Pressure Treated Wood Posts: Sizes Uses Tips

Choosing the right materials for your outdoor projects can feel a bit tricky, especially when you’re new to building. Pressure treated wood posts are super popular for decks, fences, and gardens. But knowing which size to pick and how to best use them can be confusing.

Don’t worry, this guide will break down everything you need to know about Pressure Treated Wood Posts: Sizes, Uses & Tips in a simple, step-by-step way. We’ll cover the basics and give you practical advice so your projects turn out great.

Understanding Pressure Treated Wood Posts

Pressure treated wood posts are a popular choice for many outdoor construction projects. They are strong, durable, and resistant to rot, decay, and insect damage. This makes them ideal for use in contact with the ground or exposed to the elements.

The treatment process involves forcing chemical preservatives deep into the wood under high pressure. This ensures the wood is protected from the inside out, significantly extending its lifespan compared to untreated lumber.

This section will explain the core concepts behind pressure treated wood posts. We will explore what makes them different from regular wood and why this treatment is so important for longevity in outdoor settings. Understanding these fundamentals will help you make informed decisions when selecting posts for your specific needs.

It’s all about building a solid foundation for your projects that will last for years to come.

What is Pressure Treating

Pressure treating is a wood preservation process. It forces chemical preservatives into the wood. This is done inside a large, sealed cylinder called a treating cylinder.

The wood is placed inside, and then a vacuum is pulled to remove air from the wood cells.

Next, the cylinder is filled with preservative solution, and pressure is applied. This pushes the solution deep into the wood. The higher the pressure, the deeper the preservatives penetrate.

This protection is vital for wood used outdoors, especially when it will be in contact with soil or water.

The chemicals used vary but typically include copper-based compounds. These compounds are effective against fungi that cause rot and insects like termites. Without this treatment, untreated wood would quickly degrade when exposed to moisture and pests, leading to premature failure of fences, decks, and other structures.

Why Pressure Treated Wood is Durable

The durability of pressure treated wood comes directly from the preservation process. Standard lumber is susceptible to several threats in outdoor environments. Fungi thrive in moist conditions and break down the wood’s structure, causing it to rot and lose strength.

Insects, especially termites and carpenter ants, can tunnel through wood, weakening it and eventually destroying it. Ultraviolet (UV) rays from the sun can also degrade wood over time, making it brittle and prone to cracking.

Pressure treatment combats these issues by infusing the wood with chemicals that are toxic to decay-causing fungi and insects. This creates a barrier that prevents them from attacking the wood. While UV rays can still cause surface weathering and color changes, the structural integrity of the wood remains protected for many years.

This resistance to decay and insects is what gives pressure treated wood its long lifespan.

Common Wood Types for Posts

Several types of wood are commonly used for pressure treated posts, with pine being the most prevalent. Pine is a softwood that is readily available and accepts the pressure treatment process very well. This makes it a cost-effective choice for many applications.

Fir and spruce are also frequently used. Like pine, these are softwoods that are treated to withstand outdoor conditions. The specific wood species chosen can sometimes influence the wood’s density and grain, but the pressure treatment process ensures a similar level of protection across the board for structural integrity.

Less commonly, hardwoods might be pressure treated, but this is usually for specialized applications where extreme durability or specific aesthetic qualities are required. For most standard fencing, deck support, or garden bed projects, pine, fir, or spruce posts are the go-to options due to their balance of cost, availability, and effectiveness after treatment.

Pressure Treated Wood Posts Sizes Explained

Selecting the correct size for your pressure treated wood posts is crucial for the stability and longevity of your project. Post dimensions are typically described by their nominal size (e.g., 4×4, 6×6) and their length. The nominal size refers to the rough-cut dimensions before drying and finishing, while the actual size will be slightly smaller.

Lengths vary widely depending on the intended use, from short garden stakes to long structural supports.

This section will demystify the sizing conventions for pressure treated wood posts. We will clarify what the numbers mean, discuss how to choose the right diameter and length for different projects, and highlight common sizes you’ll encounter. Making an informed choice here prevents structural issues and ensures your project looks good and performs well.

Understanding Nominal vs. Actual Dimensions

When you see dimensions like 4×4 or 6×6 for lumber, these are “nominal” sizes. They refer to the approximate size of the wood before it is surfaced and dried. After these processes, the actual dimensions of the post will be smaller.

For example, a nominal 4×4 post is roughly 4 inches by 4 inches when it’s rough-sawn. After it’s planed smooth and dried, its actual dimensions are typically closer to 3.5 inches by 3.5 inches. Similarly, a nominal 6×6 post, which starts around 6 inches by 6 inches, will finish closer to 5.5 inches by 5.5 inches.

It’s important to be aware of this difference, especially when planning precise measurements for your project. While the slight reduction in size usually doesn’t impact structural integrity for most common uses, it can be a factor in very specific builds or when using pre-made brackets designed for exact nominal dimensions. Always check the actual dimensions if precision is critical.

Common Post Sizes and Their Uses

The most common sizes for pressure treated wood posts are 4×4 and 6×6 inches. These are versatile and suitable for a wide range of projects.

- 4×4 Posts These are good for lighter-duty applications. They are often used for smaller fences, garden bed edging, clothesline poles, or as deck railing posts when structural load is minimal. Their smaller diameter makes them easier to handle and install for DIY projects.

- 6×6 Posts These are significantly stronger and more stable. They are the standard choice for the main support posts of decks, pergolas, gazebos, and sturdy fence posts that need to withstand strong winds or heavy loads. Their larger surface area also offers a more substantial look.

Other less common but available sizes include 2×4 and 2×6 for bracing or railing components, and larger dimension posts for very heavy-duty structures. For most residential projects, sticking to 4×4 and 6×6 will cover most needs.

Choosing the Right Post Length

The length of your pressure treated wood post depends on how deep it needs to be buried and how tall you want your structure to be above ground. A general rule of thumb is to bury at least one-third of the post’s total length in the ground for stability.

For example, if you are building a 6-foot fence, you will need posts that are at least 8 feet long. This allows for 2 feet to be buried (6 feet above ground + 2 feet below ground = 8 feet total). For decks, the posts need to be long enough to reach from below the frost line (if applicable in your area) up to the required deck height, plus any extra for connecting to beams.

Always check local building codes for minimum burial depth requirements, especially for structural elements like decks. For a 6-foot fence, an 8-foot post is common. For a 4-foot garden bed, 4-foot or 5-foot posts are often sufficient, with 1-2 feet buried.

Here’s a quick guide for common above-ground heights:

- Fence Posts (6 feet tall): Use 8-foot posts (2 feet buried).

- Deck Support Posts (4 feet tall): Use 8-foot or 10-foot posts (3-4 feet buried for frost line depth and stability).

- Pergola Posts (8 feet tall): Use 10-foot or 12-foot posts (2-4 feet buried depending on desired stability and wind loads).

Consider that some soil conditions might require deeper burial for extra stability, especially in areas with high winds or soft soil.

Uses for Pressure Treated Wood Posts

Pressure treated wood posts are incredibly versatile and form the backbone of many outdoor projects. Their resistance to moisture and pests makes them suitable for any application where the wood will be in contact with the ground or exposed to the weather. From simple garden features to complex structural builds, these posts provide reliable support and longevity.

This section explores the myriad ways pressure treated wood posts are used. We’ll highlight common applications such as fencing, decking, and pergolas, and also touch on some less obvious but practical uses. Understanding these applications will help you envision how these posts can serve your own outdoor project needs.

Fencing Applications

Fencing is one of the most common uses for pressure treated wood posts. They provide the necessary support structure for various types of fences, including privacy fences, picket fences, and agricultural fencing. The posts are driven or set into the ground, forming the framework to which fence panels, boards, or wire are attached.

For a standard privacy fence, 4×4 posts are often used, spaced about 6 to 8 feet apart. They are typically set at least 2 feet deep in concrete or tamped gravel for maximum stability. For areas prone to high winds or where a more robust fence is desired, 6×6 posts offer superior strength and resistance to leaning or toppling.

Here are some examples of fencing projects:

- Residential Privacy Fence A 6-foot high fence using 4×4 posts set 8 feet apart, buried 2 feet deep in concrete, provides excellent stability and privacy for a backyard.

- Farm Fence For larger agricultural areas, sturdy 6×6 posts might be used at closer intervals or for gate posts to support heavier gates and withstand animal pressure.

- Garden Fence Decorative picket fences or simple garden borders can utilize 4×4 posts for support, often set in concrete for longevity and to prevent rot at ground level.

Deck and Patio Construction

Pressure treated wood posts are essential for building safe and durable decks and patios. They serve as the primary vertical supports that hold up the deck beams and joists, which in turn support the deck surface. Because decks are elevated structures, the strength and stability of the posts are paramount for safety.

For most residential decks, 6×6 pressure treated posts are the standard. They are set into concrete footings below the frost line to prevent heaving and provide a solid anchor. The depth of these footings can vary significantly by region, often requiring 3-4 feet of depth.

The spacing of these posts is determined by the load they need to carry, influenced by the beam and joist spans. Typically, they are spaced 6 to 8 feet apart, depending on the deck design and the lumber sizes used for the framing. Proper installation ensures the deck can safely support the weight of people, furniture, and snow load.

A common deck post setup involves:

- Digging holes to the required depth (below frost line).

- Placing concrete forms and pouring concrete to create footings.

- Setting galvanized post anchors into the wet concrete.

- Attaching the 6×6 posts to the anchors once the concrete has cured.

This method ensures the wood post itself does not sit directly in the soil, further protecting it from moisture and decay.

Other Outdoor Structures

Beyond fences and decks, pressure treated wood posts are integral to numerous other outdoor structures. Their strength and weather resistance make them ideal for a wide array of building projects.

Pergolas and arbors rely heavily on these posts for their main supports. These structures, often built for aesthetic appeal and shade, require robust posts to stand against gravity and wind. Typically, 4×4 or 6×6 posts are used, depending on the size and design of the pergola.

Other uses include:

- Gazebo Frames The foundational posts for gazebos are almost always pressure treated for longevity and stability.

- Playground Equipment Swing sets, fort structures, and climbing frames benefit from the inherent safety and durability of these posts.

- Garden Structures Raised garden beds, trellises, and retaining walls often incorporate pressure treated posts for support and longevity.

- Carports and Sheds The primary framing members for smaller carports or the corner supports for sheds can be made from pressure treated posts.

The ability to withstand outdoor elements means these posts can be used in nearly any application requiring ground contact or exposure to rain and sun, making them a go-to material for many DIY and professional builders.

Tips for Using Pressure Treated Wood Posts

Working with pressure treated wood posts is generally straightforward, but a few tips can ensure your project is not only successful but also safe and long-lasting. These recommendations cover handling, installation, and maintenance, helping you get the most out of your treated lumber.

This section provides practical advice for anyone using pressure treated wood posts. We’ll cover important safety considerations, best practices for installation to maximize durability, and simple maintenance tips. Following these guidelines will help you avoid common pitfalls and ensure your projects stand strong for years.

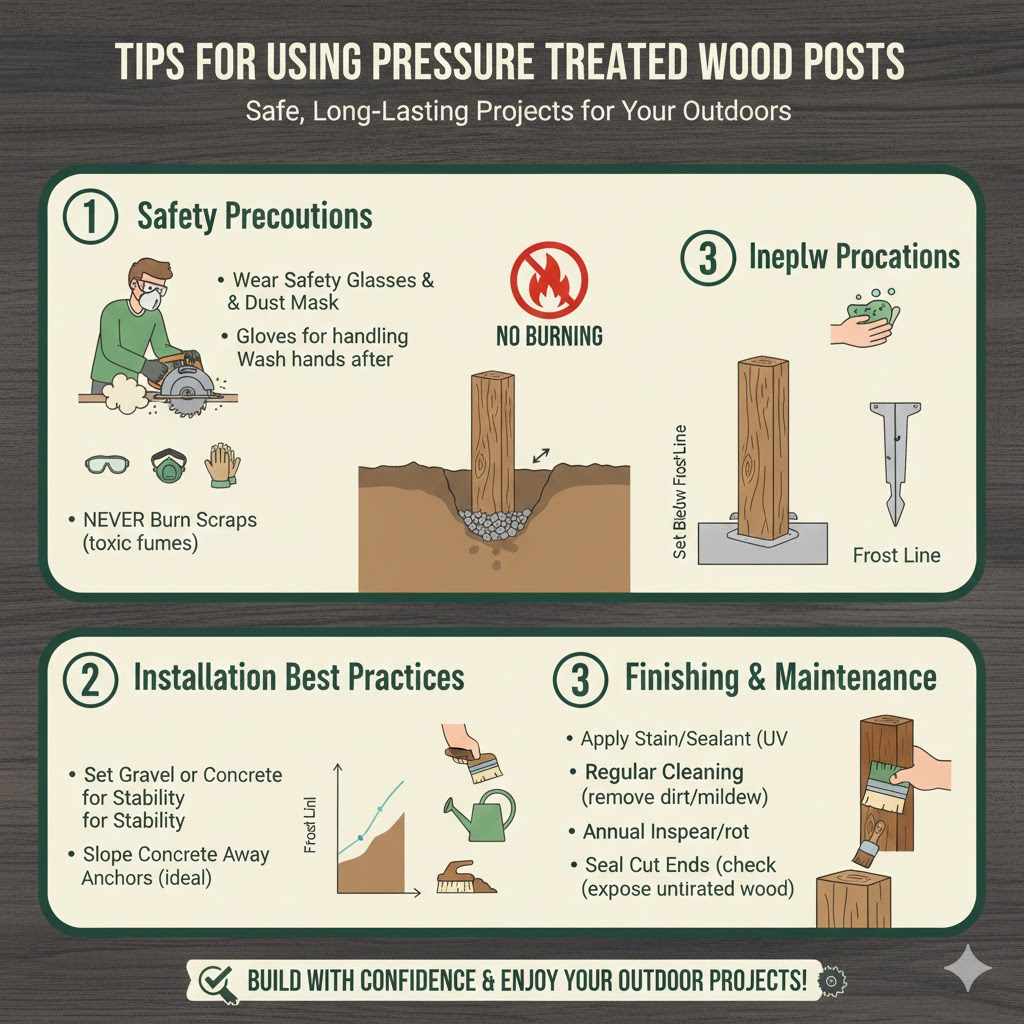

Safety Precautions When Working

While pressure treated wood is safe for its intended use in outdoor structures, there are safety precautions to observe when cutting or handling it. The chemicals used in the treatment process are designed to be inert once dried and fixed within the wood. However, during cutting, drilling, or sanding, fine sawdust particles containing these chemicals can become airborne.

It is recommended to wear safety glasses to protect your eyes from sawdust. A dust mask or respirator should be worn, especially when working in poorly ventilated areas or when creating a significant amount of sawdust. Gloves are also a good idea to prevent skin contact with the chemicals.

Wash your hands thoroughly with soap and water after handling pressure treated wood, especially before eating, drinking, or smoking. Do not burn pressure treated wood scraps, as this can release toxic fumes. Dispose of scraps responsibly according to local regulations.

It is safe to use pressure treated wood for garden beds where food is grown. However, avoid using it for cutting boards or surfaces that will come into direct contact with food.

Installation Best Practices

Proper installation is key to maximizing the lifespan and stability of your pressure treated wood posts. The most critical aspect for ground-contact posts is ensuring they are protected from constant moisture and are firmly anchored.

When setting posts in the ground, using concrete is a popular method for maximum stability, especially for decks and fences. However, for fences, tamping gravel around the post can also provide good drainage and prevent rot. If using concrete, ensure it slopes away from the post at the top to shed water.

Always set posts below the frost line in your area to prevent them from shifting or heaving due to ground freeze and thaw cycles. For decks, this is a critical building code requirement. Using galvanized metal post anchors that connect the post to a concrete footing, rather than burying the post directly, is an excellent practice.

This keeps the wood elevated off the damp concrete and soil.

Here’s a quick checklist for installation:

- Use a post hole digger or auger for clean, appropriately sized holes.

- Set posts at the correct depth, generally at least one-third of the total post length, and below the frost line for structural elements.

- Ensure posts are plumb (perfectly vertical) using a level before backfilling or pouring concrete.

- For fence posts, consider tamping gravel for drainage if not using concrete.

- Utilize galvanized post anchors for deck and structural posts to prevent direct ground contact.

Finishing and Maintenance

Pressure treated wood is designed for outdoor durability, but it can benefit from finishing and occasional maintenance. While the treatment protects against rot and insects, the wood surface can still weather, fade, and crack over time due to sun and moisture exposure.

Applying a water-repellent stain or sealant is a good idea. This helps maintain the wood’s appearance and provides an extra layer of protection against the elements. It can also help prevent excessive checking (small cracks) on the wood surface.

Choose products specifically designed for treated lumber.

Regular cleaning with a stiff brush and mild detergent can remove dirt and mildew. Inspect posts annually for any signs of damage, loose connections, or rot, especially at ground level. If you notice any issues, address them promptly.

Consider sealing cut ends of pressure treated posts. When you cut a post, you expose untreated wood. Apply a surface-applied wood preservative, such as a brand-name solution designed for this purpose, to the freshly cut ends before installation.

This ensures that the entire post is protected.

Frequently Asked Questions

Question: What is the difference between a 4×4 and a 6×6 pressure treated post?

Answer: A 4×4 post has nominal dimensions of 4 inches by 4 inches, but its actual dimensions are usually around 3.5 inches by 3.5 inches after processing. A 6×6 post has nominal dimensions of 6 inches by 6 inches, with actual dimensions closer to 5.5 inches by 5.5 inches. The 6×6 is significantly larger, stronger, and more stable.

Question: How deep should I bury pressure treated fence posts?

Answer: For most fences, burying at least one-third of the post’s total length is recommended. For a 6-foot tall fence, an 8-foot post buried 2 feet deep is common. Ensure posts are set deep enough for stability, especially in windy areas.

Question: Can I use pressure treated wood for garden beds where I grow vegetables?

Answer: Yes, it is generally considered safe to use pressure treated wood for garden beds, even for growing vegetables. Modern treatments use chemicals like alkaline copper quaternary (ACQ) or copper azole (CA), which are stable and do not leach into the soil in amounts harmful to plants or people. However, avoid using older treated wood, which might contain chromium.

You can also add a liner if you prefer.

Question: Do I need to seal pressure treated wood posts?

Answer: Sealing is not strictly required for the structural integrity of pressure treated wood, as it’s designed to resist rot and insects. However, applying a water-repellent stain or sealant can help preserve its appearance, prevent surface checking, and offer an additional layer of protection against UV rays and moisture, extending its aesthetic life.

Question: What is the lifespan of a pressure treated wood post?

Answer: With proper installation and reasonable care, pressure treated wood posts can last anywhere from 15 to 30 years, sometimes even longer. Factors like soil conditions, climate, and whether the post is in constant contact with standing water can affect their lifespan. Posts set in concrete or on metal anchors tend to last longer.

Summary

Pressure treated wood posts are a reliable and durable choice for many outdoor projects. Understanding their sizes, common uses, and best practices for installation ensures your projects are strong and long-lasting. From fences and decks to pergolas, selecting the right post dimensions and burying them correctly will set you up for success.

Remember to prioritize safety during handling and finishing your posts for lasting beauty and performance.