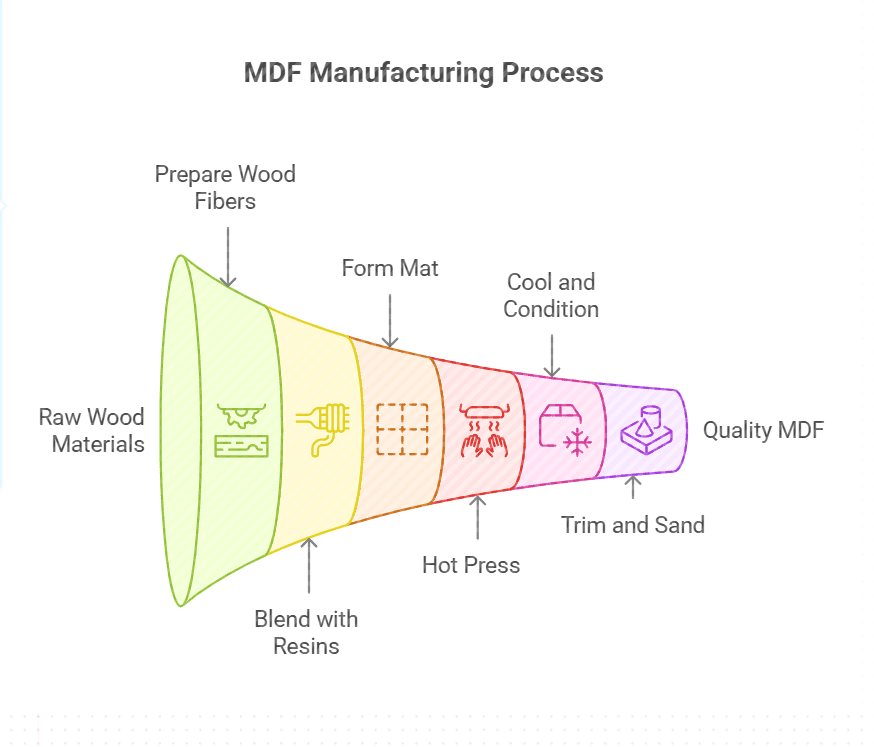

How Do You Make MDF: Step-by-Step Guide

Ever wondered what goes into creating that smooth, sturdy material often used in furniture and home projects? If you’ve heard of MDF but aren’t quite sure how it’s made, you’re in the right place.

MDF, or Medium-Density Fiberboard, is a popular choice for DIY enthusiasts and professionals alike, thanks to its versatility and affordability. But how do you transform wood fibers into this reliable product? Understanding the process not only satisfies your curiosity but also gives you an edge in your next project.

Stick around, and you’ll discover the fascinating steps involved in making MDF, and why knowing this could be your secret weapon in choosing the right materials for your home endeavors.

What Is Mdf

MDF stands for Medium-Density Fiberboard. It is a type of wood product. It is made by breaking down softwood. The wood is mixed with wax and a resin binder. Then, it is formed into panels. This happens under high temperature and pressure. MDF is smooth and strong. It is used for furniture and cabinets. It is also used for doors and panels. It can be cut and shaped easily. MDF is cheaper than solid wood. But it is not as strong. It can swell if it gets wet. MDF is popular in many homes. It is a good choice for indoor projects.

Credit: www.esshelf.com

Raw Materials Needed

Wood fibers are the main ingredient in MDF. They come from trees. These fibers are tiny pieces. They are mixed and pressed together. The process makes them strong.

Resins and adhesives hold the fibers together. They make the MDF durable. These materials are like glue. They help the MDF last longer. Without them, MDF would break easily.

Additives make MDF better. Some additives stop water damage. Others make it fire-resistant. Additives can change the color too. These extras improve the quality. They make MDF useful in many ways.

Preparing The Wood Fibers

Wood gets cut into small pieces. These pieces are called chips. Machines are used for chipping. Chippers have sharp blades. They slice the wood quickly. This makes the chips even and small. Small chips are easier to process. They help make MDF strong. Big chips are hard to use. They can cause problems.

Fibers are separated from the chips. This happens in a machine. The machine is called a refiner. It spins very fast. The spinning breaks the chips. It turns them into fibers. Fibers are soft and thin. They look like tiny strings. Fibers are important for MDF. They make it smooth. They hold the board together.

Credit: www.youtube.com

Blending With Resins

Applying resin is a key step in making MDF. Resins are sticky liquids. They help bind the wood fibers together. This makes the MDF strong and durable. Workers spray resin onto the wood fibers. They make sure every fiber gets covered. This ensures a good bond. The right amount of resin is important. Too much or too little can affect quality. Workers use machines to control the resin spray. This keeps the process even and accurate.

Mixing is the next step after applying resin. The wood fibers and resin blend together. This creates a thick, sticky mixture. Machines help with this mixing process. They spin and turn the fibers. This makes sure everything is mixed well. Proper mixing is crucial for a strong board. Once mixed, the blend is ready for the next step. It will be pressed into shape soon.

Forming The Mat

The process starts with wood fibers. These fibers are tiny. They are mixed with glue. The glue is special. It helps the fibers stick. Once mixed, the fibers form a layer. This is called the mat. The mat is flat. It needs to be thick and even. Workers use machines to make it smooth. This step is very important. It helps the MDF to be strong.

After layering, the mat goes to a press. The press is big and heavy. It squeezes the mat hard. This makes the mat thin. It also makes it strong. The pressing process is quick. It happens in seconds. After pressing, the mat is ready for the next step. The mat is now firm and ready.

Hot Pressing

Keeping the right temperature is important in hot pressing. The wood fibers need heat to stick together. Too much heat can damage the wood. Too little heat, and the fibers won’t bond well. Machines help control the temperature. They make sure it stays just right. This helps make strong MDF boards.

Pressure is another key factor in making MDF. It helps the wood fibers hold tight. Machines push hard on the wood. This creates a firm board. But too much pressure can break the fibers. Careful control is needed. This ensures the MDF is not too soft or too hard. The right balance makes quality boards.

Cooling And Conditioning

MDF needs cooling after it is made. The cooling process lowers the temperature of the board. Cool air is used to bring down the heat. This step keeps the MDF strong and prevents damage. Without cooling, the board can crack or bend. Cooling also stops moisture from building up. This is important for MDF quality. Cooling makes sure that the board stays flat. It also helps keep the board in a good shape.

After cooling, MDF needs time to rest. This is called conditioning time. It lets the board adjust to room temperature. During this time, the board becomes stable. Conditioning helps the MDF get stronger. It also makes the board easier to use. People wait for the right time to use it. This step is important for quality control. If MDF is not conditioned, it may not last long. Proper conditioning makes the MDF ready for use.

Credit: www.linkedin.com

Trimming And Sanding

MDF edges need special care. A clean edge makes a big difference. Use a sharp tool to trim. This helps avoid rough edges. Trimming makes the board look neat. It also helps with fitting pieces together. Safety goggles are a must. They protect your eyes from wood dust. Keep your workspace clean for safety too.

Sanding makes MDF smooth. Start with coarse sandpaper. Then, use fine sandpaper for a smooth finish. Sand in a circular motion. This removes all rough spots. Don’t press too hard. Light pressure works best. Always wear a mask. Sanding creates a lot of dust. A clean surface is ready for painting or sealing. Smooth surfaces look better and last longer.

Quality Inspection

Workers check the surface of MDF for any defects. Scratches and cracks are not good. The surface should be smooth and even. Color must be consistent across the board. These checks ensure the board looks good.

MDF goes through different tests. It must be strong and not break easily. Water tests show if it swells. Heat tests ensure it won’t warp. These tests make sure the MDF is good for use.

Applications Of Mdf

Crafted from wood fibers and wax, MDF offers versatility in furniture making and cabinetry. This engineered wood is smooth, allowing for easy painting and shaping. Ideal for creating affordable, durable products, MDF is popular in interior design projects.

Furniture Production

MDF is used for making furniture. It is smooth and easy to cut. Many people use it for tables and cabinets. It can be painted or covered with veneer. MDF is less expensive than solid wood. It is a good choice for cheap furniture. The material is strong and durable.

Building Materials

MDF is used in building. It is good for walls and floors. Builders use it for panels and doors. It is easy to shape. MDF helps to make houses look nice. It also helps to keep houses warm. Many builders like using MDF. It is a good material for many projects.

Frequently Asked Questions

How Is Mdf Made?

MDF is made by breaking down wood fibers, combining them with wax and resin, and pressing them under heat. The process forms dense panels, which are then cooled, sanded, and cut to size. This results in a strong and smooth composite wood product used in furniture and construction.

How To Make Mdf Step By Step?

MDF is made by breaking down wood fibers, mixing with resin, and pressing under heat and pressure. The process involves refining wood chips, blending them with adhesive, and compressing to form sheets. Finally, the sheets are cooled, trimmed, and sanded for smoothness.

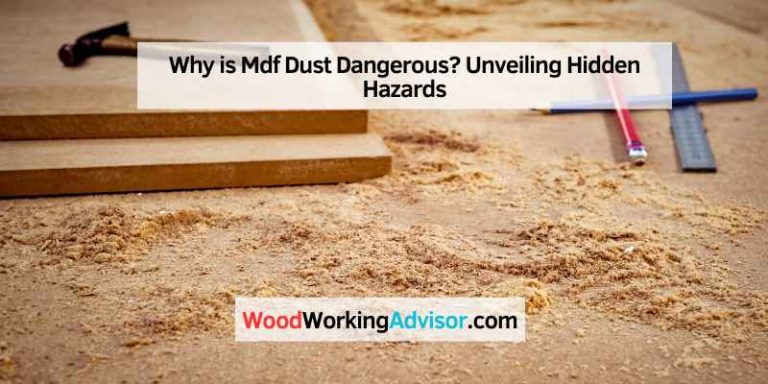

What Is The Biggest Drawback Of Using Mdf?

MDF’s biggest drawback is its susceptibility to moisture damage. It can swell and warp if exposed to water. This material is less durable compared to solid wood. MDF releases formaldehyde, posing health risks during cutting and sanding. It’s also heavier, making it challenging to handle and install.

Is Mdf Stronger Than Plywood?

MDF is generally denser and heavier than plywood. Plywood is stronger and more durable due to its layered construction. MDF is smoother and better for detailed work. Choose based on your project’s needs.

Conclusion

Making MDF involves a simple yet fascinating process. Wood fibers are combined with wax and resin. These are then heated and pressed into boards. The result? A versatile material ready for various uses. From furniture to crafts, MDF is a popular choice.

Its smooth surface and durability make it ideal. Understanding its creation helps in selecting the right materials. Perfect for your projects or business. Always ensure you choose quality MDF for best results. Enjoy working with this practical and reliable material.

Happy crafting!