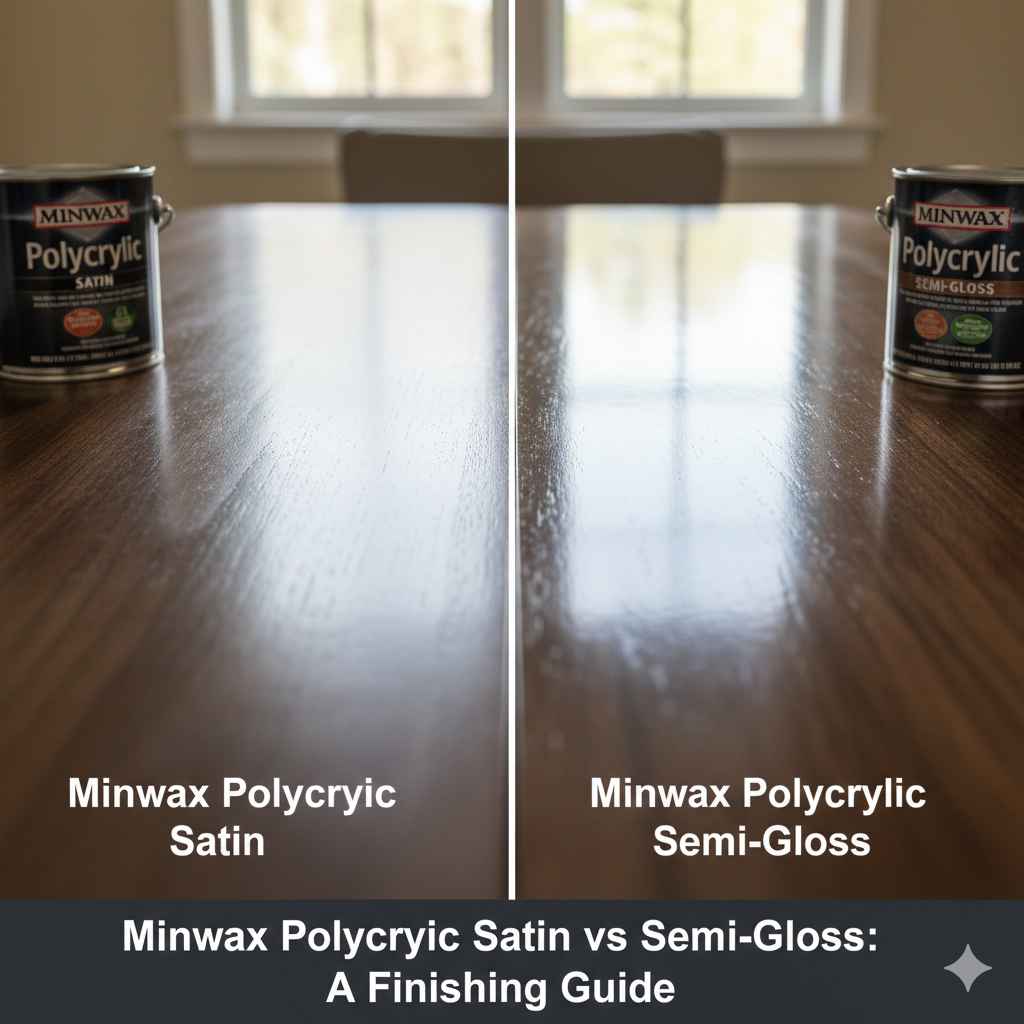

Minwax Polycrylic Satin vs Semi-Gloss: A Finishing Guide

Choosing the right finish for your woodworking projects can be tricky, especially when you’re starting out. The question of Minwax Polycrylic Satin vs Semi-Gloss: Which to Choose? often stumps beginners, simply because there’s so much to consider! Don’t worry, though. This guide will make it easy. We’ll break down everything you need to know in a clear, step-by-step way, helping you confidently select the best Polycrylic finish for your specific project. We’ll explore the main differences, how to apply each finish, and which is ideal for various applications.

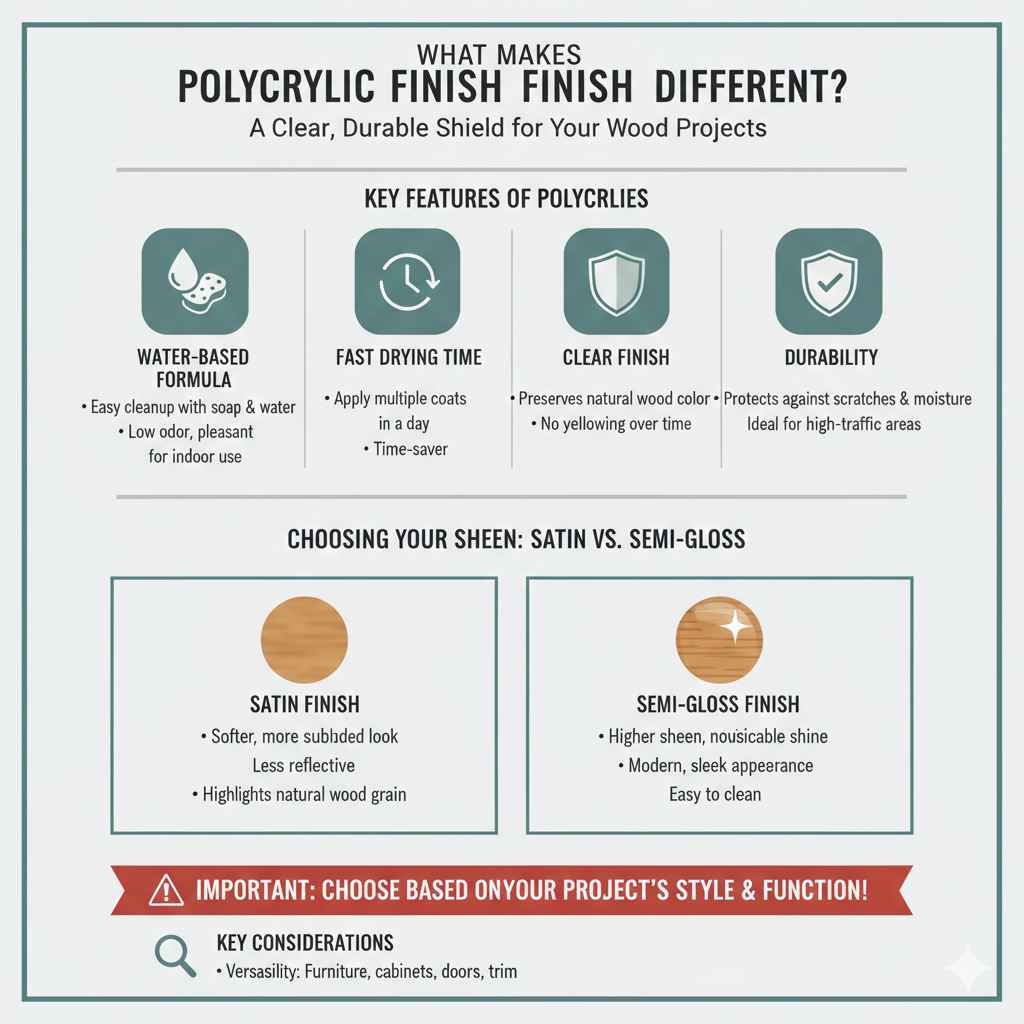

What Makes Polycrylic Finishes Different?

Polycrylic finishes are water-based topcoats that provide a protective layer and aesthetic enhancement to your wood projects. They’re popular for their ease of use, low odor, and fast drying times, making them a great choice for both beginners and experienced woodworkers. They’re also known for their clarity, meaning they don’t yellow over time, which can be a problem with some oil-based finishes. Think of Polycrylic as a clear, hard shield that protects the wood underneath from scratches, water, and other damage. They are versatile, and compatible with many different types of wood.

Choosing between satin and semi-gloss is all about the level of shine you desire. Satin offers a softer, more subdued look, while semi-gloss provides a bit more sheen. The choice depends on your personal preference and the overall style of your project. Each product offers specific advantages and disadvantages that we’ll explore below to help you decide.

Key Features of Polycrylic

- Water-Based Formula: Polycrylic is water-based, making it easy to clean up with soap and water. This also means it has a low odor, making it more pleasant to work with indoors.

- Fast Drying Time: Compared to oil-based finishes, Polycrylic dries very quickly, allowing you to apply multiple coats in a single day. This is a big time-saver.

- Clear Finish: Polycrylic dries clear, preserving the natural color of the wood underneath without yellowing over time. This is beneficial for lighter woods where you want to maintain the original appearance.

- Durability: Polycrylic provides a durable layer that protects against scratches, moisture, and everyday wear and tear. It holds up well in high-traffic areas.

- Versatility: Suitable for a wide range of wood projects, including furniture, cabinets, doors, and trim. The options of Satin and Semi-Gloss offer flexibility in style and design.

Satin Finish: The Subtle Charm

Satin finishes offer a low-luster appearance, reflecting a minimal amount of light. This subtle sheen creates a soft, elegant look that complements a variety of decor styles. It’s an excellent choice for projects where you want the wood grain to be the star, without a glossy distraction. Consider satin for pieces where you want a more understated aesthetic, focusing on natural beauty rather than a shiny appearance. The satin finish is sometimes preferred for areas with direct light to avoid excessive glare.

One of the great things about a satin finish is its forgiving nature. Because it has less shine, small imperfections in the wood or application are less noticeable. This makes it a good option for DIYers who are still getting the hang of applying topcoats. Satin finishes still provide good protection, but their main advantage lies in their aesthetic appeal, making them a popular choice for furniture and decorative items.

Advantages of Satin Polycrylic

- Reduced Glare: The low sheen minimizes reflections, making it easier on the eyes, especially in brightly lit rooms. This is great for furniture that might be near windows or under direct light sources.

- Hides Imperfections: Satin finishes are more forgiving than glossier options, making minor imperfections in the wood or application less visible. This is a benefit for less experienced users.

- Versatile Aesthetic: Satin complements a wide variety of design styles, from rustic to modern. It provides a timeless look that works well in any space.

- Natural Appearance: It allows the wood grain to be the focus, enhancing the natural beauty of the wood. This is perfect if you want to highlight the wood’s texture and character.

- Easy Maintenance: Satin finishes don’t show fingerprints or smudges as easily as semi-gloss or gloss finishes, making them relatively easy to maintain. Regular cleaning is usually sufficient.

Semi-Gloss Finish: The Balanced Sheen

Semi-gloss finishes strike a balance between shine and subtlety, providing a noticeable sheen while not being overly reflective. This makes them a popular choice for areas where you want a bit of shine, along with a durable protective layer. Semi-gloss reflects more light than satin, giving the surface a smoother, more polished look. It is an excellent middle ground, offering a polished look without being overly flashy.

Semi-gloss finishes are often chosen for areas that need to be easy to clean, such as cabinets and doors, since they have a smoother surface that is easier to wipe down. They provide a nice visual appeal while still offering excellent protection against scratches and moisture. This finish is a solid choice when you need a blend of durability and visual appeal. It can offer a more contemporary look than satin, and it is still versatile enough to fit many decorating styles.

Advantages of Semi-Gloss Polycrylic

- Enhanced Durability: Semi-gloss finishes are often more durable than satin finishes, offering excellent protection against wear and tear. This is great for high-traffic areas.

- Easy to Clean: The smoother surface of a semi-gloss finish is easier to clean and maintain, making it ideal for cabinets, doors, and other areas that need frequent cleaning.

- Subtle Shine: Semi-gloss provides a noticeable sheen without being overly reflective, adding a touch of elegance to your projects. It’s perfect if you want a slight upgrade.

- Improved Appearance: It can make the wood grain appear richer and enhance the overall look of the project, especially on darker woods. It helps the color “pop”.

- Good Protection: Like other Polycrylic finishes, semi-gloss provides a protective layer against scratches, moisture, and other damage, ensuring your project lasts for years.

Minwax Polycrylic Satin vs Semi-Gloss: A Detailed Comparison

When deciding between Minwax Polycrylic Satin and Semi-Gloss, the primary difference is the level of sheen. This directly impacts the appearance of your finished project and your choice will influence how the project will look once it’s complete. While both products offer excellent protection and ease of use, the degree of shine is the key factor in your decision. The table below provides a quick comparison to help you assess the key differences.

| Feature | Satin | Semi-Gloss |

|---|---|---|

| Sheen Level | Low sheen, minimal reflection | Medium sheen, noticeable reflection |

| Appearance | Soft, subtle, understated | Smooth, polished, balanced |

| Hides Imperfections | Better at hiding minor flaws | More visible; more sheen reflects |

| Cleanability | Good, but may show smudges | Excellent, easy to wipe clean |

| Durability | Good | Excellent |

| Best Uses | Furniture, decorative items, areas with less direct light | Cabinets, doors, trim, areas needing frequent cleaning |

The difference in sheen is the most obvious. Satin has a lower gloss level, resulting in a more matte appearance, whereas semi-gloss is more reflective and gives the surface a shinier look. The choice truly depends on the aesthetic you’re aiming for. The table helps to illustrate the key distinctions, allowing you to choose the finish that best suits your needs.

Choosing the Right Finish for Your Project

The best choice between Minwax Polycrylic Satin and Semi-Gloss depends on the project and the look you want to achieve. Consider the following scenarios:

- Furniture: For a dining table, you might choose semi-gloss for its durability and ease of cleaning, especially if you have children. For a bedroom dresser, you might select satin to give the piece a softer, more relaxed feel.

- Cabinets: Semi-gloss is a popular choice for kitchen cabinets because it is easy to wipe clean and resists moisture. Satin is an option if you prefer a less shiny look.

- Doors: Semi-gloss is commonly used for interior doors because it resists scuffs and is easy to clean. You can use satin on interior doors if the design of the room needs a more subtle appearance.

- Trim: Semi-gloss is very popular for trim and baseboards because it can endure wear and tear. If you prefer a more subtle design, satin can work for trim, too.

- Decorative Items: For items like picture frames or decorative boxes, satin is often the preferred choice to give the items an elegant, non-reflective appearance.

Factors to Consider

- Project Type: Consider the purpose of the project. Furniture in high-traffic areas may benefit from the added durability of semi-gloss. Decorative items can look great with a satin finish.

- Desired Look: Think about the overall aesthetic you want to achieve. Do you want a subtle, understated look, or a more polished and modern appearance?

- Lighting: The lighting in the space can impact how the finish looks. Satin is great for rooms with bright light where you want to minimize glare.

- Maintenance: Semi-gloss is easier to clean and maintain, making it ideal for areas that require frequent cleaning.

- Wood Type: The type of wood can also influence your choice. Some woods look better with a satin finish, while others shine more with a semi-gloss.

Application Tips and Techniques

Proper application is key to achieving a smooth, professional finish. Here’s a quick guide to help you apply Minwax Polycrylic:

Preparing Your Wood

Preparing the wood surface properly is key to a professional finish. It allows the Polycrylic to adhere correctly and ensures a smooth, even surface. This is true whether you’re working with a satin or a semi-gloss product.

- Sanding: Start by sanding the wood to a smooth finish. Begin with a coarser grit sandpaper (e.g., 120 or 150 grit) to remove imperfections, then move to a finer grit (e.g., 220 grit) for a super smooth surface. This creates an even surface for the Polycrylic to adhere to.

- Cleaning: After sanding, thoroughly clean the surface to remove all dust, debris, and sanding residue. You can use a tack cloth or a slightly damp cloth to wipe the surface. This prevents any particles from getting trapped in the finish.

- Wood Conditioning: For certain wood types, especially softwoods, a wood conditioner can be used before applying the Polycrylic. This helps to even out the absorption of the finish and prevent blotchiness.

Applying the Polycrylic

The application is just as important as preparation. Correct techniques will prevent imperfections and give your project a professional look.

- Thin Coats: Apply thin, even coats of Polycrylic. Thin coats dry faster and reduce the risk of drips, runs, and bubbles. Multiple thin coats are better than one thick coat.

- Proper Tools: Use a high-quality brush, foam brush, or sprayer. Choose the right tool based on the size and complexity of your project. A brush gives more control.

- Brush Strokes: If using a brush, apply the finish in the direction of the wood grain. This ensures an even distribution and minimizes brush marks. Light, even strokes are key.

- Drying Time: Allow each coat to dry completely before applying the next coat. Follow the manufacturer’s recommended drying times, usually a few hours between coats. Patience is key.

Finishing Touches

These finishing steps will ensure a professional-looking project. Taking the time to do these steps properly will result in a great project that will last for years.

- Light Sanding Between Coats: Lightly sand the surface between coats with fine-grit sandpaper (e.g., 320 grit) to remove any imperfections and create a smooth surface for the next coat. This is also known as “de-nibbing.”

- Number of Coats: Apply at least two to three coats of Polycrylic for optimal protection and appearance. More coats may be necessary for high-wear areas.

- Final Cure Time: Allow the finish to cure completely before using the project. This can take several days to a week. Avoid placing heavy objects on the finished surface during this period.

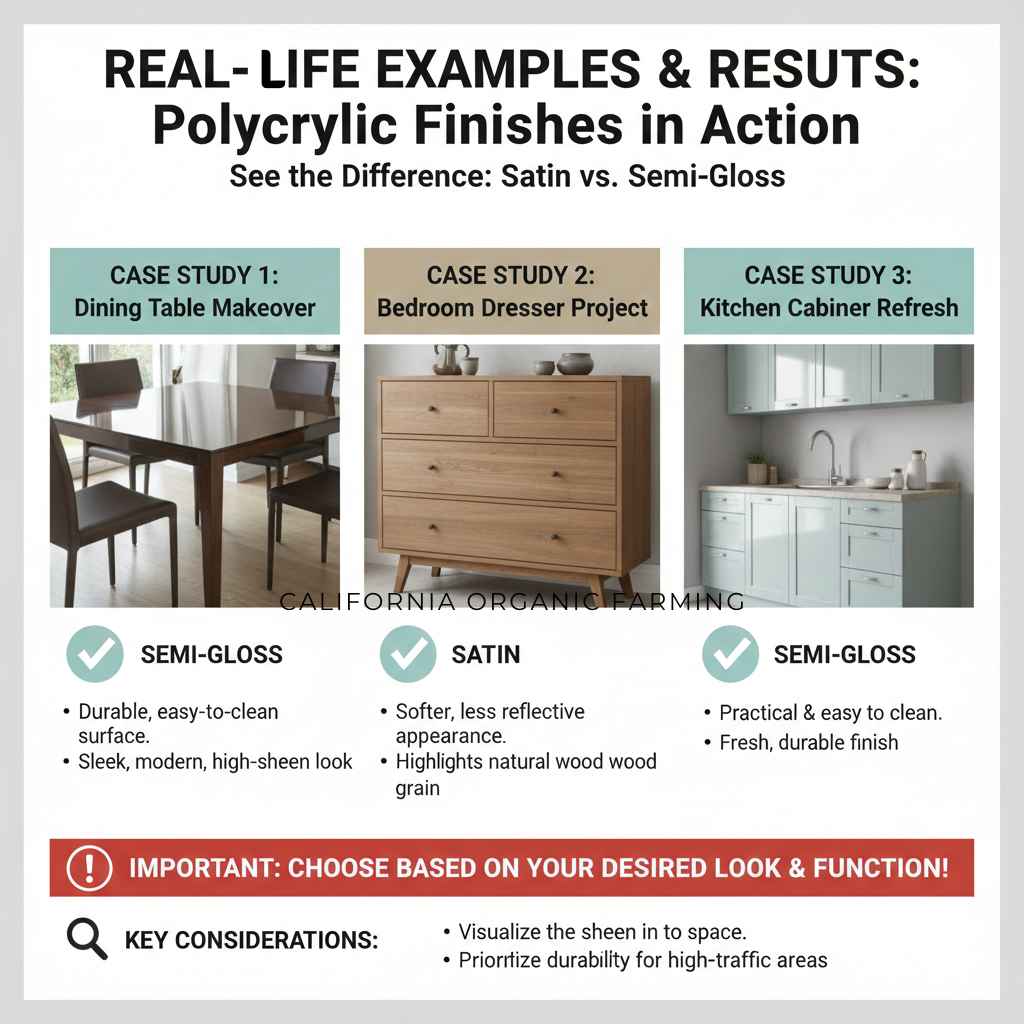

Real-Life Examples and Results

These real-world examples illustrate the outcomes you can expect from using both satin and semi-gloss finishes.

- Case Study 1: Dining Table Makeover. A DIYer refinished an old dining table. They chose semi-gloss Polycrylic to provide a durable, easy-to-clean surface. The result was a sleek, modern table that withstood daily use and spills.

- Case Study 2: Bedroom Dresser Project. A homeowner wanted to refinish a bedroom dresser. They opted for satin Polycrylic, wanting a softer, less reflective look. The finished dresser provided a gentle touch, highlighting the wood’s natural grain.

- Case Study 3: Kitchen Cabinet Refresh. A family updated their kitchen cabinets. The semi-gloss finish was chosen for its durability and ease of cleaning, resulting in a fresh and practical look.

Frequently Asked Questions

Question: Can I mix satin and semi-gloss Polycrylic?

Answer: It’s generally not recommended to mix satin and semi-gloss Polycrylic, as the different sheen levels can create an uneven finish. For best results, stick to one finish type for the entire project.

Question: How many coats of Polycrylic should I apply?

Answer: It is advisable to apply at least two to three coats of Polycrylic. More coats may be needed for areas that experience heavier use, such as tabletops or cabinet doors.

Question: Is it necessary to sand between coats of Polycrylic?

Answer: Light sanding between coats with fine-grit sandpaper (e.g., 320 grit) is a great idea to remove any imperfections and create a smooth surface for the next coat. However, it’s not always required.

Question: How long should I wait between coats of Polycrylic?

Answer: Follow the manufacturer’s directions, but a good rule of thumb is to wait at least two to three hours between coats. Ensure the previous coat is completely dry before applying the next.

Question: Can I use Polycrylic on exterior projects?

Answer: No, Polycrylic is designed for interior use only. It is not suitable for outdoor projects, as it doesn’t offer adequate protection against UV rays and weathering. Using exterior-grade finishes is better for outside.

Final Thoughts

Choosing between Minwax Polycrylic Satin and Semi-Gloss comes down to the look you want for your project and the conditions it will face. Satin offers a subtle, sophisticated charm with minimal glare, ideal for furniture and decorative items where the wood’s natural beauty should shine. Semi-gloss provides a balanced sheen and increased durability, making it ideal for cabinets, doors, and areas needing easy maintenance. Both finishes offer strong protection, but your aesthetic preference and functional needs are the determining factors. When you consider the factors, you will know which product is perfect for you!

Explore the possibilities. Consider the lighting, the wood type, and the design to choose the perfect finish to bring your projects to life. By keeping these factors in mind, you can confidently select the right Polycrylic finish. Start your next project with assurance and enjoy the satisfaction of a beautifully finished piece!