Dust Extraction Table Saw: Maximize Cleanliness & Efficiency

A dust extraction table saw helps to efficiently remove sawdust and debris during woodworking projects, ensuring a cleaner and healthier working environment. It is essential for maintaining a dust-free workspace and preventing respiratory issues caused by airborne particles.

Woodworkers can choose from various dust collection systems and accessories to suit their specific needs and budget. Effective dust extraction also contributes to better visibility, accurate cutting, and prolongs the lifespan of the equipment. Investing in a quality dust extraction system is crucial for both professional woodworkers and hobbyists, as it significantly improves overall work quality and safety.

Proper dust extraction not only enhances the workshop environment but also reduces the time and effort required for post-project cleanup.

Introduction To Dust Extraction For Table Saws

When it comes to woodworking, keeping a clean and organized workspace is crucial. One area that often gets overlooked is dust extraction for table saws. However, having an effective dust extraction system in place can bring numerous benefits to both the woodworker and the overall woodworking process. In this article, we will explore the importance of dust extraction for table saws and the advantages it offers.

Benefits Of A Clean Workspace

A clean workspace is essential for any woodworking project. Here are some of the key benefits of maintaining a clean workspace:

- Promotes safety by reducing the risk of accidents and injuries caused by clutter and debris.

- Improves efficiency by allowing for easy access to tools and materials.

- Enhances productivity by minimizing distractions and creating a focused environment.

- Prevents damage to equipment and materials by reducing the chances of spills and mishaps.

- Creates a professional and organized image, especially if clients or visitors are present in the workspace.

Efficiency Gains

Efficiency gains are one of the major advantages of implementing a dust extraction system for table saws. Here’s how a clean and dust-free workspace can improve efficiency:

- Reduces downtime: With a proper dust extraction system, woodworkers can spend less time cleaning up dust and more time working on their projects.

- Prevents clogging: Dust buildup in the table saw can lead to clogging, affecting the performance and accuracy of cuts. Effective dust extraction ensures the saw remains clear, allowing for smooth and precise cuts.

- Enhances equipment lifespan: Dust particles can be harmful to the internal components of the table saw. By removing dust from the workspace, woodworkers can extend the lifespan of their equipment and avoid costly repairs or replacements.

- Promotes better air quality: Dust particles in the air can be hazardous to health, causing respiratory issues and allergies. A dust extraction system helps to remove these particles, creating a safer and healthier working environment.

- Reduces cleanup time: With a reliable dust extraction system, the need for manual cleaning and sweeping is significantly reduced, saving time and effort.

By investing in a dust extraction system for table saws, woodworkers can enjoy a cleaner and more efficient workspace, leading to improved productivity and overall satisfaction in their woodworking endeavors.

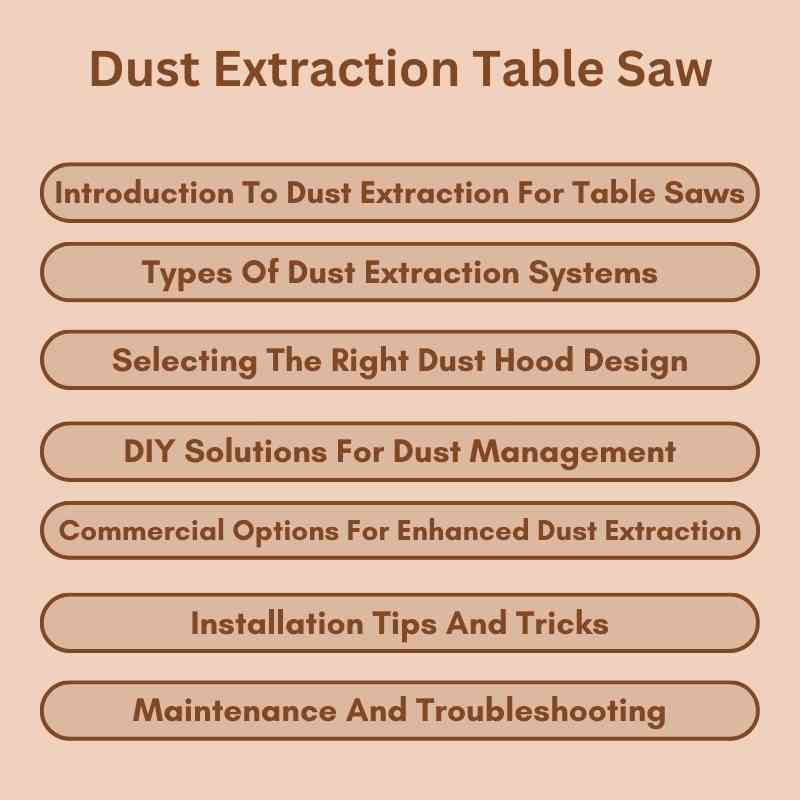

Types Of Dust Extraction Systems

When it comes to dust extraction systems for table saws, there are several types of systems that can effectively capture and remove sawdust and debris. Each type of dust extraction system has its own unique benefits and features, making it important to understand the different options available.

Overhead Guards

An overhead guard dust extraction system is designed to capture sawdust and debris directly above the cutting area of the table saw. This type of system typically features a hood or shroud that encloses the area above the saw blade, effectively capturing the dust as it is produced. The captured dust is then directed to a collection point, such as a dust bag or extraction port, for easy disposal.

Blade Surrounds

Blade surround dust extraction systems are designed to enclose the entire saw blade, capturing dust and debris at the source of the cutting action. By surrounding the blade with a shroud or enclosure, this type of system effectively contains the dust as it is generated, preventing it from dispersing into the surrounding environment. The captured dust is then directed to a collection point for easy removal.

Bottom Collection

Bottom collection dust extraction systems are focused on capturing sawdust and debris that falls below the table saw. These systems typically feature a collection bin or bag located beneath the saw, effectively capturing the dust as it falls. Some bottom collection systems may also incorporate suction or airflow to help direct the dust into the collection point, ensuring thorough removal of debris.

Selecting The Right Dust Hood Design

When it comes to dust extraction for your table saw, selecting the right dust hood design is crucial. The dust hood plays a vital role in capturing and removing dust and debris generated by your saw, keeping your workspace clean and safe. In this section, we will explore the key factors to consider when choosing a dust hood design that is compatible with your table saw.

Assessing Your Needs

Before diving into the various dust hood designs available, it is essential to assess your specific needs. Consider the following factors:

- Size of your table saw: Measure the dimensions of your table saw, including the depth and width of the table, to ensure that the dust hood will fit properly.

- Type of work: Think about the type of work you typically perform on your table saw. If you frequently make angled cuts or use accessories like dado blades, you may require a dust hood design that accommodates these features.

- Amount of dust generated: Evaluate the amount of dust and debris your table saw produces. If you work with materials that create a significant amount of dust, you will need a dust hood design that can effectively capture and contain it.

Compatibility With Your Saw

Once you have assessed your needs, the next step is to ensure that the dust hood design is compatible with your table saw. Consider the following factors:

- Mounting options: Check if the dust hood design offers multiple mounting options that are compatible with your table saw. Common mounting options include brackets, clamps, or direct attachment to the saw’s dust port.

- Adjustability: Look for a dust hood design that offers adjustable features, such as height and angle, to ensure optimal dust collection based on your specific saw setup.

- Dust collection system compatibility: If you already have a dust collection system in place, make sure the dust hood design is compatible with your existing setup. This will ensure seamless integration and efficient dust extraction.

By assessing your needs and ensuring compatibility with your table saw, you can select the right dust hood design that will effectively capture and remove dust and debris, keeping your workspace clean and improving overall safety.

DIY Solutions For Dust Management

Dust management is a crucial aspect of woodworking, especially when it comes to table saws. Fortunately, there are several DIY solutions for effectively managing dust and debris. Whether you’re building a custom dust hood or improving existing systems, these methods can significantly enhance the cleanliness and safety of your workspace.

Building A Custom Dust Hood

Creating a custom dust hood for your table saw is a highly effective way to minimize dust dispersion. By enclosing the blade and underside of the table, a custom hood can capture a significant amount of sawdust, preventing it from spreading throughout the workshop. This can be achieved using simple materials such as plywood, clear plastic, or even metal, depending on your preference and expertise.

Improving Existing Systems

If you already have a dust collection system in place, there are several ways to enhance its efficiency. Upgrading the suction power of the vacuum or dust collector, optimizing the placement of hoses and fittings, and ensuring a tight seal between the table saw and the dust collection system can all contribute to better dust management. Additionally, incorporating a pre-separator or cyclone can further improve the capture of fine dust particles, preventing them from clogging the filters and reducing overall airborne dust.

Commercial Options For Enhanced Dust Extraction

Enhance the dust extraction on your table saw with commercial options for efficient debris removal. Explore products like the Rockler Contractor Table Saw Dust Bag or the Laguna Tablesaw Dust Collection Kit, available at various price points to suit your needs and budget.

Achieve cleaner workspaces and improved air quality with these effective dust extraction solutions.

When it comes to dust extraction for your table saw, there are plenty of options available on the market. Commercial options provide enhanced dust extraction, making it easier to keep your workspace clean and safe. In this article, we’ll take a look at some of the top picks from the market and provide a cost vs. performance analysis to help you make an informed decision.

Top Picks From The Market

There are several options available for commercial dust extraction on table saws. Here are some of the top picks:

| Product | Price |

|---|---|

| Penn State Industries TSGUARD Table Saw Dust Collection Guard | $274.95 |

| Laguna Tablesaw Dust Collection Kit | $75.00 |

| Milescraft DustCutter Contractor Saw Dust Collection System | $29.90 |

| Sirocco Dustless Table Saws | $459.00 |

| SawStop TSA-ODC Overarm Dust Collection Assembly | $299.00 |

Cost Vs. Performance Analysis

When it comes to cost vs. performance, there are a few things to consider. Some options may be more expensive, but they may also provide better performance and durability. On the other hand, some options may be more affordable, but may not provide the same level of performance.

For example, the Penn State Industries TSGUARD Table Saw Dust Collection Guard is one of the more expensive options on the market, but it provides excellent performance and durability. The Milescraft DustCutter Contractor Saw Dust Collection System, on the other hand, is more affordable but may not provide the same level of performance.

Ultimately, the best option for you will depend on your specific needs and budget. Be sure to do your research and consider factors such as performance, durability, and price before making a purchase.

In conclusion, commercial options for enhanced dust extraction on table saws provide a convenient and effective way to keep your workspace clean and safe. With a variety of options available on the market, it’s important to consider factors such as cost and performance to find the best option for your needs.

Installation Tips And Tricks

Installing a dust extraction system for your table saw is crucial to maintain a clean and safe working environment. In this article, we will discuss some installation tips and tricks for a dust extraction table saw.

Ensuring A Tight Seal

The first step to a successful dust extraction system is to ensure a tight seal. Any gaps between the saw and the dust collection system will allow dust to escape, defeating the purpose of the system. Use a sealing tape or foam to seal any gaps between the saw and the dust collection system.

Optimizing Dust Flow

Another important tip for dust extraction table saw is to optimize the dust flow. Make sure that the dust collection system is properly sized for your saw and the type of work you do. A system that is too small will not be effective, while a system that is too large will waste energy and money. Additionally, consider the placement of the dust extraction system. The closer it is to the source of the dust, the more effective it will be.

Regular Maintenance

Regular maintenance is also essential for a dust extraction table saw. Clean the system regularly to prevent clogs and ensure maximum efficiency. Replace filters and bags as necessary and check for any leaks or damage to the system. A well-maintained system will provide better performance and a longer lifespan.

By following these installation tips and tricks, you can ensure that your dust extraction table saw is effective and efficient in keeping your workspace clean and safe.

Maintenance And Troubleshooting

When it comes to the longevity and performance of your dust extraction table saw, proper maintenance and prompt troubleshooting are crucial. By following regular upkeep practices and knowing how to deal with common issues, you can ensure that your table saw operates at its best while maintaining a safe working environment.

Regular Upkeep Practices

Regular maintenance of your dust extraction table saw is essential for optimal performance. Here are some upkeep practices to keep your equipment in top condition:

- Clean the dust collection system: Regularly remove accumulated dust and debris from the collection system to prevent clogs and maintain efficient airflow.

- Inspect hoses and fittings: Check hoses and fittings for any signs of damage or leaks, and replace them as needed to prevent loss of suction.

- Replace filter bags: If your dust extraction system uses filter bags, replace them according to the manufacturer’s recommendations to ensure effective dust capture.

- Lubricate moving parts: Apply lubrication to the moving parts of the dust extraction system to prevent friction and ensure smooth operation.

- Check the airflow: Regularly inspect the airflow to ensure that the system is effectively capturing dust and directing it away from the work area.

Dealing With Common Issues

Despite proper maintenance, you may encounter common issues with your dust extraction table saw. Here’s how to address some of these issues:

- Reduced suction: Check for clogs in the hoses and fittings, and clear any obstructions to restore proper suction.

- Leaking hoses: If you notice leaks in the hoses, promptly replace or repair them to prevent loss of suction and maintain efficient dust collection.

- Filter clogging: Monitor the condition of the filter bags and promptly replace them when they become clogged to maintain optimal dust capture.

- Malfunctioning motor: If the motor is not operating as expected, inspect the electrical connections and components, and seek professional assistance if needed for motor repair or replacement.

- Inadequate dust capture: Assess the positioning of the dust collection system and make adjustments to ensure effective capture of dust and debris generated by the table saw.

Real-world Applications And Results

Achieve optimal dust extraction with a table saw to improve cleanliness and safety in your woodworking projects. Explore real-world results and applications in Austin, Texas, United States, where DIY enthusiasts have re-engineered their saws for efficient dust collection. Discover affordable options such as dust collection guards, kits, and bags, available on various online platforms.

Maximize your table saw’s performance while minimizing dust and debris in your workspace.

Case Studies

In this section, we will explore real-world applications and the results of using a Dust Extraction Table Saw. These case studies will highlight the effectiveness and benefits of incorporating a dust extraction system into your woodworking projects.

User Testimonials

Don’t just take our word for it! Read what our satisfied customers have to say about their experience with the Dust Extraction Table Saw:

- “I was struggling with dust and debris accumulating on my table saw, affecting the accuracy of my cuts. After installing the Dust Extraction Table Saw, the difference was remarkable. Not only did it keep my workspace clean, but it also improved the overall performance of my saw.” – John, Woodworking Enthusiast

- “I run a professional woodworking shop, and dust management is a top priority for me. The Dust Extraction Table Saw has exceeded my expectations. It effectively captures the dust, ensuring a clean and safe working environment for me and my employees.” – Sarah, Woodworking Business Owner

- “I was skeptical about the impact of dust collection on my table saw until I tried the Dust Extraction Table Saw. The results were astounding! It significantly reduced the amount of dust in my workshop, making cleanup a breeze. I can now focus on my projects without worrying about the health hazards associated with airborne particles.” – Mark, DIY Enthusiast

These testimonials highlight the positive experiences and tangible benefits that users have witnessed by incorporating the Dust Extraction Table Saw into their woodworking routines. The effectiveness of this tool is evident in the enhanced performance, cleaner workspace, and improved safety it provides.

Investing in a Dust Extraction Table Saw is not only a practical choice but also a smart one. With the real-world applications and proven results showcased in these case studies and user testimonials, it’s clear that this tool is a game-changer for any woodworking enthusiast or professional.

Frequently Asked Questions

How Do You Collect Dust From A Table Saw?

To collect dust from a table saw, simply tape a garbage bag onto the base. However, removing the bag can be tricky and requires careful handling to avoid rips and spills. For proper dust collection, consider investing in a dust collection guard or bag designed specifically for table saws.

Misaligned blades or fences can also contribute to excessive dust, so make sure to check and correct alignment.

Will A Shop Vac Work For Table Saw Dust Collection?

Yes, a shop vac can be used for table saw dust collection. It can effectively collect the dust and debris, but you may need to use additional attachments or accessories to optimize the collection. Remember to empty the shop vac regularly to maintain its efficiency.

How Many Cfm For Table Saw Dust Collection?

For effective table saw dust collection, aim for a minimum of 350-400 CFM (cubic feet per minute) airflow.

Why Does My Table Saw Throw So Much Dust?

Your table saw throws so much dust because the fence or blade might be misaligned. This inefficiency wastes stock and leaves marks on your wood. Correct the misalignment for better dust control.

Conclusion

To ensure a clean and safe working environment, a dust extraction table saw is a must-have tool for woodworkers. With its efficient dust collection system, it effectively removes dust and debris, preventing them from polluting the air and affecting your health.

By capturing the dust at its source, you can focus on your work without worrying about the mess. Invest in a high-quality dust extraction table saw and experience the benefits of a cleaner and healthier workspace. Say goodbye to dusty workshops and hello to improved productivity and peace of mind.