Brushless Drill vs Regular: Essential Power!

Brushless drills offer more power, longer runtimes, and better durability than brushed (regular) drills, making them a superior choice for most DIYers and woodworkers seeking a reliable and efficient tool that lasts.

When you’re starting out in woodworking or tackling home improvement projects, choosing the right drill can feel like a puzzle. You see different types and wonder, “What’s the real difference?” Many folks get a little confused between a “brushless drill” and a “regular” or “brushed” drill. This can make picking the best tool for your needs a bit tricky, and honestly, a bit frustrating! Don’t worry, though. I’m here to help you sort it all out, making it super simple. We’ll break down exactly what makes these drills tick and which one is your perfect workshop companion. Stick around, and by the end, you’ll know exactly which drill will power your projects to success!

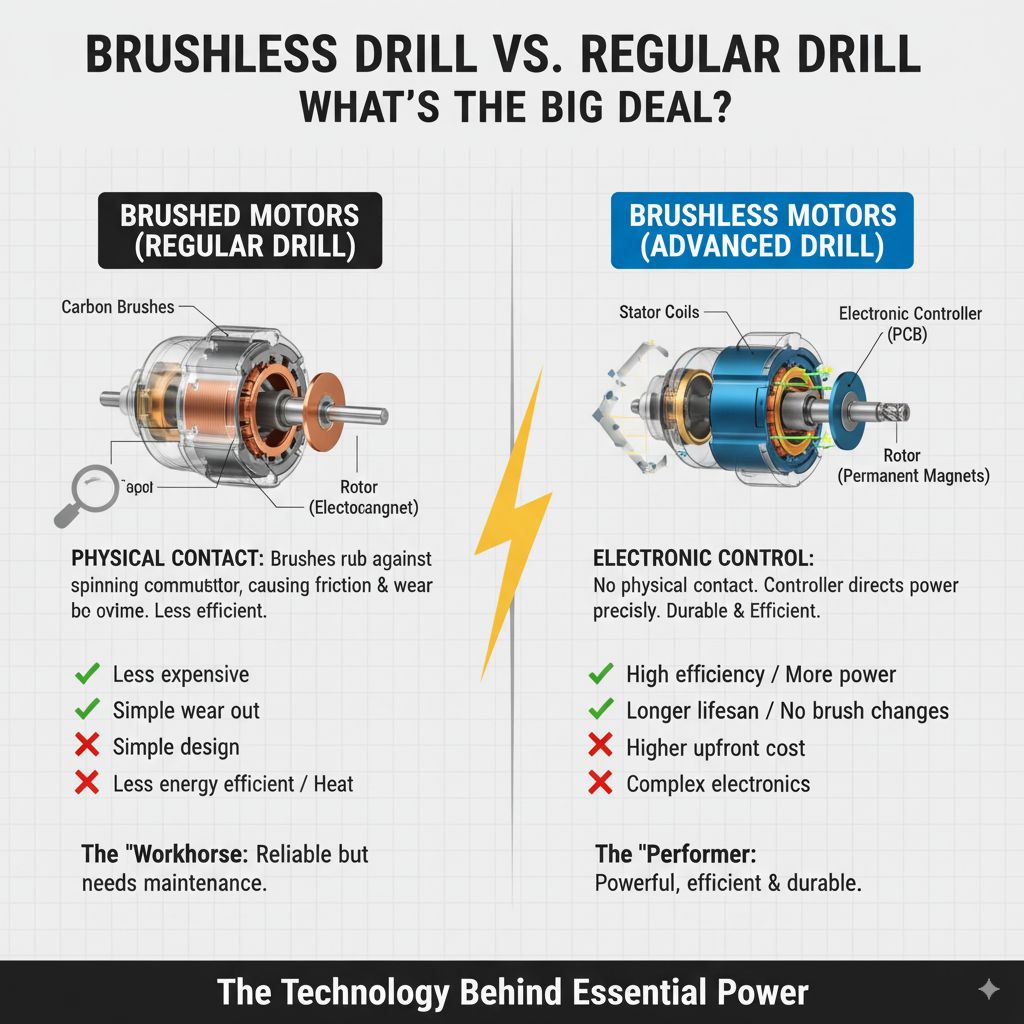

Brushless Drill vs. Regular Drill: What’s the Big Deal?

Let’s dive into the heart of the matter: what sets a brushless drill apart from its brushed counterpart? It all comes down to how the motor works. Think of a motor like the engine in your car; it’s the powerhouse that makes everything happen.

Understanding Brushed Motors (The “Regular” Drill)

The “regular” drill most of us are familiar with uses what’s called a brushed motor. Inside this motor, there are physical components called brushes. These brushes are essentially little blocks of carbon that make contact with a spinning part of the motor (the rotor). Their job is to conduct electricity. As the rotor spins, these brushes continuously rub against it, allowing electricity to flow and create the spinning motion.

While simple and effective, this friction isn’t perfect. Over time, the brushes wear down. This means they’ll need to be replaced eventually. Plus, the friction creates heat and can cause the motor to lose some efficiency. Think of it like a bicycle with a bit of constant drag – it still works, but it’s not as smooth or as powerful as it could be.

Understanding Brushless Motors (The “Brushless” Drill)

Now, let’s talk about the exciting world of brushless motors. These advanced motors ditch the physical brushes altogether! Instead, they use electronics (a controller) to manage the flow of electricity to the motor’s coils. This electronic control is much smarter and more precise.

Imagine a highly efficient, perfectly timed system that directs power exactly when and where it’s needed within the motor. This electronic control means there’s no physical friction from brushes. Because there are no brushes to wear out, brushless motors are incredibly durable and long-lasting. They also generate less heat, spin more efficiently, and can deliver more power and speed when you need it. It’s like upgrading from a regular bicycle to an electric bike – a significant leap in performance!

Key Differences: Brushless vs. Brushed at a Glance

To make it even clearer, let’s put the main differences side-by-side.

| Feature | Brushed (Regular) Drill Motor | Brushless Drill Motor |

|---|---|---|

| How it Works | Uses physical carbon brushes to conduct electricity to the rotor. | Uses electronic controllers to manage electricity flow, without physical brushes. |

| Friction | High friction due to brushes rubbing against the rotor. | Very low friction; no brushes to wear down. |

| Durability | Brushes wear out over time and need replacement. Motor lifespan is generally shorter. | Much higher durability; no parts to wear out. Motor lifespan is significantly longer. |

| Efficiency | Less efficient due to friction and heat generation. | More efficient; converts more battery power into rotational force. |

| Power Output | Generally lower power output for a given size and battery voltage. | Higher power output, better torque, and more consistent speed under load. |

| Heat Generation | Generates more heat due to friction. | Generates less heat, allowing for longer runtimes and less motor strain. |

| Battery Life | Shorter battery life due to lower efficiency. | Longer battery life (up to 50% more runtime) because of higher efficiency. |

| Noise Level | Can be noisier due to brush friction. | Typically quieter operation. |

| Cost | Generally less expensive upfront. | Typically more expensive upfront. |

Why Brushless Drills Shine for DIYers and Woodworkers

So, why should you, as a beginner or hobbyist, care about these differences? Because brushless drills offer some serious advantages that will make your projects easier, more enjoyable, and ultimately, more successful.

More Power and Torque

Brushless drills can pack a serious punch! Because their motors are more efficient and generate less heat, they can be designed to deliver more power and torque. What does this mean for you? You’ll find it easier to drill into hard materials like dense hardwoods, plaster, or even thin metal without the drill bogging down. Driving long screws into thick lumber? A brushless drill handles that task with less strain on the tool and you.

Longer Run Time on a Single Charge

This is a huge benefit, especially when you’re in the middle of a project. Brushless motors are significantly more efficient than brushed motors. This means they use battery power much more effectively. You can expect to get considerably more work done – often up to 50% more runtime – from the same battery pack compared to a brushed drill. For anyone who has ever had their drill battery die mid-screw or mid-hole, this extended power is a game-changer.

Increased Durability and Lifespan

Think about it: no brushes means no wear and tear on that critical component. Brushless motors have fewer mechanical parts that can fail. This translates to a tool that’s built to last much longer. For a DIYer or homeowner, this means a tool that will be with you for years and countless projects, saving you money in the long run by not needing to replace it as often.

Better Control and “Smarter” Performance

The electronic control in brushless drills allows for more precise management of speed and power. This means a more consistent feel when you’re drilling or driving. The drill’s internal electronics can sense the load and adjust power accordingly, preventing stalls and giving you smoother operation, especially when transitioning between different materials or tasks. Some advanced models even offer features like electronic braking, which stops the bit almost instantly when you release the trigger, enhancing safety.

Less Heat, More Work

Brushed motors generate a lot of heat due to the friction of the brushes. This heat can limit how long you can run the drill continuously and can even shorten the life of the motor over time. Brushless motors run much cooler, allowing for extended use without overheating. This is fantastic for those longer projects where you need the drill to perform consistently.

When Might a Brushed Drill Still Be a Good Choice?

While brushless drills are superior in most ways, there are a few specific scenarios where a brushed drill might still be considered.

The primary advantage of brushed drills lies in their affordability. If you are an absolute beginner on a very tight budget, just starting out with a very occasional, light-duty project (like hanging a picture frame or assembling flat-pack furniture a couple of times a year), a basic brushed drill might be sufficient and much kinder to your wallet upfront.

However, it’s important to weigh this initial cost saving against the benefits of a brushless drill. Often, the slightly higher investment in a brushless tool pays for itself in performance, durability, and extended battery life, making it a more economical choice over the tool’s lifetime.

Choosing the Right Cordless Drill: Beyond Brushless vs. Brushed

Once you’ve decided that a brushless drill is the way to go (and for most people, it is!), there are a few other things to consider to ensure you get the perfect tool for your needs:

Voltage (Power!)

Drills come in various voltages, typically 12V, 18V, and 20V MAX (which is essentially the same as 18V under load). Higher voltage generally means more power and torque.

- 12V Drills: Great for light-duty tasks, small spaces, and when you prioritize compactness and light weight. Think interior decorating, assembling small furniture, or delicate work.

- 18V/20V MAX Drills: The workhorse for most DIYers and homeowners. They offer a great balance of power, runtime, and versatility for a wide range of tasks, from drilling into drywall and wood to driving larger screws and even using hole saws.

- Higher Voltage (e.g., 36V, 40V): These are typically for heavy-duty professional use, like drilling large holes in concrete or tackling very demanding construction tasks. For most home projects, they are overkill.

Chuck Type and Size

The chuck is the part of the drill that holds the drill bit or screwdriver bit. Most modern drills have a keyless chuck, meaning you can tighten and loosen it by hand. Chuck sizes are usually measured in millimeters (e.g., 10mm or 13mm, which is 3/8″ or 1/2″). A 13mm (1/2″) chuck is more common on higher-powered drills and can hold larger bits more securely, which is beneficial for significant drilling tasks.

Features to Look For

- Variable Speed Trigger: Allows for precise control, especially when starting a hole or driving a screw slowly.

- LED Light: A work light that illuminates your drilling area is incredibly useful, especially in dimly lit spaces.

- Clutch Settings: These let you adjust the torque (turning force) to prevent over-driving screws or stripping them.

- Ergonomics and Weight: How does the drill feel in your hand? Is it comfortable to hold for extended periods? A lighter drill might be better for overhead work, while a slightly heavier one might feel more robust.

- Battery Platform: If you plan on buying other cordless tools from a particular brand (saws, sanders, etc.), consider their battery platform. Batteries are often interchangeable, which can save you money in the long run as you won’t need to buy a new charger and batteries for every tool.

The Impact of Brushless Technology: Real-World Examples for Homeowners

Let’s imagine a couple of typical home projects and see how a brushless drill might make a difference:

Project 1: Building a Deck or Fence

When you’re building a deck or fence, you’ll be driving dozens, if not hundreds, of screws. Many of these will be long lag screws into framing lumber. A brushless drill’s superior torque means it can power through these tough fasteners with ease, preventing the drill from stopping. Its efficient motor and long battery life mean you can work for longer periods without needing to swap batteries or recharge as often. You’ll finish the job faster and with less frustration. For tasks like drilling pilot holes for these screws, the consistent power of a brushless drill ensures cleaner, more accurate holes.

Project 2: Installing Kitchen Cabinets

Hanging kitchen cabinets requires precision and enough power to drive screws securely into wall studs. You’ll be working in often tight spaces, sometimes at awkward angles. A brushless drill’s lighter weight (compared to older, bulkier brushed models) and its excellent power-to-size ratio make it more maneuverable. The variable speed control and clutch settings are essential here to avoid stripping screws or damaging the cabinet material. An integrated LED light is also a lifesaver for seeing exactly where you’re placing your screws in those darker cabinet interiors or tight corners.

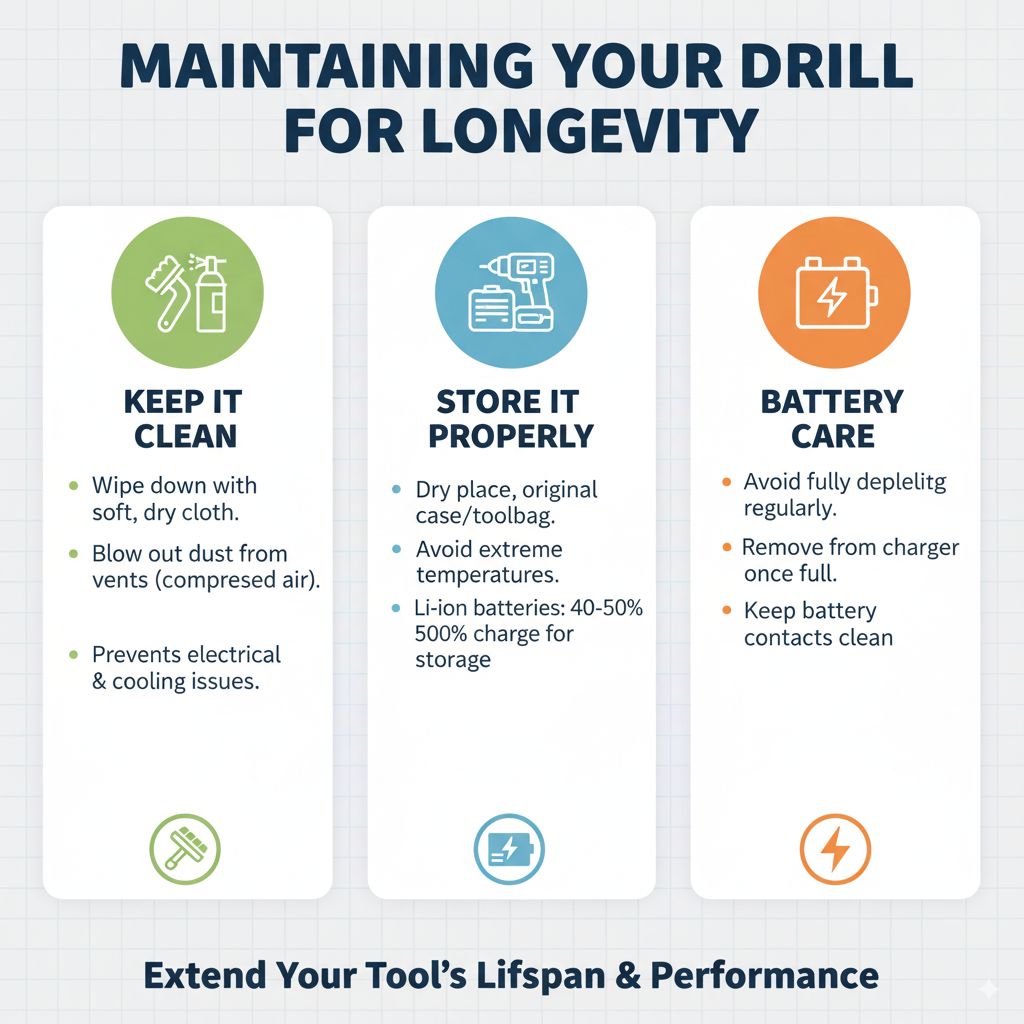

Maintaining Your Drill for Longevity

Whether you choose a brushed or brushless drill, proper care will ensure it serves you well for a long time.

Keep it Clean: After each use, especially if you’ve been working in dusty environments like construction sites or workshops, wipe down your drill with a soft, dry cloth. Pay attention to vents; use a compressed air can to blow out any dust that might have accumulated inside. This is crucial for any power tool, as dust can interfere with electrical components and cooling fans.

Store it Properly: Store your drill in a dry place, ideally in its original case or a toolbag. Avoid extreme temperatures, as these can affect battery performance and the tool’s internal parts. If your drill uses lithium-ion batteries, it’s best to store them at about a 40-50% charge if you plan on storing the tool for an extended period (several months).

Battery Care:

- Avoid fully depleting the battery regularly.

- Don’t leave batteries on the charger indefinitely after they are full; many modern chargers have trickle modes, but it’s good practice to remove them once charged.

- Keep battery contacts clean. A soft cloth is usually all that’s needed.

Handle with Care: While drills are designed to be robust, avoid dropping them. If a drill does take a tumble, inspect it for any visible damage before using it again. If you notice any unusual noises, smells, or performance issues, it’s best to have it inspected or consult the manufacturer’s manual. For troubleshooting and maintenance tips, resources from reputable organizations like Building Science Information can often offer insights into tool longevity and proper usage, though you should always refer to your specific tool’s manual first.

Frequently Asked Questions (FAQ)

Q1: What is the main difference between a brushless and a regular drill?

The main difference is the motor type. Regular drills use brushed motors with carbon brushes that wear out. Brushless drills use electronic controls, eliminating the need for brushes, which makes them more efficient, more powerful, longer-lasting, and cooler-running.

Q2: Are brushless drills worth the extra cost for a beginner?

For most beginners who plan to use their drill for more than just occasional light tasks, yes, they are generally worth it. The increased performance, durability, and longer runtimes often make them a better long-term investment.

Q3: How long does a brushless drill battery last compared to a regular drill battery?

Brushless drills are more energy-efficient, so their batteries typically last significantly longer on a single charge – often up to 50% more runtime compared to a similar voltage brushed drill.

Q4: Can I use the same drill bits with a brushless drill as with a regular drill?

Yes, absolutely! The type of drill bit you use is determined by the material you’re drilling into (wood, metal, masonry) and the size, not by whether the drill motor is brushed or brushless. You’ll use the same shanks (round, hex, SDS) and types of bits.

Q5: Do brushless drills run hotter than brushed drills?

No, brushless drills actually run cooler. Because they don’t have the friction from carbon brushes and are more efficient, they generate less heat, allowing for longer working periods without overheating.

Q6: If a brushed drill’s brushes wear out, can they be replaced?

Yes, brushed motors are designed so that their carbon brushes can be replaced. However, this is often a more involved repair, and sometimes the cost of replacement brushes and labor can approach the cost of a new, entry-level brushed drill, or even a good deal on a brushless one.

Q7: Which type of drill is better for driving screws: brushless or regular?

A brushless drill generally offers better control for driving screws due to its adjustable clutch settings and more consistent power delivery. Its higher torque is also beneficial for driving longer or larger screws without the drill bogging down.

Conclusion: Power Up Your Projects with Brushless!

So, there you have it! When it comes to choosing the right drill, understanding the difference between brushless and brushed motors is key. While a regular brushed drill might serve the absolute lightest of tasks on a shoestring budget, the clear winner for most DIYers, homeowners, and budding woodworkers is the brushless drill. Its enhanced power, incredible efficiency leading to longer runtimes, superior durability, and smarter performance make it an investment that truly pays off. You’ll find yourself tackling projects with more confidence and less frustration, knowing you have a reliable, powerful tool in your hands.

Think of it this way: an investment in a brushless drill is an investment in your projects and your crafting journey. It’s a tool that will grow with you, allowing you to take on more ambitious tasks as your skills and interests develop. So, next time you’re looking to power up your workshop, remember the essential benefits of brushless technology. It’s a simple upgrade that makes a world of difference in getting those jobs done right, and done well.