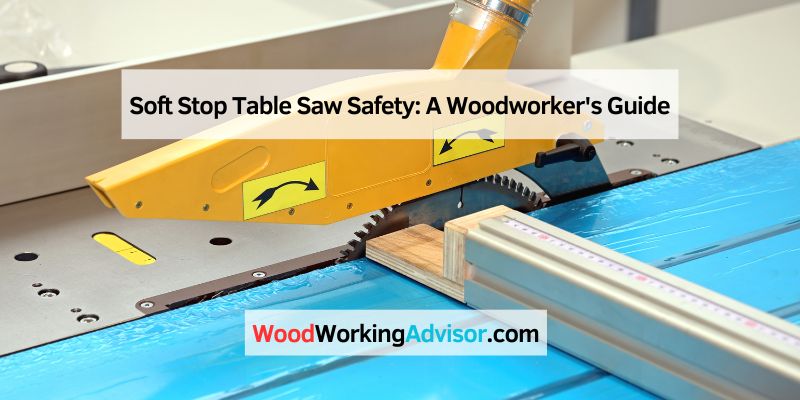

Soft Stop Table Saw Safety: A Woodworker’s Guide

A soft stop table saw features a braking system that minimizes blade movement after a cut. This design enhances user safety by preventing accidental injuries.

Table saws are essential tools for woodworkers, offering precision and efficiency in cutting materials. The soft stop feature adds an extra layer of safety, making it a preferred choice for both professionals and hobbyists. By automatically stopping the blade’s movement, these saws reduce the risk of blade-related accidents.

This technology not only protects users but also ensures smoother, more controlled cuts. For those seeking to upgrade their workshop, a soft stop table saw represents a smart investment. With proper care and maintenance, these saws can enhance your woodworking projects while keeping safety a top priority.

The Evolution Of Table Saw Safety

Table saws are vital tools in woodworking. They are powerful but can be dangerous. Over the years, safety features have improved greatly. This section explores the journey of table saw safety innovations.

Early Beginnings

In the early days, table saws lacked safety features. Craftsmen relied on skill and caution. Many accidents occurred due to the absence of protection. Some common early safety practices included:

- Using push sticks to keep hands away.

- Wearing protective gear like gloves and goggles.

- Working with a partner for added safety.

Despite these measures, injuries were frequent. The need for better safety became clear.

Modern Innovations

Today, table saws feature advanced safety technology. Innovations make woodworking safer and easier. Key modern safety features include:

| Feature | Description |

|---|---|

| Soft Stop Technology | Stops the blade quickly to prevent injury. |

| Blade Guard | Covers the blade to protect users from accidental contact. |

| Anti-kickback Pawls | Prevents wood from being pushed back towards the user. |

| Electric Brake System | Stops the blade instantly upon contact. |

These innovations help prevent serious injuries. They provide peace of mind for woodworkers. The evolution of table saw safety continues to shape the industry.

Understanding Soft Stop Technology

Soft Stop Technology is a groundbreaking feature in table saws. It enhances safety and precision while working with wood. This technology reduces the risk of accidents, making it ideal for all skill levels.

How It Works

Soft Stop Technology uses advanced sensors to detect blade contact. If the blade touches skin, the system reacts quickly. Here’s how it operates:

- Detection: Sensors monitor the blade’s position.

- Reaction: Upon contact, the saw stops immediately.

- Retraction: The blade retracts slightly, minimizing injury.

This technology ensures that woodworkers can focus on their projects without fear. The system is designed for quick and safe operation.

Benefits For Woodworkers

Soft Stop Technology offers numerous advantages for woodworkers:

- Enhanced Safety: Reduces the risk of serious injuries.

- Improved Precision: Allows for more accurate cuts.

- Increased Confidence: Users feel secure while operating the saw.

- Quick Recovery: Easy to reset after a stop.

With these benefits, woodworkers can work more efficiently. Soft Stop Technology truly transforms the table saw experience.

Comparing Soft Stop With Traditional Safety Measures

Understanding the differences between Soft Stop technology and traditional safety measures is crucial. Both aim to protect users from injuries. However, their methods and effectiveness vary significantly.

Brake Mechanisms

Brake mechanisms are essential for table saw safety. Soft Stop uses advanced technology to stop the blade quickly. Traditional saws rely on manual methods to halt operations.

| Feature | Soft Stop | Traditional |

|---|---|---|

| Reaction Time | Instant | Delayed |

| Injury Prevention | High | Moderate |

| Maintenance | Low | High |

Soft Stop’s brake mechanism detects skin contact. It stops the blade within milliseconds. This minimizes injury risk. Traditional methods often fail to stop in time. They may rely on user awareness and reflexes.

Protective Covers

Protective covers are another important safety feature. Soft Stop integrates a cover that shields users from the blade. This design ensures maximum protection during operation.

- Soft Stop Covers:

- Easy to adjust

- Durable materials

- Enhanced visibility

- Traditional Covers:

- Often cumbersome

- Limited visibility

- May obstruct the work area

Using Soft Stop’s protective covers offers more flexibility. They do not hinder the workflow. Traditional covers can sometimes make tasks harder. Users may struggle with visibility or access.

Real-life Impact: Soft Stop In Action

The Soft Stop Table Saw revolutionizes safety in woodworking. This technology saves fingers and reduces injuries. Many professionals share their experiences with this innovative saw.

Case Studies

Real-world examples highlight the effectiveness of the Soft Stop feature. Below are case studies from various users:

| Case Study | Description | Outcome |

|---|---|---|

| Builder’s Workshop | A builder accidentally touched the blade. | Soft Stop activated, preventing injury. |

| Home DIY Project | A novice user made a quick cut. | Soft Stop engaged, saving their fingers. |

| Professional Woodshop | Experienced carpenter misjudged a cut. | Soft Stop reacted quickly, avoiding a serious accident. |

Testimonials From Professionals

Many professionals trust the Soft Stop Table Saw. Here are some of their thoughts:

- John, Carpenter: “I feel safer using this saw. It protects my hands.”

- Lisa, Furniture Maker: “My workshop saw fewer accidents since I switched.”

- Tom, Builder: “The Soft Stop saved my finger. I recommend it to everyone.”

These testimonials showcase how the Soft Stop feature impacts safety. Users appreciate the peace of mind it brings. This technology is changing woodworking for the better.

Installation And Maintenance

Proper installation and maintenance ensure your Soft Stop Table Saw operates effectively. Follow these steps to set up and care for your table saw. A well-maintained saw enhances safety and performance.

Setting Up Your Soft Stop

Setting up your Soft Stop Table Saw requires careful attention. Follow these steps for a smooth setup:

- Unpack the saw and check all parts.

- Choose a stable and level surface.

- Assemble the saw according to the manual.

- Ensure the blade is properly aligned.

- Connect the power source securely.

After setup, perform a test run. Make adjustments as needed for accuracy.

Regular Maintenance Tips

Regular maintenance keeps your Soft Stop Table Saw in top shape. Follow these tips:

- Clean the saw: Remove dust and debris after each use.

- Inspect the blade: Check for dullness or damage regularly.

- Lubricate moving parts: Use appropriate lubricant on bearings.

- Check alignment: Ensure the blade remains aligned with the fence.

- Replace worn parts: Address any damaged components promptly.

Set a maintenance schedule to keep track of these tasks. Regular upkeep enhances safety and functionality.

Safety First: Best Practices For Using A Soft Stop Table Saw

Using a Soft Stop Table Saw enhances safety. Follow best practices to ensure a safe working environment. This guide covers essential checks and procedures for operation.

Pre-operation Checks

Before starting the saw, conduct these checks:

- Inspect the Blade: Ensure it is sharp and free of damage.

- Check the Fence: Confirm it is aligned properly.

- Examine the Power Cord: Look for frays or damage.

- Verify Emergency Stop: Test the emergency stop button.

- Wear Safety Gear: Use goggles, hearing protection, and gloves.

During Operation

Follow these guidelines while operating the table saw:

- Keep Hands Clear: Always maintain a safe distance from the blade.

- Use Push Sticks: Employ push sticks for narrow cuts.

- Stay Focused: Avoid distractions while cutting.

- Don’t Reach Over: Never reach across the blade.

- Monitor the Workpiece: Ensure it is stable throughout the cut.

Post-operation Care

After using the saw, follow these care steps:

- Turn Off the Saw: Ensure the power is completely off.

- Clean the Area: Remove sawdust and debris.

- Inspect the Blade: Check for any wear or damage.

- Store Safely: Keep the saw covered and unplugged.

Implementing these practices helps maintain a safe environment. Always prioritize safety while using your Soft Stop Table Saw.

Investing in a Soft Stop Table Saw raises questions about costs. Is it worth the price? Understanding the initial costs and long-term savings helps make this decision.

Initial Costs

The initial cost of a Soft Stop Table Saw is higher than standard models. Here’s a breakdown:

| Type of Table Saw | Average Price |

|---|---|

| Standard Table Saw | $300 – $600 |

| Soft Stop Table Saw | $1,200 – $2,000 |

While the Soft Stop model costs more, it offers key features:

- Advanced safety technology

- Precision cutting

- Durability and longevity

Long-term Savings

Investing in a Soft Stop Table Saw leads to long-term savings. Here are the advantages:

- Fewer Accidents: Reduced injuries save on medical bills.

- Less Material Waste: Precise cuts minimize waste.

- Increased Productivity: Fast setups save time on projects.

Consider these savings:

- Medical costs for injuries

- Replacement parts for damaged materials

- Time lost due to accidents

Over time, these savings often offset the higher initial investment. A Soft Stop Table Saw is not just a tool. It’s a wise investment in safety and efficiency.

Looking Ahead: The Future Of Woodworking Safety

The future of woodworking safety is bright. Innovations are changing how we work. New technologies make tools safer and easier to use. The goal is to reduce accidents and injuries. A key player in this evolution is the Soft Stop Table Saw.

Emerging Technologies

Technology is advancing quickly in woodworking. Here are some exciting trends:

- Smart Sensors: These detect dangers and stop blades instantly.

- Automatic Braking Systems: They halt movement when they sense contact.

- Augmented Reality (AR): AR provides real-time safety instructions.

- Machine Learning: Tools learn from user behavior to enhance safety.

These technologies aim to protect woodworkers. They reduce risks and promote safer practices.

The Role Of Education And Training

Education plays a vital role in woodworking safety. Proper training ensures users understand tools. Here are key elements of effective training:

- Hands-On Experience: Users practice with tools under supervision.

- Safety Workshops: Regular workshops keep skills fresh.

- Online Resources: Videos and guides help self-learners.

- Certification Programs: Formal training boosts credibility and knowledge.

Knowledge empowers woodworkers to use tools safely. Proper education reduces accidents significantly.

Frequently Asked Questions

What Is A Soft Stop Table Saw?

A Soft Stop Table Saw is a type of table saw designed to reduce the risk of injury. It features advanced technology that slows down the blade before stopping completely. This mechanism minimizes the chances of serious accidents while maintaining high cutting performance.

How Does A Soft Stop Work?

The Soft Stop technology employs sensors to detect contact with objects. Upon detecting an obstruction, the saw slows down immediately. This feature helps to prevent kickback and severe injuries, making woodworking safer for both professionals and hobbyists.

Why Choose A Soft Stop Table Saw?

Choosing a Soft Stop Table Saw enhances safety during woodworking projects. It minimizes injury risks without compromising cutting precision. This makes it a smart investment for both beginners and seasoned woodworkers looking for reliable equipment.

Are Soft Stop Table Saws Expensive?

Soft Stop Table Saws can be more expensive than standard models. However, the added safety features justify the cost for many users. Investing in a Soft Stop saw can lead to long-term savings by reducing the risk of accidents and injuries.

Conclusion

A soft stop table saw enhances safety and precision for woodworkers. It minimizes the risk of injury while providing accurate cuts. Investing in this technology can transform your woodworking experience. Embrace the benefits of a soft stop table saw and elevate your craftsmanship to new heights.

Your projects deserve the best tools available.