How to Draw Curves on Wood: Master Craft Techniques

To draw curves on wood, use a flexible ruler or a French curve for precision. Mark your desired shape with a pencil before cutting.

Creating curves in woodworking can transform a simple project into a stunning masterpiece. Curved designs add elegance and uniqueness to furniture or decor items. Whether you’re shaping a tabletop edge or crafting intricate designs, mastering curve drawing is essential. It allows for creativity while enhancing the overall aesthetic.

Proper tools and techniques can make this task easier and more enjoyable. Understanding how to draw curves accurately helps ensure a smooth cutting process, reducing errors. This guide will walk you through the best methods and tips for achieving beautiful curves on wood, making your projects stand out.

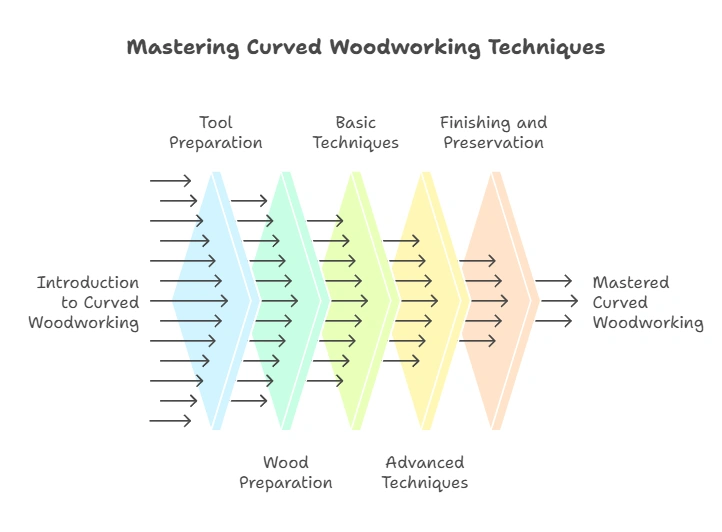

Introduction To Curved Woodworking

Curved woodworking is a unique skill. Shaping wood adds beauty and style. It transforms simple pieces into stunning designs. Curved lines catch the eye and create flow.

Benefits of curved designs include:

- Enhanced aesthetic appeal: Curves create a soft, inviting look.

- Improved ergonomics: Curved shapes often fit better in the hand.

- Increased creativity: Curves allow for endless design possibilities.

- Strength: Curved structures can be more durable than flat ones.

Mastering this art takes practice. Tools like chisels and sanders help shape wood effectively. Experiment with different woods for varied results. Enjoy the process of creating beautiful curved pieces!

Essential Tools For Curving Wood

To draw curves on wood, having the right tools is crucial. Essential tools include a jigsaw, band saw, and router. Each tool serves a unique purpose in shaping wood effectively.

Selecting the right equipment depends on the curves you want to create. For gentle curves, a jigsaw works well. For tighter curves, a band saw is better. A router helps in adding smooth edges.

Maintenance and care for tools is vital for their performance. Always clean tools after use. Store them in a dry place to prevent rust. Regularly check for any damage, and replace parts as needed.

Preparing The Wood For Curving

Choosing the right wood type is vital for successful curves. Hardwoods like maple, oak, and walnut are great options. They hold shapes well and resist damage. Softwoods, such as pine or cedar, are easier to bend but may not last.

Pre-treatment of wood enhances its flexibility. Soaking the wood in water can help. This process makes the wood malleable. Keep the wood submerged for several hours. After soaking, let it dry slightly before bending.

Conditioning the wood is also important. Use a wood conditioner or finish to protect the surface. This step helps to maintain the wood’s integrity while curving.

Basic Techniques For Drawing Curves

Drawing curves on wood can be fun and creative. Two main methods exist: freehand drawing and template use. Freehand drawing allows for more freedom. It helps develop your own style. However, it requires a steady hand.

Using templates can give precise curves. Templates ensure that every curve matches perfectly. You can use paper templates or wooden jigs. Both methods have their benefits.

Transferring patterns onto wood is essential. First, secure the pattern on the wood. Use carbon paper to trace designs. Cut carefully along the traced lines for the best results.

Steam Bending For Smooth Curves

To create smooth curves in wood, steam bending is an excellent method. A steam box helps generate heat and moisture. This setup allows wood to become flexible.

Materials needed include a steam source, a box, and clamps. Build a box from plywood or sturdy materials. Ensure the box is sealed tightly to keep steam inside.

Place the wood in the box. Make sure it does not touch the sides. Connect the steam source, letting steam fill the box. Steam the wood for about one hour per inch of thickness.

Once steamed, carefully remove the wood. Use clamps to hold it in the desired shape. Allow the wood to cool and dry completely before use.

Kerf Cutting For Complex Curves

Understanding kerfing patterns is key for creating complex curves. Kerf cuts allow wood to bend smoothly. They create spaces that help the wood flex. Choose the right saw blade for your project. A finer blade gives cleaner cuts.

Use these practical tips for kerf cutting:

- Mark your cutting lines clearly on the wood.

- Space the kerf cuts about 1/4 inch apart.

- Cut only as deep as needed; avoid cutting through.

- Use a clamp to hold the wood steady while cutting.

- Practice on scrap wood first to improve your skills.

Laminating Techniques For Strength And Aesthetics

Layering wood helps create strong and beautiful curves. Start with thin layers of wood. Use a strong adhesive to bond each layer. This technique allows flexibility and strength.

Gluing the wood layers requires careful attention. Apply glue evenly on each layer. Use clamps to hold everything in place. Ensure the pressure is consistent across all layers. This helps avoid gaps and ensures a smooth finish.

Choose the right type of wood for best results. Some woods bend better than others. Softwoods like pine are good for curves. Hardwoods may crack if not handled carefully.

Finishing Curved Wood Pieces

To achieve a smooth finish on curved wood, use the right sanding techniques. Start with coarse sandpaper to remove rough edges. Gradually move to finer sandpaper for a polished look. Always sand in the direction of the wood grain.

Using a sanding block helps maintain even pressure on curved surfaces. For intricate designs, try using flexible sandpaper. This adapts to the curves easily.

After sanding, apply a finish to enhance the wood grain. Choose a stain or varnish that suits your style. A clear finish protects the wood while showcasing its beauty.

Apply the finish with a soft brush or cloth. Allow it to dry completely before adding another coat. This ensures a smooth, professional appearance.

Advanced Crafting: Complex Curves And Shapes

Creating multi-axis curves on wood can be tricky. Special tools help shape these curves accurately. Use a band saw or jigsaw for best results. Remember to measure carefully before cutting.

Common challenges include wood splintering and uneven curves. To prevent splintering, always use a sharp blade. Sand the edges after cutting to smooth them out.

Another issue may be maintaining symmetry. Use templates to guide your cuts. This ensures both sides match perfectly.

Practice makes perfect! Start with simple shapes before advancing to complex curves. Enjoy the crafting process and experiment with different designs.

Project Ideas To Practice Curving Skills

Beginner projects can help build curving skills. Start with a simple wooden spoon. It allows for smooth curves and easy handling. Another great project is a curved shelf. This adds style to any room.

For those ready for a challenge, try making a curved chair. This project requires more planning and precision. Consider creating a decorative frame with curves. It can enhance any picture or artwork.

Remember to practice with different tools. Using a jigsaw can help create clean curves. Sandpaper also smooths out rough edges. Enjoy the process and let your creativity shine!

Troubleshooting Common Issues In Curved Woodworking

Wood splitting and breakage can occur during curved woodworking. To fix this, use wood glue to bond the pieces. Clamp the area for a strong hold. Allow sufficient drying time before further work.

For uneven curves, a sanding block can help smooth out rough edges. Use fine grit sandpaper for better results. If a mistake happens, consider re-cutting the curve carefully. Take your time to ensure accuracy.

| Issue | Solution |

|---|---|

| Wood Splitting | Use wood glue and clamps |

| Uneven Curves | Smooth with a sanding block |

| Mistakes in Curves | Re-cut carefully |

Preserving Your Curved Wood Creations

To keep your curved wood creations in great shape, focus on long-term maintenance. Protect them from humidity and extreme temperatures. Use a dehumidifier in damp areas. Avoid placing wood near heaters or air conditioners. Regularly check for signs of damage like cracks or warping.

Keep wood clean by using a soft, dry cloth. Dust can scratch the surface. Apply a wood conditioner every six months. This helps maintain the natural shine. Consider using a protective finish to guard against scratches.

Store your wood pieces in a stable environment. Avoid direct sunlight to prevent fading. Ensure proper airflow around your creations. Following these tips will help your curved wood items last for many years.

Frequently Asked Questions

How Do You Start Drawing Curves On Wood?

Begin by selecting a suitable wood type. Softwoods like pine are easier to work with. Use a pencil to sketch your desired curve lightly. This will serve as a guide. Make sure to adjust the curve until it meets your satisfaction before proceeding with cutting.

What Tools Are Needed To Draw Curves On Wood?

Essential tools include a compass, straight edge, and a flexible curve ruler. A jigsaw or bandsaw is needed for cutting. Additionally, sandpaper helps smooth the edges after cutting. These tools will ensure accurate and clean curves when working on wood projects.

Can I Use A Template For Curved Designs?

Yes, using a template is highly effective. Create a template from sturdy material like cardboard or plywood. Trace the template onto the wood before cutting. This ensures consistency and accuracy in your curved designs. It also saves time and reduces the chance of errors.

What Techniques Help Achieve Smooth Curves On Wood?

To achieve smooth curves, use a jigsaw for cutting. Follow the drawn line carefully, making gentle, continuous cuts. After cutting, sand the edges to refine the curve. For tighter curves, consider using a scroll saw. This will create a more polished finish on your curves.

Conclusion

Mastering the art of drawing curves on wood enhances your woodworking projects. With the right tools and techniques, you can create stunning designs. Practice is key to refining your skills. Embrace creativity and experiment with various styles. Soon, you’ll produce beautiful, curved patterns that elevate your craftsmanship.

Happy woodworking!