Are Metal Studs Cheaper Than Wood? Essential Guide!

While initial material costs can sometimes favor wood, metal studs often prove more cost-effective over the long term due to their durability, resistance to pests and moisture, and potential for faster construction. The overall expense depends on project scale, local pricing, and labor. This guide breaks down the factors to help you decide.

Hey everyone, Md Meraj here! Thinking about your next big project, whether it’s building a new wall, a shed, or even renovating a room? You’ve likely wondered about the best materials to use. One of the biggest questions that pops up is about framing: should you go with good old wood or the increasingly popular metal studs? It’s a common puzzle, and figuring out the cost is a huge part of it. Many people hesitate, worried about hidden expenses or complex installations. But don’t you worry!

I’m here to walk you through everything, making it super clear. We’ll look at the real costs, the benefits, and where each option shines. Stick with me, and by the end of this, you’ll feel confident knowing which stud type is right for your wallet and your project!

Are Metal Studs Cheaper Than Wood? The Big Picture

This is the million-dollar question, isn’t it? When we talk about “cheaper,” it’s not always just about the price tag on the materials themselves. We need to look at the entire picture – from purchase to project completion and even beyond. So, are metal studs cheaper than wood? The answer is: it depends, but often, metal studs can lead to overall savings, especially for larger projects or in certain conditions.

Think of it like buying tools. Sometimes a cheaper tool breaks easily, and you have to buy another one. In the long run, a slightly more expensive, durable tool is the better deal. The same applies to building materials. We need to consider not just the upfront cost of lumber versus steel, but also how long the structure will last, how quickly you can build it, and any potential maintenance. Let’s dive into the specifics!

Understanding the Costs: A Side-by-Side Look

To truly answer if metal studs are cheaper than wood, we need to compare their pricing. Keep in mind that these prices can fluctuate based on your location, the supplier, and market demand. It’s always a good idea to get local quotes!

Material Costs: The Purchase Price

Generally, when you walk into a lumber yard or a home improvement store, a single piece of wood stud (like a 2×4) might be cheaper than a comparable metal stud. Here’s a rough idea:

- Wood Studs: Prices can range from $3 to $7 for a standard 8-foot 2×4, depending on grade and type of wood.

- Metal Studs (Light Gauge Steel): Prices can range from $5 to $10 for an 8-foot stud, again depending on size, gauge (thickness), and manufacturer.

So, on a per-piece basis, wood often has the edge. But this is just the start of our cost comparison!

Other Material Considerations

Beyond the studs themselves, other materials can play a role:

- Fasteners: Wood studs are typically joined with nails or screws designed for wood. Metal studs require specialized screws (like self-tapping or sheet metal screws) which can be slightly more expensive and require different drivers.

- Sheathing/Drywall: This is where things can start to balance out or even favor metal. Metal studs are often straighter and more consistent, leading to less waste and a flatter surface for hanging drywall.

- Insulation: Both wood and metal studs can accommodate standard insulation. However, metal studs can be a thermal bridge, meaning they conduct heat more readily than wood. This might require slightly more attention to insulation strategies or specialized insulation to achieve the same R-value (thermal resistance).

- Moisture and Pest Barriers: Wood is susceptible to rot, mold, and termite damage. Metal studs are not. If your project is in a humid area or prone to pests, you might save money on treatments, repairs, and potential replacement with metal.

Labor Costs: The Time Factor

This is a HUGE area where metal studs can often win out, making them cheaper in terms of the overall project cost. Let’s break it down:

- Speed of Installation: Metal studs are lightweight and come in standardized sizes. They can be easily cut with specialized tools (like a metal chop saw or reciprocating saw with a metal blade) and screwed together quickly. Many builders find they can frame a wall with metal studs much faster than with wood. This is especially true for large commercial projects, but the efficiencies can apply to DIY as well.

- Accuracy and Straightness: Unlike wood, which can warp, twist, or cup as it dries, metal studs remain perfectly straight. This means less time spent selecting the best pieces, less waste, and a straighter wall. A straighter wall means easier hanging of drywall and a more professional finish, saving labor on those steps too.

- Ease of Handling: Metal studs are lighter than comparable wood studs, making them easier and safer to lift and maneuver, especially on job sites or for DIYers working alone.

- Less Waste: Because they are straighter and more uniform, there’s often less material waste with metal studs compared to wood, which can have knots or defects. Less waste means less material to purchase and less debris to dispose of.

Long-Term Costs: Durability & Maintenance

This is where metal studs really shine and can make them the more economical choice over time:

- Resistance to Pests: Termites, carpenter ants, and other wood-boring insects are a major concern for wooden structures. Metal studs are completely immune to these pests, potentially saving you thousands in repair costs down the line.

- Resistance to Moisture and Rot: Wood can absorb moisture, leading to rot, mold, and structural weakening, especially in damp environments like basements or bathrooms. Metal studs do not rot or decay, offering superior longevity in these conditions. This can be a significant cost saving in terms of potential repairs and maintaining the structural integrity of your home.

- Fire Resistance: Steel studs are non-combustible. While your drywall provides a fire barrier for both types of framing, the studs themselves won’t contribute to a fire. This can sometimes lead to lower insurance premiums, although this is project-specific.

- Dimensional Stability: Metal studs do not expand or contract with changes in humidity or temperature. This means your walls will remain straight and true over time, with less risk of drywall cracking at the joints due to the framing shifting.

When Are Metal Studs Cheaper Than Wood?

Based on the factors above, metal studs tend to be the more cost-effective option in these scenarios:

- Large-Scale Projects: For framing multiple rooms, entire houses, or commercial buildings, the labor savings and speed of construction with metal studs can significantly outweigh any initial material cost difference.

- Areas Prone to Pests: If you live in a region with high termite activity or other wood-destroying insects, metal studs offer a proactive cost-saving measure against future damage.

- High-Humidity Environments: Basements, bathrooms, kitchens, and exterior walls in damp climates benefit greatly from the rot and mold resistance of metal studs, preventing costly future repairs.

- Projects Requiring Straight Walls: For a perfectly plumb and straight finish, especially for high-end finishes or where precise alignment is crucial, metal studs minimize labor in achieving this.

- DIYers Prioritizing Ease and Speed: While the tools might be different, the lighter weight and consistent nature of metal studs can make them easier and faster to work with for some DIYers, particularly if they are accustomed to working with power tools.

When Might Wood Studs Be Cheaper?

This doesn’t mean wood is out of the picture! Wood studs might be the more economical choice for:

- Small DIY Projects: For a simple room divider or a small shed, the upfront material savings on wood might be more attractive and the labor difference less significant.

- Beginner DIYers Unfamiliar with Metal Tools: If you’re new to DIY and only have basic woodworking tools, the learning curve and tool investment for metal stud framing might make wood the simpler, and thus cheaper, path.

- Areas with Very Low Humidity and No Pest Issues: In arid climates with no reported pest problems, the long-term durability advantages of metal might be less critical, making the initial cost savings on wood more appealing.

Tools You’ll Need for Framing

Whether you choose wood or metal, having the right tools is key. Here’s a quick rundown, with a focus on what you might need specifically for metal studs:

For Wood Framing:

- Circular Saw or Miter Saw

- Hammer

- Tape Measure

- Pencil

- Level

- Speed Square

- Safety Glasses

- Work Gloves

- Pneumatic Nailer (optional, but speeds things up)

For Metal Stud Framing:

- Metal Stud Cutter or Aviation Snips: For scoring and snapping lighter gauge studs, or for simpler cuts.

- Reciprocating Saw with Metal Cutting Blade: Essential for faster, more precise cuts.

- Metal Chop Saw: For making clean, straight cuts on a larger scale.

- Cordless Drill/Driver with Magnetic Nut Setter and Screw Gun Bits: For driving self-tapping screws.

- Tape Measure

- Level

- Straight Edge or Chalk Line

- Safety Glasses (critical!)

- Work Gloves (essential for handling sharp metal edges)

- Hearing Protection

- Metal Stud Connectors/Screws: Specialized fasteners.

The added cost of some specialized tools for metal studs (like a good metal-cutting blade for a reciprocating saw or a magnetic nut driver) can be a consideration for a one-off small project, but for frequent use or larger projects, they are a worthwhile investment.

Metal Stud Composition and Gauge Explained

Metal studs are typically made from galvanized steel. The “gauge” refers to the thickness of the steel. Thicker steel means a stronger, more robust stud. Standard residential construction often uses 20-gauge steel for interior walls, while 18-gauge or even 16-gauge might be used for load-bearing walls or exterior applications where more strength is needed.

Understanding gauge is important because it directly affects the strength and load-bearing capacity of the wall, as well as the cost. Thicker gauge studs will be more expensive but can support more weight, potentially reducing the need for additional bracing in some designs.

For more detailed specifications on steel framing, you can refer to resources from organizations like the Steel Framing Alliance.

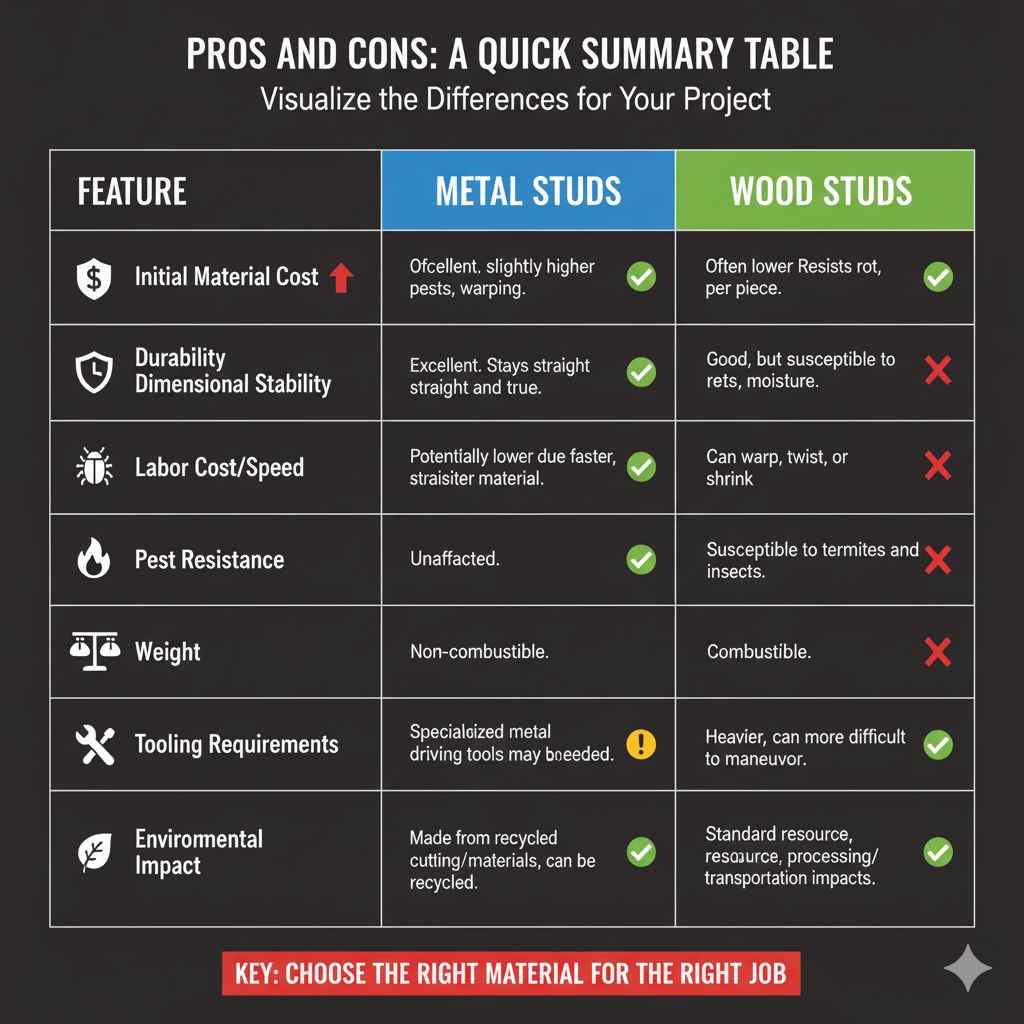

Pros and Cons: A Quick Summary Table

Let’s put it all together in a simple table to help you visualize the differences:

| Feature | Metal Studs | Wood Studs |

|---|---|---|

| Initial Material Cost | Often slightly higher per piece. | Often lower per piece. |

| Durability | Excellent. Resists rot, pests, warping. | Good, but susceptible to rot, pests, and moisture damage. |

| Dimensional Stability | Excellent. Stays straight and true. | Can warp, twist, or shrink. |

| Labor Cost/Speed | Potentially lower due to faster install, straighter material. | Can be slower, requires more selection and potential adjustments for warping. |

| Pest Resistance | Immune. | Susceptible to termites and insects. |

| Moisture Resistance | Unaffected. | Can rot or mold. |

| Fire Resistance | Non-combustible. | Combustible. |

| Weight | Lighter per piece, easier to handle. | Heavier, can be more difficult to maneuver. |

| Tooling Requirements | Specialized metal cutting/driving tools may be needed. | Standard woodworking tools suffice. |

| Environmental Impact | Made from recycled materials, can be recycled. | Renewable resource, but processing and transportation have impacts. |

FAQ: Your Burning Questions Answered

Here are some common questions beginners have about metal vs. wood studs:

Can I use metal studs for any type of wall?

Yes! Metal studs are versatile. They can be used for interior non-load-bearing walls, interior load-bearing walls (with appropriate gauge and engineering), exterior walls, and even in commercial applications. Always check local building codes for specific requirements.

Is it harder to hang things on metal studs than wood studs?

It’s different, not necessarily harder. For general wall hangings (like pictures or shelves), you’ll need to locate the studs and use the appropriate screws. For heavier items, you might need to use specialized drywall anchors designed for metal studs or bridging between studs to create a stronger mounting point. Wood offers more direct screw-holding power in many DIY situations.

Do metal studs rust?

Standard metal studs used in construction are typically galvanized steel, meaning they have a protective coating of zinc that prevents rust. However, if this coating is severely damaged or the studs are exposed to harsh, corrosive environments for extended periods without proper protection, rust can eventually occur.

Is it safe for DIYers to work with metal studs?

Yes, absolutely! Safety is paramount. You’ll need to wear sturdy gloves to protect against sharp edges, and always wear safety glasses when cutting or drilling. Working with power tools specifically designed for metal is also recommended. Many DIYers find them very manageable.

Will my home be louder with metal studs than wood?

This is a common concern. Because metal can transmit sound more easily, metal stud walls can potentially be less soundproof than well-constructed wood stud walls if not managed properly. However, this can be mitigated with proper insulation, adding resilient channels, or using specialized sound-dampening drywall products. The acoustic performance is highly dependent on the detailing of the wall assembly.

Are metal studs better for the environment?

Metal studs are often made from a high percentage of recycled steel, and steel itself is infinitely recyclable. This makes them a sustainable choice. Wood is a renewable resource, but the forestry practices and transportation involved have their own environmental considerations. Both have their environmental benefits.

What are the building code implications of using metal studs?

Building codes universally permit the use of metal studs. In fact, they are often preferred in commercial settings for their consistency and fire resistance. For residential use, ensure you are using the correct gauge for the intended application (load-bearing vs. non-load-bearing) and that your installation meets local code requirements for spacing and fastening. Consulting local building code resources or professionals is always a good practice.

Conclusion: Making the Smart Choice for Your Project

So, to circle back to our main question: are metal studs cheaper than wood? The most honest answer is that metal studs often present a better value proposition over the lifespan of a project and can lead to significant cost savings in labor and reduced long-term maintenance. While the initial purchase of a single steel stud might be higher, the benefits of speed, accuracy, durability, and resistance to moisture and pests frequently make them the more economical choice, especially for larger endeavors.

For the small, simple DIY job where budget is the absolute primary concern and you already have woodworking tools, wood might seem like the easier, cheaper path. But if you’re building anything substantial, or if you anticipate issues with pests or moisture, investing in metal studs can save you headaches and money down the road. Think about your specific project, your location, and your long-term goals. With this guide, you’re now equipped to weigh the costs and benefits to make the smartest decision for your next build. Happy building!