Difference Between LVP & Engineered Hardwood: Essential Guide

Choosing between LVP (Luxury Vinyl Plank) and engineered hardwood depends on your priorities. LVP offers superior water resistance, durability, and affordability, making it ideal for high-moisture areas and busy homes. Engineered hardwood provides a genuine wood look and feel, adding a touch of natural elegance and warmth, though it’s less forgiving with moisture and often pricier.

Picking the right flooring can feel like a puzzle, especially when you’re aiming for that beautiful wood look. Two popular choices that often get compared are Luxury Vinyl Plank (LVP) and engineered hardwood. They look similar, but they’re quite different under the surface. This guide is here to break down those differences, making it simple for you to choose the best floor for your home, your budget, and your lifestyle. No need to feel overwhelmed; we’ll walk through it together, just like we’re in the workshop!

What Exactly Are LVP and Engineered Hardwood?

Before we dive into the nitty-gritty, let’s get a clear picture of what each flooring type is made of. This will help us understand why they perform so differently.

Luxury Vinyl Plank (LVP) Explained

Think of LVP as a high-tech flooring material. It’s not like the old vinyl sheets your grandparents might have had! LVP is constructed in layers, and its top layer is designed to mimic the look and feel of natural materials, most commonly wood. Here’s a quick breakdown of its construction:

- Wear Layer: This is the protective top coating that resists scratches, stains, and everyday wear and tear. A thicker wear layer (measured in mils) generally means better durability.

- Design Layer: This is the high-definition printed image that gives LVP its realistic wood (or stone) appearance.

- Core Layer: This is the heart of the plank. LVP typically has a solid polymer core (SPC) or a more flexible core (WPC – Wood Plastic Composite or PVC). SPC is known for its rigidity and dent resistance, while WPC offers a bit more cushion and warmth.

- Backing Layer: This provides stability and sometimes an attached underlayment for sound dampening and moisture resistance.

Because of its layered, synthetic construction, LVP is remarkably resilient and versatile.

Engineered Hardwood Explained

Engineered hardwood is a more natural product. It’s made by bonding together three or more layers of wood or wood composite materials, topped with a thin layer of real hardwood veneer. The layers are cross-grained, which makes the plank more stable than solid hardwood, especially when exposed to changes in humidity and temperature. Here’s how it’s typically built:

- Veneer Layer: This is the visible top layer, made from genuine hardwood species like oak, maple, or walnut. Its thickness can vary, affecting how many times it can be sanded and refinished.

- Stabilizing Layers: These are made from plywood, high-density fiberboard (HDF), or other composite materials. They are arranged in opposing directions (cross-grained) to resist expansion and contraction.

- Base Layer: This is usually a layer of wood or composite to complete the construction.

The key difference here is the actual wood veneer on top. This gives engineered hardwood the authentic look, feel, and even scent of real wood.

Key Differences: LVP vs. Engineered Hardwood

Now that we know what they are, let’s compare them side-by-side on the factors that matter most for your home.

1. Water and Moisture Resistance

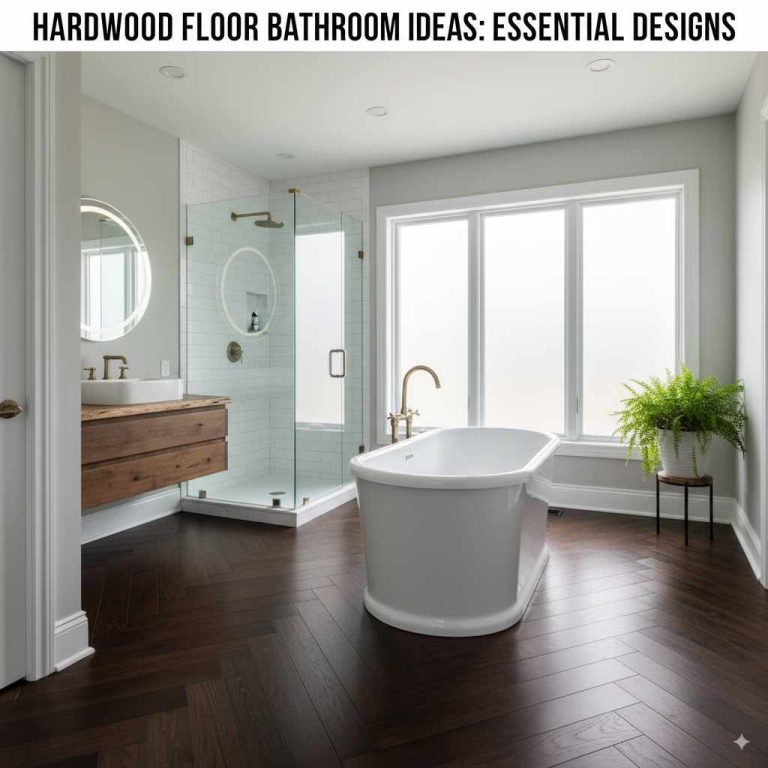

This is often the biggest deciding factor for many homeowners. If you’re flooring a kitchen, bathroom, laundry room, or basement, moisture is a major concern.

- LVP: Is exceptionally water-resistant, with many LVP products being completely waterproof. The synthetic materials used in its construction don’t absorb moisture like wood does. This makes it an excellent choice for areas prone to spills, splashes, and high humidity. Even spills that sit for a while are usually no match for LVP, and cleaning is a breeze.

- Engineered Hardwood: While more stable than solid hardwood, engineered hardwood is still made with real wood components. The wood veneer can swell, warp, or get damaged if exposed to excessive moisture or standing water. It’s generally not recommended for full bathrooms or areas where water spills are very common. Minor spills should be wiped up immediately.

2. Durability and Wear

Both LVP and engineered hardwood are known for their durability, but they handle wear and tear in different ways.

- LVP: Is highly durable and resistant to scratches, dents, and fading. The thick wear layer on quality LVP can withstand heavy foot traffic, pets, and kids’ play. It’s a workhorse flooring that’s designed to hold up to daily life.

- Engineered Hardwood: The durability of engineered hardwood largely depends on the thickness of its real wood veneer and the quality of its construction. The veneer can be scratched or dented, especially by sharp objects or high heels. However, the underlying layers provide excellent stability, preventing warping that can plague solid wood.

3. Appearance and Feel

This is where personal preference really comes into play. Both can mimic wood beautifully, but the authenticity differs.

- LVP: Advances in printing technology mean LVP can look incredibly realistic. The planks can feature detailed wood grain patterns, knots, and textures. However, a keen eye might still detect that it’s not real wood, especially in its overall feel and subtle variations.

- Engineered Hardwood: Offers genuine wood. The top veneer is real hardwood, so it has the natural warmth, unique grain patterns, and subtle imperfections that only real wood can provide. It feels warmer underfoot and often has a more premium, natural aesthetic.

4. Maintenance and Cleaning

Keeping your floors looking great is important, and how easy that is can vary.

- LVP: Is incredibly low-maintenance. Regular sweeping or vacuuming and occasional damp mopping are usually all that’s needed. Its waterproof nature means you don’t have to worry about water seeping into seams and causing problems. Minor stains are typically easy to wipe away.

- Engineered Hardwood: Requires more careful maintenance. You’ll need to sweep or vacuum regularly and clean with a wood-floor-specific cleaner. Avoid excessive water or steam mops, as they can damage the wood veneer and the core layers. Spills must be cleaned up promptly.

5. Cost Comparison

When planning a project, budget is always a key consideration.

- LVP: Generally more affordable than engineered hardwood. The price can range from budget-friendly options to higher-end luxury products, but it typically offers a lower cost per square foot. Installation can also be simpler and less expensive, especially for click-lock systems that homeowners can often install themselves.

- Engineered Hardwood: Tends to be more expensive, reflecting the cost of real wood veneer and its manufacturing process. Prices can vary widely depending on the wood species, veneer thickness, and brand. Professional installation is often recommended, adding to the overall cost.

6. Installation

How easy is it to get these floors installed?

- LVP: Is often designed for DIY-friendly installation. Many LVP products feature a click-lock system where planks simply snap together. It can often be installed as a floating floor, meaning it doesn’t need to be glued or nailed down, making it ideal for renters or quick overhauls. Some types can also be glued down.

- Engineered Hardwood: Can be installed in several ways: glued down, nailed down, or as a floating floor. While some homeowners might tackle a floating installation, many prefer professional help, especially for glued or nailed installations, to ensure the best adhesion and finish.

7. Subfloor Requirements

The surface underneath your flooring matters.

- LVP: Is quite forgiving with subfloor imperfections. Many LVP products can be installed over existing smooth, clean, and dry flooring, or a slightly uneven subfloor, especially if using an attached underlayment or a separate underlayment pad.

- Engineered Hardwood: Requires a more level and smoother subfloor. Even minor imperfections can potentially show through or cause issues with the planks over time.

8. Refinishing Capabilities

Can you refresh the look down the line?

- LVP: Generally cannot be refinished. If planks become too worn or scratched, they usually need to be replaced.

- Engineered Hardwood: Can sometimes be sanded and refinished, but this capability depends heavily on the thickness of the actual wood veneer. Planks with thicker veneers can be sanded and refinished one or two times to refresh their look and repair minor damage, similar to solid hardwood.

LVP vs. Engineered Hardwood: Which is Right for You?

Let’s put it all together to help you decide. Think about your lifestyle, the rooms you’re flooring, and what’s most important to you.

Choose LVP If:

- You need flooring for high-moisture areas like kitchens, bathrooms, laundry rooms, or basements.

- You have pets and young children and need a floor that can withstand scratches, spills, and heavy traffic.

- You’re on a tighter budget but want a durable and attractive wood-look floor.

- You’re looking for a DIY-friendly installation that can save on labor costs.

- Low maintenance and easy cleaning are top priorities.

- You appreciate modern technology that delivers realistic looks with high performance.

Choose Engineered Hardwood If:

- You desire the authentic look, feel, and warmth of real wood in living areas, dining rooms, or bedrooms.

- You want to add natural elegance and potentially increase your home’s resale value with a premium material.

- Moisture is not a significant concern in the areas you’re flooring.

- You’re prepared for a higher budget and more careful maintenance requirements.

- You like the idea of potentially being able to refinish the floor in the future (depending on veneer thickness).

- You prefer natural materials and a classic, timeless aesthetic.

Quick Comparison Table

Here’s a quick snapshot to help you see the main differences at a glance.

| Feature | Luxury Vinyl Plank (LVP) | Engineered Hardwood |

|---|---|---|

| Material | Synthetic (PVC, polymer core) with printed design | Real wood veneer over plywood/composite core |

| Water Resistance | Excellent to Waterproof | Limited; susceptible to damage from moisture |

| Durability | High; resistant to scratches, dents, fading | Good; depends on veneer thickness; can scratch/dent |

| Appearance | Realistic wood-look (printed) | Authentic real wood |

| Maintenance | Very Low; easy to clean | Moderate; requires specific wood floor cleaners, careful of water |

| Cost | Generally more affordable | Generally more expensive |

| Installation | Often DIY-friendly (click-lock) | Can be DIY (floating), but often professionally installed |

| Refinishing | Cannot be refinished | Possible, depending on veneer thickness (1-2 times) |

| Best For | High-moisture areas, busy households, budget-conscious projects | Living areas, bedrooms, spaces where real wood is desired, higher-end finishes |

Installation Tips for Both Flooring Types

No matter which you choose, proper installation is crucial for longevity and appearance. Always make sure your subfloor is clean, dry, and level. For LVP, especially click-lock systems, following the manufacturer’s instructions for expansion gaps around the perimeter of the room is vital. This allows the flooring to expand and contract naturally without buckling.

For engineered hardwood, if you’re nailing or gluing it down, using the correct fasteners or adhesive is key. This ensures the planks are securely attached and won’t shift. If you’re unsure about any part of the installation process, it’s always a good idea to consult with a flooring professional or a trusted DIY resource.

For more detailed guidance on subfloor preparation, you can refer to resources like the National Association of Home Builders (NAHB) guidance on subfloor preparation, which emphasizes its importance for any flooring type.

Frequently Asked Questions

Here are some common questions beginners have about LVP and engineered hardwood.

Q1: Can LVP really look like real wood?

A: Yes! Modern LVP uses high-definition printing and embossing to create incredibly realistic wood grain patterns, textures, and even beveled edges. While you might notice a difference up close or by touch if you’re comparing side-by-side, LVP can offer a very convincing wood look from a normal viewing distance.

Q2: Is engineered hardwood a good choice for kitchens?

A: While it can work, it’s not the most ideal choice if your kitchen is prone to frequent spills or high humidity. If you love the look of real wood and want it in your kitchen, choose engineered hardwood with a thicker veneer and be diligent about wiping up any spills immediately. For ultimate peace of mind in a kitchen, waterproof LVP is often a safer bet.

Q3: What does “wear layer” on LVP mean?

A: The wear layer is LVP’s protective top coating. It’s measured in mils (a thousandth of an inch). A thicker wear layer—typically 20 mils or higher for residential use and 30 mils or more for commercial—means better resistance to scratches, scuffs, stains, and general wear and tear. It’s a great indicator of LVP’s durability.

Q4: Can you install engineered hardwood in a basement?

A: Engineered hardwood can be installed in a basement, especially if the basement is known to be dry and has good humidity control. Many modern engineered wood floors also have enhanced stability. However, because basements can be prone to moisture issues (even from plumbing leaks or condensation), LVP or other waterproof options are often considered a more foolproof choice for basements.

Q5: Which is better for pets: LVP or engineered hardwood?

A: LVP is generally better for pet owners. Its durable, waterproof surface is highly resistant to scratches and stains from pet accidents. While engineered hardwood can be scratched by pet claws, and accidents need immediate cleanup, LVP can handle more abuse from furry friends.

Q6: Can I install LVP or engineered hardwood myself?

A: Many LVP products, especially click-lock types, are designed for DIY installation. Engineered hardwood can also be installed as a floating floor, which is more DIY-friendly. However, nailing or gluing down engineered hardwood often requires more skill and specialized tools, so many people opt for professional installation for these methods.

Conclusion

Choosing between LVP and engineered hardwood is all about understanding their strengths and weaknesses relative to your needs. LVP shines in its unbeatable water resistance, extreme durability, low maintenance, and affordability, making it a fantastic and practical choice for busy homes and moisture-prone areas. Engineered hardwood, on the other hand, offers the undeniable charm and authentic beauty of real wood, bringing natural elegance and warmth to your living spaces.

It’s a premium option for those who value natural materials and a classic aesthetic, provided they can manage its moisture sensitivities and budget. By considering these key differences, you can confidently select the flooring that will serve you well, look beautiful, and bring you joy for years to come!