What is B2 Plywood? Uncover the Robust Choice for DIY

B2 plywood is a type of plywood specifically designed for general-purpose use. It features a smooth surface, making it suitable for furniture, cabinetry, and other applications.

B2 plywood is a versatile material widely used in construction and woodworking. Its quality lies in its layers, which provide strength and durability. The plywood is typically made from softwood or hardwood, ensuring it can withstand wear and tear. Builders and DIY enthusiasts appreciate B2 plywood for its affordability and ease of use.

This type of plywood is often treated for moisture resistance, enhancing its longevity. Whether you’re crafting furniture or constructing frameworks, B2 plywood offers a reliable solution. Understanding its properties can help you make informed decisions for your projects, ensuring optimal results every time.

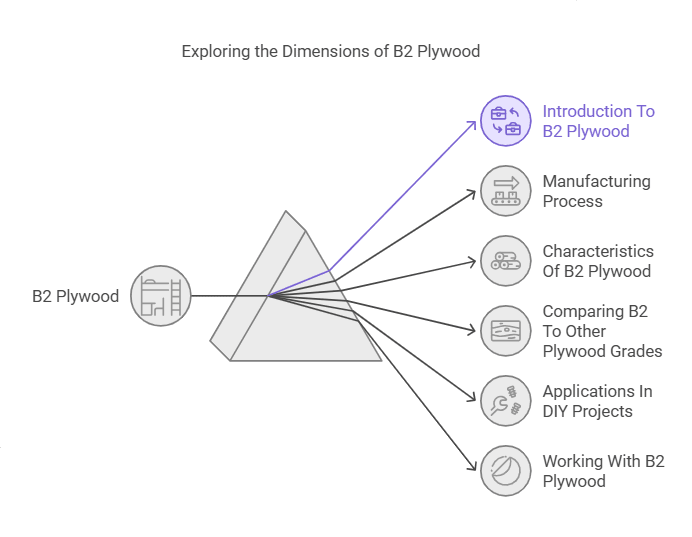

Introduction To B2 Plywood

B2 Plywood is a type of plywood made from thin layers of wood. Each layer is called a veneer. These veneers are glued together, with the grains running in different directions. This method makes the plywood strong and stable.

B2 Grade plywood is known for its good quality. It is often used for furniture and interior projects. The surface of B2 plywood is usually smooth and ready for painting or varnishing.

Here are some important points about B2 plywood:

- Durable and resistant to warping.

- Available in various thicknesses.

- Suitable for both indoor and outdoor use.

- Eco-friendly options are available.

Manufacturing Process

The manufacturing process of B2 plywood starts with logs being cut into smaller pieces. These pieces are then debarked to remove the outer layer. After that, the logs are sliced into thin sheets called veneers. Each veneer is carefully dried to reduce moisture content.

Next, the sheets are glued together in layers. The number of layers affects the strength of the plywood. After gluing, the plywood is pressed under high pressure. This creates a strong bond between the layers.

Grading and quality control are crucial. Each sheet is inspected for defects and imperfections. High-quality sheets receive a better grade. Poor-quality sheets are discarded or used for lower-grade products.

Characteristics Of B2 Plywood

B2 Plywood is known for its excellent surface quality. The surface is smooth and free from major defects. This makes it suitable for various applications, including furniture and cabinetry.

Strength is one of its key features. B2 Plywood has a high resistance to stress and impact. It can withstand heavy loads without bending or breaking. This plywood type offers long-lasting durability.

With proper care, B2 Plywood lasts for many years. Its moisture resistance helps prevent damage from water. It is also easy to maintain and clean.

Comparing B2 To Other Plywood Grades

B2 plywood is a popular choice for various projects. It offers a good balance of strength and cost. When comparing B2 to other grades, some differences stand out.

B2 plywood is often more durable than lower grades. It resists moisture better than C-grade plywood. The surface of B2 is generally smoother, making it ideal for finishing.

| Grade | Durability | Cost |

|---|---|---|

| B2 | High | Moderate |

| C | Low | Low |

| A | Very High | High |

Choosing the right plywood depends on your needs. For furniture, B2 provides great support. For outdoor projects, consider a higher-grade plywood.

Applications In DIY Projects

B2 Plywood is great for various DIY projects. It is strong and durable. Many people use it for indoor and outdoor tasks.

Indoor projects include furniture, shelves, and cabinets. B2 plywood is smooth, making it perfect for painting.

Outdoor use requires special treatment. It can resist moisture when sealed properly. Common outdoor projects are garden boxes and birdhouses.

Some popular project ideas:

- Bookshelves

- Picnic tables

- Storage units

- Wooden planters

- Dog houses

Working With B2 Plywood

Cutting B2 Plywood is easy with the right tools. Use a fine-tooth saw for smooth edges. A circular saw works well for straight cuts. Always wear safety gear while cutting.

Shaping B2 Plywood requires careful handling. Use a jigsaw for curves and intricate designs. Sand the edges after cutting to avoid splinters.

Joining B2 Plywood pieces can be done in several ways:

| Joining Technique | Description |

|---|---|

| Glue | Use strong wood glue for a solid bond. |

| Screws | Use screws for added strength in joints. |

| Dowels | Dowel joints provide alignment and stability. |

| Brackets | Metal brackets can reinforce corners effectively. |

Finishing And Maintenance Tips

Staining and painting B2 plywood can enhance its appearance. Use a high-quality stain or paint for the best results. Always test on a small area first. This helps to check color and adhesion.

Clean the surface before applying any products. This removes dirt and dust, ensuring better adhesion. Apply the stain or paint evenly using a brush or roller. Allow proper drying time between coats for a smoother finish.

For long-term care, keep plywood away from moisture. This prevents warping or damage. Use a protective sealant every few years. This helps maintain the beauty and integrity of the wood.

Regularly inspect the plywood for signs of wear. Address any issues quickly to prolong its life. Proper maintenance ensures your B2 plywood stays beautiful for many years.

Purchasing And Cost Considerations

Finding B2 plywood is easy if you know where to look. Local hardware stores often stock it. Online retailers provide a wide selection too. Some popular places include Home Depot and Lowe’s.

Price can vary based on quality and size. Here’s a quick comparison:

| Store | Price for 4×8 Sheet |

|---|---|

| Home Depot | $30 |

| Lowe’s | $28 |

| Online Retailer | $25 |

Always check for discounts or bulk buying options. This can save money on larger purchases.

Environmental Impact And Sustainability

B2 plywood is made from sustainable sources. It uses renewable materials, which help reduce waste. Many manufacturers follow eco-friendly practices to protect the environment.

Look for certifications like FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification). These labels ensure the wood comes from responsibly managed forests.

| Certification | Description |

|---|---|

| FSC | Ensures responsible forest management and sustainable sourcing. |

| PEFC | Promotes sustainable forest practices worldwide. |

Buying certified B2 plywood supports sustainable forestry. It helps protect wildlife habitats and reduces carbon footprints.

Frequently Asked Questions

What Is B2 Plywood Used For?

B2 plywood is commonly used for interior applications. It is ideal for furniture, cabinetry, and wall paneling. Its smooth surface allows for easy painting and veneering. However, it is not suitable for outdoor use due to its susceptibility to moisture.

How Is B2 Plywood Different From Other Types?

B2 plywood is known for its moderate moisture resistance. Unlike B1 plywood, which is waterproof, B2 is designed for indoor use. It offers a balance of affordability and quality, making it a popular choice for various projects. Its durability meets many construction needs without exceeding budgets.

Is B2 Plywood Suitable For Construction?

While B2 plywood can be used in some construction projects, it is not ideal for structural applications. Its primary use is in non-load-bearing areas. If you need plywood for structural purposes, consider B3 or B4 grades. Always evaluate the specific requirements of your project.

How Thick Is B2 Plywood Typically?

B2 plywood usually comes in various thicknesses, ranging from 3mm to 18mm. The thickness you choose depends on your specific project needs. Thicker plywood provides greater strength and durability. Always check the manufacturer’s specifications for the exact thickness available.

Conclusion

B2 plywood offers a reliable and cost-effective solution for various construction needs. Its durability and resistance to moisture make it ideal for both indoor and outdoor projects. Understanding its specifications helps you choose the right materials for your applications. Invest in B2 plywood for quality and performance that meets your construction standards.