How to Seal Plywood Joints: Durable & Leak-Proof Tips

To seal plywood joints, apply wood glue to the edges, then clamp them together until dry. For extra protection, coat the joints with a water-resistant sealant.

Sealing plywood joints is essential for enhancing durability and moisture resistance. Properly sealed joints prevent water from seeping in, which can lead to swelling and damage over time. This process is crucial for projects like furniture making or outdoor structures.

Using the right materials ensures long-lasting performance and a polished appearance. Various sealing options exist, from wood glue to specialized sealants. Understanding the best methods for your specific project will yield optimal results. Whether you’re a DIY enthusiast or a professional, mastering the art of sealing plywood joints will elevate your craftsmanship and extend the life of your creations.

Introduction To Sealing Plywood Joints

Sealing plywood joints is very important for many reasons. Proper sealing helps prevent water damage. It also stops air leaks and keeps moisture out. This leads to a longer lifespan for your projects.

Durable and leak-proof joints offer several benefits:

- Enhanced durability: Sealed joints resist wear and tear better.

- Improved appearance: Smooth, sealed edges look neat and professional.

- Cost-effective: Preventing damage saves money on repairs.

- Easy maintenance: Sealed surfaces are easier to clean.

Investing time in sealing plywood joints pays off in the long run.

Types Of Plywood Joints

Several common joint configurations exist for plywood. These include butt joints, dado joints, and lap joints. Each type serves a specific purpose in construction.

Butt joints are simple and easy to make. They connect two pieces end-to-end. Dado joints allow one piece to fit into another. This provides added strength. Lap joints overlap two pieces, creating a strong bond.

Selecting the right joint for your project depends on strength needs. For heavy loads, use dado or lap joints. For lighter projects, butt joints may suffice. Always consider the design and functionality of the joint.

Preparation For Sealing

Before sealing plywood joints, clean the joint area thoroughly. Remove any dirt, dust, or debris. This ensures a strong bond with the sealant.

Gather these materials for sealing:

| Material | Purpose |

|---|---|

| Sandpaper | To smooth the joint area |

| Clean cloth | To wipe away dust |

| Sealant | To fill the joints |

| Caulking gun | To apply sealant easily |

Ensure all materials are ready before starting the sealing process.

Choosing The Right Sealant

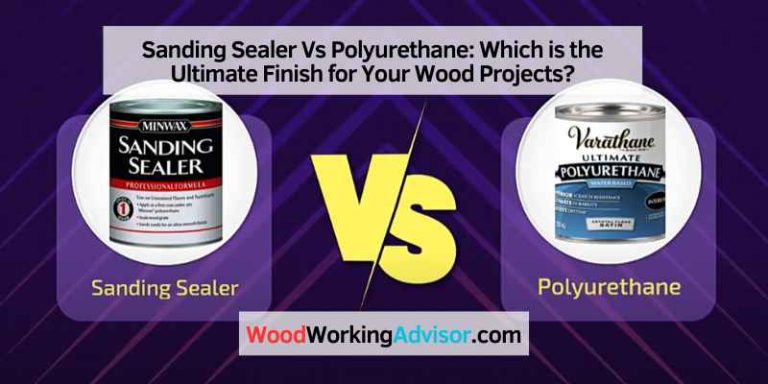

Choosing the right sealant is key for strong plywood joints. An effective sealant should be waterproof and flexible. It must resist mold and UV rays. Look for products with a long lifespan.

Different types of sealants exist, each with unique traits. Silicone sealants are great for water resistance. Polyurethane sealants offer flexibility and durability. Acrylic sealants are easy to paint over.

| Sealant Type | Advantages | Disadvantages |

|---|---|---|

| Silicone | Waterproof, flexible | Not paintable |

| Polyurethane | Durable, paintable | Long curing time |

| Acrylic | Easy to apply, paintable | Less durable |

Step-by-step Sealing Process

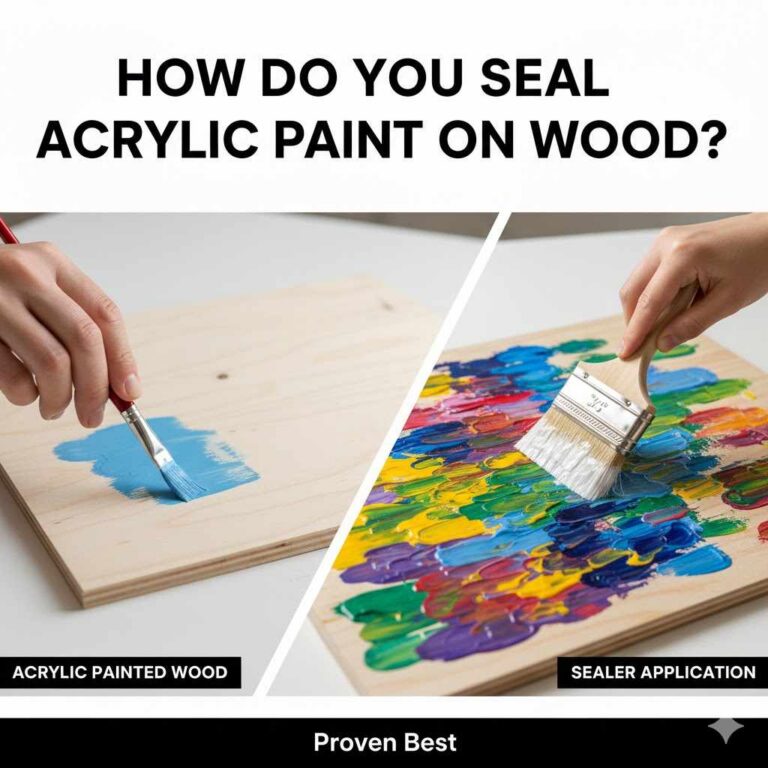

Start by choosing a good sealant for your plywood joints. Use a paintbrush or a roller to apply the sealant. Make sure to cover all areas well. Thick layers can lead to uneven results.

Check the joints for any gaps. Apply more sealant if needed. A smooth finish looks better and lasts longer. Wait for the sealant to dry completely before using the plywood.

Inspect the coverage after drying. If some spots are missing, add sealant again. This ensures that every joint is well protected.

Curing And Drying Time

Understanding cure times is essential for sealing plywood joints. Typically, most adhesives need 24 to 48 hours to cure fully. Temperature and humidity can change these times.

Several factors affect drying. Airflow plays a crucial role. Good airflow helps speed up drying. Thickness of the plywood also matters. Thicker plywood takes longer to dry.

Type of adhesive influences the drying time. Some adhesives cure faster than others. Always check the manufacturer’s instructions for specific details.

Lastly, consider the environment where the plywood is stored. A warm and dry area is best for faster curing.

Testing For Leak-proof Seals

Testing for leak-proof seals is essential for durability. Simple leak tests can easily spot issues. Use soap and water to find leaks. Apply the mixture to the joints. Bubbles will form if there is a problem.

Another method involves using a damp cloth. Wipe down the joints and check for moisture. If the cloth gets wet, you might have a leak.

Addressing potential weak spots is key. Inspect corners and edges carefully. Ensure all joints are sealed tightly. Regular checks will help maintain the integrity of the plywood.

Maintenance And Upkeep

Regular inspections help keep plywood joints in good shape. Schedule checks every few months. Look for signs of wear or damage. Pay attention to the seams and edges.

Worn seals can lead to bigger problems. Repair them quickly to avoid water damage. Use high-quality sealant for the best results. Follow the manufacturer’s instructions for application.

Check the sealant’s condition during each inspection. Replace any cracked or peeling areas. This simple task can extend the life of your plywood.

Advanced Tips For Professionals

Sealing plywood joints can improve durability and appearance. Use high-quality sealants to ensure long-lasting protection. Apply sealant evenly to avoid gaps. Let it dry completely for the best results.

Common sealing issues include bubbles and cracking. Bubbles often appear due to air pockets. To fix this, use a roller to press the sealant down. Cracking occurs from improper drying. Follow the recommended drying times to prevent this.

| Issue | Solution |

|---|---|

| Bubbles | Use a roller to press down. |

| Cracking | Follow proper drying times. |

| Uneven Application | Apply sealant evenly with a brush. |

Safety Considerations And Best Practices

Using the right Personal Protective Equipment (PPE) is essential. Always wear safety glasses to protect your eyes. A mask helps prevent inhaling harmful dust. Gloves keep your hands safe from sharp edges and chemicals.

Environmental precautions are vital when sealing plywood joints. Work in a well-ventilated area to reduce fumes. Avoid using harmful chemicals that can damage the environment. Use eco-friendly sealants whenever possible. Dispose of waste materials properly to minimize pollution.

Conclusion: Ensuring Longevity Of Sealed Joints

Sealing plywood joints is vital for durability and performance. Use the right sealant to prevent moisture damage. Choose a high-quality adhesive for strong bonds. Ensure all surfaces are clean and dry before applying the sealant.

Always allow sufficient time for the sealant to cure. This step enhances the strength of the joints. Regularly check the joints for any signs of wear or damage. Early detection can save time and effort.

DIY enthusiasts should experiment with different sealing methods. Practice makes perfect. Learning from each project builds confidence and skill. Embrace challenges and enjoy the process of creating!

Frequently Asked Questions

How Do I Seal Plywood Joints Effectively?

To seal plywood joints effectively, choose the right adhesive. Options include wood glue, epoxy, or polyurethane sealant. Ensure surfaces are clean and dry before application. Apply the sealant generously and allow it to cure fully. This prevents moisture from penetrating and enhances durability.

What Materials Are Best For Sealing Plywood Joints?

The best materials for sealing plywood joints include wood glue, silicone caulk, and epoxy resin. These materials provide strong adhesion and moisture resistance. Choose based on your project needs and environmental exposure. Properly applied, these sealants will extend the lifespan of your plywood structures.

Can I Use Paint To Seal Plywood Joints?

While paint can offer some protection, it isn’t the best sealant. Paint may not fully seal joints against moisture. Instead, use dedicated sealants like polyurethane or epoxy for better results. These provide superior waterproofing and durability compared to standard paint options.

How Long Does It Take For Sealants To Dry?

Drying times for sealants vary by product. Typically, wood glue dries in about 30 minutes, while epoxy may take up to 24 hours. Always check the manufacturer’s instructions for specific drying times. Proper curing is essential for achieving maximum strength and water resistance.

Conclusion

Sealing plywood joints is essential for durability and moisture resistance. By following the right techniques, you can achieve strong, long-lasting results. Remember to choose the right sealant and apply it properly. With these tips, your projects will stand the test of time, ensuring both functionality and aesthetic appeal.

Happy woodworking!