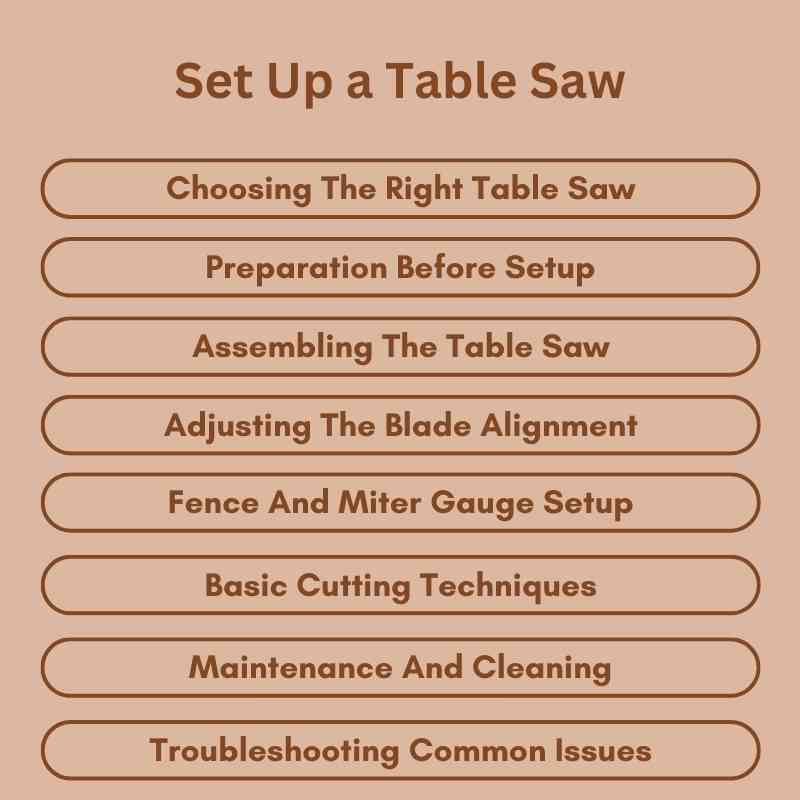

Set Up a Table Saw: Essential Tips for Beginners

To set up a table saw, start by placing it on a stable surface. Ensure the blade is aligned and the fence is square to the table.

Setting up a table saw correctly is crucial for safety and precision in woodworking. This powerful tool can create clean, straight cuts when properly calibrated. A well-set table saw enhances the quality of your work and minimizes the risk of accidents.

Taking the time to adjust the blade height and angle will ensure optimal performance. Understanding your specific model’s features is essential for effective setup. Regular maintenance and checks can prolong the life of your saw. Whether you’re a beginner or an experienced woodworker, mastering table saw setup will significantly improve your projects. Follow these steps to achieve accuracy and efficiency.

Choosing The Right Table Saw

Choosing the right table saw is crucial for any woodworking project. The right tool enhances precision and safety. Understanding types and key features helps in making an informed choice.

Types Of Table Saws

Table saws come in various types. Each serves different needs. Here’s a breakdown of the main types:

- Benchtop Table Saws: Portable and lightweight. Ideal for small projects.

- Contractor Table Saws: More powerful. Suitable for job sites and home workshops.

- Cabinet Table Saws: Heavy-duty and sturdy. Best for professional woodworkers.

- Hybrid Table Saws: Combines features of cabinet and contractor saws. Great for versatility.

Key Features To Consider

Several key features affect the performance of a table saw. Focus on these aspects before buying:

| Feature | Description |

|---|---|

| Motor Power | Higher power allows for smoother cuts. |

| Blade Size | Common sizes are 10-inch and 12-inch. |

| Rip Capacity | Measure the width of material the saw can cut. |

| Safety Features | Look for blade guards and emergency shut-off. |

| Portability | Consider weight and ease of transport. |

Evaluate these features carefully. The right combination enhances your woodworking experience.

Preparation Before Setup

Setting up a table saw requires careful planning. Proper preparation ensures safety and efficiency. Follow these steps to get started.

Selecting The Workspace

Choose a suitable workspace for your table saw. The right location makes a big difference. Here are key factors to consider:

- Space: Ensure enough room around the saw.

- Surface: Use a stable and level work surface.

- Lighting: Good lighting helps you see clearly.

- Ventilation: Proper airflow keeps dust levels low.

- Accessibility: Keep tools and materials within reach.

Safety Gear Essentials

Wearing the right safety gear is crucial. Protect yourself from potential hazards. Here’s a list of essential safety gear:

| Safety Gear | Description |

|---|---|

| Safety Glasses | Protect your eyes from flying debris. |

| Hearing Protection | Reduce noise exposure while cutting. |

| Dust Mask | Prevent inhalation of harmful dust particles. |

| Gloves | Protect hands from sharp edges. |

| Steel-Toed Boots | Protect your feet from heavy objects. |

Check your safety gear for any damage. Replace worn-out items before starting. Always prioritize your safety.

Assembling The Table Saw

Setting up your table saw correctly is crucial for safety and efficiency. The assembly process may seem daunting, but following the right steps makes it easy. This section will guide you through unboxing and identifying parts, followed by a step-by-step assembly guide.

Unboxing And Parts Identification

Unboxing your table saw is the first step. Carefully open the box and inspect all items. Ensure you have everything needed for assembly. Here’s a list of common parts you should find:

- Table Saw Body

- Table Extension

- Blade Guard

- Rip Fence

- Power Switch

- Blade

- Legs or Stand

- Wrenches and Tools

Check for any missing parts. Refer to the manual for guidance. Having all parts will make assembly smoother.

Step-by-step Assembly Guide

Follow these steps to assemble your table saw:

- Attach the Legs: Secure the legs or stand to the table saw body.

- Install the Table Extension: Align and attach the table extension to the main body.

- Mount the Blade: Use the included wrenches to attach the blade securely.

- Set the Rip Fence: Slide the rip fence onto the table and lock it in place.

- Connect the Power Switch: Ensure the power switch is installed correctly.

- Check the Blade Guard: Attach the blade guard for safety.

After assembly, double-check all parts. Ensure everything is tight and secure. Your table saw is now ready for use!

Adjusting The Blade Alignment

Proper blade alignment is crucial for accurate cuts. A misaligned blade can lead to uneven edges and unsafe operation. Adjusting the blade alignment ensures your table saw performs optimally.

Measuring Blade Parallelism

Measuring blade parallelism helps determine how well the blade aligns with the miter slot. Follow these simple steps:

- Use a tape measure or a straightedge.

- Measure the distance from the blade to the miter slot at the front.

- Repeat the measurement at the back of the blade.

Record both measurements. The difference should be minimal. Ideally, the blade should be parallel to within 1/64 inch.

Making Precise Adjustments

Adjusting the blade requires careful steps. Follow these instructions for precise alignment:

- Loosen the mounting bolts on the blade.

- Use a wrench to adjust the tilt of the blade.

- Check measurements again.

Repeat this process until the measurements match closely. Tighten the bolts securely once you achieve proper alignment.

Regularly check your blade alignment. This practice maintains accuracy and safety during use.

Fence And Miter Gauge Setup

Setting up your table saw correctly is essential for safety and accuracy. The fence and miter gauge are crucial tools. Proper setup helps achieve precise cuts. Follow these steps to ensure your tools are ready for use.

Calibrating The Rip Fence

The rip fence guides the wood for straight cuts. To calibrate it:

- Check the alignment of the fence with the blade.

- Use a square to measure the distance from the blade to the fence.

- Adjust the fence until it is parallel to the blade.

Here are some tips for calibration:

- Ensure the blade is sharp and clean.

- Tighten all screws and bolts on the fence.

- Recheck the alignment after any adjustments.

Calibrating the rip fence improves cutting accuracy. A well-aligned fence enhances your woodworking projects.

Setting Up The Miter Gauge

Basic Cutting Techniques

Understanding basic cutting techniques is vital for effective table saw use. Master these methods to achieve precise cuts. This section covers two main techniques: crosscuts and rips. You’ll also learn how to make your first cut safely and accurately.

Making Your First Cut

Before making your first cut, ensure your table saw is set up correctly. Follow these steps for a safe start:

- Check the blade height. Set it to just above the material.

- Align the fence parallel to the blade. This ensures straight cuts.

- Stand to the side of the blade. Avoid standing directly in front.

- Use push sticks for small pieces. Keep hands away from the blade.

Once you’re ready, place the wood against the fence. Turn on the saw and feed the wood slowly. Maintain a steady pace for a clean cut.

Crosscuts And Rips

Crosscuts and rips are two essential cutting techniques.

| Technique | Description | Best Uses |

|---|---|---|

| Crosscut | Cutting across the grain of the wood. | Shortening boards, making frames. |

| Rip Cut | Cutting along the grain of the wood. | Widening boards, making shelves. |

For crosscuts, use a crosscut sled or miter gauge. These tools help keep your cuts straight. For rip cuts, adjust the fence to the desired width. Always push the material through, maintaining control.

Practice these techniques to become confident. Proper technique leads to better projects and safer operation.

Maintenance And Cleaning

Keeping your table saw in top shape ensures safety and performance. Regular maintenance and cleaning extend its lifespan. This section covers essential tips for keeping your table saw clean and functional.

Routine Cleaning Tips

Regular cleaning prevents dust and debris buildup. Follow these simple steps:

- Disconnect the power before cleaning.

- Use a soft brush to remove sawdust from the table.

- Wipe down surfaces with a damp cloth.

- Clean the blade with a specialized cleaner.

- Check the miter gauge for debris buildup.

Perform these tasks after every use. Set a schedule for a deep clean every month.

Lubrication And Rust Prevention

Proper lubrication keeps your table saw running smoothly. It also prevents rust.

| Component | Lubrication Method | Frequency |

|---|---|---|

| Blade | Apply lubricant spray | Every use |

| Pivot points | Use machine oil | Monthly |

| Table surface | Wax or silicone spray | Every few months |

Store your table saw in a dry area. Use a cover to protect it from moisture.

Regular maintenance and cleaning ensure optimal performance. Keep your workspace safe and efficient.

Troubleshooting Common Issues

Setting up a table saw is essential for precise woodworking. Sometimes, problems arise. Identifying and fixing these issues helps improve your work quality.

Blade Stalling

Blade stalling is frustrating. It can halt your project. Here are common reasons for blade stalling:

- Dull Blade: A dull blade struggles to cut through materials.

- Improper Speed: Running the saw at the wrong speed can cause stalling.

- Material Too Thick: Cutting thick wood may overload the blade.

- Incorrect Alignment: Misalignment can create extra resistance.

To fix blade stalling:

- Inspect the blade for dullness.

- Sharpen or replace the blade if needed.

- Adjust the saw’s speed settings.

- Ensure proper material thickness.

- Align the blade correctly.

Inaccurate Cuts

Inaccurate cuts can ruin your project. These mistakes often stem from various issues:

- Incorrect Measurements: Always double-check your measurements.

- Unstable Workpiece: An unstable piece leads to poor cuts.

- Improper Fence Alignment: The fence must be parallel to the blade.

- Poor Technique: Use consistent pressure while cutting.

To achieve accurate cuts:

- Measure twice before cutting.

- Secure your workpiece firmly.

- Check fence alignment before each cut.

- Practice proper cutting techniques.

Advancing Your Skills

To become a master woodworker, advancing your skills is essential. A table saw is a powerful tool that opens up new possibilities. Mastering advanced techniques will enhance your projects. Let’s dive into two key areas: advanced cuts and precision tools.

Learning Advanced Cuts

Advanced cuts expand your woodworking capabilities. These cuts include:

- Bevel Cuts: Angled cuts for unique designs.

- Compound Cuts: Combining bevel and miter cuts.

- Dado Cuts: Grooves for joining pieces securely.

- Rabbet Cuts: Notches along edges for fitting.

Practice these cuts on scrap wood first. Familiarize yourself with the saw settings. Here’s a quick guide:

| Cut Type | Best Use |

|---|---|

| Bevel Cut | Creating angles for frames |

| Compound Cut | Complex joints and moldings |

| Dado Cut | Strong joints in shelves |

| Rabbet Cut | Fitting boards together |

Jigs And Fixtures For Precision

Using jigs and fixtures improves accuracy. They help keep your cuts straight and consistent. Here are some popular options:

- Crosscut Sled: For precise crosscuts.

- Dado Jig: For perfect dado cuts.

- Miter Jig: For angled cuts with ease.

Building your own jigs can be rewarding. Follow these steps to create a simple crosscut sled:

- Cut a flat base from plywood.

- Attach a fence at a right angle.

- Add runners to fit the table saw’s slots.

- Test for accuracy with a straight cut.

Invest time in learning these skills. They will greatly improve your woodworking projects.

Frequently Asked Questions

How Do I Set Up A Table Saw?

To set up a table saw, start by placing it on a stable surface. Ensure the blade is aligned with the miter gauge. Adjust the fence to the desired width, and check that the blade height is suitable for the material.

Always double-check safety features before use.

What Safety Gear Do I Need For Using A Table Saw?

When using a table saw, wear safety goggles, ear protection, and a dust mask. Additionally, use anti-slip footwear and avoid loose clothing. These safety measures protect you from flying debris and noise. Always prioritize safety to prevent accidents during operation.

How Do I Adjust The Blade Height?

To adjust the blade height, locate the blade raising mechanism on your table saw. Turn the handwheel or lever until the blade is at the desired height. Ensure the blade is just above the material you plan to cut. This adjustment improves cutting efficiency and safety.

What Is The Purpose Of The Miter Gauge?

The miter gauge helps in making accurate angled cuts. It slides along the table’s slots for precise positioning. By adjusting the angle, you can create perfect crosscuts or bevels. This tool is essential for achieving professional-quality results in woodworking projects.

Conclusion

Setting up a table saw correctly is essential for safe and precise woodworking. By following the steps outlined, you can ensure optimal performance and accuracy. A well-calibrated table saw will enhance your projects and boost your confidence. Take your time during setup, and enjoy the process of creating with your new tool.