What are the Disadvantages of MDF Board: Key Drawbacks

MDF board is prone to moisture damage, contains VOCs, and is not as durable as solid wood. MDF, or Medium Density Fiberboard, is a popular engineered wood product used in furniture and cabinetry due to its affordability and versatility.

However, it has some disadvantages to consider. One key drawback is its vulnerability to moisture, as MDF can easily warp and swell if exposed to water. Additionally, MDF contains volatile organic compounds (VOCs) and urea-formaldehyde, which can pose health risks.

Compared to solid wood, MDF is less durable and more prone to cracking or splitting under heavy stress. Understanding these limitations can help in making informed decisions when choosing materials for your projects.

Sensitivity To Moisture

MDF boards are highly sensitive to moisture, making them prone to warping and swelling if not properly sealed in humid conditions. Additionally, MDF contains urea-formaldehyde and other VOCs, posing potential health risks. The boards are also weaker and heavier than solid wood, and cannot withstand extreme stress or heavy weight.

MDF boards are highly sensitive to moisture due to their composition. Unsealed MDF in humid conditions is prone to swelling and warping, which can compromise its structural integrity and aesthetics.

Swelling And Warping

When exposed to moisture, MDF boards absorb water quickly, causing them to swell. This leads to warping of the board, resulting in uneven surfaces and potential damage.

Poor Outdoor Performance

MDF boards are not suitable for outdoor use as they are highly susceptible to moisture and extreme weather conditions. Exposure to rain or high humidity can lead to rapid deterioration and rotting of the board.

In summary, the sensitivity to moisture is a significant disadvantage of MDF boards, manifesting in issues such as swelling, warping, and poor outdoor performance.

Health And Safety Concerns

MDF boards have several disadvantages, including vulnerability to moisture, which can cause warping and swelling if not properly sealed. Additionally, MDF contains urea-formaldehyde and VOCs, posing health and safety concerns. It is also prone to damage, heavier than other materials, and cannot support heavy weight.

MDF, or Medium-Density Fiberboard, is a popular material used in furniture and cabinetry due to its affordability and versatility. However, there are some disadvantages to using MDF, particularly when it comes to health and safety concerns.

Formaldehyde Emissions

One major concern with MDF is the formaldehyde emissions. Most MDF contains urea-formaldehyde, which is a suspected carcinogen and can cause health problems, including respiratory issues, headaches, and eye irritation. These emissions can be particularly harmful in poorly ventilated areas, and prolonged exposure can lead to serious health problems.

Dust Generation During Cutting

Another health concern related to MDF is the dust generated during cutting. The dust particles can be harmful to breathe, leading to respiratory problems and irritation of the eyes, nose, and throat. Proper dust control measures, such as wearing a mask and using a dust collection system, are essential to minimize the risk of health problems.

In conclusion, while MDF is a popular material due to its affordability and versatility, it does come with some health and safety concerns. It is important to take the necessary precautions when working with MDF to minimize the risk of exposure to formaldehyde emissions and dust particles.

Structural Weaknesses

MDF Board has structural weaknesses like being weaker than wood, leading to a shorter lifespan. It can crack or split under stress and absorbs water faster than wood, making it less durable.

MDF (Medium Density Fiberboard) is a popular choice for furniture and cabinetry due to its affordability and versatility. However, it is important to be aware of its disadvantages, particularly its structural weaknesses. Understanding these limitations can help you make an informed decision when considering the use of MDF in your projects.

Limited Load Capacity

One of the major disadvantages of MDF is its limited load capacity. Due to its composition, MDF is not as strong as solid wood. It has a lower density and lacks the natural fibers that provide strength and stability to wood. As a result, MDF is not suitable for supporting heavy loads or for applications that require high structural integrity.

Cracking Under Stress

MDF boards are prone to cracking or splitting under extreme stress. The compressed fibers and resin binders used in its production make MDF more susceptible to damage compared to solid wood. This weakness becomes particularly evident when MDF is subjected to excessive pressure or impact. It is important to handle MDF with care and avoid placing excessive strain on it to prevent cracks and fractures.

To illustrate the disadvantages of MDF’s structural weaknesses, here is a comparison table:

| Structural Weaknesses | Impact on Performance |

|---|---|

| Limited Load Capacity | MDF may not be able to support heavy objects or withstand significant weight without bending or breaking. |

| Cracking Under Stress | MDF is more prone to cracking or splitting when subjected to excessive pressure or impact, compromising its overall durability. |

It is essential to consider these structural weaknesses when using MDF in your projects. If you require a material with higher load capacity and greater resistance to stress, solid wood or alternative materials may be more suitable options.

While MDF has its advantages, such as affordability and ease of manipulation, it is crucial to weigh these benefits against its limitations. By understanding the structural weaknesses of MDF, you can make informed decisions and choose the right material for your specific needs.

Workability Issues

When working with MDF boards, there are several Workability Issues that can pose challenges for DIY enthusiasts and professionals alike.

Difficulties With Screws And Fasteners

One of the primary Workability Issues with MDF boards is the challenge of using screws and fasteners. Due to its composition, MDF tends to split or crack easily when screws are driven into it, making it difficult to achieve a secure hold. This can be frustrating and may require additional care and expertise to work around this limitation.

Challenges In Achieving A Fine Finish

Another Workability Issue when working with MDF boards is the difficulty in achieving a fine finish. MDF has a smooth surface that is prone to chipping and denting during cutting, sanding, or painting. This can make it challenging to achieve a flawless and professional-looking finish on projects involving MDF boards.

Durability And Longevity

When it comes to durability and longevity, MDF boards have several disadvantages that are important to consider. From a shorter lifespan to susceptibility to damage, these factors can impact the overall performance and longevity of MDF boards.

Comparatively Shorter Lifespan

One of the primary disadvantages of MDF boards is their comparatively shorter lifespan when compared to solid wood. The engineered nature of MDF makes it more susceptible to wear and tear over time, leading to a reduced lifespan.

Susceptibility To Damage

MDF boards are also susceptible to damage, which can significantly impact their longevity. They are more prone to cracking, splitting, and warping under extreme stress, making them less durable compared to solid wood.

Weight Concerns

MDF boards have several disadvantages. Firstly, they are prone to damage and cracking under extreme stress. Additionally, MDF absorbs water more quickly than wood, making it unsuitable for humid environments. Lastly, MDF is not as strong as natural wood and cannot support heavy weights.

Heavier Than Plywood

MDF boards are notably heavier than plywood, which can pose challenges during handling and transportation.

Handling And Transportation Issues

The weight of MDF boards can make handling and transportation more cumbersome compared to lighter alternatives like plywood.

Environmental Impact

MDF board has several disadvantages including vulnerability to extreme heat and water absorption. It is also heavier and less durable than solid wood, with a shorter lifespan and limited weight-bearing capacity. Additionally, MDF may contain VOCs and urea-formaldehyde, which are harmful to the environment and human health.

Use Of Volatile Organic Compounds

MDF board is known for its heavy reliance on adhesives that contain volatile organic compounds (VOCs), such as urea-formaldehyde. These compounds can off-gas into the environment, contributing to indoor air pollution and posing potential health risks to individuals exposed to them.

Sustainability Questions

The production process of MDF board raises sustainability questions due to the use of formaldehyde-based resins and chemical additives. Additionally, the high energy consumption and emissions associated with its manufacturing contribute to its environmental footprint.

Cost Vs. Quality Trade-off

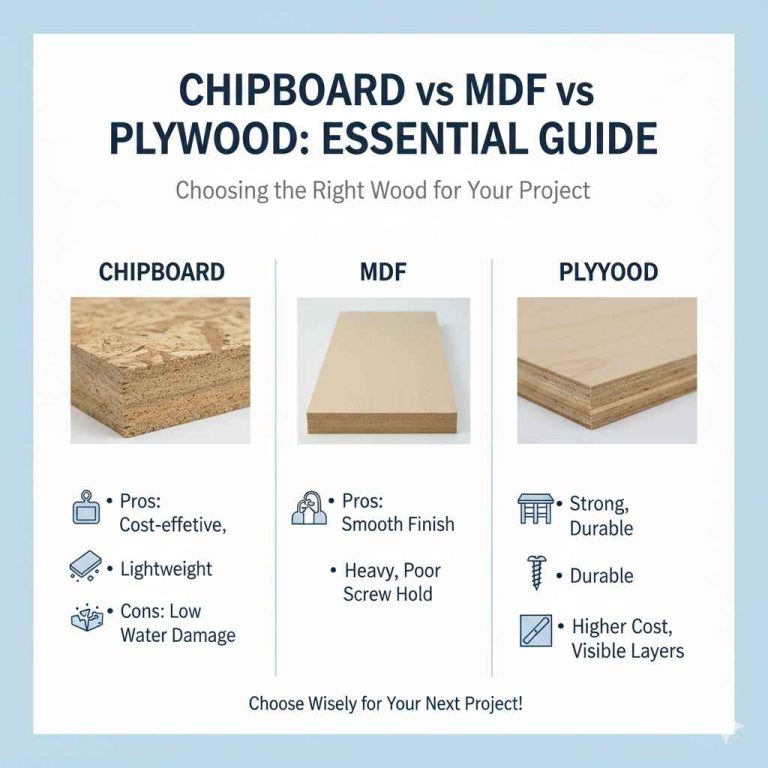

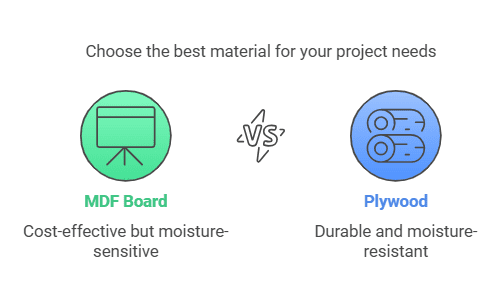

When considering the use of MDF board, it’s important to weigh the economic benefits against the performance and quality trade-offs. While MDF offers cost advantages, there are several disadvantages that need to be carefully evaluated, particularly when compared to solid wood and plywood.

Economic Benefits Vs. Performance

While MDF boards are generally more cost-effective compared to solid wood, they come with performance trade-offs. The economic benefits of MDF must be balanced against its lower durability, susceptibility to moisture, and limitations in load-bearing capacity.

Comparison With Solid Wood And Plywood

When comparing MDF with solid wood and plywood, it’s crucial to consider the differences in strength, durability, and versatility. Solid wood and plywood typically offer greater stability, longevity, and load-bearing capacity compared to MDF, making them more suitable for certain applications that require higher performance standards.

Frequently Asked Questions

When Should You Not Use MDF?

Avoid using MDF in humid areas as it warps when exposed to moisture. MDF contains harmful VOCs and may not withstand heavy weight or extreme heat.

What Is MDF Not Good For?

MDF, or medium-density fiberboard, is not suitable for use in humid environments as it can warp and swell if not sealed properly. It is also heavier and cannot support as much weight as solid wood. MDF is also vulnerable to extreme heat and contains chemicals such as urea-formaldehyde, which is a suspected carcinogen.

Additionally, it is comparatively weaker than wood and has a shorter lifespan.

How Long Does MDF Last?

MDF typically has a shorter lifespan compared to wood. It can crack or split under extreme stress and absorbs water more quickly. It is not as strong as natural wood and cannot withstand extreme pressure.

Why Use MDF Instead Of Wood?

MDF is more cost-effective and easier to work with than wood. However, it’s not as strong, struggles with screws, and lacks the natural beauty of solid wood.

Conclusion

To summarize, MDF board comes with its fair share of disadvantages. Firstly, it is prone to warping and swelling when exposed to moisture, making it unsuitable for humid environments. Additionally, MDF contains urea-formaldehyde and other VOCs, which are suspected carcinogens.

Furthermore, MDF is not as durable as solid wood and is more susceptible to damage. It is also heavier and cannot bear heavy weights. Considering these drawbacks, it is important to carefully consider the application and environment before opting for MDF board.