Best Preservative For Cedar Wood Protection

Choosing the Best Preservative for Cedar Wood Protection can feel tricky at first. Many options seem confusing. You want to keep your cedar looking great and lasting longer, but where do you begin?

It’s simpler than you think! We will walk you through it step-by-step. Get ready to learn how to pick the perfect product to shield your beautiful cedar wood.

Understanding Cedar Wood and Its Needs

Cedar wood is loved for its natural beauty and its own resistance to rot and insects. However, even the best wood needs help to stay its best over time. Exposure to sun, rain, and snow can break it down.

This section will help you grasp why cedar needs a good preservative. We will look at what makes cedar special and what threats it faces. Knowing this helps you pick the right protector.

Why Cedar Wood Needs Protection

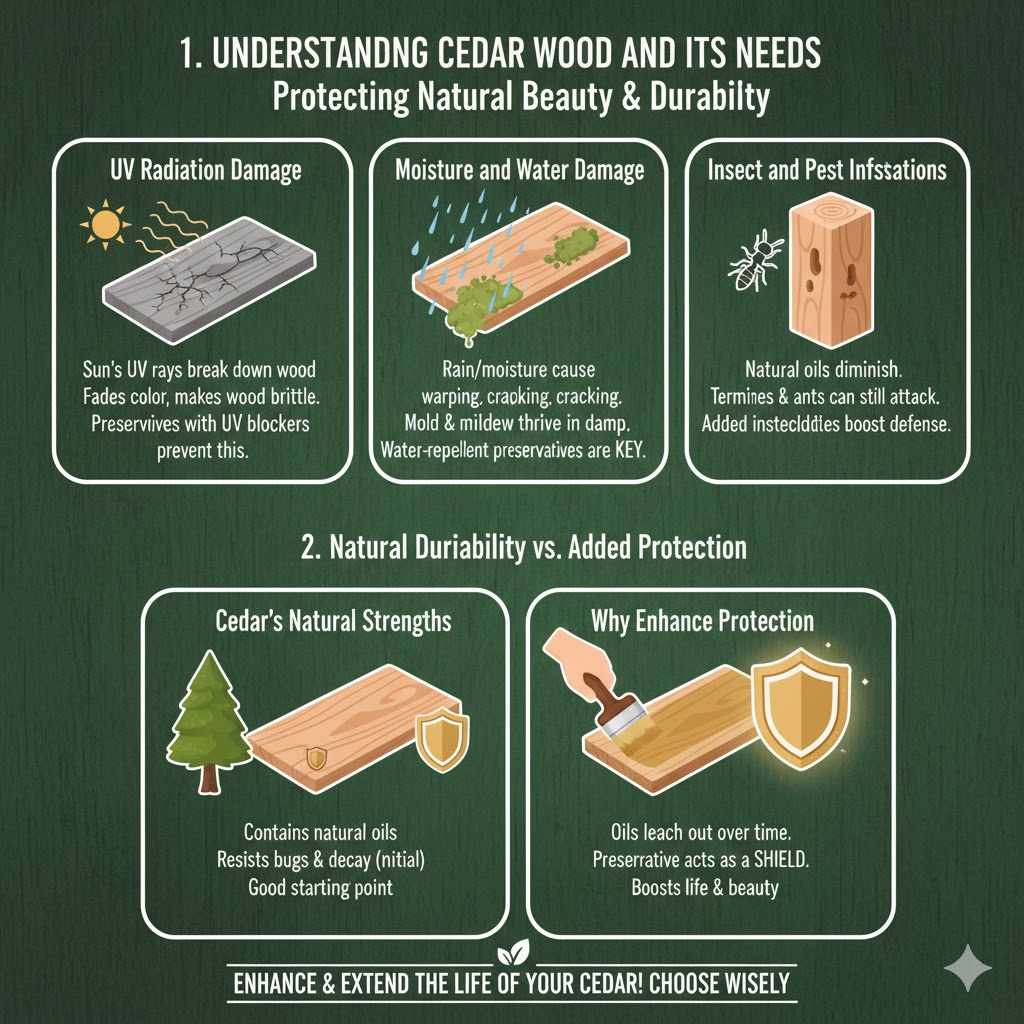

Cedar is naturally durable, which is a big reason people choose it for outdoor projects. It contains oils that help fight off bugs and decay. But these natural defenses aren’t forever.

Over time, the sun’s UV rays can fade the wood’s color and make its surface dry and brittle. Rain and moisture can soak in, creating a perfect spot for mold and mildew to grow. This can lead to rot.

Constant changes in weather, like freezing and thawing, can cause the wood to expand and contract. This can lead to cracks and splits. A good preservative acts like a shield.

It stops water from getting in too deep. It also helps block harmful UV rays from the sun. This keeps the wood strong and looking good for much longer.

- UV Radiation DamageThe sun’s ultraviolet (UV) rays are a major enemy of wood. When UV rays hit untreated cedar, they break down the lignin, which is a natural glue in the wood. This makes the wood’s surface chalky and gray.

It also makes the wood more prone to drying out and cracking. A preservative with UV blockers can stop this damage before it starts. It keeps the wood’s natural color from fading.

- Moisture and Water DamageWater is a cedar wood’s best friend for growth but a worst enemy when it’s a finished product. Wood that gets wet often and then dries out repeatedly can swell and shrink. This constant movement weakens the wood fibers.

It can lead to warping, cupping, and splitting. Mold and mildew also thrive in damp conditions. They can stain the wood and eventually rot it.Preservatives that repel water are key.

- Insect and Pest InfestationsWhile cedar has natural insect-repelling qualities, these can diminish over time. Termites, carpenter ants, and other wood-boring insects can still attack cedar, especially if it’s weakened by other environmental factors. Some wood preservatives contain insecticides that add an extra layer of defense.

This is especially important in areas known for high pest activity. Protecting against these pests ensures the structural integrity of your cedar.

Natural Durability vs. Added Protection

Cedar’s natural oils provide a good starting point for its resistance to decay and insects. This means it often performs better than woods like pine without any treatment. However, these natural oils can leach out over time, especially with prolonged exposure to the elements.

Think of it like a built-in immune system that can get tired. Adding a preservative boosts this system. It’s like giving your cedar an extra layer of armor.

The level of protection needed depends on where your cedar is used. A cedar fence in a rainy climate will need more robust protection than cedar shingles on a sheltered roof. Natural durability is a great benefit, but it’s not a guarantee against all damage.

A good preservative works with cedar’s natural strengths, enhancing them rather than replacing them. It extends the wood’s life and keeps its appearance beautiful.

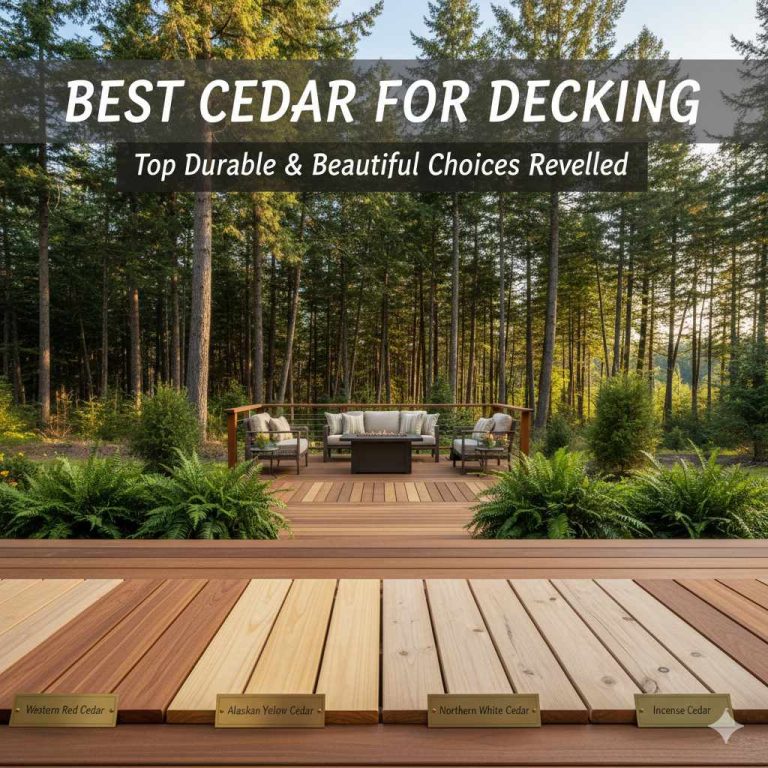

Types of Preservatives for Cedar Wood

There are several types of wood preservatives available, each with its own strengths and weaknesses. Understanding these differences is key to choosing the Best Preservative for Cedar Wood Protection. We will explore common types like water repellents, stains, and sealers.

We will explain what they do and how they work. This will help you make an informed choice for your specific needs.

Water Repellents

Water repellents are designed to stop water from soaking into the wood. They don’t usually add much color. They often contain waxes or oils that push water away from the surface.

This is a simple but effective way to prevent moisture damage.

These products are great for cedar that you want to keep looking natural. They work by creating a surface tension that makes water bead up and roll off. This significantly reduces the amount of moisture the wood absorbs.

This is crucial for preventing rot, mildew, and cracking caused by freeze-thaw cycles. Water repellents are typically easy to apply and require reapplication every year or two.

- How They WorkWater repellents use hydrophobic ingredients, meaning they repel water. These can be oils, waxes, or silicone-based compounds. When applied, these ingredients penetrate the wood slightly or form a barrier on the surface.

This barrier prevents liquid water from entering the wood’s pores. However, they usually still allow water vapor to escape, letting the wood “breathe.” This is important to prevent moisture from getting trapped inside.

- BenefitsThe main benefit is preventing water-related damage like rot and swelling. They can also help maintain the wood’s original color for longer by reducing the effects of moisture staining. They are often clear or lightly tinted, so they don’t hide the wood’s natural grain.

Application is usually straightforward, making them a good DIY option.

- LimitationsWater repellents offer little to no protection against UV rays. They also don’t provide significant protection against insect damage. Their protection against mold and mildew is also limited compared to other treatments.

They typically need to be reapplied more frequently, often annually, to maintain their effectiveness.

Stains and Sealers

Stains and sealers do more than just repel water. Stains often add color and can contain pigments that block UV rays. Sealers form a protective film on the surface.

Many products combine these features.

These treatments offer a more comprehensive approach to wood protection. They not only shield against moisture but also enhance the wood’s appearance and protect it from sun damage. Stains come in various opacities, from transparent to solid, allowing you to choose how much of the wood grain you want to show.

Sealers create a durable coating that stands up well to wear and tear.

Transparent and Semi-Transparent Stains

These stains allow the natural beauty of the cedar grain to show through. They contain pigments that offer some UV protection and water repellency. They are a good choice if you like the natural look of cedar but want a bit of added protection.

Transparent stains are like a light wash of color. They enhance the wood’s natural tones without hiding them. Semi-transparent stains add a bit more color and UV protection.

They can be good for bringing out the warmth of cedar or for subtly changing its shade. Both types penetrate the wood to some degree, offering protection from within.

- UV ProtectionThe pigments in stains are key to blocking UV rays. Even a small amount of pigment can significantly reduce the amount of UV radiation that reaches the wood fibers. This prevents fading and degradation.

The more pigment, the greater the UV protection.

- Color OptionsThese stains offer a wide range of color choices. You can go for a natural look with a clear or light brown stain, or you can opt for something bolder. The goal is to complement the cedar’s natural beauty, not overpower it.

- DurabilityWhile they offer good protection, transparent and semi-transparent stains typically need reapplication more often than solid stains. They penetrate the wood, so wear and tear can affect them more quickly. Reapplication might be needed every 2-3 years, depending on exposure.

Solid Color Stains and Paints

Solid color stains and paints cover the wood completely, hiding the grain. They offer the highest level of UV protection and can last for many years. However, they also change the wood’s natural look.

These options act like a protective shell for your cedar. They are excellent for maximizing durability and longevity. Because they form a film on the surface, they provide a robust barrier against moisture and UV damage.

If you want to change the color of your cedar or cover up imperfections, solid stains or paints are excellent choices.

- Maximum ProtectionSolid stains and paints offer the best protection against UV rays and moisture. The solid pigment covers the wood completely, creating a powerful shield. This significantly slows down the weathering process and helps prevent rot.

They are often fortified with mildewcides.

- Appearance ChangeThe main drawback is that they completely hide the natural wood grain. This is a matter of personal preference. Some people prefer the painted look, while others want to see the wood’s natural beauty.

If you choose this option, ensure it aligns with your aesthetic goals.

- Application and MaintenanceApplying solid stains and paints requires careful preparation. The wood surface must be clean and dry. Once applied, they can last for 5-7 years or even longer before needing recoating.

If they start to peel or crack, the surface may need to be scraped and sanded before reapplication.

Oils and Waxes

Pure oils and waxes are natural options that penetrate the wood. They enhance the wood’s natural color and provide moisture resistance. They are great for a very natural look.

These products feed the wood rather than coating it. They soak into the wood fibers, replenishing natural oils and providing a barrier from within. This helps prevent the wood from drying out and cracking.

They also give the wood a rich, natural sheen. While they offer good moisture protection, their UV protection is minimal.

- PenetrationOils like tung oil or linseed oil penetrate deeply into the wood. They bond with the wood fibers, making the wood more resistant to moisture absorption. Waxes can provide a surface seal but are less durable on their own.

- Natural AppearanceThese treatments enhance the natural color and grain of cedar beautifully. They often make the wood look richer and deeper in tone. This is ideal for those who love the authentic look of natural wood.

- Reapplication FrequencyOils and waxes typically require more frequent reapplication, often every 6-12 months, especially in harsh weather conditions. This is because they don’t form a surface film and can wear away over time. Regular maintenance is key to their effectiveness.

Choosing the Best Preservative for Cedar Wood Protection

Deciding on the Best Preservative for Cedar Wood Protection involves considering several factors. Your choices depend on the look you want, the environment your cedar is in, and how much maintenance you’re willing to do. Let’s break down how to make the best choice for your project.

Consider Your Environment

The climate where your cedar wood is located plays a huge role in the type of protection it needs. If you live in a place with intense sun and heat, UV protection is very important. For areas with lots of rain or snow, water repellency is key.

Coastal areas with salty air can also be harsh.

Think about constant moisture versus dry heat. A place with frequent rain might need a stain with good water repellency and mildew resistance. A very sunny and dry climate might benefit more from a product with strong UV blockers.

High humidity environments require good breathability to avoid trapping moisture. Understanding these environmental demands helps narrow down your options.

- High UV ExposureIf your cedar is in direct sunlight for most of the day, UV damage is a significant concern. Look for products specifically labeled as “UV protection” or those with high pigment content. Solid stains offer the most UV protection, but semi-transparent stains with good pigments can also work well.

- High Moisture or RainIn rainy or humid regions, preventing water absorption is critical. Water repellents, water-based sealers, and stains with excellent water-repelling properties are ideal. Ensure the product allows the wood to breathe to avoid trapping moisture, which can lead to rot and mold.

- Extreme TemperaturesAreas with extreme temperature fluctuations (hot summers, freezing winters) can cause wood to expand and contract significantly. This can lead to cracking and splitting. Preservatives that maintain wood flexibility and prevent excessive drying are beneficial.

Some oil-based products can help here.

Desired Appearance and Aesthetics

What do you want your cedar wood to look like? Do you love its natural light color, or do you want to give it a warmer tone or even a completely new color? Your aesthetic goals will heavily influence your choice of preservative.

The visual aspect is very important for many people. Cedar is often chosen for its beautiful natural grain. If you want to highlight this, transparent or semi-transparent finishes are best.

If you are looking to match a specific color scheme or protect the wood with a solid color, then solid stains or paints are the way to go. Consider the long-term look you want for your project.

- Natural LookIf you want to keep the natural look of cedar, choose clear water repellents, oils, or transparent stains. These products enhance the wood’s natural color and grain without obscuring it. They offer protection while maintaining the authentic appearance of the wood.

- Enhanced Natural ToneSemi-transparent stains can give cedar a richer, deeper color while still allowing the grain to show. They offer a good balance between enhancing the wood’s appearance and providing protection. Many shades are available to suit different tastes.

- Color Change or CoverageSolid color stains and paints will completely transform the look of your cedar. They offer the widest range of color options and hide the wood grain. This is a good choice if you want to match your cedar to other features or simply want a bold new look.

Maintenance and Longevity

Some wood preservatives last longer than others, and some require more frequent reapplication. Think about how much time you want to spend on maintenance. A product that lasts longer might cost more upfront but save you time and effort later.

Longevity is a key consideration for many homeowners. A product that offers long-lasting protection will mean fewer reapplication tasks. However, sometimes, more frequent, simpler maintenance is easier than less frequent, more involved maintenance.

Weigh the pros and cons based on your lifestyle and expectations for the wood’s appearance.

- Low Maintenance OptionsProducts that last longer and require less frequent reapplication are ideal for those seeking a low-maintenance solution. Solid stains and high-quality exterior paints generally offer the longest lifespan, often lasting 5-7 years or more.

- Moderate Maintenance OptionsSemi-transparent and transparent stains typically need reapplication every 2-3 years. While this is more frequent than solid stains, it’s often manageable. These offer a good balance of protection, appearance, and maintenance effort.

- High Maintenance OptionsPure oils and waxes offer beautiful natural finishes but require the most frequent reapplication, often annually. This is because they penetrate the wood and don’t form a lasting surface film. If you enjoy the process of wood care and want a very natural look, this might be for you.

Specific Product Types to Consider

When looking for products, keep an eye out for certain formulations. Water-based vs. oil-based can also make a difference in application, cleanup, and how the product performs over time.

Many brands offer products specifically designed for cedar or softwood protection. Reading labels carefully is important. Look for key features like UV blockers, water repellency, mildew resistance, and ingredients like linseed oil, tung oil, or acrylic polymers.

These components contribute to the product’s effectiveness in protecting your cedar wood.

- Acrylic Latex StainsThese are water-based and offer good flexibility, making them suitable for wood that expands and contracts. They generally provide good UV resistance and mildew protection. Cleanup is easy with soap and water.

They adhere well and are a popular choice for many outdoor projects.

- Oil-Based Stains and SealersThese penetrate the wood deeply, offering excellent water repellency and a rich, natural look. They are particularly good at conditioning the wood and preventing drying. However, they can take longer to dry, have stronger odors, and require mineral spirits for cleanup.

They can also be prone to mildew growth if not formulated with additives.

- Penetrating OilsAs mentioned, oils like tung oil, linseed oil, or specialized deck oils are great for feeding and protecting the wood from within. They enhance the natural beauty and provide moisture resistance. They are best for a natural, low-sheen finish and require regular upkeep.

Application Tips for Best Results

Applying your chosen preservative correctly is just as important as picking the right one. Proper application ensures the product works effectively and lasts as long as possible. Follow these tips for the best results.

Getting the application right makes a big difference. It’s not just about slapping it on. A clean surface, the right tools, and following the product’s instructions are essential.

These steps ensure the preservative penetrates well and forms a lasting protective layer on your cedar wood.

Preparation is Key

Before you apply any preservative, the wood must be clean and dry. Remove any old finish, dirt, mildew, or sap. Sanding might be necessary to create a smooth surface for the product to adhere to.

This is the most critical step. If the wood is dirty, the preservative won’t soak in properly. Old finishes can prevent new products from bonding.

Mildew needs to be killed and removed to prevent it from growing back. For new cedar, it’s often best to let it weather for a few weeks or months before applying a finish, or use a specific product for new wood.

- Cleaning the WoodUse a dedicated wood cleaner or a solution of mild detergent and water. For stubborn stains or mildew, a specialized deck cleaner or a diluted bleach solution might be needed. Always rinse thoroughly and let the wood dry completely.

- Removing Old FinishesIf the wood has an old coating that is peeling or cracking, it must be removed. This can be done with a scraper, wire brush, or chemical stripper. Sanding afterward helps smooth out any rough spots.

- SandingLight sanding can open up the wood’s pores, allowing better penetration of the preservative. It also creates a smooth, uniform surface. For most finishes, a medium-grit sandpaper (around 80-120 grit) is sufficient.

Always sand in the direction of the wood grain.

Application Methods

You can apply wood preservatives using a brush, roller, or sprayer. Each method has its own advantages. Choose the one that best suits your project and the product you are using.

Brushes offer good control for detailed areas and help work the product into the wood grain. Rollers are faster for large, flat surfaces. Sprayers provide a quick and even coat, but often require back-brushing to ensure good penetration.

Always follow the manufacturer’s recommendations for application.

- BrushingA good quality synthetic brush is best for water-based products, while a natural bristle brush is better for oil-based ones. Brushing allows you to control the amount of product applied and ensures it is worked into the wood. This is often the best method for detailed work or for ensuring complete coverage.

- RollingUsing a long-handled roller can speed up the process on large areas like decks or siding. It provides a relatively even coat. For best results, it’s often recommended to follow up with a brush to even out the application and ensure penetration.

- SprayingSprayers, whether pump sprayers or airless sprayers, can apply product quickly and uniformly over large areas. However, sprayers can sometimes lead to overspray and may not force the product deeply into the wood. Back-brushing after spraying is highly recommended for oil-based products and some water-based stains to ensure proper adhesion and penetration.

Drying Times and Reapplication

Pay close attention to the product’s drying and recoating times. Applying a second coat too soon or in damp conditions can cause problems. Always check the weather forecast and ensure you have enough dry time before rain or dew.

Understanding drying times helps achieve a professional finish. Rushing the process can lead to a sticky surface, uneven color, or failure of the finish. Proper drying allows the preservative to cure and form a protective barrier.

Knowing when to reapply keeps your cedar looking its best for years to come.

- Drying Between CoatsMost products specify a drying time between coats. This can range from a few hours to 24 hours. Ensure the surface is dry to the touch before applying another coat.

This prevents trapping solvents or moisture, which can compromise the finish.

- Curing TimeCuring is a longer process than drying. During curing, the finish hardens and reaches its maximum durability. Avoid heavy use or cleaning of the wood until the product is fully cured, which can take several days to a week or more.

- Reapplication ScheduleThe need for reapplication depends on the product used and environmental exposure. Regular inspection of the wood is important. Look for signs of wear, fading, or water penetration.

Stick to the manufacturer’s recommended reapplication schedule for optimal protection.

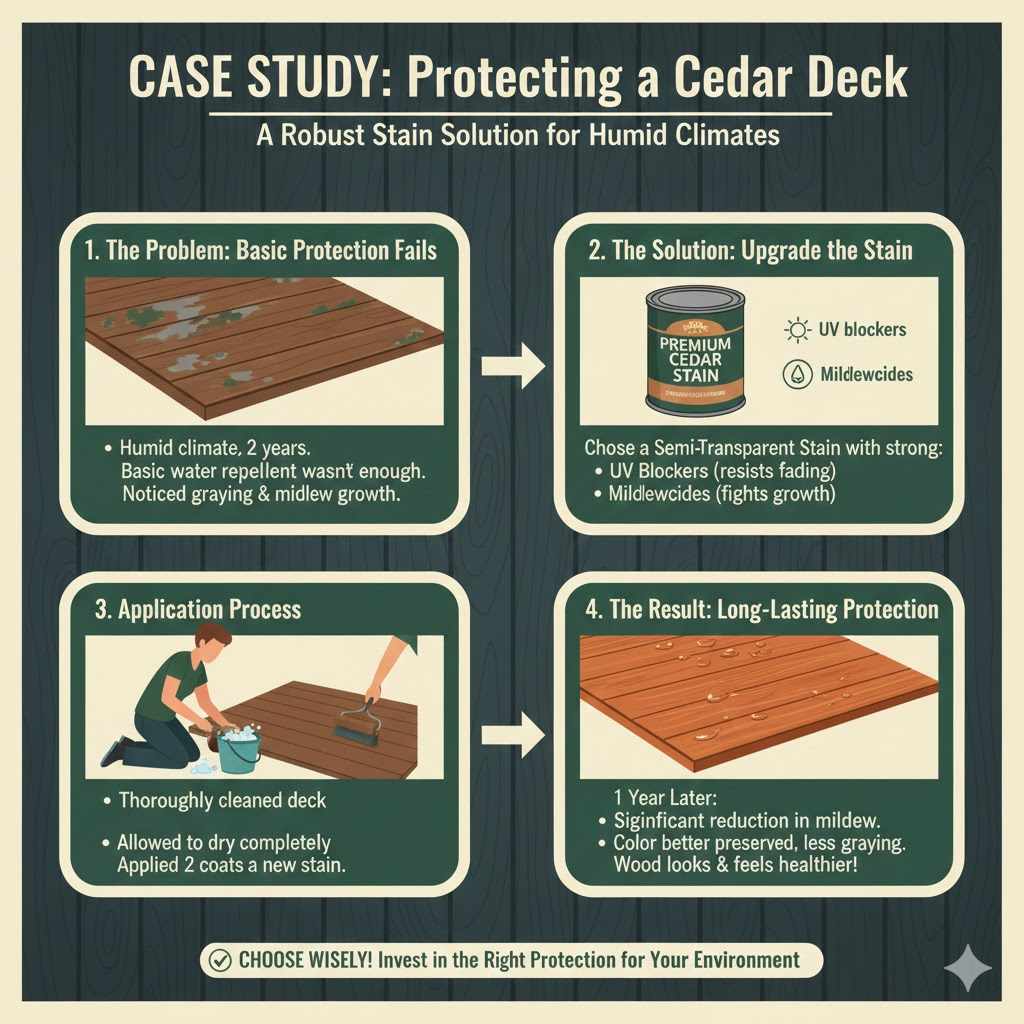

Case Study: Protecting a Cedar Deck

A homeowner in a humid region noticed their cedar deck started showing signs of mildew and graying after just two years. They had previously used a basic water repellent, but it wasn’t enough. They decided to try a semi-transparent stain with strong mildewcides and UV blockers.

After cleaning the deck thoroughly and letting it dry, they applied two coats of the new stain. Within a year, they observed a significant reduction in mildew growth. The wood’s original color was also better preserved, with less graying.

This case shows how choosing a more robust product suited to the environment can greatly improve cedar wood protection.

FAQ

Question: What is the easiest preservative to use on cedar wood

Answer: For ease of use, clear water repellents or penetrating oils are often the simplest to apply. They usually require less prep and are forgiving if applied unevenly, though they need more frequent reapplication.

Question: Can I paint my cedar wood instead of using a stain

Answer: Yes, you can paint cedar wood. Paint offers excellent protection against UV and moisture but completely covers the natural wood grain, changing its appearance significantly.

Question: How often should I reapply preservative to my cedar

Answer: This depends on the product. Clear water repellents may need reapplication every year, while solid stains can last 5-7 years. Check the product label and inspect your wood regularly.

Question: Does cedar wood need protection if it’s naturally rot-resistant

Answer: Yes, while cedar is naturally resistant, it still benefits from protection against UV rays, moisture, and eventual wear. Protection extends its lifespan and maintains its appearance.

Question: What are the downsides of oil-based preservatives

Answer: Oil-based preservatives can have strong odors, take longer to dry, and require mineral spirits for cleanup. They can also be more prone to mildew if not properly formulated.

Wrap Up

Finding the Best Preservative for Cedar Wood Protection involves understanding your wood’s needs and your preferences. By considering the environment, desired look, and maintenance effort, you can select a product that keeps your cedar beautiful and strong for years to come. Choose wisely and enjoy your well-protected cedar.