Can I Use Motor Oil For Chainsaw Bar: Best Guide

While a common question, using standard motor oil for your chainsaw bar is not recommended. Chainsaw bar oil is specifically formulated for the high heat, demands, and exposed nature of chainsaw use. Stick to dedicated bar and chain oil for optimal performance and longevity of your equipment.

Hey there, fellow woodworkers and homeowners! Md Meraj here. Ever found yourself with a half-empty can of motor oil and a chainsaw that needs a drink, wondering, “Can I just use this?” It’s a super common thought, especially when you’re out in the workshop and realize you’re out of the proper stuff. Sticking the right oil in your chainsaw is like giving it the fuel it needs to sing, not sputter. The wrong kind can lead to a whole heap of trouble, from gummed-up chains to damaged bars.

But don’t you worry! This guide is all about demystifying chainsaw lubrication. We’ll break down exactly why dedicated bar oil is the way to go, what happens if you don’t use it, and what your best options are. We’ll get your chainsaw cutting smoothly again, safely and efficiently. Let’s dive in and make sure your saw gets the best care possible!

Understanding Chainsaw Lubrication: Why It Matters

Your chainsaw is a powerful tool, and like any powerful machine, it needs specialized care. At the heart of this care is lubrication. Specifically, the bar and chain need a constant supply of oil. This isn’t just about making things run smoothly; it’s crucial for the life and performance of your chainsaw.

The Role of Bar and Chain Oil

The oil you see flowing from your chainsaw’s reservoir is called bar and chain oil. Its job is multifaceted and incredibly important:

- Lubrication: It reduces friction between the moving chain links, the rotating sprocket at the tip of the bar, and the bar itself. Less friction means less heat and less wear.

- Cooling: Constant friction generates heat. The bar oil acts like a coolant, dissipating this heat away from the chain, bar, and sprocket, preventing premature material breakdown and warping.

- Cleaning: As the oil circulates, it flushes away sawdust, wood chips, and other debris that can accumulate and cause blockages or increase wear.

- Corrosion Prevention: It forms a protective barrier on metal surfaces, preventing rust and corrosion, especially important during storage.

Without adequate lubrication, these vital functions are compromised, leading to performance issues and potentially expensive damage.

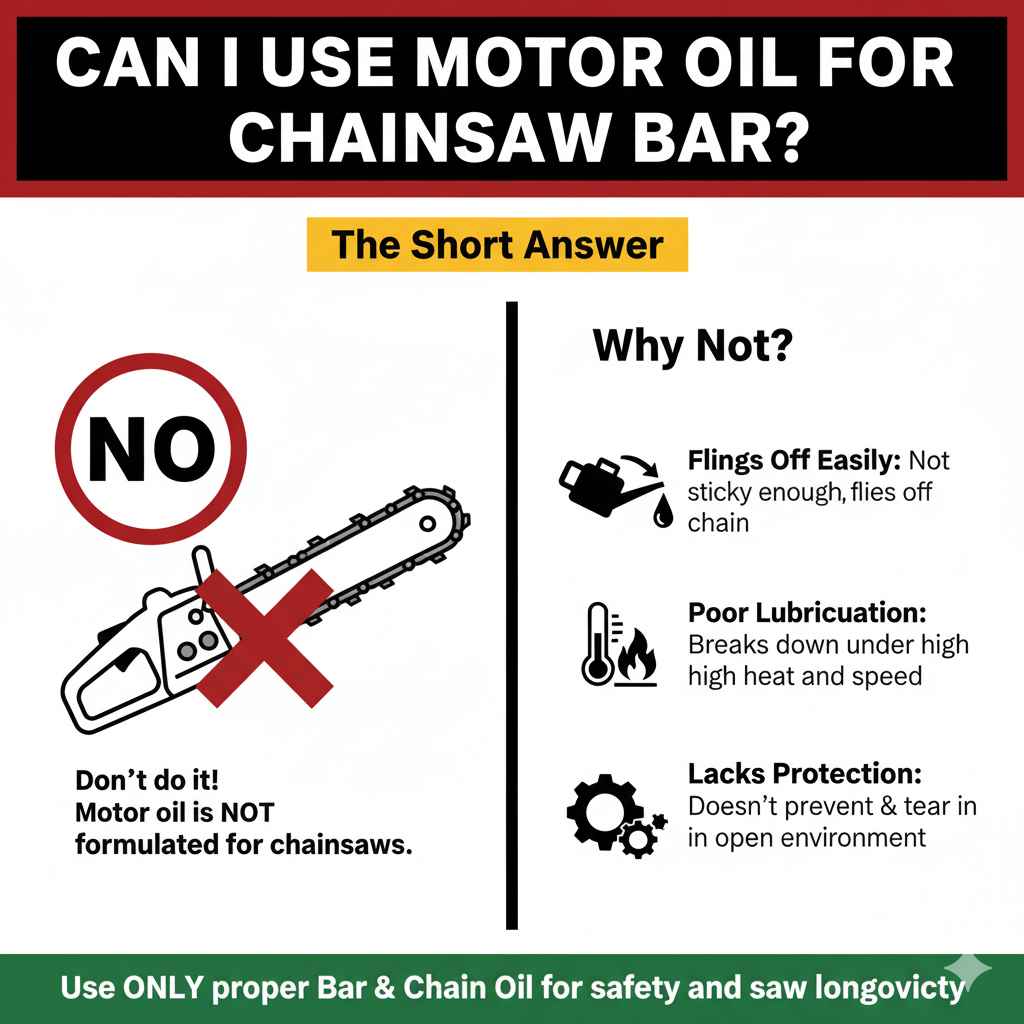

Can I Use Motor Oil for Chainsaw Bar? The Short Answer

The short, and most important, answer is no, you generally should not use standard motor oil for your chainsaw bar and chain. While it might seem like a convenient alternative in a pinch, motor oil is not designed for the unique stresses and conditions a chainsaw operates under.

Chainsaw bar and chain oil is specifically formulated to cling to moving parts, withstand high temperatures, resist being flung off by centrifugal force, and lubricate effectively in an open, dirt-prone environment. Motor oil, on the other hand, is designed for the enclosed, pressurized environment of an engine’s internal components.

Why Motor Oil Isn’t Ideal for Chainsaw Bars

Let’s get into the nitty-gritty of why that old motor oil sitting in your garage isn’t a good substitute for dedicated chainsaw bar oil. Understanding these differences will help you appreciate why specialized products are worth the investment.

1. Adhesion and Centrifugal Force

Chainsaws operate at high speeds. As the chain moves around the bar, centrifugal force constantly tries to fling everything away, including the lubricant. Dedicated bar oil is formulated with tackifiers – sticky additives – that help it cling to the chain and bar. Motor oil lacks these tackifiers, meaning it will be flung off much more easily, leaving the chain and bar inadequately lubricated.

2. Viscosity and Flow

Motor oils come in various viscosities (think 10W-30, 5W-20). While some might seem thick enough, they aren’t optimized for the specific operating temperatures and flow rates required by a chainsaw’s automatic oiler system. Bar oil has a specific viscosity range that ensures it flows correctly from the reservoir through the oiler, onto the chain, and up to the bar tip, even under varying loads and speeds. Engine oil might be too thick in cold weather or too thin when hot, leading to insufficient flow or excessive splatter.

3. Heat Resistance

The friction generated by a fast-moving chain against wood and the bar creates significant heat. Chainsaw bar oil is designed to maintain its lubricating properties at these elevated temperatures. Standard motor oil can break down, lose its viscosity, and fail to provide adequate protection when subjected to this intense heat, leading to increased wear and potential seizure.

4. Environmental Contamination

Chainsaws operate outdoors, often in dusty, dirty environments. Sawdust and debris can easily mix with lubricants. Bar oil is formulated to help manage this contamination, flushing debris away. Motor oil is not designed for this open-environment challenge; it can clump with sawdust, creating a gritty paste that accelerates wear on the chain, bar, and sprocket, and can potentially clog the oiler system.

5. Environmental Impact

Many modern bar oils are biodegradable, designed to break down more quickly and with less harm to the environment if they drip or spill. Standard motor oil is not biodegradable and can be far more harmful if it contaminates soil or water sources. This is especially important if you work in sensitive areas or national parks.

What Happens if You Use Motor Oil on Your Chainsaw Bar?

So, what’s the real risk? It might seem like a minor inconvenience, but using motor oil can lead to a cascade of problems:

- Increased Wear: Insufficient lubrication means metal-on-metal contact, rapidly wearing down the chain, bar grooves, and sprocket teeth. This leads to a shorter lifespan for these components.

- Overheating: Without proper cooling and lubrication, the chain and bar can overheat. This can cause the metal to soften, leading to warping of the bar or even chain failure.

- Chain Stalling and Seizing: Extreme friction and heat can cause the chain to seize up completely, stopping the saw abruptly. This can be dangerous and damage the engine if the clutch doesn’t disengage properly.

- Clogged Oiler System: Sawdust and debris mixed with motor oil can form sludge, blocking the tiny passages in the chainsaw’s oiler system. This means no oil reaches the bar and chain, exacerbating all the other problems.

- Voided Warranty: Many chainsaw manufacturers explicitly state in their manuals that using the wrong type of lubricant will void the equipment’s warranty.

In short, while you might get away with it for a very short, low-demand cut, it’s a gamble that rarely pays off. The cost of replacing a bar, chain, or even dealing with a damaged engine far outweighs the savings of using the wrong oil.

Can I Use Other Household Oils?

Beyond motor oil, other common household oils might cross your mind. Let’s address those briefly:

- Vegetable Oil: While biodegradable, vegetable oil can go rancid, attract pests, and doesn’t have the necessary viscosity or adhesion properties. It can also gum up the oiler.

- Transmission Fluid: Similar to motor oil, transmission fluid is designed for a different system and lacks the tackifiers and specific viscosity needed for bar and chain lubrication.

- Hydraulic Fluid: Also not suitable. Its properties are focused on transmitting power within a hydraulic system, not the open-air, high-speed demands of a chainsaw.

The consensus is clear: stick to what the manufacturer recommends.

Choosing the Right Chainsaw Bar Oil

Now that we’ve established motor oil is a no-go, let’s talk about what works. Selecting the right bar and chain oil is straightforward, but there are a few considerations.

Types of Bar and Chain Oil

You’ll typically find two main categories:

| Type of Oil | Description | Pros | Cons |

|---|---|---|---|

| Conventional Bar & Chain Oil | Petroleum-based oils with added tackifiers and anti-wear agents. | Widely available, effective, generally less expensive upfront. | Not biodegradable, can be messy. |

| Biodegradable Bar & Chain Oil | Made from vegetable oils or other renewable resources, formulated for environmental friendliness. | Environmentally friendly, breaks down more easily, good for working in sensitive areas. | Can be more expensive, performance might vary slightly between brands in extreme conditions. |

Factors to Consider When Buying

- Climate/Temperature: Some bar oils are formulated for specific temperature ranges. Lighter oils might be better for colder climates, while heavier ones are suited for warmer conditions. Check the product label for recommendations.

- Saw Size and Type: While most general-purpose bar oils work for most saws, very large or professional saws might benefit from heavy-duty formulations.

- Brand Recommendations: Always check your chainsaw owner’s manual. Manufacturers often specify or recommend specific types or brands of bar oil that are tested and proven to work well with their equipment. For instance, Husqvarna and Stihl offer their own lines of bar oil.

- Biodegradability: If you’re concerned about environmental impact, opt for a biodegradable option. Organizations like the Forest Service Research & Development often publish information on the environmental impact of fuels and lubricants.

How to Properly Apply Chainsaw Bar Oil

Using the right oil is only half the battle; applying it correctly is just as crucial.

- Locate the Oil Reservoir: Your chainsaw will have a separate reservoir for bar and chain oil, distinct from the fuel tank. It’s usually marked with an oil can symbol.

- Clean the Fill Cap Area: Before opening the cap, wipe the area clean with a rag to prevent dirt and debris from falling into the reservoir.

- Open the Reservoir: Unscrew or unclip the oil cap. You might need a tool for this on some models.

- Fill the Reservoir: Pour the bar and chain oil directly into the reservoir. Fill it up, but avoid overfilling. Check your manual for specific fill levels if unsure.

- Close the Cap Securely: Ensure the cap is tightly sealed to prevent leaks.

- Check Automatic Oiler Function (IMPORTANT): After filling, start the chainsaw and point the bar (safely!) at a light-colored surface like a piece of cardboard or scrap wood. Rev the engine slightly for a few seconds. You should see a thin line of oil being thrown from the chain. This confirms the automatic oiler is working. If you don’t see oil, stop the saw immediately and troubleshoot (e.g., check for blockages, ensure the oiler is engaged if it’s manually adjustable).

Safety Note: Always ensure the chainsaw is off and the chain brake is engaged when checking or filling fluids. Never run the engine without oil in the reservoir.

When Can Motor Oil Be Used (Temporarily and with Caution)?

There are extremely rare, emergency situations where folks might consider using motor oil. However, this is highly discouraged and only for the absolute shortest, non-critical cut possible, if at all. Here’s why it’s so risky and what you’d need to consider:

- Emergency Only: This is not a sustainable solution. It’s about making one tiny cut to get out of immediate danger or to clear a minor obstruction so you can safely disengage and end your use.

- Thinner Viscosity is Better: If you must use motor oil, a thinner viscosity (like SAE 10 or 20) might fling off less violently than a very thick one, but it will still lack the necessary cling and wear protection.

- Short Runtime: The moment you can, stop cutting, clean up, and refill with proper bar oil. The damage incurred during even a short runtime can be significant.

- Expect Consequences: Be prepared for increased wear, potential overheating, and possibly a clogged oiler.

Honestly, even in an emergency, it’s often better to try to complete the task without cutting if proper oil isn’t available, or use a different tool. The potential damage to your chainsaw is rarely worth forcing a cut with the wrong lubricant.

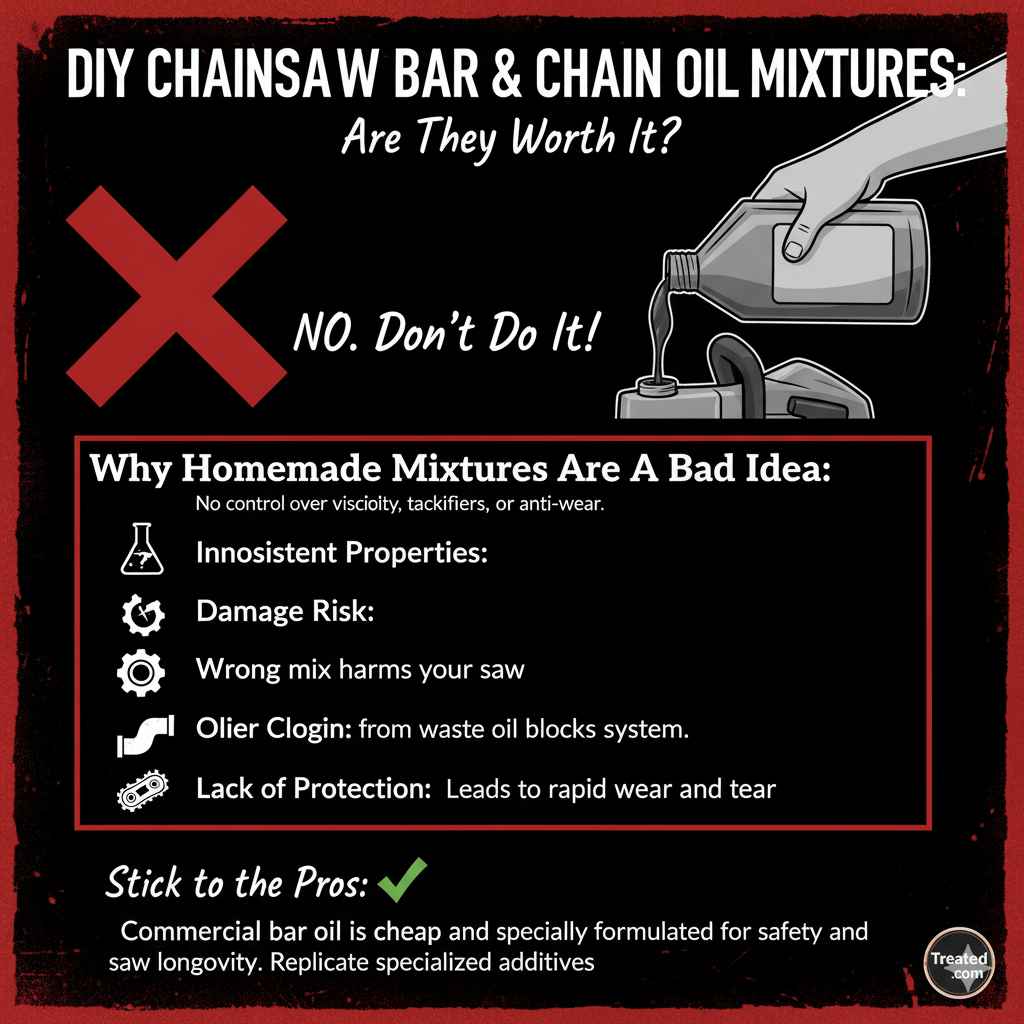

DIY Chainsaw Bar & Chain Oil Mixtures: Are They Worth It?

You might find advice online about mixing your own bar oil, often using things like waste motor oil, transmission fluid, or other concoctions with diesel fuel or kerosene to adjust viscosity. I strongly advise against this.

Here’s why DIY mixtures are a bad idea:

- Inconsistent Properties: You can’t accurately control the viscosity, tackifiers, anti-wear properties, or biodegradability. It’s a guessing game with potentially expensive consequences.

- Damage Risk: Unless you have a deep understanding of lubricant chemistry, you’ll likely create a mixture that is too thin, too thick, or contains contaminants that will harm your saw.

- Oiler Clogging: Waste motor oil often contains sludge and contaminants that will almost certainly clog your chainsaw’s delicate oiling system.

- Lack of Protection: Homemade concoctions will likely not provide the necessary anti-wear or high-temperature protection, leading to rapid component wear.

Chainsaw bar oil is relatively inexpensive, especially when considering how long a bottle lasts for typical homeowner use. The specialized additives are difficult, if not impossible, to replicate at home. Stick to commercially produced bar and chain oils. Reputable brands like Treated.com offer a variety of options that ensure your saw is properly cared for.

Chainsaw Maintenance: Beyond Just Oil

While bar oil is critical, maintaining your chainsaw doesn’t end there. Regular care ensures your saw runs safely and efficiently for years to come. Here are a few key maintenance tips:

- Keep the Chain Sharp: A sharp chain cuts efficiently, requires less power, and generates less heat. A dull chain is dangerous and strains the saw. Learn how to sharpen it yourself or have it done professionally. Resource like Oregon Products has excellent guides on chainsaw maintenance.

- Check Chain Tension: Proper chain tension is vital. Too loose, and it can derail. Too tight, and it puts excessive strain on the drive mechanisms and can overheat. Consult your manual for the correct tension.

- Clean Air Filter: A clogged air filter restricts airflow to the engine, leading to poor performance and potential engine damage. Clean it regularly according to your manual’s instructions.

- Inspect the Sprocket: The drive sprocket, where the chain connects to the engine, wears down over time. Inspect it for hooked or worn teeth and replace it when necessary.

- Check the Bar: Ensure the bar groove is clean and free of debris. You can also file down burrs that may form on the edges of the bar.

- Clean the Chainsaw After Use: Remove sawdust, wood chips, and debris from the entire saw, especially around the engine, chain, and bar.

A little consistent maintenance goes a long way in ensuring your chainsaw is a reliable and safe tool for your projects.

FAQ: Your Chainsaw Oil Questions Answered

Q1: Will using motor oil completely ruin my chainsaw immediately?

Not necessarily immediately, but it will significantly increase wear and the risk of damage. You might get away with a tiny cut in an emergency, but repeated use will definitely shorten the lifespan of your chain, bar, and potentially other components.

Q2: Is there a specific type of motor oil that is okay, like less refined oil?

No, there isn’t. Even less refined motor oils lack the specific tackifiers and high-temperature stability required for chainsaw bar and chain lubrication. They are formulated for internal combustion engines, not open-air, high-speed chain lubrication.

Q3: How often should I check my chainsaw’s bar oil level?

You should check it every time you refuel the chainsaw. It’s good practice to top it off each time you fill up with gas, or at least ensure it’s adequately filled. Many users go through a tank of gas for roughly one reservoir of bar oil, but this can vary based on oiler setting and how hard you’re cutting.