How to Prevent Snipe on a Planer: Expert Tips and Tricks

Snipe on a planer can ruin your woodworking projects. It leaves unwanted dips on your wood.

So, how do you prevent this? Preventing snipe on a planer involves simple techniques. These can save your wood and your patience. Snipe usually happens when the wood enters or exits the planer. The pressure changes, causing the blades to cut deeper at the ends.

This guide will explain easy methods to reduce or eliminate snipe. With these tips, your planed wood will have a smooth, even surface. Let’s dive into the techniques to keep your projects perfect.

Introduction To Planer Snipe

Planer snipe is a common woodworking problem. It happens at the start or end of a board. The planer cuts deeper, leaving a gouge. This gouge is called a snipe. It can ruin the surface of your wood. Snipe can be frustrating for woodworkers.

Several factors cause snipe. One main cause is uneven pressure. When the board enters or exits the planer, the pressure is not even. Another cause is improper support. Boards not supported well can move up or down. This movement causes snipe. Also, loose infeed and outfeed tables can lead to snipe. Proper adjustments can help.

Proper Machine Setup

Ensure the planer is on a flat surface. Use a level to check the base. Adjust the feet if needed. The planer must not wobble. A stable planer reduces snipe.

Check that the infeed and outfeed tables are aligned. They should be level with the planer bed. Use a straight edge to confirm this. If not, adjust them. Proper alignment helps prevent snipe.

Material Preparation

Prevent snipe on a planer by supporting the wood at the start and end of each pass. Use consistent feed pressure.

Choosing The Right Wood

Always use good quality wood. Soft woods like pine are easier to work with. Hard woods like oak need more care. Check the wood for any knots or cracks. These can cause problems. Cut the wood to the right size. Make sure the edges are smooth. Rough edges can cause snipes.

Inspecting For Warps And Twists

Look at the wood from all angles. Warped wood can cause snipe. Twist the wood slightly. It should not bend easily. Use a straight edge to check for bends. Lay the wood flat on a table. It should not rock back and forth. Replace twisted wood with straight pieces.

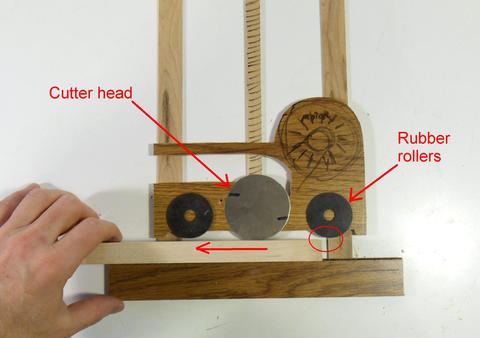

Credit: www.youtube.com

Feeding Techniques

Prevent snipe on a planer by supporting the wood at both ends. Keep the board flat and use a sacrificial piece. Adjust the infeed and outfeed tables to the same height as the planer bed.

Consistent Feed Rate

Maintain a steady speed when feeding wood into the planer. Avoid sudden stops or starts. This helps in achieving a smooth cut. Also, keep your hands firm on the board.

Using Support Boards

Place support boards at the start and end of the wood. This keeps the main board level. It prevents snipe by stopping the wood from tilting. Ensure the support boards are the same thickness.

Maintenance Practices

Sharp blades are key for smooth cuts. Dull blades can cause sniping. Sharpen or replace blades often. Check them before each use. Clean the blades regularly to remove any debris. This helps in maintaining the blade sharpness.

Dust and wood chips can affect the planer’s performance. Always clean the planer after use. Remove any stuck wood chips from the machine. Wipe down the surfaces to prevent buildup. Lubricate moving parts to keep them working smoothly. Regular cleaning ensures better results.

Credit: www.keatonbeyerwoodworking.com

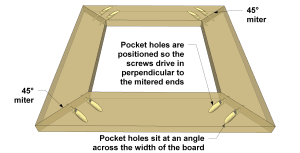

Using Jigs And Fixtures

Homemade snipe jigs can help prevent snipe. These jigs hold the wood firmly. This stops the wood from moving. Movement causes snipe. Make jigs from scrap wood. They are cheap and easy to make. Use clamps to secure them. Always test the jig with scrap wood first. Adjust the jig if needed. This ensures the best results.

Commercial fixtures can also stop snipe. They are designed for planers. These fixtures hold the wood tight. This keeps the wood stable. Stability is key to preventing snipe. Some fixtures are adjustable. Adjust them for different wood sizes. Always follow the instructions. Proper use gives the best results. Investing in a good fixture saves time and wood.

Alternative Methods

Trim the edges before using the planer. This can help in reducing snipe. Snipe often occurs at the beginning or end of the wood. By trimming, you can avoid this problem. Make small cuts and take your time. It’s better to be careful than to rush. This method is easy and effective.

A drum sander can help smooth the wood. It removes small amounts of wood evenly. This reduces the chance of snipe. Use the drum sander before planing. This will save you time and effort. Remember to sand the wood lightly. Heavy sanding can damage the wood. Be gentle and take your time.

Credit: www.youtube.com

Troubleshooting Tips

Watch the wood carefully. Check for dips or gouges at the ends. These are called snipe. Measure the length of the affected area. This helps in understanding the severity. Note if the snipe is at the start, end, or both.

Use support stands to keep the wood level. Adjust the planer’s infeed and outfeed tables. Ensure they are aligned. Test with scrap wood first. Make small adjustments. Check your blades. They should be sharp and level. Slow down the feed rate. This can help reduce snipe.

Frequently Asked Questions

What Causes Snipe On A Planer?

Snipe occurs when the wood is unsupported as it enters or exits the planer. This causes uneven pressure.

How Can I Reduce Snipe On My Planer?

To reduce snipe, support the wood at both ends. Use extension tables or rollers for added stability.

Is Snipe Preventable On All Planers?

While snipe is common, it can be minimized. Proper technique and adjustments significantly reduce snipe on most planers.

Does Planer Maintenance Affect Snipe?

Yes, regular maintenance like blade sharpening and alignment helps reduce snipe. Keep your planer in top condition.

Conclusion

Preventing snipe on a planer can save time and materials. Use these tips to get smoother, more accurate cuts. Ensure you support the wood properly and adjust the infeed and outfeed tables. Regular maintenance on your planer also helps. Follow these steps, and you’ll achieve better results with your woodworking projects.

Happy planing!