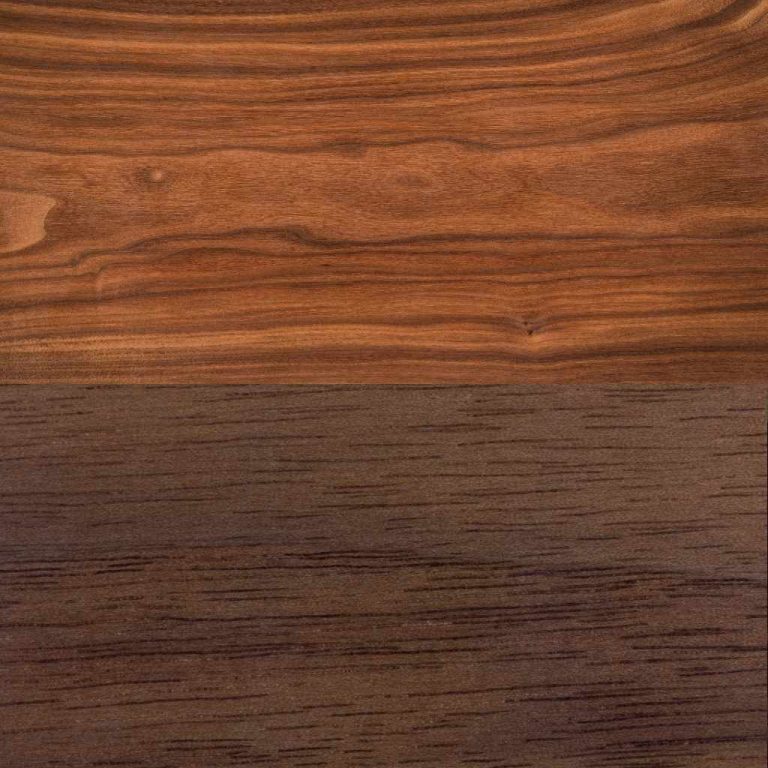

Can I Get Walnut At The Farmer Market In Texas: Essential Guide

While finding whole, marketable quantities of Black Walnut directly at a typical Texas farmers market is rare, you might occasionally find small batches of nuts, specialty wood products, or prepared foods made with walnut. This comprehensive guide explains the reality, where to look, and better Texas sourcing methods for novice woodworkers.

Welcome to the workshop! I’m Md Meraj, and I know how exciting it is when you decide you want to start a woodworking project, especially if you have your heart set on a beautiful, rich hardwood like walnut. You’ve heard it’s amazing to work with, and you’re thinking, “Why wouldn’t I just grab some fresh, local wood right where I buy my tomatoes—the Texas farmers market?”

It’s a great thought rooted in supporting local! However, sourcing lumber, especially specialty hardwood like walnut, through typical retail farmers markets in Texas is surprisingly difficult. It’s not impossible, but it’s not the usual stop on your weekend errands. Don’t worry if you feel a little stuck; this guide is here to clear up the confusion.

We’ll walk through exactly what you can expect to find (or not find) at a Texas farmers market regarding walnut, and—most importantly—I’ll show you the better, more reliable ways a beginner woodworker can successfully source quality walnut right here in the Lone Star State. Let’s turn that lumber dream into a real project!

Why Sourcing Walnut at a Texas Farmers Market is Tricky

For many DIYers starting out, the farmers market seems like the perfect place for everything local. You can get fresh produce, local honey, and perhaps even some local crafts. But lumber is a different beast entirely. Understanding why walnut isn’t always sitting next to the peaches helps set realistic expectations.

The Nature of Walnut Trees in Texas

Black Walnut (Juglans nigra) prefers rich, deep soils and is often found in East Texas, which is much different from the dry plains and Hill Country many farmers markets serve. Commercial harvesting is also a specialized industry.

- Slow Growth: Walnut trees take many decades to mature enough for lumber harvesting. This isn’t a crop harvested every season.

- Specialized Milling: Turning a massive log into usable, stable lumber requires large bandsaw mills, drying kilns, and storage facilities—operations far too big for a typical market stall.

- Demand vs. Supply: When a local sawyer does mill walnut, the finished, dried lumber is usually immediately sold directly to established cabinet shops or online lumber retailers because the demand is so high.

This means that while the tree might be local, the wood product you need for your router and table saw is usually processed far away from where you buy your greens.

What You MIGHT See at a Farmers Market

While you likely won’t find stacks of rough-sawn 4/4 walnut slabs, don’t give up entirely! A savvy vendor might have small, related items:

- Finished Wood Crafts: Look for small items like cutting boards, bowls, pens, or small decorative boxes made from walnut scraps. This confirms a local woodworker is active in the area.

- Walnut Food Products: Expect to find shelled black walnuts used in baked goods, jams, or homemade candies. Remember, these are for eating, not building!

- Firewood or Wood Chips: Occasionally, someone selling firewood might have chunks or rounds of local hardwood, but these pieces are often too small, too green, or too checky (cracked) for quality joinery.

The Better Route: Where Texas Woodworkers Actually Find Walnut

As a woodworker, success comes from knowing where the real material is sourced. Forget the farmers market for your main lumber supply; let’s focus on the three best, most reliable avenues for getting quality, dried walnut lumber in Texas.

Option 1: Local Sawmills and Specialty Lumberyards (The Best Bet)

This is where the real treasure lies. Texas has excellent hardwood suppliers who deal directly with logs or source rough-sawn lumber from sustainable operations.

When you talk to these suppliers, remember to ask specific questions. They are often used to dealing with serious woodworkers, but don’t be shy—they love helping beginners get started correctly!

Key Lumberyard Questions to Ask:

- “Is this Black Walnut kiln-dried or air-dried?” (Kiln-dried is best for immediate projects.)

- “What are the dimensions available (e.g., 4/4, 8/4 stock)?” (4/4 means 1 inch actual thickness, 8/4 means 2 inches actual thickness.)

- “Do you sell to hobbyists, or only to contractors?” (Most seasoned yards sell to everyone.)

Search online for terms like “Hardwood Lumber Dealer Dallas,” “Kiln Dried Wood Houston,” or “Specialty Wood Supply Austin.” Check their websites for inventory lists before visiting.

Option 2: Urban Loggers and Wood Recycling Programs

In metropolitan areas, large walnut trees come down regularly due to storms, construction, or old age. Urban loggers specialize in salvaging this wood before it hits the chipper. This wood is often incredible—old growth, large boards—but it requires patience.

Warning for Beginners: Wood sourced this way is often sold “green” (wet). You must be prepared to dry it yourself using carefully constructed air-drying stickers or pay a specialized kiln service. Using wood that hasn’t dried properly will result in warping, cracking, and ruined projects. The U.S. Forest Products Laboratory provides great guidance on wood seasoning.

Option 3: Online Retailers and Wood Buying Communities

If local options fail, reputable online retailers ship dimensioned, dried lumber right to your door. This can sometimes be more expensive due to shipping, but the quality control is usually excellent.

Additionally, look at local woodworking clubs or online forums (like Texas woodworking groups on social media). Sometimes, a hobbyist or small shop has extra, properly dried walnut they are willing to sell off cheaply to fund their next purchase.

Understanding Walnut Grades and Pricing for Beginners

Walnut is one of the pricier domestic hardwoods. When buying, especially for your first project, understanding the grading system will save you money and frustration. You don’t always need “Select & Better” grade if you are making something rustic or operational.

Common Hardwood Grading for Walnut (NHLA Standards)

Most lumberyards adhere to National Hardwood Lumber Association (NHLA) standards. Here is a simplified breakdown for a beginner:

| Grade Name | Typical Use/Aesthetic | Suitability for Beginners |

|---|---|---|

| Firsts & Seconds (FAS) | Nearly flawless, largest usable clear face area. Wide boards. | Best for fine furniture where aesthetics are paramount. Expensive. |

| Select | Nearly as good as FAS, but may have slightly smaller clear areas. | Excellent blend of high quality and slightly better price point. |

| No. 1 Common | Good supply of clear wood, but with knots and character marks allowed. | Great for general projects, tabletops, and pieces where some character is welcome. |

| No. 2 Common | More defects (knots, discoloration), but still lots of usable wood between them. | Ideal for smaller projects, cutting boards, or practice pieces where you expect to cut around defects. |

Lumber grading involves complex rules; always confirm the selling grade with the supplier.

Pricing Comparison (Estimate Per Board Foot)

Prices fluctuate constantly based on the market, where the wood came from, and its dryness. This table gives you a general idea of how much you might expect to pay, helping you budget away from the farmers market and towards the specialized yard.

| Wood Type/Condition | Estimated Price Range (Per Board Foot) | Sourcing Confidence |

|---|---|---|

| Green, Rough-cut Walnut (Urban Log) | $4.00 – $7.00 | High Effort, High Wait Time |

| Air-Dried Walnut (No. 2 Common) | $10.00 – $14.00 | Medium Effort, Medium Wait Time |

| Kiln-Dried Walnut (Select/No. 1 Common) | $15.00 – $25.00+ | Low Effort, Immediate Use |

Beginner Walnut Project Planning: What Size to Buy?

One of the biggest hurdles for new woodworkers is estimating how much wood they actually need. Buying too little is frustrating; buying way too much burns your budget. For your first few walnut projects, I strongly recommend sticking to smaller dimension lumber (like 4/4 or 8/4 thickness) sourced from a reputable yard.

Tools Necessary for Working Walnut

Walnut is relatively easy to machine compared to some denser exotics, but it still requires good, sharp tools. Since you are just starting, focus on having these essentials ready:

- Safety Gear: Essential! Safety glasses, hearing protection, and a good dust mask (walnut dust is an irritant).

- Accurate Measuring Tools: High-quality tape measure and combination square. Millwork is only as good as your initial measurements.

- Planing/Flattening: A jointer and a thickness planer are ideal for making boards flat and parallel. If you don’t own these, you will need to buy wood that is already surfaced (S4S) or have the lumberyard mill it for you.

- Sawing: A table saw or circular saw with a track setup for dimensioning.

- Clamps: Always buy more clamps than you think you need!

How to Calculate Board Footage

Never just ask for “a piece of walnut.” Use this simple formula to calculate exactly what you need:

Board Feet = (Length in Inches x Width in Inches x Thickness in Inches) / 144

Example: You need one piece that is 48 inches long, 10 inches wide, and 1 inch thick (4/4 stock):

(48 x 10 x 1) / 144 = 3.33 Board Feet

Always factor in 10% extra for waste due to defects, cleanup cuts, or mistakes. If you need 3.33 board feet, aim to buy around 3.7 board feet.

Safety First: Handling Walnut Dust

Walnut, especially Black Walnut, is beautiful, but its dust can cause irritation and, in rare cases, respiratory issues. This is critical, especially when working indoors or in a garage with less ventilation than a professional shop.

Always prioritize keeping the air clear when sanding or routing walnut:

- Use dust collection bags on all power tools if possible.

- Wear an N95 or better respirator when sanding fine dust.

- Avoid using walnut scraps for burning indoors, unless you are certain they are completely clean of glue or finish residue.

For more in-depth information on safe handling of common workshop materials, resources from OSHA (Occupational Safety and Health Administration) are invaluable for setting up your home shop correctly.

A Quick Comparison: Walnut vs. Common Texas Woods

If the search for walnut proves too challenging or expensive for your initial attempts, Texas offers fantastic local alternatives that are often easier to source at local markets or small mills. Consider these if you need to start building today!

| Wood Type | Key Characteristics | Sourcing Availability in Texas (Relative to Walnut) |

|---|---|---|

| Pecan (Hickory Family) | Very strong, often great color variation, excellent figure when available. | Easier to find; often available from urban loggers or mills. |

| Red Oak/White Oak | Classic, dependable, readily available rough lumber. Good for painted or stained finishes. | Very easy to find reliably. |

| Cedar (Aromatic Red) | Lightweight, easy to work, great scent. Not as hard as walnut. | Extremely easy to find everywhere in Texas. |

| Mesquite | Extremely hard, beautiful grain, often comes from crooked urban trees. Requires sharp tools. | Moderately easy to find from specialty suppliers; check farmers market woodworkers. |

FAQ: Beginner Questions About Sourcing Wood

Q1: If I find walnut slabs at a farmers market, can I use them right away for a table?

A: Probably not. Wood sold casually at markets is often green (wet). If you build with wet wood, it will shrink, warp, cup, and crack as it dries in your controlled home environment. Only use wood that is certified kiln-dried or air-dried for at least one year per inch of thickness.

Q2: Is it safe to ask a farmer at the market if they know a local sawyer?

A: Absolutely! Farmers usually know everyone in the agricultural/local craft community better than anyone. They might direct you to a local guy who processes pecan or oak, and that sawyer might have walnut on the side. It’s worth asking politely!

Q3: How much does a small walnut project (like a charcuterie board) cost in wood material?

A: It varies widely. For a small board requiring maybe one board foot of high-quality, dried walnut, expect the raw wood cost to be between $15 and $30. If the board is already made, the price jumps significantly to cover labor and finishing.

Q4: What’s the difference between buying a log and buying dry, milled lumber?

A: Time and effort. Buying a log means you must cut, mill, sticker, and wait months or years for it to dry, plus invest in drying equipment or pay a kiln service. Buying milled lumber means you pay a premium to skip all that work and start building immediately.

Q5: Can I use wood stain to make cheap pine look like walnut on my first project?

A: You can try, but it rarely looks authentic. Walnut has a deep, rich color and a particular grain pattern. Stain can mimic the tone, but it won’t replicate the depth or the subtle cellular structure. For rich projects, it is worth saving up for the real thing, even if you start small.

Q6: Are there any specific Texas state resources for finding local, sustainable lumber?

A: Yes. Look up the Texas A&M Forest Service or local county extension offices. They sometimes maintain directories of small-scale, sustainable loggers or mills operating within Texas, which is a fantastic way to find high-quality, locally sourced material for your projects.

Building Confidence: Your Next Steps to Walnut

I hope this guide has taken the mystery out of finding walnut. It’s natural to want the most beautiful wood available, but sometimes the path to that wood requires thinking beyond the easiest, closest option—like the farmers market.

For the beginner woodworker, the most crucial step right now is not finding the wood, but ensuring you buy wood that is stable and ready to use indoors. That means prioritizing kiln-dried stock from a dedicated local lumberyard or buying from a trusted online source. Use those measurement calculations we covered, call ahead, and be polite when inquiring about grades.

Don’t let the initial sourcing hurdles stop you! If you can’t get walnut this week, grab some good quality oak or pecan from a local spot you found via your searches. Practice your milling, jointing, and gluing techniques on that wood. That practice is invaluable. When you finally get your hands on that beautiful, dried walnut, you’ll be prepared, confident, and safe to execute the stunning project you’ve been dreaming about. Happy building, neighbor!