How To Measure Chainsaw Bar: Quick & Accurate Guide

To measure a chainsaw bar, use a measuring tape to determine the distance from the tip of the bar to where the chain enters the housing. This measurement should be taken along the bar’s bottom edge.

A chainsaw bar is an essential component of a chainsaw and needs to be measured to ensure it is the correct size for the saw. Before using a chainsaw, it is crucial to know the correct bar length. The bar length of a chainsaw is determined by measuring the distance from the tip of the bar to where the chain enters the housing.

This measurement should be taken along the bar’s bottom edge. Measuring the chainsaw bar accurately is crucial to ensure the saw’s optimal performance and safety. We will discuss the steps to measure a chainsaw bar accurately.

Introduction To Chainsaw Bars

Learn how to measure a chainsaw bar accurately to ensure compatibility with your tool. Understanding the correct way to measure chainsaw bars is essential for selecting the right replacement or upgrade. Follow these simple steps for precise measurement and optimal performance.

Before delving into how to measure a chainsaw bar, it’s important to understand what a chainsaw bar is and its role in the functioning of a chainsaw. A chainsaw bar is a long, metal guide that holds the chainsaw chain in place and helps it rotate around the guide bar. It’s an essential part of a chainsaw and comes in a variety of lengths and sizes to fit different chainsaw models.

Importance of Correct Measurement

Getting the correct measurement of your chainsaw bar is crucial to ensure that the chainsaw operates efficiently and safely. A chainsaw bar that is too long or too short can cause the chainsaw to overheat, damage the engine and chain, and increase the risk of accidents. Therefore, measuring your chainsaw bar correctly is essential to maintain your chainsaw’s performance and longevity.

Tools Needed for Measuring

To measure your chainsaw bar, you’ll need a measuring tape or ruler and a few other tools, such as a flathead screwdriver, a small wrench, and a chainsaw file. These tools will help you accurately measure the length and size of your chainsaw bar and make any necessary adjustments to ensure optimal performance.

Measuring a chainsaw bar requires precision and attention to detail. The process may vary depending on the type and brand of chainsaw you own. However, by following the manufacturer’s instructions and using the right tools, you can ensure that your chainsaw bar is measured correctly and operates safely.

In conclusion, measuring your chainsaw bar correctly is crucial to ensure optimal performance and safety. By understanding the importance of correct measurement and using the right tools, you can maintain your chainsaw’s efficiency and prevent any potential accidents.

Identifying Chainsaw Bar Types

When it comes to measuring your chainsaw bar, it is important to first identify the type of bar you have. This will help ensure that you select the correct replacement bar and maintain the optimal performance of your chainsaw. In this section, we will explore two common types of chainsaw bars: standard bars and replaceable sprocket bars.

Standard Bars Vs. Replaceable Sprocket Bars

Standard bars and replaceable sprocket bars are the two main types of chainsaw bars you will come across. Each type has its own unique features and benefits.

Standard Bars

Standard bars are the most commonly used type of chainsaw bars. They consist of a solid metal bar with a groove along the top, which guides the chain during operation. These bars are typically lighter and more affordable compared to replaceable sprocket bars. Standard bars are suitable for general-purpose cutting tasks and are commonly found on homeowner-grade chainsaws.

Here is a breakdown of the anatomy of a standard chainsaw bar:

| Component | Description |

|---|---|

| Guide Bar Body | The main body of the bar that provides support and stability to the chain. |

| Guide Bar Tip | The front end of the bar that houses the nose sprocket or roller, allowing the chain to smoothly glide along the bar. |

| Guide Bar Groove | The groove on the top of the bar where the chain sits and moves during cutting. |

Replaceable Sprocket Bars

Replaceable sprocket bars, also known as interchangeable sprocket bars, offer added versatility and convenience. These bars feature a replaceable sprocket tip at the end, allowing you to easily replace the worn sprocket instead of the entire bar. Replaceable sprocket bars are commonly used in professional-grade chainsaws that endure heavy-duty cutting applications.

Here is a breakdown of the anatomy of a replaceable sprocket chainsaw bar:

| Component | Description |

|---|---|

| Guide Bar Body | The main body of the bar that provides support and stability to the chain. |

| Guide Bar Tip | The front end of the bar that houses the replaceable sprocket, allowing for easy replacement when worn. |

| Guide Bar Groove | The groove on the top of the bar where the chain sits and moves during cutting. |

Now that you understand the different types of chainsaw bars, you can accurately measure your bar and make the right choice when it comes to replacements or upgrades. Remember to refer to your chainsaw’s manual for specific instructions and consult a professional if you are unsure about any measurements or bar types.

Preparation Steps Before Measuring

Before measuring your chainsaw bar, ensure the saw is turned off and the chain is tensioned correctly. Remove the bar and chain cover, then measure the bar length from the front tip to the farthest cutter. Additionally, check the pitch and gauge of the chain to ensure compatibility with the new bar.

Safety Precautions

Before measuring your chainsaw bar, it is important to prioritize safety. Taking the necessary precautions will help prevent accidents and ensure a smooth measuring process. Here are some safety tips to keep in mind:

- Always wear protective gear such as safety glasses, gloves, and ear defenders.

- Make sure the chainsaw is turned off and the engine is cool before proceeding.

- Keep the chainsaw away from flammable materials or liquids.

- Work in a well-ventilated area to avoid inhaling any fumes.

- Ensure you have a stable work surface and good lighting conditions.

Cleaning The Bar

Before you can accurately measure your chainsaw bar, it is essential to clean it properly. Removing any dirt, debris, or sawdust will ensure accurate measurements and extend the lifespan of your equipment. Here’s how you can clean your chainsaw bar:

- Start by removing the chain from the bar.

- Use a brush or compressed air to remove any loose debris or sawdust.

- Inspect the bar for any signs of damage or wear.

- If necessary, use a mild detergent and a soft cloth to gently clean the surface of the bar.

- Allow the bar to dry completely before proceeding with the measurement.

Remember, taking the time to clean your chainsaw bar will not only improve the accuracy of your measurements but also help maintain the overall performance of your chainsaw.

Measuring The Length Of The Chainsaw Bar

When it comes to using a chainsaw, knowing the correct bar length is crucial for safety and efficiency. Measuring the length of the chainsaw bar is a straightforward process that ensures you get the right replacement chain and guide bar. Let’s delve into the details of finding the cutting length and measuring from tip to base.

Finding The Cutting Length

Before measuring the chainsaw bar, it’s important to understand the cutting length. The cutting length is the distance from the tip of the bar to the point where the chain enters the housing. This measurement provides an accurate indication of the bar length and is crucial when selecting a replacement guide bar or chain.

Measuring From Tip To Base

Measuring the chainsaw bar involves determining the length from the tip to the base of the bar. This measurement is essential for identifying the correct bar length for your chainsaw. It’s important to follow the correct procedure to ensure an accurate measurement.

Calculating The Effective Cutting Length

When it comes to measuring a chainsaw bar, one important aspect to consider is the effective cutting length. This refers to the portion of the chainsaw bar that actually comes into contact with the material being cut. By accurately determining the effective cutting length, you can ensure optimal performance and safety while using your chainsaw.

Determining True Length Vs. Advertised Length

In order to calculate the effective cutting length of your chainsaw bar, it’s crucial to differentiate between the true length and the advertised length. The true length refers to the actual measurement of the chainsaw bar, while the advertised length is the rounded-up measurement typically used for marketing purposes.

For example, if the advertised length of your chainsaw bar is 18 inches, the true length may be slightly shorter, such as 17.5 inches. It’s essential to determine the true length for accurate measurements.

Rounding To The Nearest Inch

Once you have determined the true length of your chainsaw bar, it’s important to round it to the nearest inch. This helps simplify the calculation and ensures compatibility with the available chain sizes.

For example, if the true length of your chainsaw bar is 17.5 inches, you would round it up to 18 inches. This rounded measurement will be used to determine the effective cutting length.

Now that you have the rounded measurement of your chainsaw bar, you can calculate the effective cutting length. This can be done by subtracting a specific length from the rounded measurement.

Typically, a chainsaw bar requires a specific length to be deducted to account for the distance from the tip of the bar to the chainsaw’s body. This length may vary depending on the make and model of your chainsaw.

Refer to your chainsaw’s user manual or manufacturer’s guidelines to determine the specific length that needs to be subtracted. Once you have this information, subtract it from the rounded measurement to obtain the effective cutting length.

For example, if the rounded measurement is 18 inches and the specified deduction length is 2 inches, the effective cutting length would be 16 inches.

By accurately calculating the effective cutting length of your chainsaw bar, you can ensure precise and efficient cutting performance, as well as maintain the safety of your chainsaw operation. Remember to always refer to your chainsaw’s user manual for specific instructions and guidelines related to measuring and using your chainsaw bar.

Gauging The Bar Groove

When it comes to gauging the bar groove of your chainsaw, it’s essential to measure the width and depth accurately. This ensures the chain fits snugly and operates smoothly. Let’s delve into the details of gauging the bar groove to maintain optimal performance of your chainsaw.

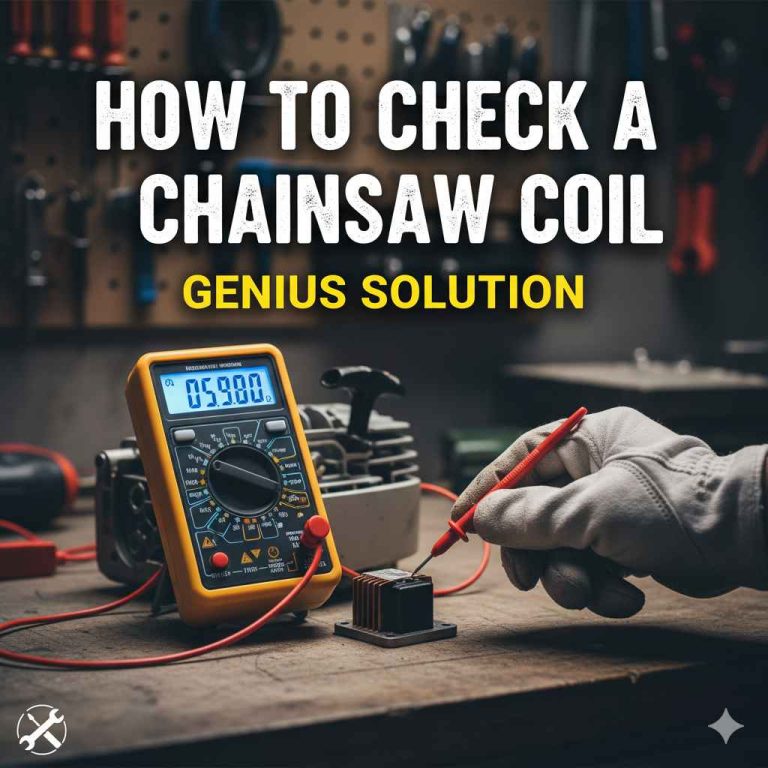

Width Of The Groove

Start by measuring the width of the bar groove using a caliper or a specialized groove gauge tool. Ensure the tool is clean and free of debris to prevent inaccurate measurements. Place the tool inside the groove and take the measurement at multiple points to determine any irregularities. Record the narrowest width for accuracy.

Depth Of The Groove

Next, measure the depth of the bar groove using a depth gauge tool. Place the tool inside the groove and align it parallel to the bar surface. Carefully note the depth measurement, ensuring it meets the manufacturer’s specifications. Avoid measuring worn-out areas, as this can lead to incorrect readings.

Pitch And Drive Link Count

When measuring a chainsaw bar, understanding the pitch and drive link count is crucial.

Understanding Pitch Measurement

The pitch refers to the distance between three consecutive rivets divided by two.

To measure the pitch, count the number of drive links in three rivets and divide by two.

- Measure from the center of the first rivet to the center of the third rivet.

- Divide this measurement by two to get the pitch.

Counting The Drive Links

Drive links are the part of the chainsaw chain that fits into the bar’s groove.

To count the drive links, ensure each link fits into the bar’s groove properly.

- Place the chain on a flat surface to count the links easily.

- Ensure accurate counting for the correct fit and operation of the chainsaw.

Maintenance Tips For Chainsaw Bars

When it comes to maintaining your chainsaw bar, following proper maintenance tips is crucial to ensure its longevity and efficiency.

Regular Inspection And Cleaning

- Inspect for wear and tear regularly.

- Remove debris and sawdust after each use.

- Clean the bar groove and oil holes.

Bar Oiling And Maintenance

- Keep the bar properly lubricated.

- Use high-quality bar oil for optimal performance.

- Check oil levels before each use.

Troubleshooting Common Measurement Mistakes

When measuring your chainsaw bar, it’s crucial to avoid common mistakes that could lead to inaccurate results. By understanding and addressing these errors, you can ensure that you have the correct measurements for your chainsaw bar.

Incorrect Length Identification

One of the most common mistakes is incorrectly identifying the length of the chainsaw bar. This can lead to using the wrong chain, affecting the performance of your chainsaw.

Misinterpreting Groove Measurements

Misinterpreting the groove measurements on the chainsaw bar can result in improper fitting of the chain. It’s essential to accurately measure the groove to ensure compatibility.

Frequently Asked Questions

How Do I Measure A Chainsaw Bar Correctly?

To measure a chainsaw bar, remove the chain and measure from the tip to where it enters the housing. Use a measuring tape for accurate results. Ensure the measurement is in inches for compatibility with replacement bars.

What Is The Standard Chainsaw Bar Length?

The standard chainsaw bar length ranges from 10 to 24 inches, with the most common sizes being 16 and 18 inches. Select a bar length based on the intended use and the size of the trees you will be cutting.

Can A Longer Chainsaw Bar Affect Performance?

Yes, a longer chainsaw bar can affect performance. Longer bars require more power to operate and may cause the saw to be heavier and more difficult to handle. It’s important to match the bar length to the power of your chainsaw for optimal performance.

Conclusion

Accurately measuring your chainsaw bar is crucial for safety and efficiency. By following the simple steps outlined in this guide, you can ensure that your chainsaw is properly maintained and ready for any task. With the right measurement, you can confidently tackle any cutting job with precision and confidence.