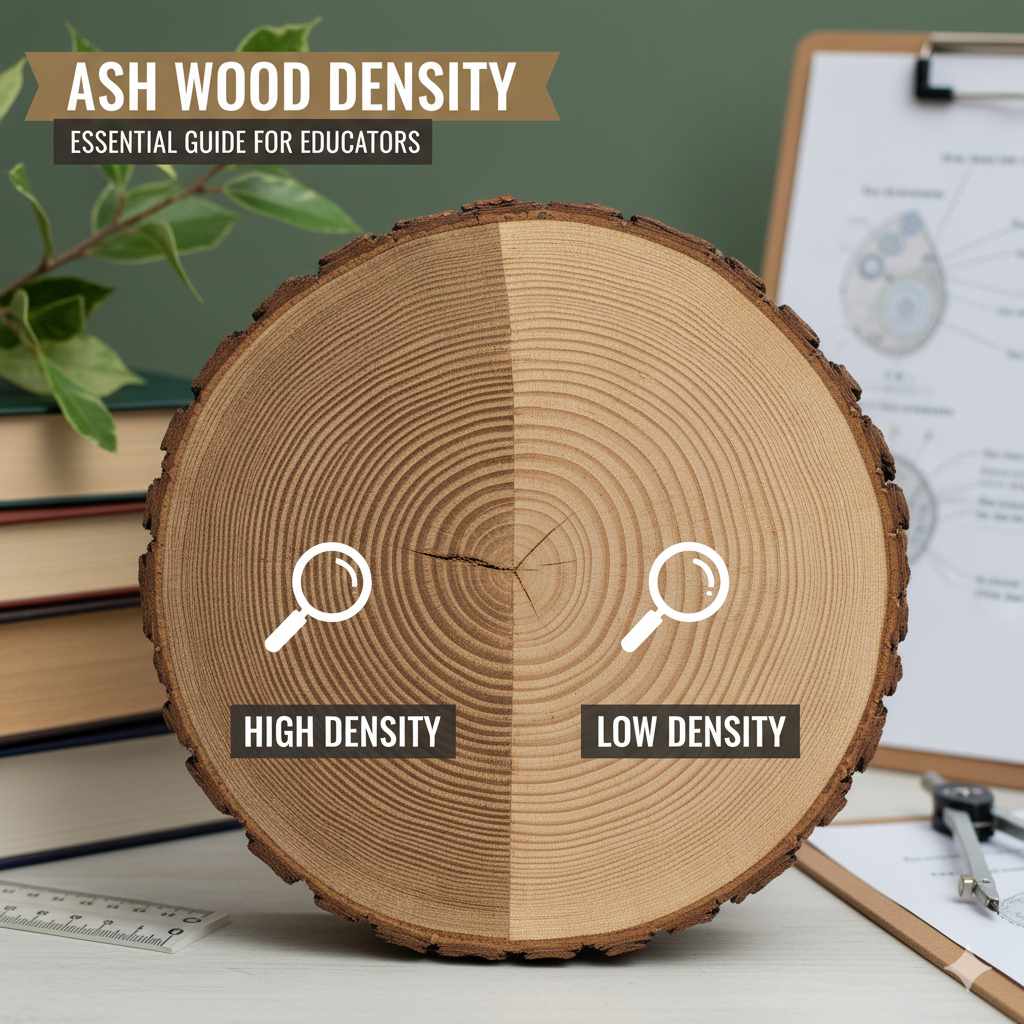

Ash Wood Density: Essential Guide For Educators

Ash wood density is a crucial property for educators to understand, as it directly impacts its strength, durability, and workability. Knowing the specific gravity and weight per board foot allows for better material selection in woodworking projects, ensuring both safety and successful learning outcomes for students.

Hey there, fellow woodworking enthusiasts and aspiring craftspeople! Md Meraj here, your guide to making woodworking fun and achievable. Ever found yourself staring at a piece of ash wood, wondering how it compares to other woods, or if it’s the right choice for your next project? You’re not alone! Understanding wood density might sound a bit technical, but it’s actually super important, especially if you’re teaching or learning the craft. It’s like knowing how heavy a tool is before you pick it up – it helps you use it best!

We’ll break down exactly what ash wood density means in simple terms. We’ll cover what makes one piece of wood heavier or lighter than another, and why that matters for everything from building a sturdy chair to just sanding a smooth finish. Think of this as your friendly workshop guide, clearing up any confusion. Ready to get a better handle on ash wood? Let’s dive in!

Understanding Wood Density: The Basics

Density, in simple terms, is how much “stuff” is packed into a certain amount of space. For wood, it’s usually measured by its weight compared to its volume. Think of it like comparing a bag of feathers to a bag of rocks – both bags might be the same size, but the rocks bag is much heavier because more “rock stuff” is packed in. This “stuff” in wood is mainly the solid wood material itself, but it also includes the moisture content and any air pockets within the wood structure.

Why does this matter so much? Because a wood’s density tells us a lot about its characteristics. Denser woods are generally stronger, heavier, and more durable. They can handle more stress and are less likely to dent or scratch. Lighter woods, on the other hand, might be easier to work with and move around, but they might not be as robust. For educators, understanding this is key because it helps you choose the right wood for student projects, considering factors like safety, durability, and even the cost-effectiveness of the materials.

The scientific way we often talk about wood density is through “specific gravity.” This is basically a ratio comparing the density of the wood to the density of water. A specific gravity greater than 1 means the wood is denser than water and will sink. A specific gravity less than 1 means it’s less dense and will float. While this is a scientific measure, for most practical woodworking purposes, we’re more interested in how dense a wood feels and how it performs in projects.

Ash Wood Density: What You Need to Know

Ash is a fantastic hardwood, popular for its strength, shock resistance, and attractive grain. When we talk about ash wood density, we’re usually referring to several common species, such as White Ash (Fraxinus americana) and Green Ash (Fraxinus pennsylvanica). These woods are known for being moderately dense, striking a great balance that makes them suitable for a wide range of applications.

The density of ash wood can vary a bit depending on the specific species, where it grew, and its moisture content. However, it generally falls into a range that makes it a top choice for furniture, tool handles, baseball bats, gymnasium flooring, and even musical instruments. This versatility is a big reason why it’s found its way into many educational woodworking programs.

For educators, knowing the typical density of ash helps in explaining to students why this wood is chosen for certain projects. For example, its good shock resistance is why it’s perfect for hammer handles. Its strength-to-weight ratio is excellent, meaning it’s strong without being excessively heavy, which is great for projects that need to be handled easily.

Typical Ash Wood Density Values

To give you a clearer picture, let’s look at some common metrics for ash wood density. These numbers are usually based on wood dried to an average moisture content (around 12%), which is typical for finished lumber.

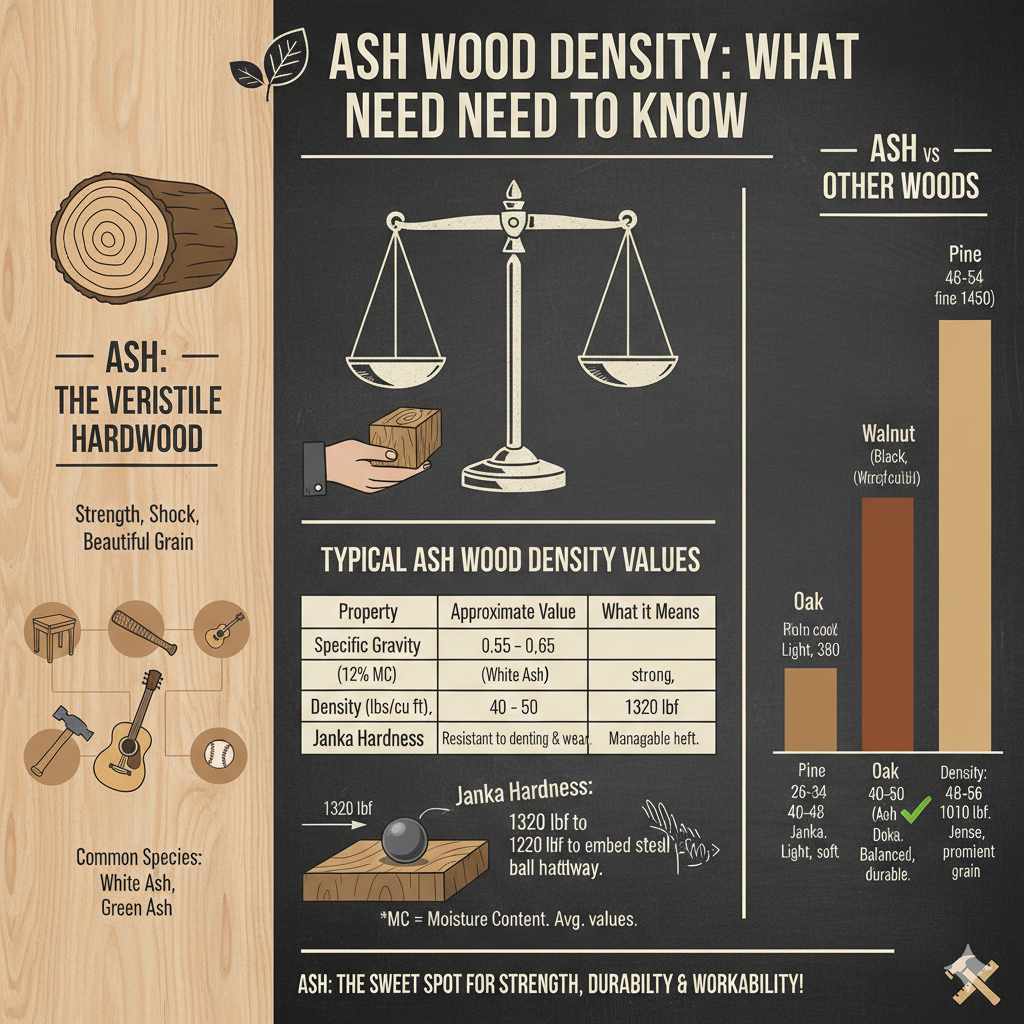

Here’s a table showing approximate density values for White Ash, a very common type of ash wood:

| Property | Approximate Value (for White Ash) | What it Means for You |

|---|---|---|

| Specific Gravity (at 12% MC) | 0.55 – 0.65 | Indicates it’s moderately dense and strong. Floats in water. |

| Density (lbs/cubic foot at 12% MC) | 40 – 50 lbs/cu ft | Gives a good sense of its heft. Heavier than many softwoods, but manageable. |

| Janka Hardness | 1320 lbf (pound-force) | Measures resistance to denting and wear. It’s quite hard, making it durable. |

Note: MC stands for Moisture Content. These are average values and can vary.

The Janka hardness test, for instance, is a great indicator of how well a wood will stand up to physical impact and wear. A Janka rating of 1320 lbf for White Ash means it requires 1320 pounds of force to embed a steel ball halfway into the wood. This tells us it’s a robust material, capable of withstanding the rigors of use, which is a significant advantage for projects that might see a lot of action.

Where Does Ash Stand Compared to Other Woods?

To truly appreciate ash wood’s density, it’s helpful to compare it with other common hardwoods and softwoods. This comparison helps educators illustrate to students the different properties and best uses for various wood types.

Let’s take a look at how ash stacks up:

- Oak (Red Oak): Typically denser and harder than ash, with specific gravity around 0.65-0.75 (48-56 lbs/cu ft) and Janka hardness around 1290 lbf. Oak is known for its prominent grain and excellent durability.

- Maple (Hard Maple): Similar to or slightly denser than ash, with specific gravity around 0.65-0.70 (48-52 lbs/cu ft) and Janka hardness around 1450 lbf. Hard maple is often chosen for its fine, uniform texture and exceptional hardness.

- Pine (Eastern White Pine): Significantly less dense and softer, with specific gravity around 0.35-0.45 (26-34 lbs/cu ft) and Janka hardness around 380 lbf. Pine is much lighter and easier to cut and shape but dents much more easily.

- Walnut (Black Walnut): Slightly less dense than ash, with specific gravity around 0.55-0.65 (40-48 lbs/cu ft) and Janka hardness around 1010 lbf. Walnut is prized for its rich color and workability, offering a different aesthetic and moderate durability.

This comparison clearly shows that ash wood offers a sweet spot: it’s significantly stronger and more durable than softwoods like pine but often a bit lighter and easier to work than some of the “woods in the super-dense club,” like very hard maples or some exotic hardwoods. This makes it a great “middle-ground” material for educational settings.

The Practical Implications of Ash Wood Density for Educators

As an educator, knowing the density of ash wood translates into concrete advantages for your classroom or workshop. It influences material selection, project design, safety considerations, and even how you teach students about wood properties.

Material Selection and Project Suitability

Ash’s moderate density makes it an excellent choice for a wide array of student projects:

- Strength and Durability: Projects that need to withstand regular use, such as stools, small tables, tool caddies, or even simple structures, benefit from ash’s robust nature. Students can be taught that using a wood like ash means their creations are more likely to last.

- Shock Resistance: This is why ash is traditionally used for tool handles. For projects involving mallets or items that might experience impact, ash is a safe and effective material. Educators can explain this property when teaching about tool use.

- Workability: While dense, ash generally machines and cuts well. Its straight grain can make it relatively predictable for beginner woodworkers, unlike some woods with more complex grain patterns that can lead to tear-out. You can teach students about grain direction and how it affects cutting.

- Finishing: Ash has an open grain structure that takes stains and finishes beautifully, allowing for diverse aesthetic outcomes. This offers a good learning opportunity for students to experiment with different finishes and understand how they interact with different wood pores.

Demonstrating Wood Properties to Students

Ash is an ideal wood for hands-on learning experiences:

- Weight Comparison: Bring in similarly sized pieces of ash and pine. Have students lift them to feel the difference in weight. Discuss why this difference occurs (density!). This is a simple, memorable lesson.

- Strength Testing (Safe Demonstrations): While you won’t be breaking boards in class, you can discuss how a denser wood like ash stands up better to forces than a lighter wood. For example, comparing how easily a nail bends in pine versus ash when hammered.

- Grain Structure: Show students the prominent grain of ash. Explain how the density relates to the wood’s cellular structure – more wood cells packed tightly together.

- Shock Absorption: If you have old ash tool handles, show them to students and explain why ash was historically the go-to material. Talk about how it absorbs the shock of striking, making it more comfortable for the user.

Safety Considerations Tied to Density

The density of a wood also plays a role in workshop safety:

- Tool Handling: Heavier woods require more force to cut or shape. While ash is manageable, it’s important to teach students proper techniques for handling tools safely, especially when working with denser materials. This includes secure clamping and appropriate feed rates on machines.

- Project Stability: A denser wood contributes to the overall stability and weight of a finished piece. For larger projects, the density of the material chosen can affect how stable the final item is and whether it’s prone to tipping or wobbling.

- Dust Control: All wood dust can be a respiratory irritant, but denser woods can sometimes produce finer dust particles. Emphasizing the use of dust collection systems and personal protective equipment (like dust masks) becomes even more crucial. You can explain that while ash is great, treating all wood dust with respect is a universal workshop rule. For more on wood dust safety, the Occupational Safety and Health Administration (OSHA) provides invaluable guidance on wood dust hazards and controls.

Working with Ash: Tips for the Classroom

Ash wood is a joy to work with once you understand its properties. Here are some tips specifically for educators and beginner students:

Cutting and Shaping

Ash cuts beautifully with sharp tools. It’s important to emphasize using well-maintained blades and bits. A dull blade will struggle with denser wood, leading to tear-out and potentially dangerous situations.

- Saws: Sharp carbide-tipped blades on table saws, miter saws, and band saws will provide clean cuts. Ensure blades are appropriate for the task and the wood.

- Planing and Joiniing: Ash planes well, but a sharp, well-set plane is essential. A slight bevel on the plane iron can help prevent tear-out, especially around knots or in areas of interlocked grain.

- Routing: Ash is excellent for routing. Straight bits, pattern bits, and roundover bits will all perform well. Remember to take shallow passes to avoid overloading the router or the wood.

Sanding and Finishing

Ash has a relatively open grain. This can be a pro or a con depending on the desired finish.

- Sanding: Start with a coarser grit (like 80 or 100) if there are machine marks, then progress through grits (120, 150, 180, 220). Because of the pores, you might not need to go to extremely fine grits like 400 unless you are aiming for a glass-smooth tabletop finish.

- Filling Pores: For a very smooth, modern finish, you might consider using a pore filler before applying your topcoat. This is a great advanced technique to introduce to students.

- Staining: Stain penetrates ash well due to its open grain. Be mindful that applying stain to very dense areas versus less dense areas might result in slightly different color depths, which can be an interesting learning point about wood uniformity.

- Varnishes and Lacquers: These finishes build nicely on ash and provide good protection. Their durability complements the inherent strength of the wood.

Gluing Ash

Ash glues well, but its density means you need good joint preparation.

- Joint Fit: Ensure that any joints—whether for frame-and-panel construction or edge-gluing boards—are perfectly fitted. Any gaps will be more noticeable and harder to close with dense wood.

- Clamping Pressure: Apply adequate clamping pressure to ensure a strong bond. However, don’t over-tighten clamps to the point where you squeeze all the glue out or crush the wood fibers, especially with denser woods.

- Glue Choice: Standard PVA wood glues (like yellow glue) work very effectively with ash.

Environmental Considerations and Sustainability

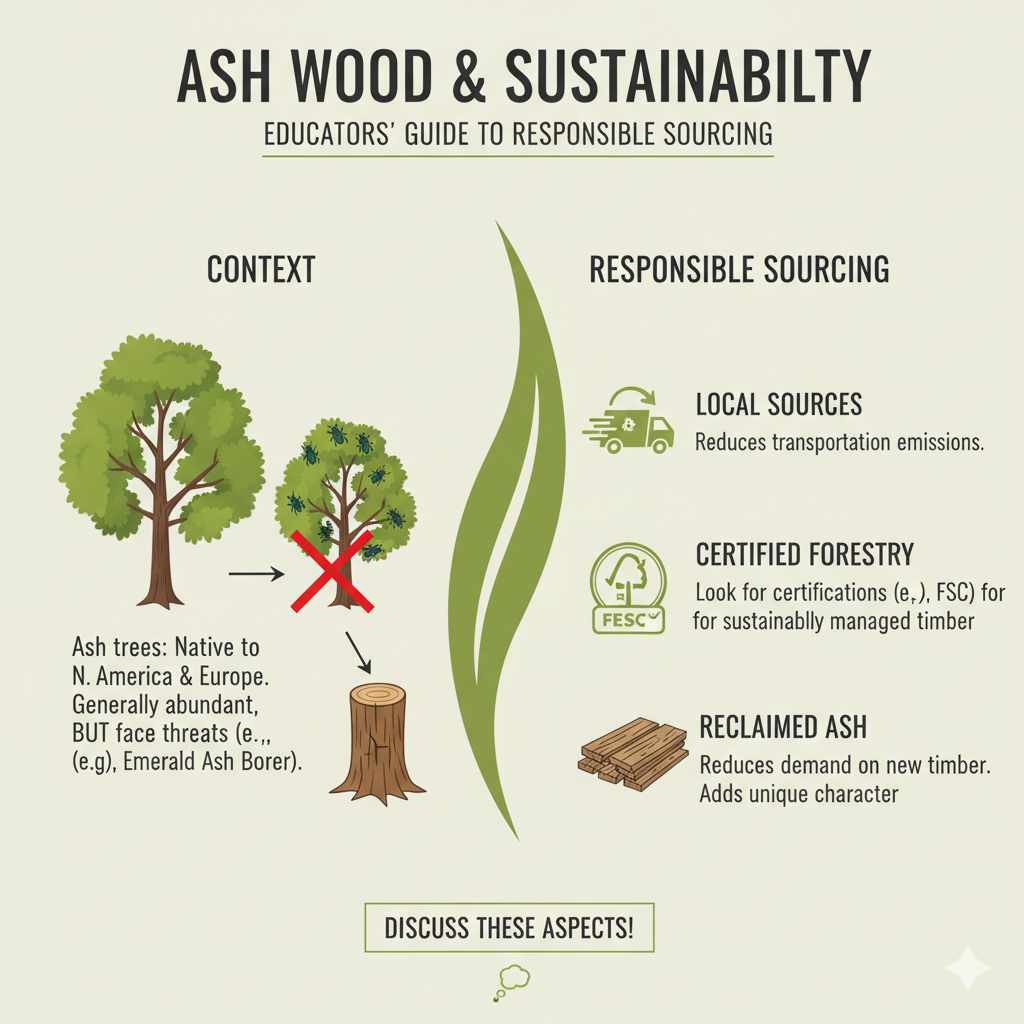

As educators, it’s also valuable to touch upon the sustainability of the materials we use. Ash trees are native to North America and Europe and are generally considered abundant. However, like many tree species, they face threats from pests and diseases. For instance, the Emerald Ash Borer has significantly impacted ash populations in North America.

When sourcing ash wood, it’s good practice to:

- Look for Local Sources: This reduces transportation emissions.

- Check for Sustainable Forestry Practices: Look for certifications or inquire about how the wood was harvested. Organizations like the Forest Stewardship Council (FSC) provide resources for finding sustainably managed timber.

- Consider Reclaimed Ash: Using reclaimed wood is a fantastic way to reduce demand on new timber and often provides unique character.

Discussing these aspects with students adds a layer of environmental awareness to their woodworking education, showing them that craftsmanship can go hand-in-hand with responsible resource management.

Frequently Asked Questions (FAQ) about Ash Wood Density

What is the average weight of a board foot of ash wood?

A typical board foot (1 inch thick, 12 inches wide, 1 foot long) of ash wood, at about 12% moisture content, weighs roughly between 4 to 5 pounds. This can vary a bit depending on the species and exact moisture level, but it gives you a good estimate for handling and project cost calculations.

Is ash wood stronger than oak?

Generally, ash is slightly softer and less dense than red oak, but it possesses superior shock resistance. While oak might be marginally stronger in terms of pure compressive strength and hardness, ash is often favored for applications requiring toughness and the ability to absorb impact, like tool handles or sports equipment.

How does the density of ash wood affect its cost?

While density itself isn’t the sole factor in lumber pricing, denser hardwoods like ash are typically more expensive than softwoods because they grow slower and require more effort to harvest and process. However, ash is often more affordable than some extremely dense or exotic hardwoods like mahogany or ebony, making it a good value for its strength and durability.

Is ash wood difficult for beginners to work with due to its density?

No, ash is considered moderately easy to work with for beginners. It machines, cuts, and sands well with sharp tools. Its primary characteristic that beginners need to be aware of is that it requires sharp tools and a bit more force than softwoods. Its straight grain, however, makes it forgiving compared to woods with more complex grain patterns.

Does the moisture content of ash wood affect its density?

Yes, absolutely. As wood absorbs moisture, it gets heavier, and its density increases. Conversely, as wood dries and loses moisture, its weight and density decrease. The density figures usually quoted are for wood dried kiln-dried to around 12% moisture content, which is standard for furniture and construction lumber.