Concrete Adhesive Glue: The Secret to Durable Bonds

Concrete adhesive glue is a strong bonding agent designed for adhering concrete surfaces. It ensures a durable connection, ideal for repairs and construction.

Concrete adhesive glue plays a vital role in construction and repair projects. This specialized adhesive offers a robust solution for bonding various concrete elements, such as blocks, tiles, and slabs. Its unique formulation allows it to penetrate porous surfaces, creating a lasting hold.

Whether you’re fixing a crack or installing new concrete features, using the right adhesive is crucial for achieving durability and strength. A quality concrete adhesive can withstand harsh weather conditions, ensuring that your repairs or installations remain intact over time. Selecting the right product based on your specific project needs will lead to optimal results and long-lasting performance.

Introduction To Concrete Adhesive Glue

Concrete adhesive glue plays a crucial role in construction. It creates strong bonds between materials. These bonds enhance the durability and stability of structures.

Without strong connections, buildings risk damage and failure. Using quality adhesive glue ensures safety and longevity.

The use of adhesives dates back to ancient times. Early builders used natural substances like resins and animal glues. Modern adhesives are more advanced and reliable.

Today, concrete adhesive glue is vital for many applications. It is widely used in repair, renovation, and new constructions.

Types Of Concrete Adhesive Glues

Epoxy-based adhesives are strong and durable. They bond well to many surfaces. This type of glue works best for heavy-duty projects.

Polyurethane adhesives are flexible and resist water. They are great for outdoor use. These adhesives can also fill gaps between surfaces.

Acrylic adhesives dry quickly and are easy to use. They provide a clear finish, making them ideal for visible areas. These glues are effective for light to medium tasks.

Characteristics Of High-quality Adhesives

Bonding strength is crucial for effective concrete adhesives. It determines how well the glue holds materials together. A strong bond ensures durability and prevents breakage.

Durability and weather resistance are essential characteristics. High-quality adhesives withstand extreme temperatures and moisture. This resistance protects against wear and tear over time.

The setting time and curing process affect how quickly the adhesive works. Fast-setting options allow for quicker projects. Proper curing ensures maximum strength and effectiveness.

Preparation For Application

Start by ensuring the surface is clean and dry. Remove dust, dirt, and any grease. Use a suitable cleaner for stubborn stains. A clean surface helps the adhesive bond better.

After cleaning, apply a primer if needed. Primers can improve adhesion and durability. Follow the manufacturer’s instructions for the best results.

| Step | Action | Notes |

|---|---|---|

| 1 | Clean the surface | Use a cloth or sponge |

| 2 | Dry the area | Make sure it’s completely dry |

| 3 | Apply primer | Use as directed |

Mixing instructions for two-component adhesives are simple. Follow the recommended ratio of components. Use a clean container for mixing.

Stir the mixture thoroughly for even consistency. Avoid bubbles during mixing. Use the adhesive within the recommended time frame.

Application Techniques

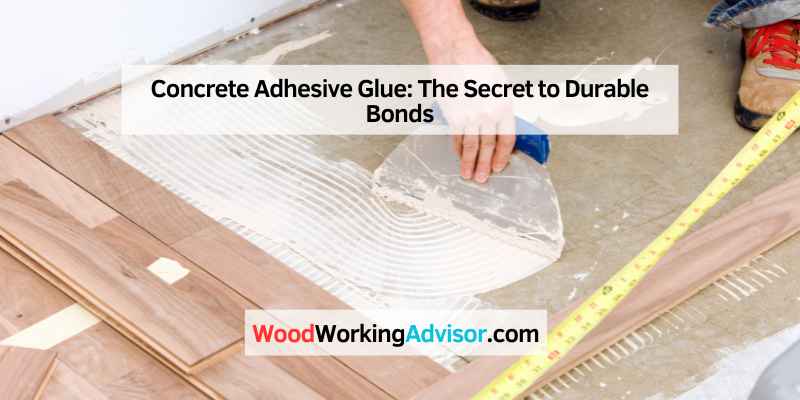

Using the right tools is essential for an even spread of concrete adhesive glue. A notched trowel helps create uniform ridges. A roller can also work well for large areas. Make sure to apply enough pressure for a smooth finish.

Common mistakes can lead to poor adhesion. Always clean the surfaces before applying glue. Avoid using too much or too little adhesive. Check the temperature and humidity, as they can affect drying time. Never rush the process; patience leads to better results.

Curing And Bonding Time

Several factors influence the curing and bonding time of concrete adhesive glue. Temperature plays a major role; warmer conditions speed up the process. Humidity levels can either help or hinder curing. High humidity may lead to slower drying times.

The type of adhesive used also affects curing. Different formulations have unique drying times. Surface conditions, like cleanliness and porosity, impact how well the glue bonds. A clean and dry surface will ensure better adhesion.

To accelerate the curing process, consider the following tips:

- Increase the ambient temperature around the adhesive.

- Use a fan to improve air circulation.

- Apply a heat source like a heat lamp.

- Ensure the surface is clean and dry before application.

Uses And Applications In Construction

Concrete adhesive glue is essential for securing floor tiles. It provides a strong bond that prevents tiles from shifting. This type of glue is water-resistant and durable, making it ideal for high-traffic areas.

Attaching fixtures to concrete walls requires a reliable adhesive. Concrete glue helps hold items like shelves and cabinets firmly in place. It ensures that fixtures remain stable and safe over time.

Repairing cracks and chips is another important use. Concrete adhesive glue fills gaps and restores the original surface. It is easy to apply and dries quickly, providing a smooth finish.

Safety Measures And Precautions

Using concrete adhesive glue requires careful handling of chemicals. Always wear personal protective equipment (PPE). This includes gloves, goggles, and masks. These items help protect your skin, eyes, and lungs from harmful substances.

Before starting, read the safety data sheet (SDS) for the glue. This sheet provides important information about safe use and potential hazards. Ensure proper ventilation in the area to avoid inhaling fumes.

Store chemicals in a cool, dry place. Keep them away from heat sources and sunlight. Always label containers clearly to avoid confusion.

| PPE Item | Purpose |

|---|---|

| Gloves | Protect skin from chemicals |

| Goggles | Shield eyes from splashes |

| Mask | Prevent inhalation of fumes |

Future Of Adhesives In Construction

The future of adhesives in construction is bright. Innovations in adhesive technology are changing the industry. New types of concrete adhesive glue are being developed every day. These glues offer strong bonds and faster curing times.

Many companies focus on sustainable and eco-friendly alternatives. These products use less harmful chemicals. They help reduce the overall environmental impact of construction.

Using these advanced adhesives can lead to better performance and safety. As technology progresses, expect to see even more exciting developments in adhesive solutions. Builders and designers will benefit greatly from these changes.

Comparative Analysis

Adhesive glues offer several advantages over traditional binding methods. They are often more cost-effective, saving money on materials and labor. Traditional methods may require expensive tools, while adhesive glues can be applied easily.

Using adhesive glues also leads to faster project completion. Workers can bond materials quickly without waiting for drying times associated with other methods. This increases overall productivity.

On the other hand, traditional methods can be labor-intensive. They often need skilled workers, raising costs. For simple tasks, adhesive glues are an ideal choice.

| Aspect | Adhesive Glues | Traditional Methods |

|---|---|---|

| Cost | Lower | Higher |

| Speed | Faster | Slower |

| Skill Required | Lower | Higher |

Maintenance And Longevity

Regular check-ups ensure strong adhesive bonds. Inspect the joints for any signs of wear. Look for cracks or gaps that may appear over time.

Immediate repairs can prevent bigger issues. Fixing small problems early helps maintain bond strength. Use the right concrete adhesive glue for repairs.

Extending the life of adhesive bonds is important. Keep the area clean and dry. Avoid exposing the adhesive to harsh weather conditions.

Store adhesive glue properly to maintain its quality. Follow the manufacturer’s instructions for best results. Regular maintenance can save time and money.

Case Studies

Concrete adhesive glue has many successful applications in real-world projects. For instance, a construction company used it to fix cracked walls. They reported high durability and excellent bonding strength.

Another case involved a homeowner who repaired their patio. The glue worked perfectly, preventing water damage and enhancing aesthetics.

On the flip side, some projects faced issues. A factory used the glue improperly, leading to bond failure. Lessons learned include following instructions and preparing surfaces correctly.

Testing the adhesive in small areas can also prevent larger failures. Proper application ensures lasting results and reduces costs.

Frequently Asked Questions

What Is Concrete Adhesive Glue Used For?

Concrete adhesive glue is primarily used for bonding concrete surfaces. It enhances the strength of repairs and ensures a strong hold between concrete and other materials. Ideal for construction and DIY projects, it is essential for both indoor and outdoor applications.

How To Apply Concrete Adhesive Glue?

To apply concrete adhesive glue, start with clean surfaces. Ensure they are free of dust, oil, or debris. Use a brush or roller to spread a thin, even layer. Allow the adhesive to set before placing the materials together for optimal results.

Is Concrete Adhesive Glue Waterproof?

Yes, many concrete adhesive glues are waterproof. This feature makes them suitable for outdoor projects and wet environments. Always check the product specifications to ensure it meets your specific needs for waterproofing.

Can I Use Concrete Adhesive On Wood?

Concrete adhesive can be used on wood if specified by the manufacturer. It provides a strong bond between concrete and wood materials. However, ensure that both surfaces are clean and dry for the best adhesion results.

Conclusion

Choosing the right concrete adhesive glue is essential for lasting results. It enhances bond strength and durability. Whether for home projects or professional applications, understanding the different types is crucial. Invest time in selecting the best product. This will ensure your concrete repairs and installations stand the test of time.