Table Saw Workbench DIY: Build Your Dream Workshop

Creating a DIY table saw workbench enhances your woodworking experience. It provides stability, organization, and increased safety during projects.

A well-designed table saw workbench is essential for any woodworker. It not only supports your saw but also offers ample space for tools and materials. Building your own workbench allows customization to fit your specific needs and workspace. Use quality materials to ensure durability and stability.

Consider features like storage solutions, extensions, and adjustable heights for added convenience. A well-planned workbench can significantly improve your efficiency and safety while working on various projects. This guide will walk you through the essential steps to create a functional and effective table saw workbench tailored to your woodworking style. Start building your ideal workspace today!

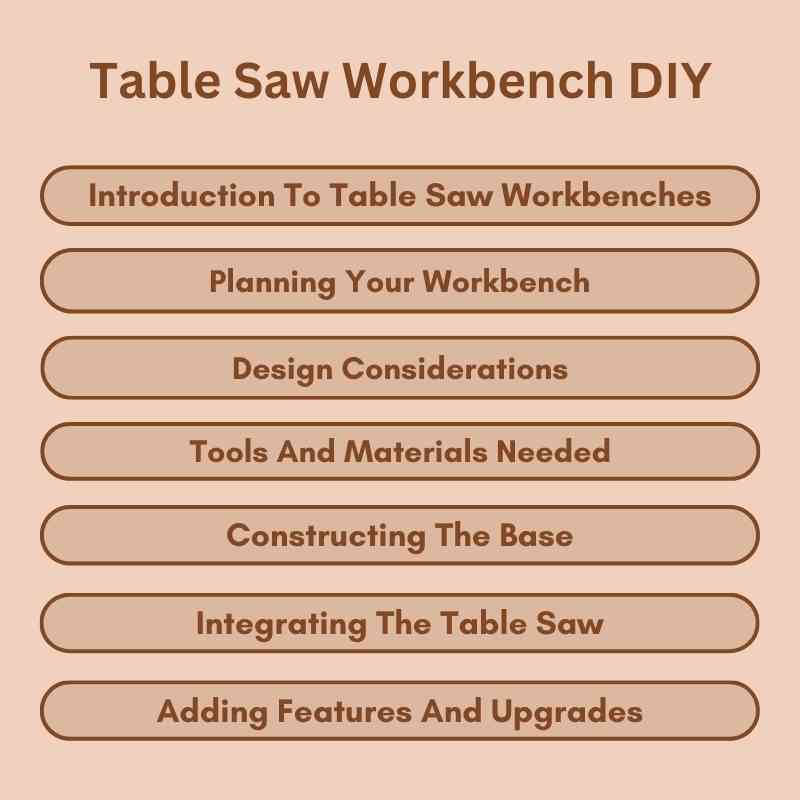

Introduction To Table Saw Workbenches

A table saw workbench is essential for any woodworker. It provides a stable surface for cutting and assembling projects. Building a workbench allows for customization. You can design it to fit your space and needs. Let’s explore the importance of having a sturdy workbench and the benefits of a DIY approach.

Importance Of A Sturdy Workbench

A sturdy workbench supports your table saw. It helps with accuracy and safety. Here are key reasons why a solid workbench matters:

- Stability: Keeps your saw in place during use.

- Precision: Ensures straight cuts and clean edges.

- Durability: Withstands heavy use over time.

- Safety: Reduces the risk of accidents while working.

Benefits Of A DIY Approach

Building your own table saw workbench has many advantages. Here are some benefits:

- Customization: Tailor the size and features to your needs.

- Cost-Effective: Save money compared to buying pre-made options.

- Skill Development: Improve your woodworking skills through the process.

- Satisfaction: Enjoy the pride of creating something yourself.

Building a workbench is an exciting project. It can enhance your woodworking experience greatly.

Planning Your Workbench

Creating a table saw workbench requires careful planning. Proper planning ensures functionality and efficiency. Consider size, space, and materials for your workbench.

Determining Size And Space

Size and space are crucial factors. Measure your workshop area first. Aim for a comfortable working environment. Here are some tips:

- Leave at least 3 feet around the bench.

- Consider the length of your table saw.

- Account for storage needs underneath the bench.

Typical workbench dimensions:

| Dimension | Recommended Size |

|---|---|

| Length | 6 to 8 feet |

| Width | 2 to 3 feet |

| Height | 34 to 36 inches |

This size range offers stability and usability. Adjust based on your personal height and needs.

Choosing The Right Materials

Selecting quality materials is vital. Durable materials ensure longevity and safety. Here’s what to consider:

- Top Surface: Use plywood or MDF for a flat surface.

- Frame: Choose sturdy hardwood or metal for strength.

- Finish: Apply a protective finish to resist wear.

Popular materials:

| Material | Benefits |

|---|---|

| Plywood | Affordable, lightweight, and strong. |

| MDF | Smooth surface, easy to work with. |

| Hardwood | Very durable and aesthetically pleasing. |

Choose materials based on your budget and project requirements. A well-constructed workbench enhances your woodworking experience.

Design Considerations

Building a table saw workbench requires careful planning. Focus on features that enhance usability and efficiency. Consider ergonomics, workflow, and storage options. Each factor plays a vital role in creating a functional workspace.

Ergonomics And Work Flow

Ergonomics ensures comfort while working. A well-designed table saw workbench reduces strain. Here are some key points to consider:

- Height: Adjust the bench height to your waist level.

- Space: Allow for ample space around the saw.

- Accessibility: Keep tools and materials within arm’s reach.

- Movement: Plan for smooth movement between tasks.

Designing for workflow boosts efficiency. Arrange tools based on usage frequency. This minimizes unnecessary movement. Consider the following:

- Place the table saw near the entrance.

- Position frequently used tools close by.

- Keep a clear path for material handling.

Incorporating Storage Solutions

Storage solutions help keep your workspace organized. A clutter-free area enhances focus. Here are effective storage ideas:

| Storage Type | Description |

|---|---|

| Drawers | Store small tools and accessories out of sight. |

| Shelves | Hold larger items like power tools and materials. |

| Hooks | Hang tools for quick access and visibility. |

| Cabinets | Securely store hazardous materials and equipment. |

Choose storage that fits your needs. Customizing your workbench increases utility. Utilize vertical space for added storage. This keeps the floor clear for safety.

Tools And Materials Needed

Building a DIY table saw workbench requires careful planning. Selecting the right tools and materials is crucial. Below, discover the essential items to get started.

Essential Power Tools

Power tools make the building process easier and faster. Here are the must-have tools:

- Table Saw: The heart of the workbench.

- Circular Saw: For cutting large sheets.

- Drill/Driver: For making holes and driving screws.

- Router: For shaping edges and joining pieces.

- Jigsaw: For intricate cuts and curves.

Hardware And Accessories

Choosing the right hardware and accessories ensures durability. Check out this list:

| Item | Purpose |

|---|---|

| Plywood: | For the workbench surface and structure. |

| Wood Screws: | For assembling parts securely. |

| Metal Brackets: | For added support and stability. |

| Wood Glue: | For extra bonding strength. |

| Casters: | For mobility of the workbench. |

Gather these tools and materials before starting. Being prepared leads to a smoother building experience.

Constructing The Base

Building a sturdy base for your table saw workbench is crucial. This foundation supports your saw and ensures safety during use. A well-constructed base enhances precision and stability.

Assembling The Frame

Start by gathering your materials:

- 2×4 lumber

- Wood screws

- Wood glue

- Measuring tape

- Level

Follow these steps to assemble the frame:

- Cut the 2×4 lumber to desired lengths.

- Build a rectangular frame. Use screws and glue for strength.

- Add cross supports for extra stability.

- Check all corners for right angles.

Ensure the frame is square. This will help the table saw sit evenly. Use the level to check for flatness.

Ensuring Stability And Level

A stable base prevents wobbling. Follow these tips for stability:

- Attach adjustable feet to the bottom of the legs.

- Use plywood sheets for the top surface.

- Secure the frame to the floor if needed.

Check the level regularly. Use a level tool on all sides. Adjust the feet until the frame sits flat.

| Material | Purpose |

|---|---|

| 2×4 Lumber | Construct the frame |

| Wood Screws | Join the pieces together |

| Wood Glue | Add extra strength |

| Measuring Tape | Ensure accurate dimensions |

| Level | Check flatness and stability |

By following these steps, you create a solid base. This base will support your workbench and enhance your woodworking projects.

Building The Table Top

Creating a sturdy table top for your DIY table saw workbench is essential. This part supports all your projects. Choosing the right materials and making precise cuts will ensure durability and stability.

Selecting The Wood

Choosing the right wood is the first step. Various types of wood offer different benefits. Here are some popular options:

| Type of Wood | Benefits |

|---|---|

| Plywood | Affordable, strong, and resistant to warping |

| Hardwood | Durable, long-lasting, and attractive finish |

| Particle Board | Cost-effective, good for light-duty projects |

Consider the thickness of the wood. A thickness of 3/4 inch works well for most projects. Always choose wood that is free from defects. This ensures your table top remains flat and stable.

Precision Cutting And Assembly

Accurate cuts lead to a well-fitted table top. Here’s how to achieve that:

- Measure your desired dimensions carefully.

- Mark the cuts clearly on the wood.

- Use a table saw for straight cuts.

- Sand the edges for a smooth finish.

Assemble your pieces by following these steps:

- Use wood glue for strong joints.

- Clamp the pieces together until the glue dries.

- Consider using screws for added strength.

Ensure your table top is flat. A flat surface enhances precision in all your woodworking tasks.

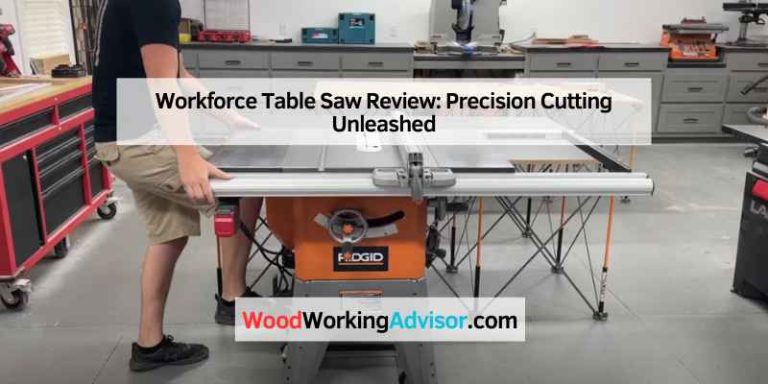

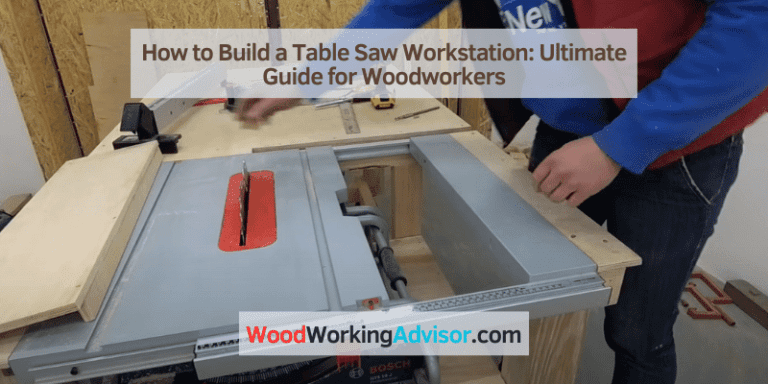

Integrating The Table Saw

Integrating the table saw into your workbench enhances your woodworking experience. A well-integrated saw boosts efficiency and safety. Follow the steps below to achieve a seamless setup.

Securing The Table Saw

Start by securely fastening the table saw to the workbench. This prevents movement during use. Here are steps to follow:

- Place the table saw on the workbench.

- Mark the location of the saw’s base.

- Use screws or bolts to secure it.

- Check stability before using the saw.

Use a level to ensure the saw is even. An uneven saw can lead to inaccurate cuts.

Alignments And Calibrations

Proper alignments and calibrations are key to safe and precise cuts. Follow these steps:

- Adjust the saw blade to 90 degrees.

- Check the fence alignment with the blade.

- Calibrate the miter gauge for angles.

Use a square to verify the angles. A well-calibrated saw cuts smoother and safer.

Consider this table for quick reference:

| Step | Action |

|---|---|

| 1 | Check blade angle |

| 2 | Align fence to blade |

| 3 | Calibrate miter gauge |

Regular maintenance keeps your table saw functioning well. Always check the settings before starting a project.

Adding Features And Upgrades

Enhancing your DIY table saw workbench boosts its functionality. These upgrades make your workspace more efficient and organized. Simple additions can save time and improve safety.

Customizable Modules

Customizable modules allow flexibility in your workbench design. You can create sections tailored to your needs. Here are some ideas:

- Storage Compartments: Add drawers or shelves for tools.

- Tool Holders: Install racks for easy access to frequently used tools.

- Extension Tables: Create foldable surfaces for larger projects.

Consider these options for your modules:

| Module Type | Benefits |

|---|---|

| Drawer Units | Organizes small tools and accessories. |

| Open Shelves | Easy access to larger items. |

| Clamp Storage | Keeps clamps off the surface and organized. |

Dust Collection Systems

A dust collection system keeps your workspace clean. It prevents sawdust from accumulating. Clean work areas improve safety and visibility.

Here are some effective options:

- Shop Vac: Connect a shop vac to your table saw.

- Dust Ports: Install ports for easy connection to dust collectors.

- Hoses: Use flexible hoses for better maneuverability.

Benefits of a good dust collection system:

- Reduces respiratory hazards.

- Keeps tools functioning better.

- Makes cleanup faster and easier.

Finishing Touches

Finishing touches transform your table saw workbench into a masterpiece. These final steps enhance durability and add a personal touch.

Sealing And Protecting The Wood

Sealing wood protects it from moisture, scratches, and wear. Use high-quality sealants for the best results. Here’s a simple process:

- Sand the surface to smooth it out.

- Clean the dust off thoroughly.

- Apply the first coat of sealant.

- Let it dry completely.

- Sand lightly between coats.

- Apply a second coat for added protection.

Choose sealants like:

- Polyurethane for durability.

- Water-based sealants for easy cleanup.

- Oil-based sealants for a rich finish.

Personalizing Your Workbench

Make your workbench truly yours. Personal touches make it special and functional. Consider these ideas:

| Personalization Idea | Description |

|---|---|

| Color Scheme | Choose colors that inspire you. |

| Decals or Stickers | Add fun designs or your logo. |

| Custom Storage | Build compartments for tools and materials. |

| Measure Markings | Paint or etch measurement lines for easy use. |

Personalizing your workbench boosts creativity and functionality. Enjoy making it uniquely yours!

Safety Precautions And Maintenance

Building a DIY table saw workbench is exciting. Safety is crucial to protect yourself and others. Regular maintenance keeps your tools in top shape. Follow these tips for a safe and efficient workspace.

Operating Safely

Follow these important safety tips:

- Wear safety goggles to protect your eyes.

- Use ear protection to guard against noise.

- Keep your hands away from the blade.

- Always use a push stick for small pieces.

- Ensure the workspace is clear of clutter.

- Check for loose clothing or jewelry.

- Keep children and pets away from the work area.

Stay focused while operating the saw. Avoid distractions. Always read the manufacturer’s manual before use.

Routine Maintenance Tips

Routine maintenance extends the life of your table saw. Follow these guidelines:

| Task | Frequency |

|---|---|

| Clean the saw table | After each use |

| Check blade alignment | Monthly |

| Lubricate moving parts | Every 3 months |

| Inspect power cord | Monthly |

Perform these tasks regularly:

- Unplug the saw before cleaning or inspecting.

- Use a soft cloth to wipe the saw table.

- Adjust the blade alignment using a square.

- Apply lubricant to hinges and pivot points.

- Replace damaged cords immediately.

Keep your table saw well-maintained. It ensures safety and efficiency.

Expanding Your Workshop

Expanding your workshop can boost your woodworking skills. A well-organized space makes projects easier. Adding a table saw workbench can transform your workflow.

Additional Equipment Considerations

New tools bring new possibilities. Here are some essential pieces of equipment to consider:

- Dust Collection System: Keeps the air clean.

- Router Table: Adds precision to your cuts.

- Workbench Accessories: Clamps and vises improve stability.

- Storage Solutions: Organize your tools efficiently.

Each piece enhances your table saw workbench experience. Choose tools that fit your projects and space.

Space Management For New Tools

Manage your workshop space wisely. Here are some tips:

- Plan Your Layout: Sketch your workshop layout before adding tools.

- Utilize Vertical Space: Install shelves and pegboards.

- Mobile Tool Carts: Keep tools accessible and movable.

- Compact Storage: Use drawers or bins for smaller items.

Efficient space management maximizes your workshop’s potential. A tidy space inspires creativity and productivity.

| Equipment | Benefits |

|---|---|

| Dust Collection System | Improves air quality |

| Router Table | Enhances cut precision |

| Workbench Accessories | Increases stability |

| Storage Solutions | Organizes tools |

Frequently Asked Questions

What Materials Do I Need For A Table Saw Workbench?

To build a table saw workbench, you’ll need plywood, 2×4 lumber, screws, and wood glue. Additionally, consider investing in a sturdy work surface, such as melamine or MDF. Don’t forget clamps and a level to ensure your workbench is stable and accurate during assembly.

How Do I Design A Diy Table Saw Workbench?

Start by measuring your table saw dimensions and workspace. Sketch a design that includes storage options and a sturdy surface. Ensure the height is comfortable for you. Use online resources or software for detailed planning and visualizing your workbench layout before cutting materials.

Can I Customize My Table Saw Workbench?

Absolutely! Customizing your table saw workbench allows you to tailor it to your specific needs. You can add features like drawers, shelves, or even tool organizers. Consider your workflow and adjust dimensions to create a functional workspace that enhances your efficiency while working on projects.

What Are The Benefits Of A Table Saw Workbench?

A dedicated table saw workbench improves precision and stability during cuts. It provides ample storage for tools and materials, reducing clutter. Additionally, a well-designed workbench enhances safety by keeping your workspace organized. Ultimately, it boosts productivity and makes woodworking tasks more enjoyable.

Conclusion

Creating a DIY table saw workbench enhances your woodworking experience. With careful planning and the right materials, you can build a functional and efficient workspace. This project not only saves money but also tailors to your specific needs. Enjoy the satisfaction of crafting something unique that boosts your creativity and productivity.