How Long Does Mdf off Gas: Quick Insights & Solutions

MDF off-gassing typically takes around two years to dissipate. The formaldehyde gas emitted decreases over time.

Medium Density Fiberboard (MDF) is known to release formaldehyde gas, which is a major concern due to potential health risks associated with exposure. The glue used in MDF often contains urea formaldehyde, leading to the emission of volatile organic compounds (VOCs).

While the duration of off-gassing varies, it usually diminishes significantly after two years. Concerns about formaldehyde off-gassing from MDF furniture and the impact on indoor air quality have prompted discussions within online communities. It is important to consider these factors when using MDF products in living spaces, especially in areas frequented by children or pets.

Introduction To Mdf And Off-gassing

Medium Density Fiberboard (MDF) typically off-gasses for about two years, emitting formaldehyde gas from the product. The off-gassing process decreases over time, and it’s generally believed that MDF stops off-gassing after a couple of years.

When it comes to furnishing our homes and offices, we often encounter various types of engineered wood products. One such popular choice is Medium Density Fiberboard (MDF). MDF is made by compressing wood fibers with a resin binder under high temperature and pressure, resulting in a strong and versatile material that can be used for furniture, cabinetry, and decorative elements. However, there is one concern associated with MDF that is often raised – off-gassing.

What Is Mdf?

MDF, or Medium Density Fiberboard, is an engineered wood product made from wood fibers, resin binders, and other additives. It is known for its smooth surface, uniform density, and dimensional stability. MDF is widely used in the construction and furniture industries due to its affordability and ease of use.

Why Does Mdf Off-gas?

MDF off-gassing refers to the release of volatile organic compounds (VOCs) and formaldehyde gas from the board over time. The primary culprit behind MDF off-gassing is the resin binder used during its manufacturing process. Most MDF boards are made with urea formaldehyde (UF) resin, which contains formaldehyde, a chemical known to emit strong odors and potentially harmful fumes.

As MDF ages, the formaldehyde within the board gradually breaks down and off-gasses into the surrounding environment. The duration of off-gassing can vary depending on several factors, including the specific type of MDF, the conditions in which it is stored or used, and the level of ventilation in the space.

It’s important to note that MDF off-gassing is typically more pronounced in newly manufactured or freshly cut boards. Over time, the release of formaldehyde diminishes, and the levels of off-gassing decrease significantly. While there is no fixed timeline for how long MDF off-gassing lasts, it is generally believed that most MDF boards stop off-gassing after a couple of years.

However, it’s crucial to be aware of the potential health risks associated with prolonged exposure to formaldehyde gas. Individuals with respiratory conditions, allergies, or sensitivities may experience symptoms such as eye and throat irritation, coughing, and difficulty breathing when exposed to high levels of formaldehyde. Therefore, it is recommended to take appropriate precautions and ensure proper ventilation when working with or using MDF products.

In the next sections, we will explore the potential health concerns related to MDF off-gassing and discuss ways to minimize exposure to formaldehyde gas in order to create a safer and healthier living or working environment.

Health Concerns With Mdf Off-gassing

MDF, or Medium Density Fiberboard, is a popular material used in furniture and construction due to its affordability and versatility. However, there are health concerns associated with MDF off-gassing, particularly related to the release of formaldehyde gas.

Exposure To Formaldehyde

Formaldehyde is a volatile organic compound (VOC) that is commonly used as an adhesive in the production of MDF. When MDF is manufactured, formaldehyde is released into the air as a byproduct of the adhesive curing process. This off-gassing can continue for a certain period of time, which raises concerns about indoor air quality and potential health risks.

Potential Health Risks

Exposure to formaldehyde gas emitted from MDF can have various health effects, especially when individuals are exposed to high levels over an extended period. Some potential health risks associated with formaldehyde exposure include:

- Respiratory Issues: Formaldehyde can irritate the respiratory system, leading to symptoms such as coughing, wheezing, and shortness of breath.

- Allergic Reactions: Some individuals may develop allergic reactions to formaldehyde, resulting in skin rashes, itching, and nasal congestion.

- Asthma Exacerbation: For people with asthma, exposure to formaldehyde can trigger asthma attacks and worsen symptoms.

- Eye and Nose Irritation: Formaldehyde gas can cause irritation and burning sensations in the eyes and nose.

It is important to note that the severity of these health risks can vary depending on factors such as the concentration of formaldehyde in the air, duration of exposure, and individual susceptibility.

While MDF off-gassing is a concern, it is worth mentioning that the levels of formaldehyde emitted decrease over time. The duration of off-gassing can vary widely, but typically, after two years, the release of formaldehyde drops significantly. This means that if you have had MDF furnishings for a couple of years, the off-gassing is likely to have reduced considerably.

To minimize the health risks associated with MDF off-gassing, it is recommended to ensure proper ventilation in indoor spaces. This helps to reduce the concentration of formaldehyde in the air and improve indoor air quality. Additionally, selecting MDF products that have low formaldehyde emissions or opting for alternative materials can also be considered.

Understanding the health concerns related to MDF off-gassing allows individuals to make informed decisions when it comes to their furniture and construction choices, prioritizing both their well-being and the quality of their indoor environment.

Duration Of Off-gassing

MDF off-gassing duration can vary widely, but typically it diminishes over time. While some furniture may stop off-gassing within two years, others could take up to five years, and in some cases may never fully finish off-gassing.

Factors Affecting Off-gassing Time

The off-gassing time of MDF (Medium Density Fiberboard) depends on several factors. The type of MDF, the adhesive used, the thickness of the board, the temperature, and the humidity all affect the duration of off-gassing.

Typical Off-gassing Period

MDF board releases formaldehyde gas, which is a known carcinogen. The duration of off-gassing is the time it takes for the gas to dissipate. The typical off-gassing period for MDF board is between six months to two years. However, the duration can vary depending on several factors, as mentioned earlier.

It is important to note that the off-gassing period is not an exact science and can vary from one product to another. Therefore, it is essential to keep the room well-ventilated during the off-gassing period to minimize exposure to formaldehyde gas.

How To Reduce Off-gassing Time

There are several ways to reduce the off-gassing time of MDF. One way is to choose MDF boards that have low formaldehyde emissions. Another way is to choose MDF boards that use alternative adhesives such as soy-based or formaldehyde-free adhesives.

Another way to reduce off-gassing time is to coat the MDF board with a low-emission paint or sealant. This helps to lock in the formaldehyde gas and prevent it from being released into the air.

In conclusion, the duration of off-gassing for MDF depends on several factors such as the type of MDF, the adhesive used, the thickness of the board, the temperature, and the humidity. The typical off-gassing period is between six months to two years. However, it is important to keep the room well-ventilated during the off-gassing period to minimize exposure to formaldehyde gas.

Identifying Off-gassing In Your Home

Off-gassing from materials like MDF can impact indoor air quality, leading to potential health concerns. It’s important to recognize the signs of off-gassing and take necessary steps to address it.

Signs Of Mdf Off-gassing

- Odor: Strong, chemical-like smell.

- Physical Symptoms: Headaches, dizziness, or irritation.

- Visible Changes: Warping or discoloration of materials.

How To Test For Formaldehyde

- Home Test Kits: Purchase kits to detect formaldehyde levels.

- Professional Testing: Hire experts for accurate assessment.

- Monitoring Devices: Use air quality monitors for continuous tracking.

Reducing Exposure To Mdf Off-gases

Medium Density Fiberboard (MDF) is a commonly used material in the construction of furniture and cabinetry, but it can emit off-gases, including formaldehyde, which may pose health risks. To minimize exposure to MDF off-gases, it’s important to implement effective strategies and choose low-emission MDF products.

Ventilation Strategies

Proper ventilation is crucial in reducing exposure to MDF off-gases. Here are some ventilation strategies to consider:

- Use exhaust fans to improve air circulation in areas where MDF products are present.

- Open windows and doors to allow fresh air to flow into the space.

- Consider using air purifiers with activated carbon filters to help remove off-gases from the air.

Choosing Low-emission Mdf Products

When selecting MDF products, opt for those with lower emissions to minimize off-gassing. Consider the following factors:

- Look for MDF products labeled as “low formaldehyde emission” or “CARB Phase 2 compliant” to ensure they meet stringent emission standards.

- Consider using MDF products with no-added formaldehyde (NAF) or ultra-low emitting formaldehyde (ULEF) resins, which can significantly reduce off-gassing.

- Consult with manufacturers or suppliers to inquire about the emission levels of their MDF products and choose those with the lowest emissions.

Solutions For Mitigating Off-gassing

Mitigating off-gassing from MDF involves time as the chemicals released diminish gradually over the years. The off-gassing duration varies widely, typically ceasing after two years of the product being in use.

When dealing with MDF off-gassing, it’s essential to implement effective solutions to minimize its impact. By understanding the process of off-gassing and utilizing appropriate techniques, it’s possible to create a healthier indoor environment. Here are some practical strategies for mitigating off-gassing:

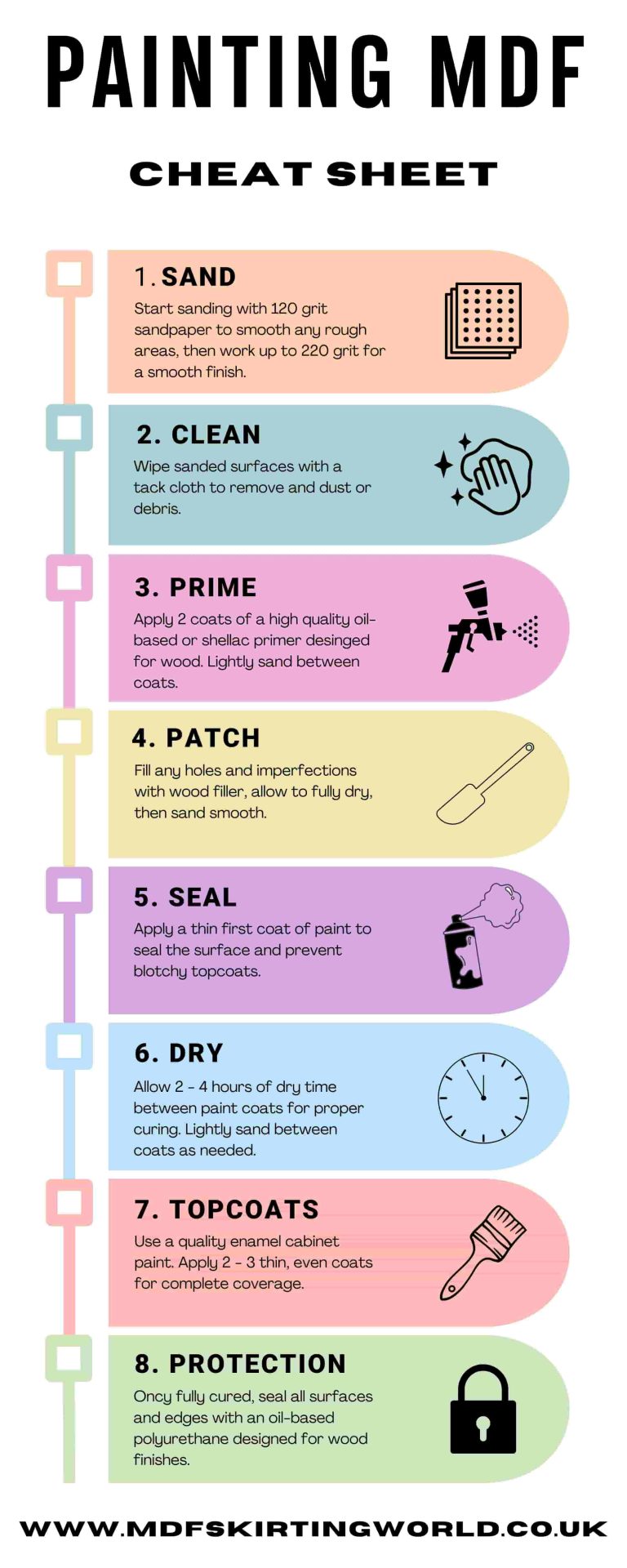

Sealing Mdf Surfaces

To minimize off-gassing from MDF, sealing the surfaces with a suitable sealant or primer can be highly effective. This creates a barrier that reduces the release of volatile organic compounds (VOCs) and formaldehyde into the surrounding air. Opt for low-VOC or zero-VOC sealants to ensure minimal additional chemical emissions.

Air Purifying Solutions

Implementing air purifying solutions can significantly reduce the impact of MDF off-gassing. Utilize high-quality air purifiers equipped with activated carbon filters to effectively trap and neutralize VOCs and other harmful substances released during off-gassing. Additionally, increasing ventilation in the area can help disperse the off-gassed chemicals more rapidly.

By employing these strategies, you can effectively mitigate the off-gassing effects of MDF, creating a healthier and more comfortable indoor environment.

Safe Use Of Mdf In Home Projects

Medium Density Fiberboard (MDF) is a popular material for DIY enthusiasts, but concerns about off-gassing of formaldehyde can arise. Understanding the best practices and precautions when working with MDF is essential for ensuring a safe and healthy home environment.

Best Practices For Diy Enthusiasts

When working with MDF, it’s important to prioritize safety. Here are some best practices for DIY enthusiasts to consider:

- Work in a well-ventilated area to minimize exposure to any potential off-gassing.

- Use a respirator or mask to protect yourself from inhaling any airborne particles.

- Seal the edges and surfaces of MDF with a suitable primer or sealant to minimize off-gassing.

- Follow manufacturer’s guidelines for cutting, sanding, and finishing MDF to minimize the release of particles and fumes.

Precautions When Working With Mdf

While MDF can be a versatile and cost-effective material, it’s important to take precautions to minimize potential health risks associated with off-gassing. Here are some precautions to consider:

- Wear protective gloves and eyewear when handling MDF to avoid skin and eye irritation.

- Avoid prolonged exposure to MDF dust and fumes, and take regular breaks to allow for ventilation.

- Dispose of MDF waste in accordance with local regulations to minimize environmental impact.

Future Of Mdf And Environmental Concerns

MDF board, commonly used for furniture, does off-gas formaldehyde, which is a potential health concern. The length of off-gassing can vary widely, but typically lasts for up to two years, after which the chemicals released drop off.

Advancements In Mdf Manufacturing

In recent years, the manufacturing of Medium Density Fiberboard (MDF) has undergone significant advancements. Manufacturers are implementing innovative techniques to reduce the emission of harmful gases, particularly formaldehyde, during the production process. By utilizing advanced adhesive technologies and modifying the composition of raw materials, the industry is striving to create MDF with lower emissions, thereby addressing environmental concerns and enhancing the safety of the end product.

Eco-friendly Alternatives To Mdf

As environmental consciousness continues to grow, the demand for eco-friendly alternatives to traditional MDF is on the rise. Sustainable materials such as bamboo, reclaimed wood, and wheatboard are gaining popularity as substitutes for MDF. These alternatives not only offer comparable structural integrity and durability but also contribute to reducing the environmental impact associated with furniture and construction materials. Additionally, the use of non-toxic adhesives and binders in these eco-friendly alternatives further promotes a healthier indoor environment.

Frequently Asked Questions

How Long Does Particle Board Take Off Gas?

Particle board typically takes about 2 years to off-gas formaldehyde. The glue used in particle board, usually urea formaldehyde (UF), emits formaldehyde gas over time. While off-gassing duration can vary, it is likely that particle board has stopped off-gassing after 2 years.

How Long Does Formaldehyde Take Off Gas?

MDF (Medium Density Fiberboard) typically takes about two years to off-gas formaldehyde. The glue used in MDF, which is usually urea formaldehyde, emits formaldehyde gas over time. However, the off-gassing decreases gradually, and after about two years, it has usually stopped.

It’s important to note that MDF does not off-gas indefinitely.

Does Mdf Give Off Fumes?

Yes, MDF gives off fumes, specifically formaldehyde gas. The glue used in MDF is usually urea formaldehyde (UF), which emits formaldehyde gas. The off-gassing of MDF varies widely but typically lasts for about 2 years. While it drops off over time, exposure to formaldehyde gas is still a concern.

Does Mdf Give Off Vocs?

MDF emits VOCs, including formaldehyde gas, which can pose health risks due to off-gassing.

Conclusion

MDF can off-gas formaldehyde for a variable period, often up to a few years. Monitoring ventilation and allowing time for off-gassing can help reduce exposure risks. Understanding the off-gassing process is essential for creating a safer indoor environment.