How to Build a Plywood Workbench: Easy DIY Guide

To build a plywood workbench, start by cutting plywood sheets to your desired dimensions. Assemble the pieces using wood glue and screws for stability.

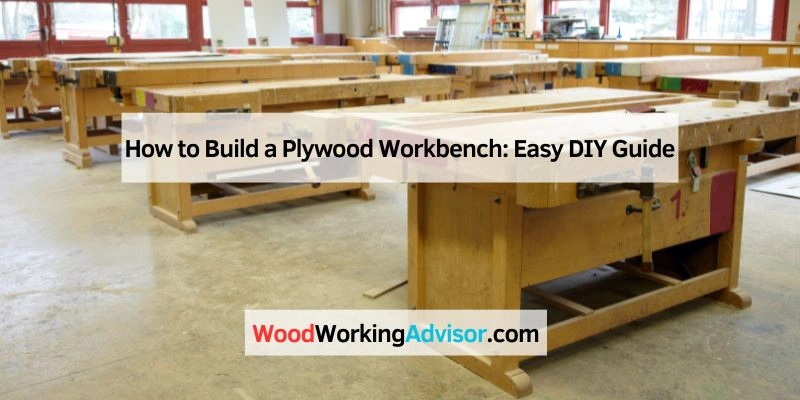

A sturdy workbench is essential for any DIY enthusiast or woodworker. It provides a solid surface for projects, tools, and materials. Building a plywood workbench is a straightforward task that offers customization to fit your specific needs. With just a few materials and tools, you can create a workspace that enhances your productivity.

Plywood is a durable option, making it ideal for heavy-duty tasks. This guide walks you through the steps needed to create a reliable and functional workbench. Enjoy the satisfaction of crafting your own workspace while saving money on pre-made options. Let’s get started!

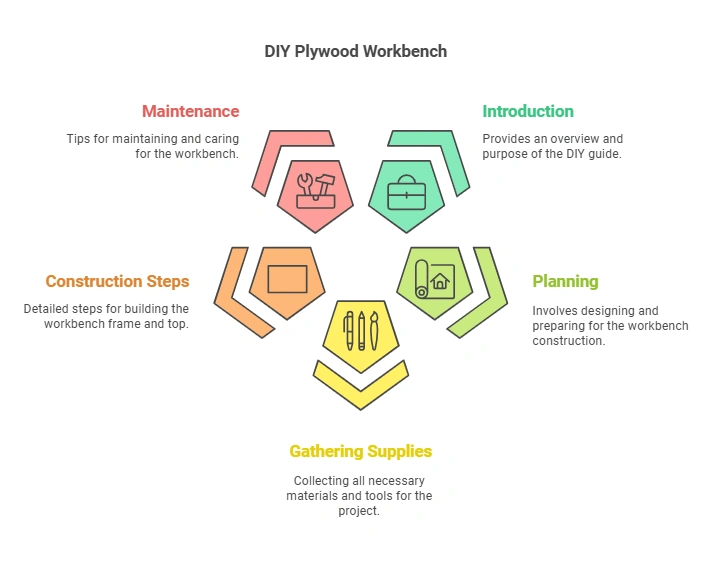

Introduction To DIY Plywood Workbenches

Building your own plywood workbench offers many benefits. It saves money and allows customization to fit your needs. A DIY workbench can be made to any size, perfect for your space.

Also, crafting a workbench can be a fun project. It enhances your woodworking skills and provides a sense of accomplishment. You control the materials, ensuring quality and durability.

| Tools | Materials |

|---|---|

| Measuring Tape | Plywood Sheets |

| Power Drill | Wood Screws |

| Saw | Wood Glue |

| Screwdriver | Sandpaper |

Planning Your Workbench Design

Start by deciding the size of your workbench. Measure the space available in your workshop. A good size is around 4 feet long and 2 feet wide. Adjust the height to match your comfort. Most workbenches are between 28 and 36 inches tall.

Next, choose the right plywood. Look for plywood that is strong and durable. A thickness of at least 3/4 inch is ideal. This thickness provides stability and support for heavy projects. Check for voids or blemishes in the plywood. Quality plywood will have a smooth surface for easy work.

Consider using birch or maple plywood. These types are sturdy and look great. They are perfect for a long-lasting workbench. Always buy extra plywood for future repairs or projects.

Gathering Your Building Supplies

Gathering your building supplies is important for a successful workbench. Start with the right plywood and lumber cuts. Here is a list to help you:

| Material | Dimensions |

|---|---|

| Plywood | 3/4″ thick, 4′ x 8′ |

| 2×4 Lumber | 8′ lengths |

| 2×6 Lumber | 8′ lengths |

Don’t forget the hardware and additional tools. These are essential for building:

- Screws

- Nails

- Wood glue

- Measuring tape

- Power drill

- Saw

Cutting And Assembling The Workbench Frame

Start by measuring the height of your workbench. Typically, a height of 34 to 36 inches works well. Use a square to mark the cut lines on your plywood.

Cut the legs to your desired length. Make sure each leg is the same length. This ensures a stable workbench. Use a saw for clean cuts.

After cutting, sand the edges to remove any splinters. This helps to keep your hands safe. Assemble the legs by using screws or wood glue for a strong hold.

Check for squareness by measuring the diagonals. Adjust as needed to ensure everything is level. Your workbench frame is now ready for the next steps!

Installing The Workbench Top

Start by measuring the plywood. Cut it to the desired size using a circular saw. Make sure to wear safety goggles for protection.

After cutting, smooth the edges with sandpaper. This helps prevent splinters and makes the surface safe.

To secure the top to the frame, place it carefully on the workbench frame. Use wood screws to attach the plywood. Make sure the screws are evenly spaced.

Check that the top is level. Adjust if needed by adding shims under the frame. This ensures a stable working surface.

Adding Strength With Support Beams

To build a strong workbench, support beams are essential. They add strength and stability. Start by positioning the lower shelf support correctly. This will help hold the weight of tools and materials.

Ensure the lower shelf is level. Use a level tool to check. Secure the support beams with screws. This prevents wobbling and keeps everything in place.

Cross beams are also important. They connect support beams diagonally. This design helps distribute weight evenly. Use sturdy wood for these beams. Proper installation makes your workbench durable and reliable.

Finishing Touches For Durability And Functionality

Sanding the surfaces of your plywood workbench is very important. Use fine-grit sandpaper for a smooth finish. This helps prevent splinters and improves appearance. Wipe away dust after sanding for best results.

Applying a protective finish keeps the wood safe from moisture and wear. Choose a finish that suits your needs, like polyurethane or varnish. Follow the manufacturer’s instructions for application.

Installing vises can improve your workbench’s functionality. Choose vises that fit your projects. Secure them firmly to the bench for stability.

Tool holders help keep your workspace organized. Consider magnetic strips or pegboards. They allow easy access to tools while keeping them off the bench.

Maintenance And Care Tips

Regular cleaning keeps your plywood workbench in great shape. Wipe it down with a damp cloth. Use mild soap for tough stains. Inspect the surface for scratches or dents regularly. This helps find problems early.

Dealing with wear and tear is important. Sand down rough spots to keep it smooth. Apply a fresh coat of finish every year. This protects the wood and extends its life. Tighten any loose screws or bolts to keep it sturdy.

Storing tools properly prevents extra damage. Use tool organizers to keep everything in place. Avoid heavy items that can warp the surface. Proper care ensures your workbench lasts a long time.

Conclusion: Enhancing Your Diy Skills

Building a plywood workbench involves several key steps. Start by gathering all materials. Use quality plywood for durability. Cut pieces to the right size for your design.

Next, assemble the frame and secure it tightly. Ensure that the bench is sturdy and stable. Sand the surfaces to avoid splinters. Finally, finish with paint or varnish for protection.

After completing the workbench, explore other DIY projects. Consider making shelves or a tool organizer. Each project helps improve your skills. Practice different techniques to gain confidence.

Share your creations online to inspire others. Connect with DIY communities for tips and ideas. Learning from others can enhance your DIY journey.

Frequently Asked Questions

How Much Plywood Do I Need For A Workbench?

The amount of plywood needed depends on your workbench size. A standard workbench often requires about 4 to 6 sheets of plywood. Measure your desired dimensions to calculate the exact amount. Consider thickness for durability; typically, 3/4-inch plywood is recommended for stability.

What Tools Are Required To Build A Plywood Workbench?

Essential tools include a circular saw, drill, and measuring tape. You’ll also need clamps, a square, and sandpaper for finishing touches. Safety equipment like goggles and gloves is crucial. Having the right tools ensures a smoother and more efficient building process.

Can I Customize My Plywood Workbench Design?

Absolutely! Customizing your plywood workbench design allows you to meet your specific needs. You can adjust the height, add drawers, or include a tool rack. Tailoring the design enhances functionality and makes the workbench more suitable for your projects.

Is Plywood Durable Enough For A Workbench?

Yes, plywood is quite durable and suitable for workbenches. High-quality plywood can withstand heavy loads and resist warping. Properly finished and maintained, a plywood workbench can last for years. Ensure you choose the right thickness for maximum strength and durability.

Conclusion

Building a plywood workbench is a rewarding project. It enhances your workspace and boosts productivity. With the right tools and materials, anyone can create a sturdy bench. Follow the steps outlined, and enjoy the satisfaction of completing this DIY task.

Start your woodworking journey today with your new workbench!