Metal Circular Saw Blade Essentials: Cut with Precision!

A metal circular saw blade is specifically designed for cutting various metals with precision. These blades feature durable materials and teeth configurations for efficient performance.

Metal circular saw blades are essential tools in metalworking and construction. They excel in cutting through materials like aluminum, steel, and other alloys. These blades come in various sizes and tooth designs, allowing users to achieve specific cutting results. Choosing the right blade depends on the material and thickness being cut.

High-speed steel and carbide-tipped options are popular for their durability and longevity. Proper maintenance enhances blade performance and lifespan. Understanding the features and applications of metal circular saw blades can significantly improve your cutting efficiency and project outcomes. Invest in quality blades to ensure clean, accurate cuts every time.

Introduction To Metal Circular Saw Blades

Metal circular saw blades are essential tools for cutting various metals. They are designed for precision and durability. Users can benefit from their sharp teeth and strong materials. Blades are available in different types, each suited for specific tasks.

Key features include high-speed steel and carbide tips. These features enhance the blade’s lifespan and performance. Many blades also have anti-friction coatings. This reduces heat and improves cutting efficiency.

| Type | Best For |

|---|---|

| Carbide-Tipped Blades | General metal cutting |

| High-Speed Steel Blades | Thin materials and light metals |

| Diamond Blades | Hard metals and alloys |

Materials And Design

Metal circular saw blades have a special composition. They often use high-speed steel (HSS) or carbide tips. These materials help blades cut through tough surfaces easily.

Carbide-tipped blades are very popular. They stay sharp longer than regular steel blades. This means less frequent replacements.

Innovations in blade design focus on better performance and durability. Many blades now feature special coatings. These coatings reduce friction and heat during cutting.

Some new designs include tooth geometry improvements. This helps in making smoother cuts with less effort. Understanding these features can enhance cutting efficiency.

Choosing The Right Blade

Choosing the right metal circular saw blade is crucial for your project. Each blade has specific specifications that match different tasks. Understand the tooth count, kerf width, and material type for the best results.

The tooth count affects the cut quality. More teeth give a smoother finish. Fewer teeth cut faster but may leave rough edges.

Kerf width is the amount of material removed during cutting. A thinner kerf means less waste and easier cutting. Choose based on your project’s needs.

Match the blade to the material type being cut. For wood, use a blade with a high tooth count. For metal, opt for fewer teeth and a stronger material.

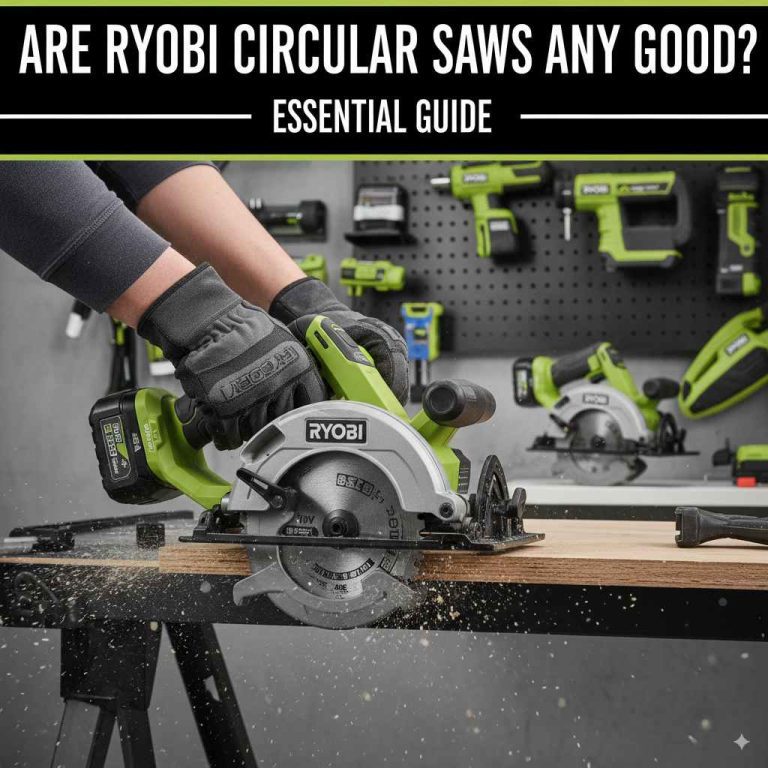

Cutting Techniques

Proper saw operation is crucial for safe and effective cutting. Always ensure the blade is sharp. A dull blade can cause kickback and uneven cuts. Check the alignment of the blade before starting. This helps in making straight cuts.

For advanced cutting tips, try using a guide rail. This keeps the blade on a straight path. Always wear safety gear like goggles and gloves. Keep hands away from the blade while cutting. Adjust the saw speed based on the material type. Different materials require different speeds for the best results.

Maintenance For Longevity

Regular cleaning of your metal circular saw blade is essential. Use a soft brush to remove sawdust. A damp cloth can help clean any residue. Avoid using harsh chemicals that may damage the blade.

Proper storage is also important for longevity. Store blades in a protective case or on a rack. Keep them away from moisture and extreme temperatures. This helps prevent rust and bending.

Sharpening your blades keeps them effective. Use a sharpening tool designed for metal blades. Follow the manufacturer’s instructions for the best results. Regular sharpening extends the life of your blade.

Safety Considerations

Always wear personal protective equipment (PPE) when using a metal circular saw blade. This includes safety goggles, ear protection, and gloves. Proper gear helps to prevent injuries. Ensure your clothing is tight-fitting and free of loose ends.

Consider using a dust mask to protect against sawdust. Sawdust can cause breathing issues. A face shield offers extra protection for your face.

Always check that the saw blade is sharp and in good condition. A dull blade can cause accidents. Keep your work area clean and free of distractions.

Follow all safety guidelines to reduce the risk of injury. Be aware of your surroundings at all times. Stay focused on the task at hand.

Accessories And Upgrades

Upgrading your metal circular saw blade can greatly improve performance. Quality accessories help achieve better cuts and extend tool life.

Consider these must-have add-ons for professionals:

- Dust Blower: Keeps the cutting line clear for better visibility.

- Laser Guide: Ensures precise cuts every time.

- Table Extensions: Provide extra support for larger materials.

- Adjustable Blade Guard: Enhances safety while cutting.

- Vibration Dampening Handles: Reduce fatigue during extended use.

These accessories enhance overall functionality. Investing in the right tools pays off in the long run.

Industry Applications

Metal circular saw blades are essential tools in metalworking and construction. They are designed to cut through various metals with precision. These blades are suitable for tasks like cutting steel, aluminum, and other alloys.

In specialized industrial uses, metal circular saw blades excel in:

| Application | Description |

|---|---|

| Fabrication | Used for creating metal structures and components. |

| Construction | Ideal for cutting metal frames and supports. |

| Automotive | Used in manufacturing and repairing vehicles. |

| HVAC | Essential for ductwork and metal fittings. |

Frequently Asked Questions

What Is A Metal Circular Saw Blade?

A metal circular saw blade is a cutting tool designed specifically for cutting metal materials. These blades are typically made from high-speed steel or carbide-tipped materials. They provide precision and durability, making them ideal for tasks such as metal fabrication and construction projects.

Proper usage ensures clean cuts and longevity.

How To Choose A Metal Circular Saw Blade?

Choosing a metal circular saw blade depends on several factors. Consider the type of metal you will cut, the thickness, and the desired finish. Additionally, look for the blade’s tooth count and material type. A higher tooth count generally provides smoother cuts.

Always match the blade to your saw’s specifications.

Can I Use A Metal Blade On Wood?

Using a metal circular saw blade on wood is not recommended. Metal blades are designed for cutting harder materials and may not cut wood effectively. They can also cause splintering or damage to the wood. For wood cutting, always use blades specifically designed for that purpose to ensure quality cuts.

How Do I Maintain My Metal Circular Saw Blade?

To maintain your metal circular saw blade, regularly clean it to remove debris and resin build-up. Inspect the blade for wear or damage after each use. Sharpen the blade when necessary to maintain cutting efficiency. Proper storage in a dry environment can also extend its lifespan significantly.

Conclusion

Choosing the right metal circular saw blade is crucial for achieving precise cuts. Consider factors like material, tooth design, and size to enhance your projects. A quality blade not only improves performance but also extends the life of your saw.

Invest wisely for better results and enjoy smoother cutting experiences every time.