How to Make Wood Ash Glaze: A Step-by-Step Guide

Have you ever looked at a beautifully glazed piece of pottery and wondered how to achieve that unique finish? If you’re searching for a natural and rustic way to glaze your ceramics, wood ash glaze might just be the answer.

You can transform simple ash into a stunning, glass-like coating that enhances your pottery’s charm. Imagine impressing your friends with creations that tell a story of tradition and craftsmanship. By learning how to make wood ash glaze, you not only gain a new skill but also connect with an age-old technique that adds a personal touch to your work.

Intrigued? Dive into the world of wood ash glaze and discover how you can elevate your pottery with this timeless method.

Materials Needed

Wood ash is key for making glaze. It must be clean and dry. Store it in a safe place. Avoid mixing with dirt or dust. Use a fine mesh sieve to remove large bits. Ash from hardwoods works best.

Clay is another vital part. It gives glaze strength. Use clay that is fit for pottery. It should be smooth and wet. This helps in mixing.

Use clean water for the mix. Do not use dirty or salty water. It should be at room temperature. Too hot or too cold can ruin the mix.

Mixing tools are needed for blending. A bowl and a spoon are enough. Make sure they are clean. This keeps the glaze smooth and even.

Collecting Wood Ash

Different woods make different ash. Hardwoods like oak and maple are best. They produce more ash.

This gives a better glaze. Softwoods like pine burn fast. They make less ash. The glaze might not be

as smooth. Always use clean wood. Never use wood with paint or chemicals. This can make the glaze unsafe.

Choosing the right wood is very important.

Safety is very important. Always wear gloves when handling ash. It can be sharp and dusty.

Protect your eyes with goggles. Ash can fly around. A mask is good for protecting your lungs.

Never touch ash when it’s hot. Always let it cool first. Keep water nearby in case of fire. Stay safe always.

Preparing The Ash

Wood ash can have big chunks and small bits. Sifting helps get the fine powder. Use a sieve or a mesh screen. Shake it gently to let the small pieces through. Throw away the big pieces. They can cause problems later. Keep only the smooth ash. It will make the glaze better and even.

Washing the ash is very important. It removes impurities and soluble salts. These can cause problems in the glaze. Mix ash with water. Stir it well. Let it sit. The heavy particles will go down. Pour off the water carefully. Repeat if needed. Keep the clean ash for glazing. It ensures the glaze is smooth and pure.

Creating The Glaze Mixture

Start by gathering your wood ash and water. Use a measuring cup to get the right amount. You need one cup of wood ash. Add two cups of water. Pour the water slowly to avoid spills. Mix in a bowl or bucket. The ratio is important for the glaze to work well. Always measure carefully. This keeps the mixture balanced.

Stir the mixture with a stick or spoon. Mix until smooth and even. No lumps should be there. If lumps form, stir more. Keep mixing for about five minutes. This helps the glaze stick to pottery. A smooth glaze gives a shiny finish. Always mix in a well-ventilated area. Safety is important when mixing. Wear a mask if needed.

Testing The Glaze

Apply the wood ash glaze evenly on test tiles. Use a brush for even coating.

Wait for it to dry before firing. Some glazes may bubble if too thick.

Thin layers often work best. Experiment with different thicknesses.

Place the tiles in a kiln. Set the temperature gradually. High heat can cause cracks.

Keep an eye on the process. Different kilns heat at different rates.

Cooling down slowly is important. Rapid cooling can damage the glaze.

Always wear safety gear when handling hot tiles.

Adjusting The Glaze

To change the texture of wood ash glaze, you can add different materials. Clay makes it thicker. Sand gives it a gritty feel. Try using feldspar for a smoother finish. Small changes make a big difference. Mix well for even results.

Colors change by adding oxides. Iron oxide gives a brown color. Cobalt oxide turns it blue. For green, use copper oxide. Mix small amounts first. Watch for changes. Each oxide brings a new color. Try different blends for unique results.

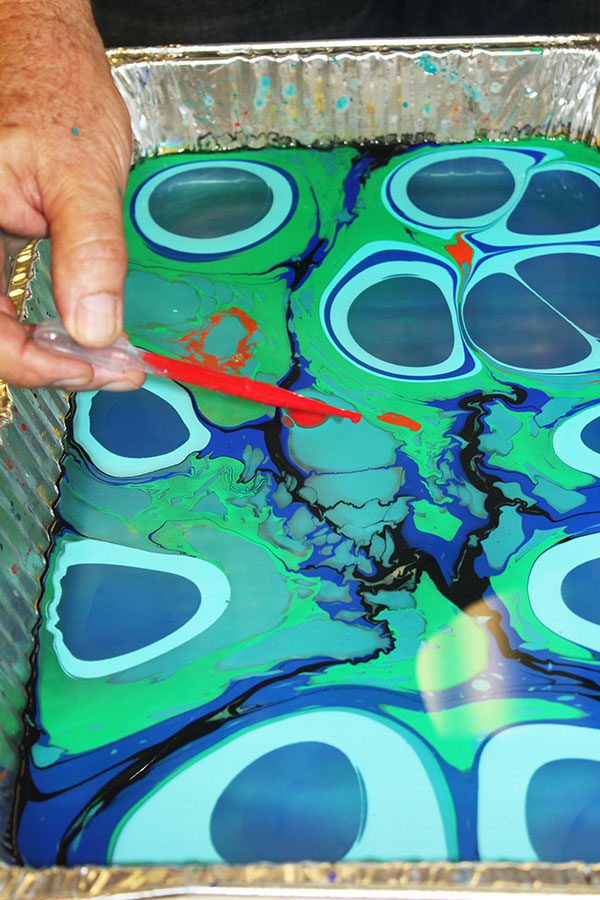

Applying The Glaze

Use a clean brush. Pick a size that fits your project. Brushes help spread glaze evenly. Some people use sponges. Sponges give a different texture. Try both to see what you like. Safety goggles are important. Glaze can splash. Keep eyes safe. Wear gloves too. Protect your skin. Kiln is needed for drying. It sets the glaze. Follow safety rules. Kilns get very hot. Never touch when in use.

Start with a thin layer. Thin layers dry quickly. Add more layers for depth. Wait for each layer to dry. Too many layers can crack. Experiment with different layers. Find what looks best. Some use three layers. Others use five. Smooth out each layer. Avoid bumps and lumps. Layers should blend. Practice makes perfect. Try different techniques. Each piece is unique.

Credit: ceramicartsnetwork.org

Firing The Glazed Piece

Set the kiln temperature right. Different clay needs different heat. Check the clay’s heat limit. Use a pyrometer for accurate readings. The kiln should heat slowly. This helps the glaze to melt evenly. Fast heating can crack the pottery. Keep the kiln closed during firing. This stops heat loss. Let the piece cool down inside. Sudden cooling is bad for the glaze. It can cause cracks or defects. Follow the kiln manual for safe firing.

Set the kiln temperature to the right level. Use the manual for guidance. Regular checks help maintain temperature. Adjust settings for different clays. Some clays need more heat. Others need less. Keep an eye on the pyrometer. Make sure the kiln is working right. If the kiln is too hot, reduce the temperature. If it’s too cold, increase it slightly. Safety first, always.

Let the kiln cool slowly. Quick cooling can harm the glaze. Leave the kiln closed during cooling. This keeps the temperature stable. Open the kiln when it’s cool enough. Use gloves to handle hot pottery. Check for any cracks or defects. Slow cooling gives a smooth finish. Fast cooling can ruin the piece. Follow cooling instructions in the manual. Patience is key for good results.

Troubleshooting Common Issues

Cracks can appear in your glaze. This happens due to uneven drying. Ensure the clay and glaze are compatible. Different materials expand differently. This leads to cracks. Apply the glaze evenly. Thin layers help reduce cracking. Let each layer dry well. Avoid fast drying. Cover pieces if needed. Maintain a stable environment.

A smooth finish makes your piece shine. Sanding helps achieve this. After glazing, check for bumps. Gently sand them away. Use fine-grit sandpaper. Rinse well after sanding. This removes dust. Ensure the glaze is even. Uneven glaze looks rough. Practice makes perfect. Each piece teaches something new. Keep experimenting.

Credit: www.youtube.com

Frequently Asked Questions

How Do You Make Wood Ash Glaze?

To make wood ash glaze, mix wood ash with clay and water. Adjust ratios based on desired thickness. Test for melting properties by firing samples. Wood ash provides a unique finish, enhancing pottery aesthetics. Experiment with different types of wood ash for varied results.

What Are The Ingredients In Ash Glaze?

Ash glaze typically contains wood ash, clay, silica, and fluxes like feldspar. Wood ash contributes unique textures and colors. Clay provides structure, while silica aids in melting. Feldspar helps lower melting temperature. The combination creates a rustic, natural finish.

How Do You Make Wood Ash Solution?

Mix one part wood ash with five parts water. Stir well and let it sit overnight. Strain the mixture through a fine cloth to remove solids. Your wood ash solution is ready for use.

How To Wash Wood Ash For Glaze?

To wash wood ash for glaze, first sift the ash to remove debris. Mix it with water and stir. Let it settle for a few hours, then pour off the water. Repeat until the water is clear. Dry the ash completely before using it in your glaze recipe.

Conclusion

Creating wood ash glaze is an exciting process. It adds unique texture and depth to pottery. Gather ash from untreated wood. Clean it thoroughly to remove debris. Mix ash with water, then sieve. Combine with clay and other materials. Test and adjust ratios for desired effect.

Experimenting helps find your perfect glaze. Use safely and responsibly. Each piece reflects your creativity. Enjoy the journey of crafting something beautiful. Embrace the imperfections that make it special. With practice, you’ll improve. Keep exploring and learning. Your pottery will shine with the natural beauty of wood ash glaze.