How to Seal Vinyl on Wood Securely

It can feel tricky to get vinyl to stick well on wood projects. Many beginners wonder How to Seal Vinyl on Wood: Secure Adhesion Method because the surfaces are so different. Wood has pores, and vinyl is smooth, which makes a strong bond a bit of a puzzle.

But don’t worry! We’ll walk through this together. This guide will give you simple steps to make sure your vinyl stays put, looking great for a long time.

Let’s get started with easy ways to achieve a lasting seal.

Mastering Vinyl Adhesion on Wood Surfaces

This section covers the fundamental steps and best practices for successfully adhering vinyl to wood. It explores the unique challenges posed by wood as a substrate and how to overcome them. Understanding the materials and preparation is key to achieving a durable and appealing finish for your projects. We will look at cleaning wood properly, selecting the right vinyl, and the best tools for the job. Getting this right means your vinyl decorations or coverings will last much longer.

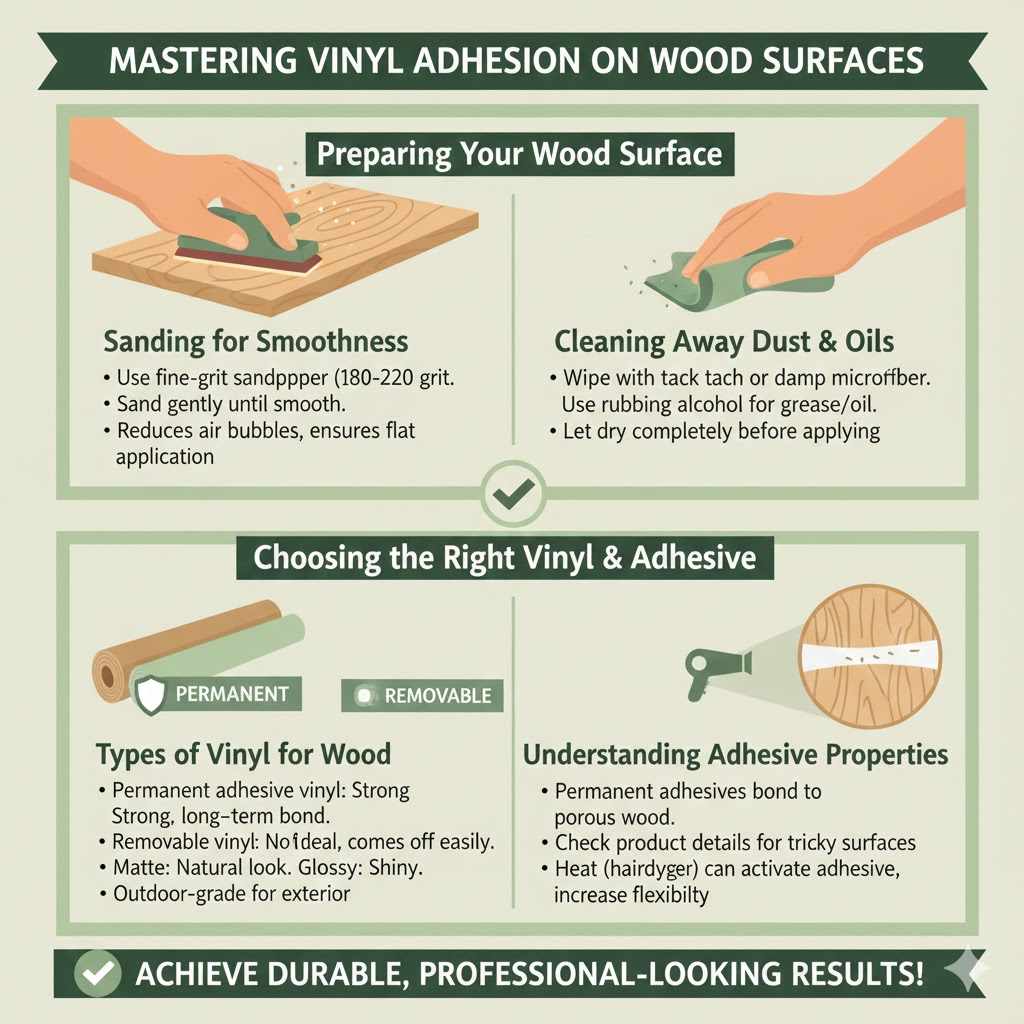

Preparing Your Wood Surface

Getting wood ready is a very important step. Wood can be rough or oily, which stops vinyl from sticking well. We need to make it smooth and clean. This means sanding and wiping it down.

Sanding for Smoothness

Sanding smooths out any bumps or rough spots on the wood. This gives the vinyl a better surface to grip.

- Use fine-grit sandpaper, like 180 or 220 grit. This is not too rough but gets the job done.

Sand the wood surface gently until it feels smooth to the touch. This helps the adhesive on the vinyl make full contact. A smooth surface reduces air bubbles and ensures the vinyl lies flat.

Cleaning Away Dust and Oils

After sanding, you must clean the wood. Dust left behind will get stuck under the vinyl. Oils from your hands or the wood itself can also prevent sticking.

- Wipe the surface with a tack cloth or a slightly damp microfiber cloth.

This will pick up fine dust particles. For wood that might have grease or oil, a little rubbing alcohol on a clean cloth can help. Let the wood dry completely before applying the vinyl.

Choosing the Right Vinyl and Adhesive

Not all vinyl is made the same. Some vinyl is better for wood than others. The kind of glue or adhesive on the vinyl matters a lot.

Types of Vinyl for Wood

There are different kinds of vinyl. For wood crafts, you usually want vinyl that has a strong permanent adhesive.

- Permanent adhesive vinyl is designed to stick long-term. It holds up well to wear and tear.

- Removable vinyl is not ideal for wood if you want it to last. It’s made to come off easily.

Consider the finish you want. Matte vinyl can look more natural on wood. Glossy vinyl offers a bright, shiny look. Think about where the wood piece will be. If it’s outdoors, you might need special outdoor-grade vinyl.

Understanding Adhesive Properties

The sticky back of vinyl is called adhesive. Its strength determines how well it sticks.

- Permanent adhesives are strong and meant for surfaces that won’t be moved often. They bond well to porous materials like wood.

- Some vinyl brands offer special adhesives for tricky surfaces. Always check the product details.

Heat can sometimes help activate the adhesive. A hairdryer on a low setting can be useful, but use it with care. It makes the vinyl more flexible and helps it mold to the wood.

Applying Vinyl Securely to Wood

This section focuses on the practical steps of applying vinyl to a prepared wood surface. It details techniques for avoiding common issues like bubbles and lifting edges. Proper application is crucial for a professional and lasting result. We’ll cover how to transfer the vinyl, smooth it down, and secure the edges. This ensures your project looks great and the vinyl stays put.

Transferring and Applying Vinyl

Once your wood is ready and you have your vinyl, it’s time to put it on. This needs to be done carefully to avoid mistakes.

Using Transfer Tape

Most craft vinyl comes on a backing sheet. You’ll often use transfer tape to move your cut design from the backing to the wood.

- Peel the backing from your cut vinyl design.

- Place the transfer tape over the top of your vinyl design.

- Rub the transfer tape firmly over the vinyl. This helps the vinyl stick to the tape.

Then, you carefully peel the vinyl design away from its original backing. The vinyl should now be stuck to the transfer tape, ready to be placed on the wood.

Smoothing Out Air Bubbles

Air bubbles can ruin the look of your vinyl. They happen when air gets trapped between the vinyl and the wood.

- Start applying the vinyl from one edge or center and work outwards.

- Use a squeegee or a credit card to smooth the vinyl down as you go.

If you see a bubble, gently lift the vinyl back to that spot and re-smooth it. Small pinpricks with a fine needle can release trapped air if you can’t remove the bubble otherwise.

Securing the Edges for Durability

The edges are where vinyl is most likely to lift. Taking extra steps here is important.

Sealing the Edges

Once the vinyl is on and smoothed, pay close attention to the edges.

- Use your squeegee to press down firmly along all the edges of the vinyl.

- You can also use a craft heat gun on a low setting for a few seconds.

The heat makes the vinyl a little softer and more pliable. This allows it to really seal onto the wood grain. Be careful not to overheat the vinyl, as it can melt or warp.

Using a Sealer or Top Coat

For the best results, especially on outdoor projects or items that get handled a lot, a top coat is recommended.

- Apply a clear sealant over the vinyl and wood.

- Choose a sealant that is compatible with vinyl. Many clear acrylic sprays work well.

This sealant acts like a protective barrier. It helps to keep the vinyl edges from peeling up over time. It also protects the vinyl and wood from moisture and UV rays.

Advanced Techniques and Troubleshooting

Sometimes, even with the best steps, things can go wrong. This section offers solutions for common problems and ways to improve your vinyl adhesion on wood.

Dealing with Textured or Uneven Wood

Some wood pieces have a very rough texture or uneven grain. This can make it hard for vinyl to stick well.

Creating a Smoother Surface

Even on textured wood, you can improve the surface for vinyl.

- Use a wood filler to fill in any deep gouges or cracks.

- Once the filler is dry and sanded smooth, you might apply a thin coat of primer or a sealer.

This creates a more uniform surface. It helps the vinyl adhesive bond better. Ensure the filler and primer are fully cured before applying vinyl.

Contouring Vinyl to the Surface

If the wood is naturally bumpy, you might need to help the vinyl conform.

- Use gentle heat from a hairdryer. Stretch and press the vinyl into the dips and curves.

- For very intricate textures, you may need to cut your vinyl into smaller pieces to fit the shapes better.

This takes patience. The heat makes the vinyl flexible enough to mold. Think of it like applying skin to a slightly uneven surface.

Troubleshooting Common Adhesion Issues

Even experienced crafters face problems sometimes. Here are solutions for common sticking issues.

Vinyl Lifting After Application

If your vinyl starts to lift at the edges, don’t despair.

- Gently heat the area with a hairdryer on low.

- Use your squeegee to press the vinyl back down firmly.

- If it still lifts, you might need to apply a small amount of strong craft glue or a liquid adhesive specifically for vinyl to the underside of the edge.

This is a last resort but can save a project. Ensure the glue is fully dry before reapplying pressure.

Bubbles Appearing Over Time

Sometimes, bubbles can appear days or weeks after application.

- Try to push these bubbles out towards the nearest edge using a squeegee.

- If a bubble is stubborn, you can carefully use a very fine needle to make a tiny prick in the center of the bubble.

Then, gently press the air out. You can also try to use a tiny bit of clear glue under the edge if it starts to lift.

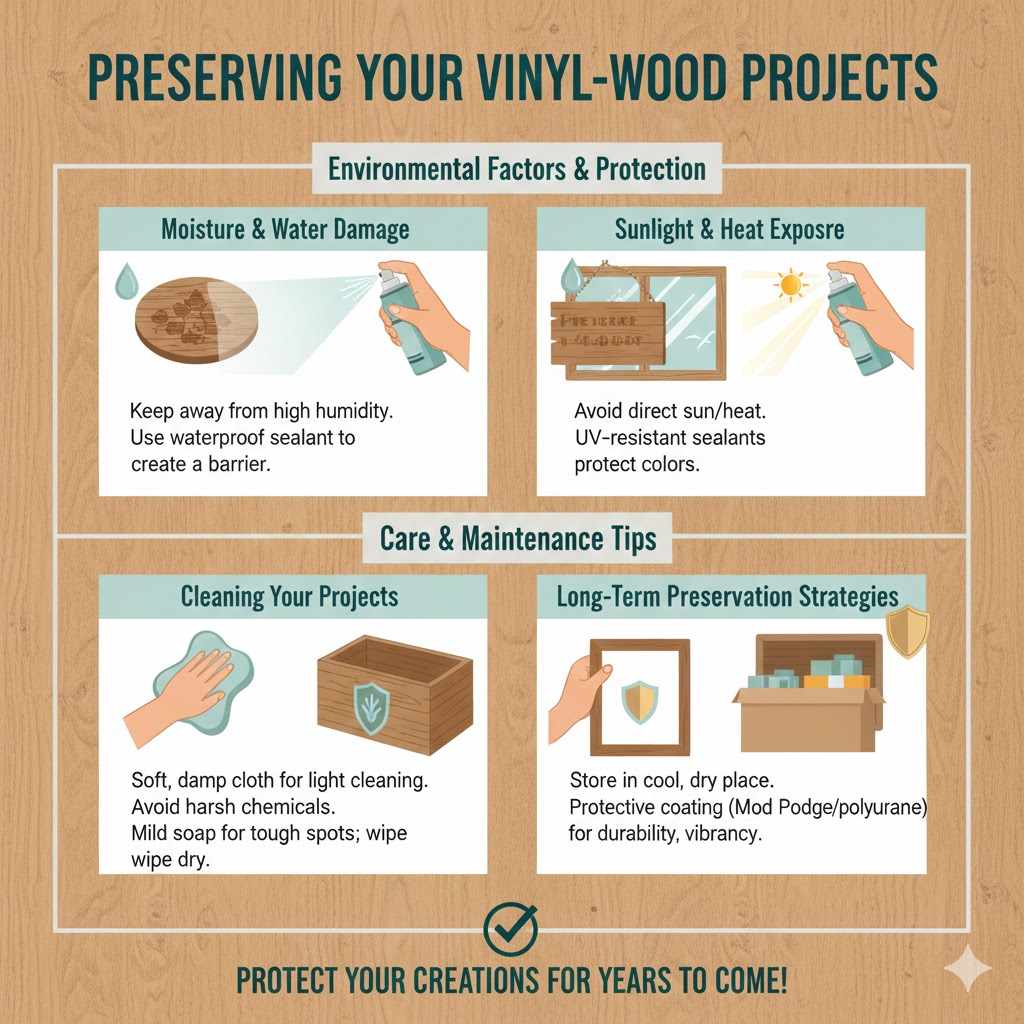

Preserving Your Vinyl-Wood Projects

Keeping your creations looking good means taking care of them. This section provides tips for protecting your vinyl-covered wood from damage and wear.

Environmental Factors and Protection

Wood and vinyl can be affected by their surroundings. Protecting them helps them last.

Moisture and Water Damage

Water is not good for wood or vinyl adhesion.

- Keep your projects away from high humidity areas.

- If the item might get wet, a good waterproof sealant is essential.

This sealant creates a barrier against moisture. It stops water from seeping into the wood or under the vinyl edges.

Sunlight and Heat Exposure

Direct sun can fade vinyl colors. Extreme heat can soften adhesives.

- Place your projects out of direct sunlight.

- Avoid placing them near heat sources like radiators or vents.

UV-resistant sealants can help protect the colors. These are often found in spray-on clear coats for crafts.

Care and Maintenance Tips

Simple cleaning and care can make a big difference.

Cleaning Your Projects

Regular cleaning keeps your projects looking fresh.

- Use a soft, damp cloth for light cleaning.

- Avoid harsh chemicals or abrasive cleaners. These can damage the vinyl or the sealant.

For tougher spots, a mild soap and water solution can be used, but always wipe dry afterward.

Long-Term Preservation Strategies

Think about how you store and use the item.

- For seasonal items, store them in a cool, dry place.

- Consider a protective coating like Mod Podge or a clear polyurethane varnish for extra durability.

These coatings add an extra layer of protection against scratches and wear. They also help maintain the vibrancy of the colors.

Frequently Asked Questions

Question: What is the best type of vinyl to use on wood

Answer: For most wood projects where you want a permanent finish, permanent adhesive vinyl is the best choice. It is designed to stick strongly and last a long time.

Question: Can I put vinyl on painted wood

Answer: Yes, you can put vinyl on painted wood, but make sure the paint is fully cured and smooth. A light sanding can help the vinyl adhere better.

Question: How do I prevent bubbles when applying vinyl to wood

Answer: Apply the vinyl slowly and carefully, starting from one edge and smoothing as you go with a squeegee. Work from the center outwards to push air away.

Question: Will vinyl stick to unfinished wood

Answer: Vinyl can stick to unfinished wood, but it’s best to sand it smooth first. The porous nature of unfinished wood can sometimes cause issues with adhesion if not prepared.

Question: How long does vinyl typically last on wood

Answer: With proper application and care, permanent vinyl can last several years on wood. Factors like exposure to sun, moisture, and heavy use can affect its lifespan.

Wrap Up

Achieving a secure vinyl seal on wood involves careful preparation and application. By sanding and cleaning your wood, choosing the right vinyl, and using good smoothing techniques, you ensure strong adhesion. Always pay attention to the edges and consider a protective top coat. This method helps your projects last and look great.