DIY Drill Bit Sharpener: Ultimate Guide to Restore Sharpness Fast

Are your drill bits starting to lose their edge? Dull drill bits can slow down your projects and leave you frustrated.

What if you could sharpen them yourself quickly and easily? A DIY drill bit sharpener is just what you need to save time and money while keeping your tools in top shape. You’ll discover simple ways to bring your drill bits back to life without buying expensive equipment.

Keep reading to learn how to sharpen your drill bits like a pro and get the most out of every project you tackle.

Choosing The Right Drill Bit Sharpener

Choosing the right drill bit sharpener makes a big difference in your DIY projects. A sharp drill bit works better and lasts longer. Picking the best sharpener depends on your needs and skills. This guide helps you understand your options clearly.

Types Of Sharpeners

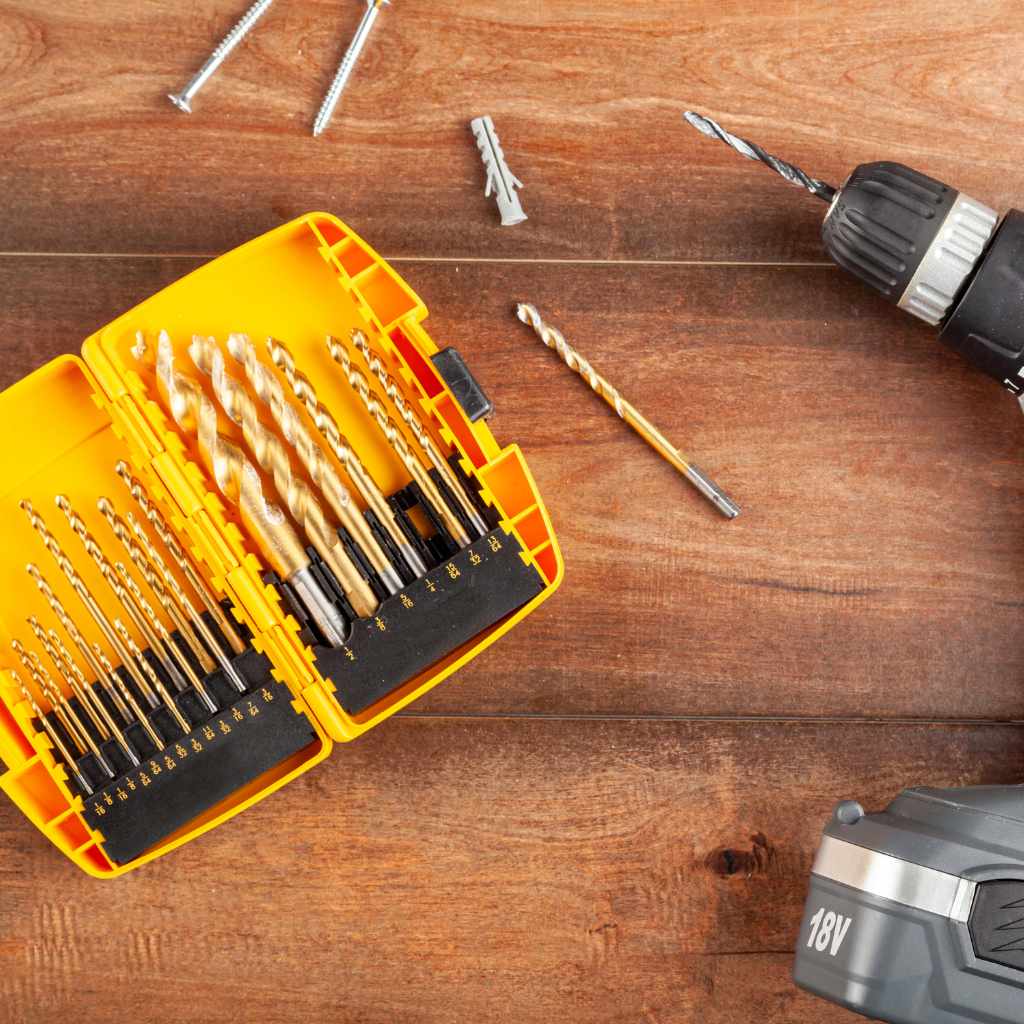

There are several types of drill bit sharpeners. Manual sharpeners need you to turn the bit by hand. They are simple and low cost. Electric sharpeners use power to do the job fast. They offer more precision and save time. Some sharpeners are versatile and fit many bit sizes. Others focus on specific drill bits like twist or masonry bits. Choose based on the types of bits you use most.

Factors To Consider

Think about ease of use first. Beginners should pick simple models with clear instructions. Check how fast the sharpener works. Faster models save time but may cost more. Look at the sharpener’s size and weight. Portable sharpeners suit small workshops and home use. Consider durability and build quality. A strong sharpener lasts longer and handles tough bits well. Also, see if the sharpener works with your drill bit sizes.

Budget-friendly Options

Affordable drill bit sharpeners offer good value for money. Manual sharpeners are usually cheaper and work well for light use. Some electric models come at a low price and provide decent results. Look for products with positive reviews and basic features. Avoid very cheap sharpeners that can damage your bits. Saving a little now may cost more in the long run. Choose a sharpener that fits your budget and meets your needs.

Preparing Drill Bits For Sharpening

Preparing drill bits for sharpening is an important step. Proper preparation helps you get the best results. It also saves time and effort during sharpening. Clean and check your drill bits carefully. Look for signs of wear or damage. Follow safety tips to protect yourself.

Cleaning And Inspection

Start by cleaning the drill bits with a brush. Remove dirt, grease, and rust. Use a cloth to wipe them dry. This helps you see the bit’s condition clearly. Inspect the cutting edges for dullness or chips. Clean bits sharpen more evenly.

Identifying Wear And Damage

Check the tip and edges for wear. Look for rounded or chipped cutting edges. Notice any bent or broken parts. Worn or damaged bits may need replacement. Only sharpen bits that are fixable. Proper inspection avoids wasting time on bad bits.

Safety Precautions

Wear safety glasses to protect your eyes. Use gloves to avoid cuts from sharp edges. Keep your work area clean and well-lit. Handle drill bits carefully to prevent injury. Follow all safety steps before and during sharpening.

Step-by-step Sharpening Process

Sharpening drill bits at home saves money and improves tool life. The step-by-step process is simple and effective. Follow these steps to get sharp, ready-to-use drill bits.

Setting Up Your Sharpener

Start by placing the drill bit sharpener on a stable surface. Secure it firmly to avoid movement. Insert the drill bit into the holder. Adjust the bit so the tip faces the grinding wheel. Make sure the bit is straight and tight.

Sharpening Angle Tips

Keep the correct angle for best results. Most drill bits sharpen at 59 to 60 degrees. Hold the bit steady at this angle. Too steep or too flat will dull the bit faster. Use the sharpener’s guide to maintain the angle.

Maintaining Consistency

Move the drill bit smoothly across the grinding wheel. Keep the pressure light and even. Check the bit tip often for a uniform shape. Sharpen both sides equally to balance the cutting edges. Consistency ensures a sharp, long-lasting drill bit.

Troubleshooting Common Issues

Troubleshooting common issues with a DIY drill bit sharpener helps keep your tools in top shape. Problems can slow your work or damage bits. Fixing these issues saves time and money. Below are solutions to typical challenges faced during sharpening.

Uneven Sharpening

Uneven sharpening happens when the bit edge is not smooth or balanced. Check if the bit is held at the right angle. Keep steady pressure during sharpening. Rotate the bit evenly to avoid flat spots. Clean the sharpener’s grinding surface often. This prevents rough edges and ensures even wear.

Overheating Drill Bits

Drill bits get too hot if you press too hard or sharpen for too long. Overheating can ruin the bit’s metal. Cool the bit by dipping it in water regularly. Use light, steady strokes instead of heavy pressure. Take breaks during sharpening to avoid heat build-up. Cooler bits stay sharper and last longer.

Handling Complex Bit Types

Some drill bits have unique shapes or coatings. They need special care during sharpening. Study the bit’s design before starting. Use appropriate sharpening tools for complex bits. Avoid removing too much material to keep the bit’s shape. Take your time and follow the bit’s guidelines closely.

Maintaining Sharp Drill Bits

Maintaining sharp drill bits is key for smooth and safe drilling. Sharp bits cut better and last longer. Dull bits cause more heat and damage the material. Proper care keeps your drill bits ready for any task.

Proper Storage

Store drill bits in a dry, organized place. Use a case or holder to keep them apart. Avoid tossing bits in a toolbox. This stops them from getting dull or bent. Clean bits before storing to remove dust and oil.

Regular Inspection

Check bits before each use. Look for chips, cracks, or dull edges. Run your finger lightly along the cutting edge to feel sharpness. Remove any debris that might affect cutting. Early spotting of damage prevents bigger problems.

When To Replace Bits

Replace bits if they no longer cut well. Bits that slip or burn the material need changing. Bent or cracked bits are unsafe and should be discarded. Using sharp bits saves time and effort on every project.

Enhancing Efficiency With Accessories

Enhancing your DIY drill bit sharpener with the right accessories makes the process faster and easier. Accessories help keep the drill bits steady and improve the sharpening angle. This leads to sharper bits and longer tool life.

Simple add-ons can save time and improve results. They make your sharpening more precise and protect your tools from damage. The right accessories can transform your workspace into a more efficient setup.

Using Guides And Jigs

Guides and jigs hold drill bits steady during sharpening. They keep the angle consistent, which is key for sharp edges. With a jig, you avoid uneven sharpening and reduce mistakes.

These tools make it easier to sharpen many bits quickly. Even beginners get better results by using guides. They help maintain the correct position and pressure on the bit.

Cooling Techniques

Drill bits heat up during sharpening. Heat can damage the bit and reduce its sharpness. Cooling techniques stop this problem and keep the bit strong.

Use water or oil to cool bits while sharpening. Dip the bit in water often or spray it lightly. This keeps the metal from overheating and losing hardness.

Upgrading Your Setup

Upgrading your drill bit sharpener setup improves efficiency. Add a stronger motor or better grinding wheel for faster work. A stable base reduces vibrations and increases control.

Extra lighting helps you see the bit clearly. Good lighting prevents mistakes and improves precision. Small upgrades can make a big difference in your sharpening quality.

Frequently Asked Questions

How Do I Sharpen Drill Bits At Home?

You can sharpen drill bits using a bench grinder or a DIY sharpening tool. Hold the bit at a 60-degree angle to the grinding wheel. Move it gently to restore the cutting edge. Always wear safety glasses and work carefully.

What Tools Are Needed For A Diy Drill Bit Sharpener?

Common tools include a bench grinder, a file, or a rotary tool with a grinding attachment. You may also need a jig to hold the bit steady. These tools help you sharpen drill bits precisely and safely at home.

How Often Should Drill Bits Be Sharpened?

Sharpen drill bits when they become dull or cut inefficiently. Frequent sharpening improves performance and extends bit life. Regular inspection before use helps determine if sharpening is necessary.

Can I Sharpen All Types Of Drill Bits Myself?

Most standard twist drill bits can be sharpened at home. Specialty bits like masonry or carbide require professional sharpening. Always check the bit type before attempting DIY sharpening to avoid damage.

Conclusion

Sharpening drill bits at home saves money and time. You only need simple tools and a little practice. A sharp drill bit works better and lasts longer. This DIY method keeps your tools ready for any job. Try sharpening your bits to see the difference.

Keep your drills sharp and your projects smooth. Small effort, big results. Easy, quick, and useful. Give it a go!