes, material composition, and resulting properties make them suited for vastly different applications.

Understanding these differences is crucial to ensuring your project is both structurally sound and aesthetically pleasing. This guide aims to demystify the world of MDF and OSB, providing clear insights into their characteristics and best uses.

What is MDF Board

MDF, or Medium-Density Fiberboard, is an engineered wood product made by breaking down hardwood and softwood into wood fibers. These fibers are then combined with wax and a resin binder. Heat and pressure are applied during a process that bonds the fibers together.

This creates a dense, uniform panel with a smooth surface. It’s like a very fine particle board but much smoother and stronger because the fibers are smaller and more uniform. The resulting board has no grain pattern, which makes it easy to cut and shape without splintering.

Its density also means it’s quite heavy and can hold screws well when they’re not too close to the edge. The smooth surface is perfect for painting, veneering, or laminating, giving a flawless finish.

Composition and Manufacturing

The creation of MDF starts with separating wood into fine fibers. This is often done using a process that grinds the wood and then uses steam to soften it. Afterward, a binder, typically a synthetic resin like urea-formaldehyde, is added.

This glue helps hold the fibers together. A thin mat of these fibers and the binder is formed. This mat is then hot-pressed under high temperature and pressure.

This pressing step compresses the mat into a solid board. The density of MDF can vary, but it’s generally quite high, often ranging from 500 to 800 kg/m³. This high density is what gives MDF its smooth finish and excellent workability.

Unlike natural wood, it doesn’t have knots or grain lines that can cause issues during finishing.

Key Properties of MDF

MDF is known for its exceptionally smooth and uniform surface. This makes it an ideal material for applications where a fine finish is desired, such as furniture making, cabinetry, and decorative molding. It machines cleanly, allowing for intricate details and sharp edges when routed or carved.

Because it’s made from fibers, it doesn’t warp or crack like solid wood. It also has a consistent density throughout, meaning it performs predictably when cut or drilled. However, it can absorb moisture, so it’s best used in dry indoor environments unless treated or sealed properly.

It is also heavier than many other wood composite boards. The edges can be easily shaped and painted for a professional look.

Common Uses for MDF

Due to its smooth finish and ease of machining, MDF is a popular choice for interior applications. It is widely used in the manufacturing of furniture, especially for cabinet doors, drawer fronts, and shelving units. Its paintability makes it excellent for custom built-ins and decorative panels.

Architects and designers often specify MDF for wall paneling, wainscoting, and trim work. It’s also utilized in the creation of speaker boxes because its dense nature helps to minimize sound distortion. In some cases, it’s used for shelving in closets and garages where moisture is not a significant concern.

The ability to create clean lines and edges makes it a favorite for detailed woodworking projects.

What is OSB Board

OSB, or Oriented Strand Board, is another type of engineered wood panel. It’s made from large, precisely cut strands of wood, like flakes or wafers, that are layered and bonded together with adhesives under heat and pressure. What makes OSB unique is how these strands are oriented.

In each layer, the strands are aligned in a specific direction. Typically, the strands in the outer layers are aligned parallel to the panel’s length, while the inner layers have strands oriented perpendicularly. This cross-oriented structure gives OSB exceptional strength and stiffness, similar to plywood.

It’s commonly used in structural applications for homes and buildings.

Composition and Manufacturing

The manufacturing of OSB begins with fast-growing trees, often aspen or pine. These trees are processed into large, thin flakes or strands of wood. These strands are then dried and screened to remove any debris or undersized particles.

Next, a resin binder, often phenolic or urea-formaldehyde, is mixed with the wood strands. The key step is the layering and orientation of these strands. They are arranged in cross-directional patterns, meaning strands in one layer are perpendicular to the strands in the layer above and below it.

This alignment is what gives OSB its directional strength and stability. The layered mat of strands is then hot-pressed under high pressure and temperature. This process fuses the strands together, creating a strong, rigid panel.

The quality of the wood strands and the precision of their orientation significantly impact the final strength of the OSB.

Key Properties of OSB

OSB is renowned for its strength and structural integrity. The cross-oriented strand design provides excellent load-bearing capabilities and resistance to bending and shear forces. This makes it a preferred material for structural sheathing in walls, roofs, and floors.

It is also more dimensionally stable than solid wood, meaning it expands and contracts less with changes in humidity. OSB panels are typically thicker and more robust than MDF. While it offers good structural support, its surface is rougher and less uniform than MDF, making it less ideal for visible finishes without additional treatment.

It can also be susceptible to swelling if exposed to excessive moisture for prolonged periods. The edges are also less suited for decorative treatments compared to MDF.

Common Uses for OSB

OSB’s primary strength lies in its structural applications. It is extensively used as sheathing for the walls and roofs of residential and commercial buildings. Its rigidity and strength make it an excellent choice for subflooring, providing a stable base for finished flooring materials.

It’s also employed in the manufacturing of prefabricated building components like wall panels and roof trusses. In some industrial packaging applications, such as crates and pallets, OSB is used for its durability and cost-effectiveness. While not typically chosen for its aesthetic appeal, it serves as a dependable structural core for many construction projects.

Some builders also use it for temporary barriers or rough shelving.

Comparing MDF vs OSB Board Which Should You Use

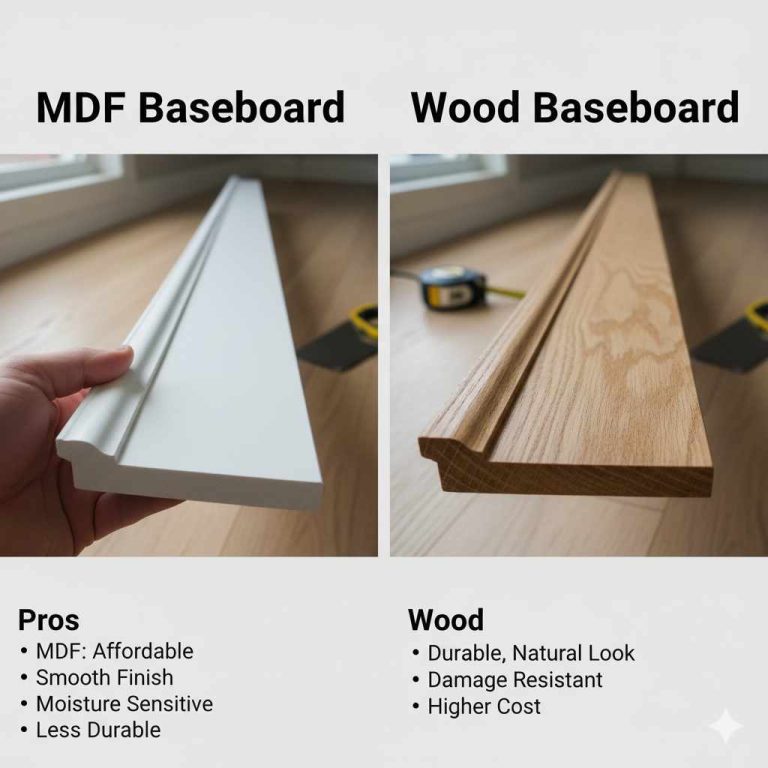

When deciding between MDF and OSB, the most important factors to consider are the project’s requirements and the desired outcome. If your project demands a smooth surface for painting, veneering, or detailed finishing, MDF is usually the better choice. Its fine texture and lack of grain make it perfect for furniture, cabinetry, and decorative elements.

On the other hand, if you need a strong, structural panel for building, framing, or subflooring, OSB is the superior option. Its oriented strand structure provides exceptional load-bearing capacity and stability. Understanding the core differences in their composition and properties will guide you to the right material.

Strength and Durability Comparison

The structural strength of OSB is significantly higher than that of MDF. OSB is engineered with layers of wood strands oriented in different directions, creating a panel that can withstand substantial loads and stresses. This makes it ideal for applications where the material will bear weight or be subjected to structural forces.

Think of it like a criss-cross pattern in fabric; it’s very hard to tear. MDF, while dense, is more brittle and less resistant to shear forces. It’s made from very fine wood fibers, which give it a uniform consistency but lack the directional strength of OSB’s strands.

Therefore, for any application requiring structural integrity, such as framing or subflooring, OSB is the preferred material. MDF is more suitable for applications where strength is secondary to surface finish and machinability.

Here is a simple comparison of their strength properties:

| Property | MDF | OSB |

|---|---|---|

| Tensile Strength | Low | High |

| Shear Strength | Low | High |

| Load Bearing Capacity | Low (for structural loads) | High |

| Impact Resistance | Moderate | High |

Moisture Resistance

Neither MDF nor OSB is inherently waterproof, but their performance in humid conditions varies. Standard MDF is highly susceptible to moisture. When exposed to water, it can swell, warp, and even disintegrate.

Its fine fiber structure readily absorbs water. Special moisture-resistant grades of MDF are available, often colored green, but these are still not suitable for prolonged direct water exposure. OSB also absorbs moisture, which can cause it to swell.

However, its layered strand construction can sometimes make it slightly more resistant to immediate damage from incidental moisture compared to standard MDF. If exposed to prolonged wetness, both can degrade. For applications where moisture is a significant concern, alternative materials like exterior-grade plywood or specially treated engineered panels should be considered.

Let’s look at how they handle moisture:

- Standard MDF: Very poor moisture resistance. Swells and degrades easily.

- Moisture-Resistant MDF: Better than standard, but still not waterproof. Suitable for damp environments with protection.

- Standard OSB: Moderate moisture resistance. Can swell but generally holds together better than standard MDF initially.

- Exterior Grade OSB: Specifically designed for better moisture tolerance in construction.

Workability and Finishing

When it comes to working with the boards, MDF and OSB offer different advantages. MDF is exceptionally easy to cut, drill, and route. Its smooth, uniform surface means that cuts are clean with no splintering, and edges can be shaped to create decorative profiles.

This makes it perfect for detailed furniture components and trim. It also provides an excellent base for painting, with primers and paints adhering very well for a smooth, flawless finish. OSB, on the other hand, is more challenging to cut cleanly due to its layered strand structure; edges can be rough.

It’s not designed for fine decorative finishes. Its surface is coarse and uneven, making it unsuitable for painting directly without significant preparation like skim coating. However, it holds screws very well, which is a significant advantage in construction.

MDF Workability

MDF machines beautifully. Its consistent density means that when you cut it, the edges are smooth and splinter-free. This is a big deal for furniture makers who want a clean look.

You can use standard woodworking tools like saws, routers, and sanders. Routers are especially great with MDF because you can create really nice, decorative edges on cabinet doors or shelves. Because it’s so smooth, it takes paint exceptionally well.

A coat of primer followed by your chosen paint color will give you a professional, furniture-like finish. You can also veneer MDF with thin sheets of real wood to give it the appearance of solid wood. It also holds screws quite well, but you need to be careful not to over-tighten them, as it can strip the fibers.

For best results, use specialized screws or anchors for MDF.

OSB Workability

Working with OSB is more about its structural function than its finish. Cutting OSB can produce a lot of dust, and the edges can be rough and irregular. You’ll typically use a circular saw or a table saw for straight cuts.

While you can technically paint OSB, achieving a smooth finish is difficult. You would need to fill any imperfections and use a high-quality primer designed for wood composites. It’s not typically used for visible decorative elements because of its appearance.

However, OSB excels at holding fasteners. Nails and screws drive into it firmly and hold well, which is vital for structural applications like framing and subflooring. This means the structure you build with OSB will be very secure.

Cost Considerations

In general, OSB is often more cost-effective than MDF, especially for larger projects. The raw materials used for OSB are typically less expensive, and the manufacturing process can be more efficient for producing large structural panels. For instance, if you are building a house and need to sheath the walls and roof, OSB will likely be a more budget-friendly option than using MDF for the same purpose.

MDF tends to be more expensive due to the finer processing of wood fibers and the resins used to create its smooth, dense surface. However, when considering the cost of finishing materials, MDF might offer a better value if a painted or veneered surface is required, as it requires less preparation and fewer coats of paint compared to OSB.

Here’s a general cost comparison:

- OSB: Generally less expensive per square foot, especially for structural grades.

- MDF: Typically more expensive per square foot due to its fine fiber composition and manufacturing.

Environmental Impact

Both MDF and OSB are engineered wood products that utilize wood byproducts and waste. This is a positive aspect as it reduces the need for virgin lumber and makes use of materials that might otherwise be discarded. However, the environmental impact also depends on the binders and adhesives used.

Many conventional MDF and OSB products use resins containing formaldehyde, which can off-gas volatile organic compounds (VOCs) into the air. Low-VOC or formaldehyde-free options are available for both materials, which are better for indoor air quality. OSB, often made from fast-growing trees and recycled wood, can be considered relatively sustainable, especially when sourced from responsibly managed forests.

MDF manufacturing often requires more energy due to the fine fiber processing.

Formaldehyde Emissions

Formaldehyde is a chemical compound commonly used as a binder in wood composite products like MDF and OSB. It helps to hold the wood fibers or strands together. However, formaldehyde can be released into the air over time, a process known as off-gassing.

This can impact indoor air quality. Many manufacturers now offer products that are classified as “No Added Formaldehyde” (NAF) or “Low Formaldehyde Emission” (LFE). When choosing between MDF and OSB, especially for interior projects where air quality is a concern, it’s important to look for these certifications.

These low-emission products are a healthier choice and help reduce environmental concerns related to VOCs.

It is important to be aware of formaldehyde emissions:

- Standard MDF/OSB: May emit formaldehyde.

- NAF MDF/OSB: No added formaldehyde, a safer option.

- LFE MDF/OSB: Low formaldehyde emissions, also a good choice.

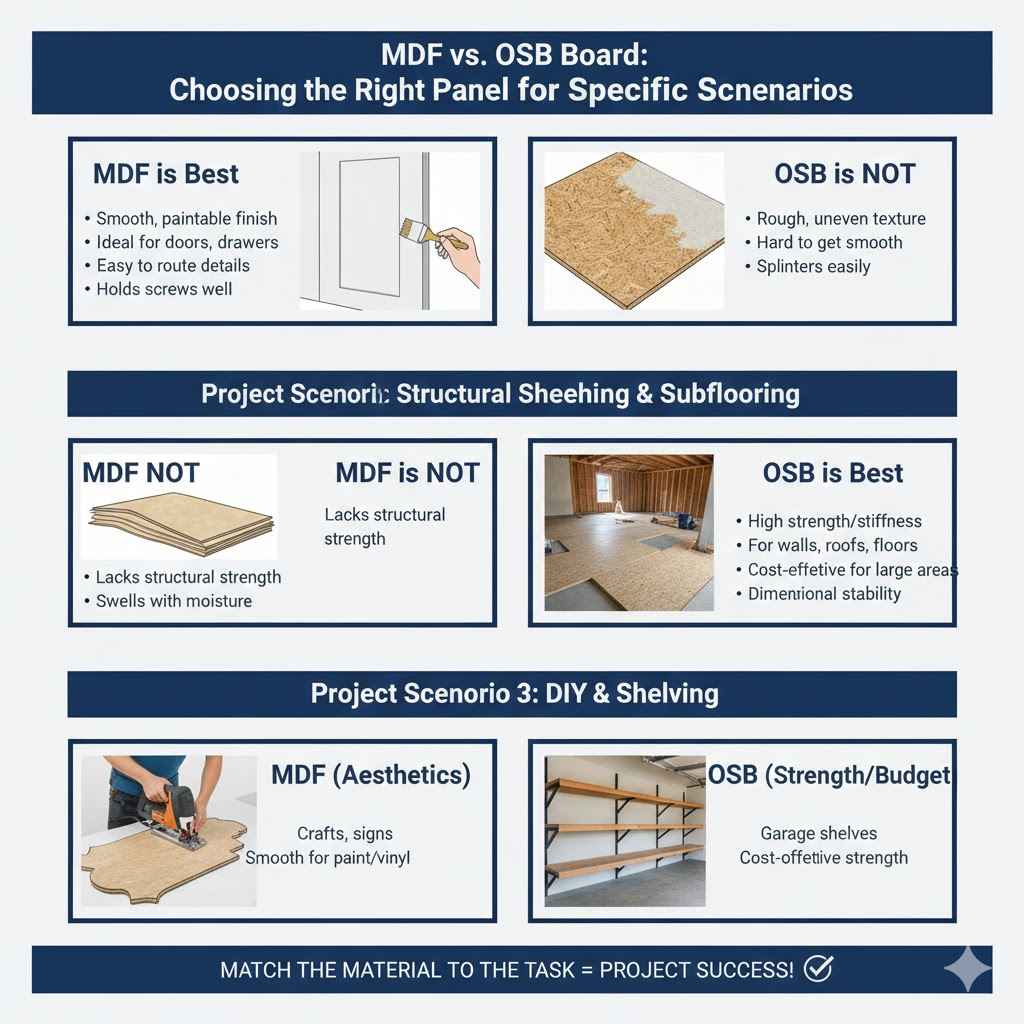

MDF vs OSB Board Which Should You Use Specific Scenarios

The choice between MDF and OSB often comes down to the specific demands of your project. For a DIYer building custom bookshelves that will be painted, MDF is the clear winner. Its smooth surface ensures a beautiful painted finish, and it’s easy to work with.

If you’re framing a new wall in your home, OSB is the structural material you need. Its strength and stability are essential for the integrity of the building. Consider the conditions too; if the area is prone to moisture, you’ll need to account for that with either material, perhaps opting for moisture-resistant grades or additional sealing.

Think about what the board will do and how it will look in its final application.

Project Scenario 1 Cabinetry and Furniture

When building cabinets and furniture that will be painted or veneered, MDF is often the preferred choice. Its extremely smooth and uniform surface allows for a flawless finish. You can easily route decorative edges on cabinet doors, and painted MDF looks like high-quality painted wood.

It also holds screws well, making assembly straightforward, although care must be taken not to over-tighten. For internal cabinet structures where aesthetics are less critical, a less expensive material might suffice, but for visible parts like doors and drawer fronts, MDF shines. It won’t warp or crack, which is important for the longevity of furniture.

For a high-end look, consider veneering MDF with a beautiful hardwood like oak or walnut.

Project Scenario 2 Structural Sheathing and Subflooring

For structural elements like wall sheathing, roof decking, and subflooring, OSB is the go-to material. Its strength and stiffness are specifically engineered for these load-bearing applications. OSB panels provide a stable base for walls and floors, and their interlocking strand structure resists movement.

This is critical in construction to ensure the building is solid and durable. OSB is also generally more cost-effective for these large-scale structural needs. While it’s not ideal for visible finishes, its rough surface provides good grip for flooring adhesives and finishes.

When installing OSB for subflooring, ensure all joints are properly supported and glued to prevent squeaks and movement. For exterior applications, always use OSB rated for such use.

Project Scenario 3 DIY Craft Projects and Shelving

For smaller DIY projects, like creating custom shelves for a dry closet, a decorative sign, or craft items, MDF is an excellent option due to its ease of use and finishing capabilities. It’s easy to cut with hand saws or jigsaws for intricate shapes. Its smooth surface makes it perfect for applying vinyl, paint, or other decorative finishes.

For open shelving in a garage or workshop where aesthetics are less important and strength is needed, OSB can also be a practical and cost-effective choice. However, if the shelves will hold very heavy items, you might want to consider thicker MDF or reinforce OSB with framing. Always consider the weight the shelves will carry and choose the material accordingly.

Frequently Asked Questions

Question: Is MDF stronger than OSB for general use

Answer: For general structural use where load-bearing capacity is key, OSB is stronger than MDF. MDF is denser but more brittle, making it better for smooth finishes rather than structural strength.

Question: Can I paint MDF and OSB

Answer: Yes, you can paint both. MDF provides a much smoother, easier-to-finish surface that takes paint beautifully for a furniture-like look. OSB has a rougher surface that requires more preparation for a good paint finish.

Question: Which board is better for humid environments

Answer: Neither is ideal for wet conditions. Standard MDF is very sensitive to moisture. OSB can swell if wet but may resist immediate damage better than standard MDF.

For humid or wet areas, look for specialized moisture-resistant grades or consider other materials like exterior plywood.

Question: Is OSB cheaper than MDF

Answer: Generally, yes. OSB is typically more affordable than MDF per square foot, especially for large construction projects. MDF is more expensive due to its finer composition and manufacturing process.

Question: Can I use OSB for furniture

Answer: While you can technically use OSB for furniture, it’s not ideal for visible parts due to its rough surface and lack of fine finishing capabilities. MDF is far better for furniture that requires a smooth, paintable, or veneered finish.

Wrap Up

Deciding between MDF and OSB hinges on your project’s needs. For smooth, paintable surfaces in furniture and cabinetry, MDF is superior. For structural integrity in building walls, floors, and roofs, OSB is the robust choice.

Consider strength, finishing, cost, and moisture exposure. Choose wisely, and your project will be well-built and look great.