Are Stainless Steel Screws Magnetic? Essential Guide

Most common stainless steel screws are not magnetic, or only weakly so. This is due to their alloy composition, specifically the presence of chromium and nickel, which makes them corrosion-resistant but less magnetic than plain steel. However, some types of stainless steel screws can be magnetic.

Hello there, fellow DIYers and home crafters! It’s Md Meraj here, ready to tackle a question that pops up more often than you might think in workshops and on job sites: “Are stainless steel screws magnetic?” You’ve probably grabbed a handful of shiny screws, maybe for a weather-exposed project or because you just want something that won’t rust. Then, you reach for your trusty magnet, expecting it to instantly latch on, only to find… well, not much. Frustrating, right?

Especially when you need to quickly retrieve dropped screws or sort through a bin. Don’t worry, this is a super common puzzle, and we’re going to unravel it together. We’ll break down exactly why this happens and what you can expect, so you can confidently choose the right fasteners for your projects every time. Stick around, and by the end of this guide, you’ll be a pro at understanding stainless steel and magnetism!

Why the Confusion? Understanding Stainless Steel Types

Stainless steel is a fantastic material, celebrated for its resistance to rust and corrosion. This makes it a go-to choice for outdoor projects, marine applications, kitchens, and anywhere moisture might be an issue. However, not all stainless steel is created equal, and this is where the magnetic confusion comes from. The key lies in the different grades and structures of stainless steel alloys.

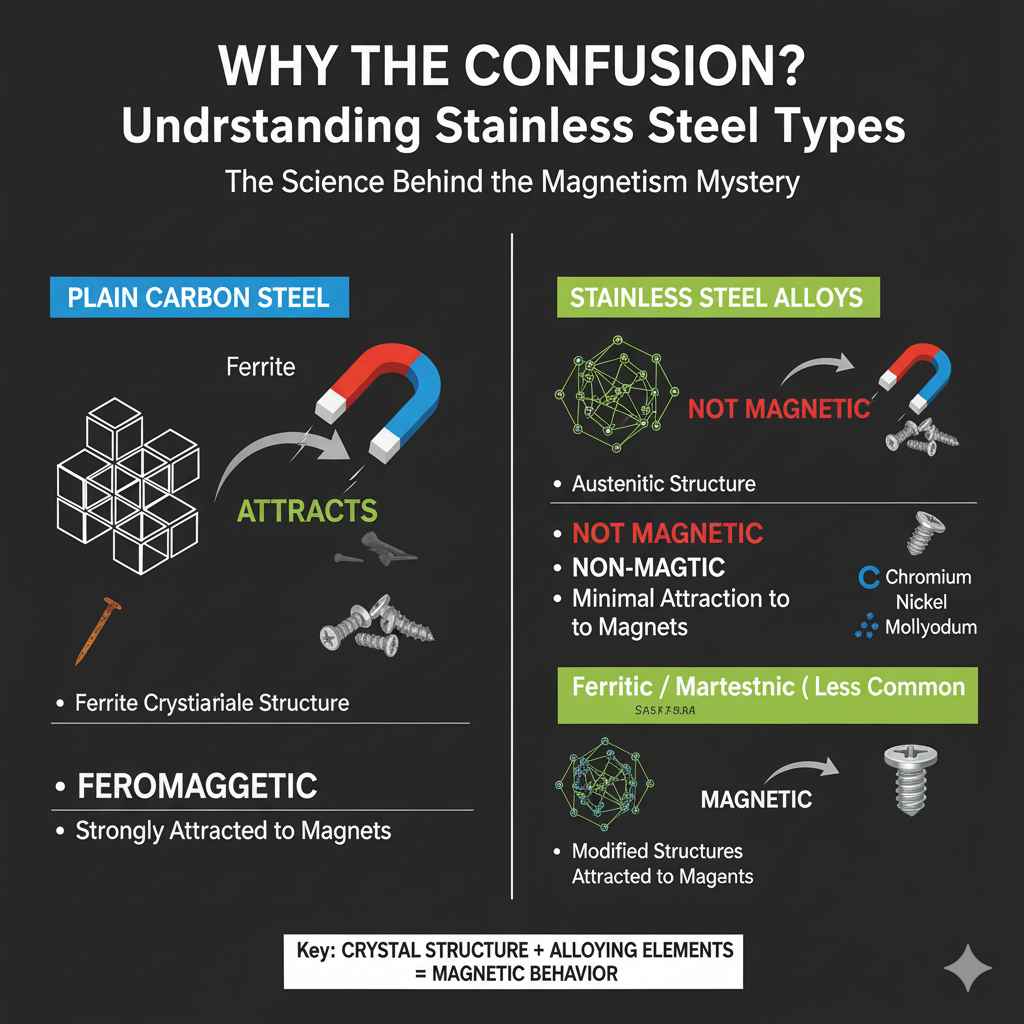

When we talk about magnetism in metals, we’re usually looking at how their internal structure allows them to be easily magnetized. Plain carbon steel, the kind often used for standard nails and screws, has a crystalline structure called “ferrite.” Ferrite is ferromagnetic, meaning it strongly attracts magnets.

Stainless steel, on the other hand, gets its corrosion resistance primarily from chromium. When chromium is added to iron alloy, it often forms a different crystalline structure called “austenite.” Austenitic stainless steels are typically non-magnetic because their structure doesn’t align well with magnetic fields. These are the most common types you’ll find for general-purpose fasteners.

Additionally, stainless steel often includes nickel and molybdenum, which further enhance its non-corrosive properties and affect its magnetic behavior. The exact combination of these elements determines the specific grade of stainless steel and, consequently, how it interacts with magnets.

The Short Answer: Most of the Time, No

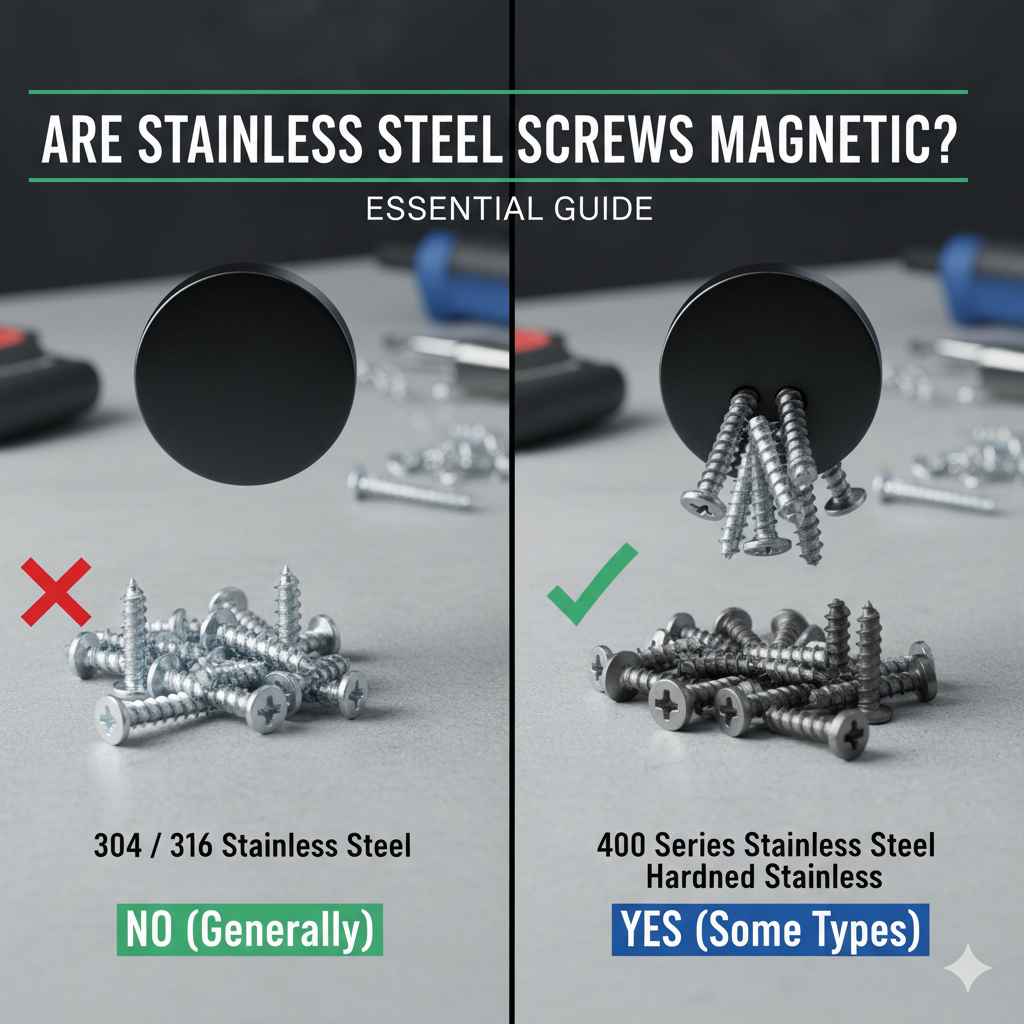

So, to get straight to the point for those of you who just need a quick answer: No, most stainless steel screws are not magnetic, or they are only very weakly magnetic.

This applies to the most common types, like 304 and 316 stainless steel, which are widely used for fasteners. These are austenitic stainless steels, and their crystal structure makes them largely non-magnetic. You’ll find these screws are excellent for resisting rust and look great, but they won’t stick firmly to a magnet.

This is often why people are surprised when their stainless steel screws don’t behave like their standard zinc-plated or galvanized counterparts. It’s a characteristic of the material itself, designed for durability and resistance rather than magnetic attraction.

When Stainless Steel Is Magnetic: Ferritic and Martensitic Grades

While austenitic stainless steels are the most common for corrosion-resistant applications like fasteners and cookware, there are other types of stainless steel that are magnetic. These are primarily ferritic and martensitic stainless steels.

Ferritic Stainless Steels: These steels have a primarily ferritic microstructure, similar to plain carbon steel. This makes them magnetic. They offer good corrosion resistance, though generally not as good as austenitic types, and are often used in automotive exhaust systems and some architectural applications. Some cheaper or specialized screws might be made from ferritic stainless steel.

Martensitic Stainless Steels: These steels have a very hard microstructure. They are also magnetic. Martensitic stainless steels are known for their high strength and hardness and are often used for knives, surgical instruments, and some types of industrial fasteners where strength is paramount, and corrosion resistance is secondary to extreme durability.

The key takeaway here is that if a stainless steel screw is strongly magnetic, it’s likely not made from the common 304 or 316 grades. It might be a ferritic or martensitic grade, or it could even be a different type of steel altogether that looks like stainless steel but isn’t.

Why Do We Use Them Anyway? Pros and Cons of Stainless Steel Screws

Given that they’re often not magnetic, you might wonder why we bother with stainless steel screws. The answer is simple: their incredible benefits often outweigh the lack of magnetic attraction, depending on your project needs.

Let’s break down the advantages and disadvantages:

Pros of Using Stainless Steel Screws

Superior Corrosion Resistance: This is the star of the show! Stainless steel is incredibly resistant to rust, staining, and corrosion. This means your project will look good and hold up longer, especially when exposed to moisture, salt, or chemicals. This is crucial for outdoor decks, fences, marine projects, and even indoor projects in humid environments like bathrooms or kitchens. The U.S. General Services Administration (GSA) offers guidance on material selection for various environmental conditions, highlighting the importance of corrosion resistance in construction.

Aesthetic Appeal: Stainless steel screws have a bright, clean, and premium look. They complement many materials, especially wood and composite decking, and don’t develop unsightly rust streaks that can stain surrounding surfaces.

Durability and Strength: While not always as strong as some hardened alloy steels, stainless steel fasteners offer excellent strength for most general construction and woodworking applications. They’re less prone to snapping under load than some softer metals.

Hygiene: In food processing, medical, or laboratory environments, stainless steel is preferred for its ease of cleaning and resistance to bacterial growth.

Low Maintenance: Once installed, stainless steel fasteners require very little maintenance. You don’t need to worry about painting or treating them to prevent rust, saving you time and effort down the line.

Cons of Using Stainless Steel Screws

Cost: Generally, stainless steel screws are more expensive than carbon steel screws (like zinc-plated or galvanized ones). This can add up on larger projects, but the longevity and reduced maintenance often justify the initial investment.

Softer Than Some Steels: While strong, stainless steel can be softer than hardened alloy steels. This means the heads can be more prone to stripping if you over-torque them or use a poorly fitting driver bit. Using the correct size and type of driver (like Phillips, square drive, or Torx) and applying steady pressure is always important, but especially with softer metals.

Non-Magnetic Nature (Sometimes a Con): As we’ve discussed, the most common types are not magnetic. This means they won’t stick to a magnetic screwdriver tip or a magnetic pickup tool. This can be a minor inconvenience when working in tight spaces or when dropping a screw. While some specialized magnetic screwdrivers exist, standard ones won’t hold a stainless steel screw firmly.

Galvanic Corrosion (if paired incorrectly): While stainless steel itself resists corrosion, it can react with other metals when in contact with an electrolyte (like saltwater or even just moisture). This is called galvanic corrosion. For instance, using stainless steel screws with aluminum or copper components can lead to accelerated corrosion of the less noble metal. When in doubt, consult material compatibility charts.

How to Tell If Your Stainless Steel Screws Are Magnetic

The easiest and most foolproof way to determine if your stainless steel screws are magnetic is, of course, to test them. Here’s how:

1. Grab a Magnet: Any common magnet will do – a refrigerator magnet, a magnetic pickup tool, or even a magnet from a toy.

2. Test the Screw: Simply hold the magnet near the screw.

Strong Attraction: If the magnet snaps to the screw with a noticeable pull, it’s definitely magnetic.

Weak Attraction: If the magnet sticks, but with very little force, it might be weakly magnetic. This could indicate a ferritic or martensitic grade, or perhaps a stainless steel that has undergone work hardening.

No Attraction: If the magnet refuses to budge, the screw is non-magnetic. This is typical for austenitic stainless steels like 304 and 316.

Pro Tip: If you’re unsure about a batch of fasteners, always test a few. It’s a quick check that can save you trouble down the line, especially if magnetism (or lack thereof) is important for your specific application.

Common Stainless Steel Grades and Their Magnetic Properties

Understanding the different grades of stainless steel can shed more light on their magnetic behavior. The numbering system for stainless steel can seem complex, but focusing on the common families helps a lot.

Here’s a look at some widespread types:

| Stainless Steel Grade Family | Common Grades | Primary Metallic Composition (Key Elements) | Generally Magnetic? | Typical Applications for Fasteners |

|---|---|---|---|---|

| Austenitic | 304 | Iron, Chromium (18%), Nickel (8%) | No | General construction, outdoor projects (decks, fences), kitchen and bathroom hardware, marine hardware |

| Austenitic | 316 | Iron, Chromium (16–18%), Nickel (10–14%), Molybdenum (2–3%) | No | Marine environments, coastal installations, chemical plants, and high-corrosion applications |

| Ferritic | 430 | Iron, Chromium (14–18%) | Yes | Automotive trim, decorative components, appliances, and light structural use |

| Martensitic | 410 | Iron, Chromium (11.5–13.5%), Carbon | Yes | High-strength tools, industrial fasteners, and mechanical components |

| Duplex | 2205 | Iron, Chromium (21–23%), Nickel (4.5–6.5%), Molybdenum (2.5–3.5%) | Weakly to Moderately Yes | Offshore structures, chemical processing, high-strength and corrosion-resistant fasteners |

As you can see from the table, the most popular grades for corrosion-resistant fasteners, 304 and 316, are non-magnetic. Grades like 430 and 410, which are often chosen for other properties like hardness or cost-effectiveness, are magnetic. Duplex steels are a bit of a hybrid, offering both good corrosion resistance and strength, and can exhibit some magnetic properties.

The Impact of Work Hardening on Magnetism

Here’s a subtle point that can further complicate the “are stainless steel screws magnetic” question: work hardening.

When austenitic stainless steels (like 304 and 316) are cold-worked – meaning they are formed, bent, or subjected to stress without being heated – their crystalline structure can change slightly. This process, known as work hardening, can reorient some of the metal’s atoms, making slightly magnetic areas.

What does this mean for your screws?

Slight Magnetism: You might find that some stainless steel screws, particularly those that have been heavily processed during manufacturing (like certain types of self-tapping screws or screws formed using cold heading), exhibit a weak magnetic attraction.

Not a Flaw: This weak magnetism is usually not a sign of poor quality or a defect. It’s just a natural consequence of the manufacturing process and the inherent (though low) magnetic potential within the austenitic structure.

Still Excellent Corrosion Resistance: Importantly, this slight increase in magnetism does not significantly compromise their excellent resistance to corrosion. They will still perform admirably in wet and humid conditions.

So, if you run a magnet over a bunch of 304 screws and a few barely cling, don’t be alarmed. They will still offer the rust protection you expect from stainless steel.

Practical Implications for Your DIY Projects

Now that we’ve demystified the science, let’s talk about what this means for your everyday woodworking and DIY tasks.

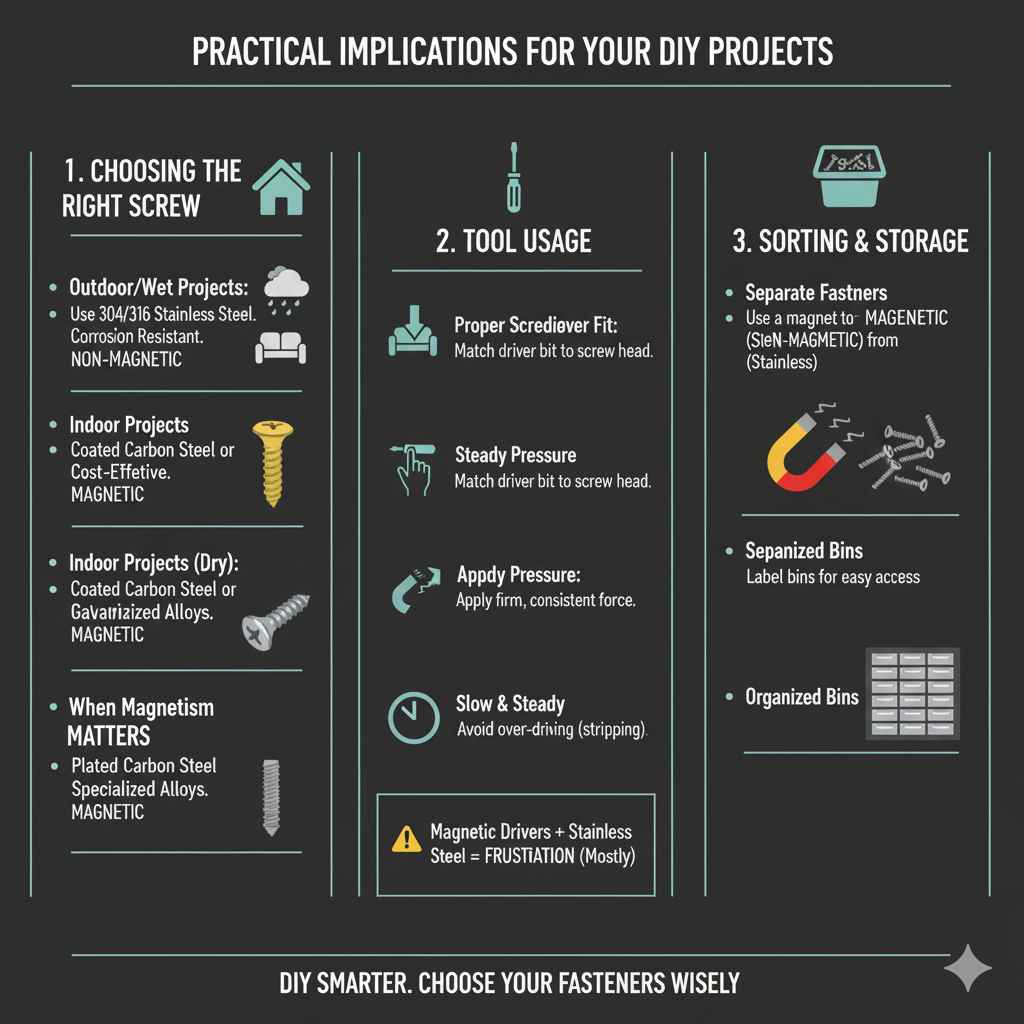

1. Choosing the Right Screw:

Outdoor/Wet Projects: Always opt for 304 or 316 stainless steel screws. Their corrosion resistance is invaluable. Don’t worry if they aren’t attracted to a magnet. Websites like Fasteners Inc. offer a wide range of stainless steel fasteners suitable for various environments.

Indoor Projects (where rust isn’t a major concern): You might still choose stainless steel for its looks or durability, but you can often save money by using high-quality coated carbon steel screws (like ceramic-coated or polymer-coated screws for some moisture resistance) or even galvanized screws.

When Magnetism Matters: If you absolutely need a screw that will stick to your magnetic screwdriver tip (e.g., working overhead, in tight spaces), you’ll need to steer clear of standard austenitic stainless steel. This might mean using specialized magnetic stainless steel alloys (which are less common and more expensive) or reverting to plated carbon steel screws.

2. Tool Usage: Since most stainless steel screws aren’t magnetic, you’ll need to rely on good driving technique.

Proper Screwdriver Fit: Always use a driver bit that perfectly matches the screw head recess to avoid stripping.

Steady Pressure: Apply firm, consistent downward pressure as you drive the screw, especially at the start.

Slow and Steady: Avoid over-driving, which can strip the head or even damage the material you’re fastening into.

Magnetic Tool Buyers Beware: If you’re buying a magnetic screwdriver or magnetic nut drivers, be aware that they won’t be very useful with standard stainless steel screws. They work best with steel fasteners.

3. Sorting and Storage:

Non-Magnetic Fasteners: If you have a mixed bin of screws, a magnet can be a quick way to separate your magnetic steel screws from your non-magnetic stainless steel ones. Just run the magnet over the pile.

How to Select the Best Screws for Your Project: A Quick Guide

Choosing the right fastener is crucial for the success and longevity of any project. Here’s a simple checklist to help you decide:

Environment:

Indoors, Dry: Standard coated or plated carbon steel screws are usually adequate and cost-effective.

Indoors, Humid (Bathroom, Kitchen): Stainless steel (304) or premium coated screws are recommended.

Outdoors, Sheltered: High-quality coated screws (e.g., ceramic or polymer) or 304 stainless steel.

Outdoors, Exposed (Deck, Fence, Marine): 304 or, for maximum protection, 316 stainless steel.

Material Being Fastened:

Wood: Most standard screws work well.

Composite Decking: Always use specialized composite deck screws or 316 stainless steel.

Metals: Special purpose screws are required, often with specific plating or stainless steel grades.

Strength Requirements:

General Use: Most common screws are sufficient.

Structural (e.g., framing, heavy loads): Look for structural screws or lag bolts made from hardened alloy steel or high-strength stainless steel.

Aesthetics:

Hidden Screws: Functionality and strength are key.

Exposed Screws: Stainless steel, decorative heads, or coated screws that match the material.

Budget:

Tight Budget: Coated carbon steel screws offer a good balance.

Willing to Invest in Longevity: Stainless steel is often worth the higher initial cost.

By considering these factors, you can move beyond the magnetic question and make an informed choice for each specific application.

FAQs: Are Stainless Steel Screws Magnetic?

Here are some common questions beginners have about stainless steel screws and magnetism:

Q1: Are all stainless steel screws rust-proof?

While “stainless steel” implies resistance to rust, no material is completely impervious. The most common grades (304 and 316) are highly rust-resistant, especially in typical environments. However, prolonged exposure to harsh chemicals, saltwater, or de-icing salts, particularly in crevices or under debris, can eventually lead to surface discoloration or corrosion. For extreme environments, grade 316 is superior to 304.