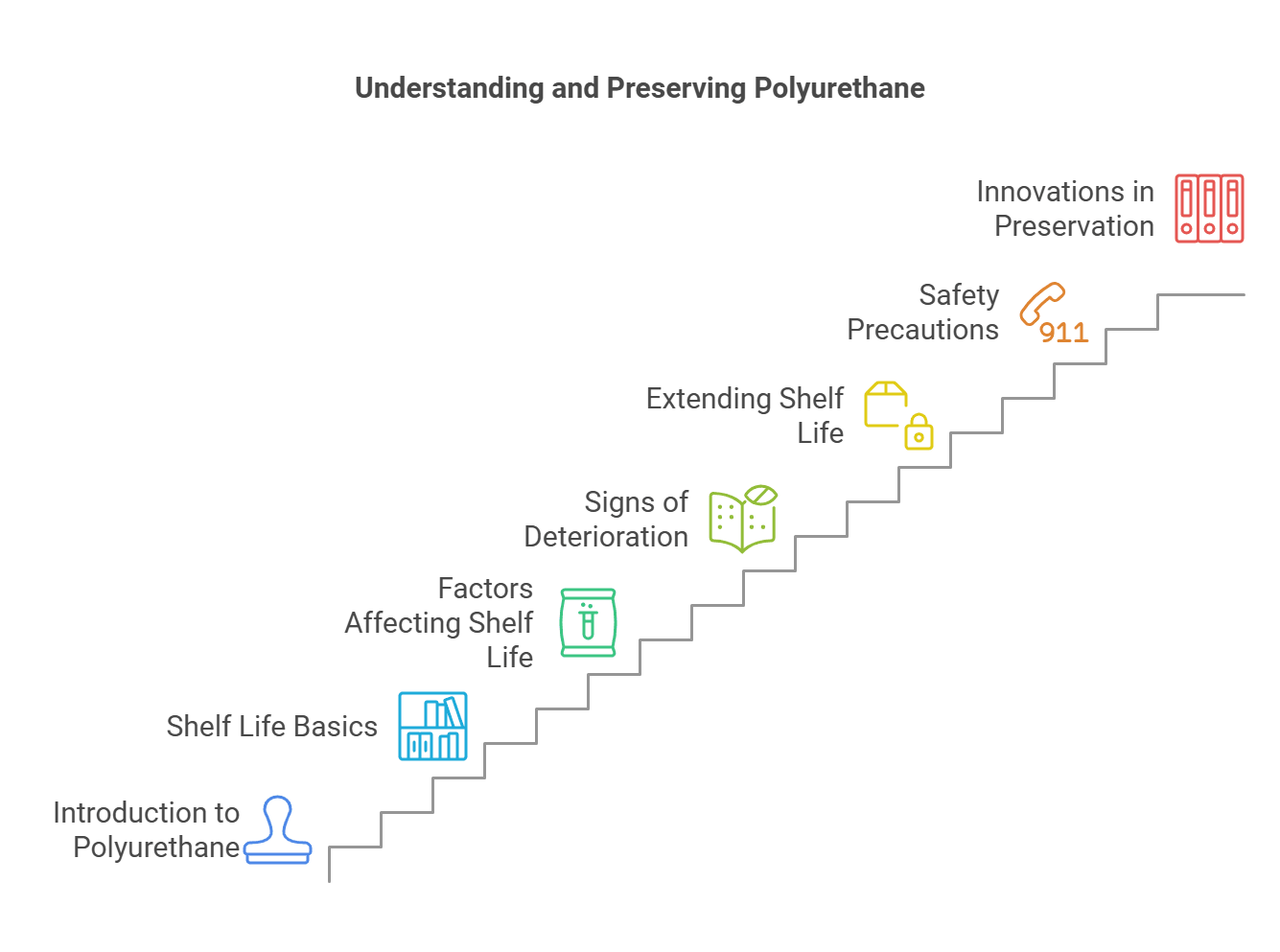

Can Polyurethane Go Bad?: Uncover Shelf Life Secrets!

Polyurethane can go bad, particularly if it’s stored improperly or past its expiration date. Signs of spoilage include a foul odor, thickening, or changes in color.

Polyurethane is a versatile material used in various applications, from furniture finishes to insulation. It provides durability and a smooth finish but has a limited shelf life. Understanding how to store and recognize spoilage is vital for achieving the best results.

Proper storage involves keeping it in a cool, dry place and sealing it tightly. Knowing the signs of bad polyurethane can save you time and money. This guide will help you identify when your polyurethane has gone bad, ensuring your projects remain successful and efficient.

Introduction To Polyurethane And Its Uses

Polyurethane is a versatile material found in many products today. It is a polymer made from organic units. This material is known for its durability and flexibility. Many industries rely on polyurethane for various applications.

From furniture to automotive parts, its uses are widespread. Understanding polyurethane helps to appreciate its importance in everyday life.

Common Applications

- Furniture: Used in cushions and upholstery.

- Flooring: Provides durable and water-resistant surfaces.

- Insulation: Offers energy efficiency in buildings.

- Automotive: Used in seats and interior components.

- Footwear: Provides comfort and support in shoes.

Types Of Polyurethane

| Type | Description | Common Uses |

|---|---|---|

| Flexible Polyurethane | Soft and flexible material. | Cushions, mattresses, and insulation. |

| Rigid Polyurethane | Hard and strong material. | Insulation boards, spray foam. |

| Coatings and Adhesives | Used for protective layers. | Wood finishes, sealants, and glues. |

Shelf Life Basics

Understanding the shelf life of polyurethane is crucial for effective use. Knowing how long it lasts helps avoid waste. Proper storage can extend its lifespan. Let’s explore the factors that affect shelf life.

What Determines Shelf Life?

Several factors influence the shelf life of polyurethane:

- Temperature: Higher temperatures can shorten shelf life.

- Humidity: Moist conditions may degrade the material.

- Exposure to Light: UV light can cause chemical changes.

- Container Type: Proper sealing helps maintain quality.

General Shelf Life Expectancy

On average, polyurethane can last:

| Type | Shelf Life |

|---|---|

| Unopened Container | 1 to 3 years |

| Opened Container | 6 months to 1 year |

Follow these tips for better shelf life:

- Store in a cool, dry place.

- Keep containers tightly sealed.

- Avoid direct sunlight exposure.

Regularly check for changes in color or consistency. These can indicate that the polyurethane has gone bad.

Factors Affecting Polyurethane Shelf Life

Understanding the factors that impact the shelf life of polyurethane is crucial. Several elements can influence its durability and effectiveness over time. Here, we explore key factors that can cause polyurethane to degrade.

Temperature And Humidity

Temperature and humidity play a significant role in polyurethane’s longevity. Extreme conditions can lead to deterioration. Here’s how:

- High Temperatures: Excessive heat can cause polyurethane to cure prematurely.

- Low Temperatures: Cold can make it thick and hard to apply.

- High Humidity: Moisture can affect the chemical reactions during curing.

- Low Humidity: Lack of moisture can lead to poor adhesion.

Keep polyurethane in a controlled environment. A stable temperature between 60°F and 80°F is ideal. Aim for humidity levels below 70% for best results.

Storage Conditions

Proper storage is essential for extending the shelf life of polyurethane. Here are key storage tips:

| Storage Factor | Recommended Conditions |

|---|---|

| Container Type | Keep in a sealed, original container. |

| Light Exposure | Avoid direct sunlight to prevent degradation. |

| Location | Store in a cool, dry place away from heat sources. |

| Expiration Date | Check and respect the manufacturer’s expiration date. |

Following these storage guidelines keeps polyurethane effective for longer. Always inspect before use. Look for changes in color or consistency.

Signs Of Deterioration

Polyurethane is a popular material used in many products. Over time, it can show signs of deterioration. Recognizing these signs is crucial for maintaining quality. Let’s explore the visual indicators and changes in viscosity.

Visual Indicators

Look out for these visual signs of polyurethane deterioration:

- Discoloration: Yellowing or fading indicates aging.

- Cracking: Small fissures on the surface suggest weakness.

- Peeling: Layers coming off signal poor adhesion.

- Brittleness: A hard, glass-like texture means loss of flexibility.

These signs can help identify if your polyurethane is past its prime. Regular checks can save costs on replacements.

Changes In Viscosity

Viscosity changes indicate the quality of polyurethane. Here are key points to consider:

| Viscosity Change | Possible Cause |

|---|---|

| Thickening | Moisture absorption or contamination. |

| Thinning | Exposure to heat or chemicals. |

| Separation | Incompatibility with other materials. |

Check viscosity regularly. Use a viscosity cup for accurate measurement. Consistent changes can indicate deterioration.

Extending Shelf Life

Polyurethane is a versatile material used in many projects. Knowing how to extend its shelf life is essential. Proper storage and use of protectants can keep polyurethane effective longer.

Proper Storage Tips

Storing polyurethane correctly ensures it stays usable. Follow these tips:

- Keep it sealed: Always close the container tightly.

- Store in a cool place: Ideal temperature is between 60°F and 80°F.

- Avoid sunlight: Store away from direct sunlight.

- Use a dry area: Humidity can affect the material.

Sealant And Protectant Use

Using sealants can help maintain polyurethane’s quality. Follow these steps:

- Choose the right sealant: Look for products designed for polyurethane.

- Apply evenly: Use a brush or roller for smooth application.

- Follow drying times: Allow adequate time before using the surface.

Using a protectant can extend the life of polyurethane. It helps prevent damage from moisture and UV rays.

Safety Precautions

Using expired polyurethane requires caution. Safety should always come first. Follow these guidelines for safe handling and disposal.

Handling Expired Polyurethane

Expired polyurethane can pose risks. Use the following tips to handle it safely:

- Wear protective gear: Use gloves, goggles, and a mask.

- Work in a well-ventilated area: Ensure fresh air flows through the space.

- Avoid skin contact: Expired products may irritate skin.

- Check for foul odor: A strong smell can indicate spoilage.

Keep expired polyurethane away from heat sources. Avoid open flames and sparks. Store it in a cool, dry place.

Disposal Guidelines

Proper disposal of expired polyurethane is essential. Follow these steps:

- Check local regulations: Some areas have specific rules.

- Seal the container: Ensure it is tightly closed.

- Take it to a hazardous waste facility: Find a local drop-off center.

- Never pour it down the drain: This can harm the environment.

Consider recycling options where available. Always prioritize safety during disposal.

Innovations In Polyurethane Preservation

Preserving polyurethane is essential for its longevity and effectiveness. New innovations are emerging to enhance its durability and performance. These advancements help to prevent degradation over time. Let’s explore the recent developments and future prospects in polyurethane preservation.

Recent Developments

Recent innovations focus on improving the lifespan of polyurethane products. Here are some key developments:

- Advanced Additives: New chemical additives reduce degradation rates.

- Smart Coatings: These coatings offer protection against UV rays and moisture.

- Biodegradable Options: Eco-friendly formulations are now available.

Researchers are exploring various methods to enhance performance. They aim to create products that last longer and are safer for the environment. The incorporation of these features leads to better usability and less waste.

Future Prospects

The future of polyurethane preservation looks promising. Here are some expected trends:

- Nanotechnology: Tiny particles may enhance resistance to wear and tear.

- Self-Healing Materials: Products may soon repair themselves from minor damages.

- Integration with IoT: Smart products can monitor their condition in real-time.

These advancements will likely change how we use polyurethane. They may also lead to new applications in various industries, from construction to automotive.

Frequently Asked Questions

Can Old Polyurethane Still Be Used?

Old polyurethane may not perform well. Over time, it can lose its effectiveness and become sticky or clumpy. If it has a foul smell or strange texture, it’s best to discard it. Always check for any signs of deterioration before use to ensure optimal results in your projects.

How Can You Tell If Polyurethane Is Bad?

To determine if polyurethane has gone bad, check for changes in texture or color. If it appears lumpy, clumpy, or has separated, it’s likely no longer usable. Additionally, a strong or unusual odor can indicate spoilage. Always perform a test application to ensure proper consistency before using.

What Causes Polyurethane To Go Bad?

Polyurethane can go bad due to exposure to air, moisture, and extreme temperatures. These factors can lead to chemical breakdown and reduce its effectiveness. Storing it improperly in unsealed containers also accelerates deterioration. Always keep it in a cool, dry place to maximize shelf life.

How Long Does Polyurethane Last Unopened?

Unopened polyurethane can last for several years, typically around 3 to 5 years. The exact shelf life depends on storage conditions and the specific formula. Always check the manufacturer’s guidelines for more accurate information. Proper storage significantly impacts its longevity and performance when finally opened.

Conclusion

Polyurethane can degrade over time, affecting its performance. Factors like exposure to heat, moisture, and sunlight play a significant role. To ensure longevity, store it properly and check expiration dates. Understanding its shelf life helps you make informed decisions for your projects.

Protect your investment by using quality polyurethane.