Replacing Wood Spindles With Metal: An Evaluation of Options

Thinking about Replacing Wood Spindles With Metal: Is It Worth It?? It can seem like a big project, especially if you’re new to home improvements. Wood spindles are classic, but metal ones offer a different look and different strengths. There’s a lot to consider: the styles, costs, and effort involved. Don’t worry, though. This guide makes the process straightforward. You’ll explore the main considerations, making it easy to decide if this update is right for your home. Let’s get started!

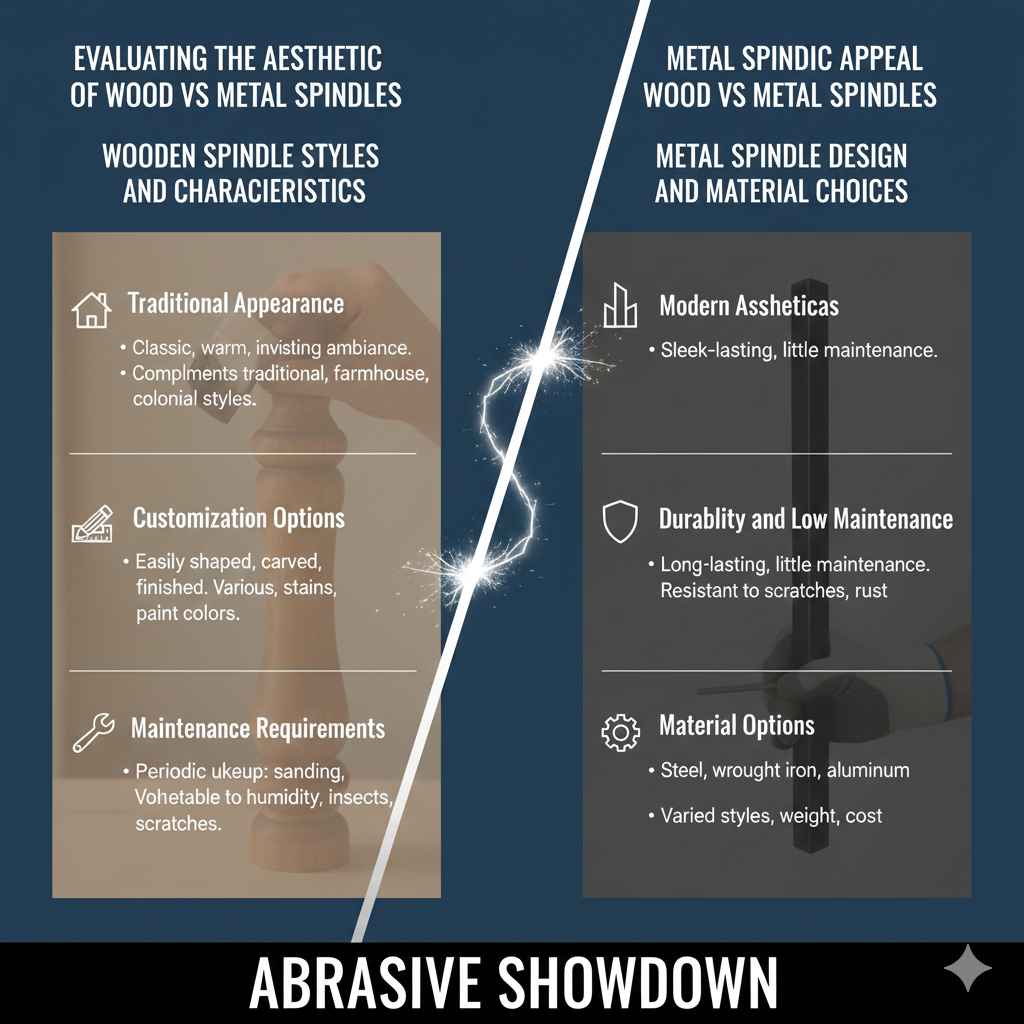

Evaluating the Aesthetic Appeal of Wood vs Metal Spindles

The visual impact of spindles is a primary concern for homeowners. Wood spindles have been a staple for ages, bringing a sense of warmth and traditional charm. They come in many shapes, sizes, and finishes, so matching existing styles or creating new ones is simple. On the other hand, metal spindles offer a more modern and streamlined look.

They can be powder-coated in various colors, adding a contemporary touch. The design choices, from simple bars to ornate patterns, can greatly influence the overall design of your space. Choosing between wood and metal often hinges on personal preferences and the home’s existing aesthetic.

Wooden Spindle Styles and Characteristics

Wood spindles offer many options for customization, making them adaptable to different tastes. They can be turned on a lathe to create intricate designs or left simple and sleek. Popular styles include colonial, craftsman, and Victorian, each with its unique details and patterns. Wooden spindles can be painted, stained, or varnished to match any decor. The natural grain of the wood adds visual texture, providing warmth and a classic feel. However, they require ongoing care to maintain their appearance and prevent damage.

Traditional Appearance: Wood spindles enhance a classic, warm, and inviting ambiance.

Wood spindles naturally complement a wide array of interior design styles, including traditional, farmhouse, and colonial designs. The natural warmth of wood is visually appealing and creates a cozy environment. Additionally, the availability of different wood types and finishing options lets you customize your staircase to perfectly match your home’s color palette and decor.

Customization Options: Wood is easily shaped, carved, and finished to match specific design needs.

Wood’s versatility lets you choose between various finishes, stains, and paint colors. You can easily select a color that perfectly matches your decor or opt for a unique wood grain that adds character. With the right tools and craftsmanship, you can create unique spindles that complement any design, be it classic or modern.

Maintenance Requirements: Wood requires periodic upkeep like sanding, staining, or painting to prevent wear and damage.

Wood is affected by changes in humidity and temperature, causing it to expand or contract. Regular inspections are critical to prevent cracks or warps. Proper sealing and finishing are essential for protection. Wood spindles can be subject to scratches and dents, and they can be vulnerable to wood-boring insects. Periodic maintenance keeps them looking their best.

Metal Spindle Design and Material Choices

Metal spindles bring a different set of design options. They are favored for a more modern, clean aesthetic. Metal spindles are commonly made of wrought iron, steel, or aluminum. These materials offer strength and durability. They are often powder-coated to resist rust and come in various shapes, like straight bars, twists, or decorative patterns. These choices offer options that complement contemporary and industrial design styles. Metal spindles may not offer the same degree of customization as wood, they make up for it with longevity and a distinct visual appeal.

Modern Aesthetics: Metal spindles often create a sleek, minimalist, or industrial aesthetic.

Metal spindles are known for their clean lines and modern appearance, making them ideal for contemporary settings. The look is well-suited to minimalist interiors or industrial designs. They can be powder-coated in a wide range of colors. They seamlessly integrate with a variety of design schemes, including modern, industrial, and minimalist.

Durability and Low Maintenance: Metal spindles are usually very long-lasting and require little maintenance.

Metal spindles are resistant to scratches, dents, and weathering, unlike wood spindles that need to be regularly maintained. They are usually powder-coated to resist rust. This means you do not have to worry about sanding, painting, or staining. Metal spindles are an excellent choice for those seeking a low-maintenance, long-lasting solution.

Material Options: Different metals, like steel, wrought iron, and aluminum, offer varied styles and cost levels.

The material impacts the appearance, weight, and cost. Wrought iron provides a classic, ornate style, while steel provides strength and a modern appeal. Aluminum is a lightweight option that’s resistant to rust. The choice impacts the overall feel and budget. Consider the design, the required level of upkeep, and your budget when selecting the ideal metal for your spindles.

Cost Evaluation: Wood vs Metal Spindles

Budget plays a massive role in making the decision about Replacing Wood Spindles With Metal: Is It Worth It? The costs of wood and metal spindles differ. Wood spindles often have lower upfront costs. This is especially true for simpler styles and materials. Metal spindles, particularly those made of wrought iron or with intricate designs, can cost more initially.

You must consider installation costs, including labor, and any professional help needed. Additionally, you should consider long-term expenses, like maintenance and repairs. Your choice can impact the overall project budget, the value of your property, and your financial planning.

Estimating Wood Spindle Costs

The cost of wood spindles varies, depending on wood type, design complexity, and finish options. Simple, straight spindles made from pine or similar woods will be less costly than more detailed styles made from hardwoods like oak or maple. The finish also affects the price. Staining or painting adds to the material costs. Installation is another factor; DIY projects will save money on labor, while hiring a professional can add significant expense.

It is essential to get estimates from multiple sources to compare prices and ensure they fit your budget. Local lumberyards and home improvement stores are good starting points for cost estimates.

Material Costs: The type of wood and design complexity are important factors.

Cheaper options might include pine or fir, while more expensive options might include hardwoods like oak and maple. The design of the spindle also affects the price. Simple, straight spindles are usually cheaper than those with carvings, turnings, or other decorative elements. Comparing the prices of several materials and design options helps you find an affordable choice.

Installation Costs: Consider the expense of a professional versus DIY installation.

Professional installation often costs more, but it guarantees a polished finish and compliance with safety standards. For homeowners with some DIY experience, installing wooden spindles can be a cost-effective option. You will need to consider the tools and time needed for installation. The cost of installation will vary, based on the local labor rate and the complexity of the job. Obtain estimates from several contractors before deciding.

Long-term Expenses: Maintenance requirements of wood contribute to the total cost.

Wooden spindles need regular maintenance, including sanding, staining, or painting, which adds to the long-term cost. Wood spindles can be damaged by wear and tear, humidity changes, and pests. Properly maintaining wooden spindles will preserve their appearance and lifespan. Factor in these costs to get a complete view of the total expenses over time.

Metal Spindle Price Factors

Metal spindle pricing differs, depending on the material, design, and finish. Steel and aluminum are generally less costly than wrought iron, which has more labor involved and is known for its intricate designs. Powder coating can add to the cost, but it provides a durable, low-maintenance finish. Installation can be simpler than with wood, but it still varies, based on design complexity and the installer’s expertise.

Shop around and compare prices for materials, finishes, and installation services. Research and planning will lead to savings and satisfaction.

Material and Design: The material and design complexity impacts the cost.

Wrought iron, known for its intricate designs, tends to be more costly than steel or aluminum. The design’s detail affects the production process. A simple, straight design is more affordable than a design with curves, twists, or decorative elements. The choice of material and design will impact the overall cost of your project, so think carefully about your budget and aesthetic preferences.

Installation Costs: Labor and expertise influence the installation price.

Installing metal spindles may require welding or other specialized techniques, which could impact the installation cost. Prices change based on the installer’s experience and the scope of the project. Always get several quotes. DIY installations might save on labor costs. Make sure you have the skills and tools before trying it.

Maintenance Costs: Low maintenance lowers the total expenses over time.

Metal spindles are known for their low maintenance requirements. Powder coating is designed to protect the metal. They do not need the regular painting or staining that wood spindles need. This is a big advantage over time. While the upfront cost may be higher, metal spindles provide savings on maintenance, making them cost-effective in the long run.

Durability and Safety Considerations for Spindle Materials

The strength and safety of your spindles are major considerations. Spindles have to hold up against daily wear and tear. Metal spindles are known for their durability and resistance to damage, making them a good option for homes with kids or pets. Wood spindles offer a classic appeal. Regular upkeep is vital to keep them safe and durable. The design and installation affect the safety of the balustrade. Ensuring compliance with local building codes, professional installation, and routine checks will help guarantee your home’s safety.

Strength and Longevity of Wood Spindles

Wood spindle strength varies, based on the type of wood and construction quality. Hardwoods are usually more durable than softwoods. Wood spindles can be subject to damage. They can be prone to scratches, dents, and wear over time. Weather conditions, like humidity and temperature changes, can lead to cracking, warping, and loosening of the spindles.

Regular inspections, preventative maintenance, and timely repairs keep them safe and functional for years. Choosing high-quality wood and correct installation practices are key to extending the life of your wood spindles.

Wood Types: The type of wood used impacts durability and strength.

Hardwoods, like oak and maple, offer better strength and durability than softwoods like pine and fir. The wood’s density and grain pattern contribute to its ability to resist damage. Select the best wood for your needs. Consider the design, location, and how much traffic the area sees. Ensure the spindles are installed correctly and are well-maintained for maximum life.

Maintenance Impact: Routine maintenance preserves structural integrity.

Wood spindles need regular upkeep to maintain their integrity and appearance. Sanding and refinishing keep the surface protected from wear and weather. Regular inspection detects early signs of problems, like cracks or loose connections. Timely repairs prevent minor issues from becoming major, costly problems. Proper maintenance extends the lifespan of the spindles and ensures safety.

Environmental Factors: Humidity and weather impact wood spindles.

Wood expands and contracts with changes in humidity and temperature. Exposure to sunlight, rain, and snow can cause damage, like warping, splitting, and rot. Protecting wood spindles with proper finishes, like paint or sealant, can minimize the effects of weather. Installing spindles in a sheltered area helps, too. Consistent care ensures the spindles withstand the elements and maintain their safety and appearance.

Metal Spindle Durability and Safety Features

Metal spindles offer exceptional durability. They are known for being strong and needing little upkeep. Metals like steel and wrought iron are resistant to damage, including scratches, dents, and environmental factors. Metal spindles are less affected by humidity and temperature changes. They provide a long-lasting, low-maintenance option for homeowners.

The powder-coated finishes improve resistance to rust and corrosion, extending their lifespan. Correct installation is important to ensure their stability and safety. These factors all contribute to a safer, more durable stair system.

Material Resistance: Metal spindles resist wear, damage, and environmental factors.

Steel and wrought iron are very durable and resistant to scratches, dents, and other common forms of wear and tear. They are not affected by humidity and temperature changes the way wood is. Metal spindles are ideal for high-traffic areas and homes with children or pets. They maintain their appearance and structural integrity for years. Powder coating adds another layer of protection.

Installation Importance: Proper installation is essential for safety.

Metal spindles should be installed by professionals. They will ensure proper alignment, spacing, and fastening to meet local building codes. Securely installed spindles prevent wobbling or instability, which could be a safety hazard. Proper installation extends the lifespan and ensures that the spindles offer maximum safety and protection for the users.

Code Compliance: Ensure the balustrade design meets local safety standards.

Compliance with local building codes is critical. They set the standards for spindle spacing, height, and handrail requirements. A professional installer should be familiar with these rules. They will guarantee that the balustrade meets the necessary safety measures. Regular checks and maintenance help to maintain the balustrade’s safety and functionality over time. A properly constructed and maintained balustrade gives you safety and peace of mind.

The Installation Process: Wood Versus Metal

The installation process varies, based on the type of spindles you choose. Understanding the steps can help you assess the difficulty and decide whether to handle the project yourself or hire a professional. Wood spindle installation requires accurate measurements, cutting, and securing the spindles in place. Metal spindle installation often includes welding or using specialized fasteners. While some homeowners opt for a DIY approach, others choose professional installers for accuracy, safety, and code compliance. No matter your choice, planning, the right tools, and following detailed instructions are essential for a successful outcome.

Installing Wood Spindles: Step-by-Step Guide

Installing wood spindles requires a methodical approach. Start with precise measurements to ensure that the spindles are evenly spaced and fit the railing height. Securely attach the base rail and top rail to the existing structure. Measure, cut, and install the spindles. Fasten the spindles to the top and bottom rails using appropriate methods, like wood glue, screws, or dowels.

Verify the alignment, make adjustments if needed, and ensure that the installation meets building codes. The finish will improve the look of the spindles and protect them from wear. A good installation requires planning and a keen attention to detail.

Measure and Plan: Take careful measurements and sketch out your design.

Measure the space where the spindles will go, including the length of the railing and the required height. Decide on the spacing between the spindles, considering the aesthetics and safety codes. Create a detailed plan that will help you throughout the installation.

Prepare the Rails: Securely attach the top and bottom rails.

Attach the top and bottom rails to the posts and the staircase structure using screws or other suitable fasteners. Verify that the rails are level and properly aligned. Make sure the installation is solid, as the rails are the base for the spindles.

Cut and Install Spindles: Place and secure the spindles.

Measure and cut the spindles to the correct length. Securely attach the spindles to the top and bottom rails. Use wood glue and screws. Double-check the alignment to make sure the spindles are straight and evenly spaced.

Finishing Touches: Sand, stain, or paint the spindles.

Once the spindles are installed, sand them to smooth out any rough edges or imperfections. If you are staining the spindles, apply the stain evenly and let it dry. If you are painting the spindles, apply a primer and several coats of paint for a durable finish.

Metal Spindle Installation Methods

Metal spindle installation usually requires more specialized tools and techniques than wood spindles. Depending on the design and material, the installation may involve welding, bolting, or using special fasteners. Professional installers have the experience and equipment to handle these tasks safely and efficiently.

The base and top rails must be prepared to accept the metal spindles. Precise measurements and alignment are essential. Follow safety guidelines when working with metal and power tools. If you are not familiar with these techniques, it’s usually best to hire a professional for metal spindle installation.

Prepare the Rails: Make sure the rails are ready.

The top and bottom rails must be prepared to accept the metal spindles. This may involve drilling holes or welding brackets. Ensure that the rails are straight, level, and securely attached to the posts.

Install the Spindles: The spindles must be set up correctly.

The metal spindles are then set in place. This could involve welding, bolting, or using special fasteners. Make sure the spindles are vertically straight and evenly spaced. Make certain that the installation is strong and meets safety standards.

Finishing: Make the final touches.

After the spindles are installed, the welds or fasteners should be checked. If necessary, touch up the paint or powder coating to blend the installation. Make sure the spindles are stable and securely fastened. The final product should be both aesthetically pleasing and safe.

Frequently Asked Questions

Question: Are metal spindles stronger than wood spindles?

Answer: Generally, metal spindles, particularly those made of steel or wrought iron, are stronger and more durable than wood spindles. They’re more resistant to impacts and wear.

Question: Can I install metal spindles myself, or do I need a professional?

Answer: Metal spindle installation often requires specialized tools and skills, such as welding. It’s usually best to hire a professional for safety and code compliance.

Question: Do metal spindles require less maintenance than wood spindles?

Answer: Yes, metal spindles typically require less maintenance. They are often powder-coated to prevent rust and require no painting or staining.

Question: What’s the best metal for spindles in terms of durability and looks?

Answer: Steel and wrought iron are excellent choices for durability. Wrought iron offers a classic look, while steel provides a more modern appearance. The best choice depends on your design preferences.

Question: How do I measure for new spindles when replacing old ones?

Answer: Carefully measure the height from the base rail to the top rail and the space between the posts. Ensure that your measurements are accurate and consistent to guarantee the new spindles fit well.

Final Thoughts

Deciding if Replacing Wood Spindles With Metal: Is It Worth It? comes down to personal taste and practical considerations. Wood spindles offer traditional charm and are easy to customize with paint or stain. Metal spindles give a more modern aesthetic and are generally more durable and low-maintenance. Weigh the aesthetic preferences, budget, and desired level of upkeep. Wood may be a good choice if you like traditional design and are prepared for regular care. If a modern style, longevity, and low maintenance are the goals, metal might be best.

Carefully explore your options, consider all factors, and find the perfect balance for your home. Ultimately, the best choice enhances the visual appeal and improves the value of your property. If you’re ready, start researching local suppliers and installers today. That way, you can get started with your project. Get creative, and enjoy the process!