What is Bevel Cutting?: Essential Guide for Precision Cuts

Bevel cutting is a technique in metal and woodwork. It involves cutting the edge of a material at an angle.

This method is used in various industries, including construction and manufacturing. Understanding bevel cutting is essential for many projects. It helps in creating joints that fit together well. This technique is not just for professionals. Even hobbyists can benefit from knowing how to bevel cut.

By learning this method, you can improve the strength and appearance of your work. It is a skill worth adding to your toolkit. So, what exactly is bevel cutting? Let’s dive deeper to understand its uses and benefits.

Introduction To Bevel Cutting

Bevel cutting is a process that cuts metal at an angle. This is different from a straight cut. The angle can be very precise. This helps in creating edges that fit together well. Bevel cuts are often used in welding. They make it easier to join metal pieces. The cut angle can range from 0 to 45 degrees. Machines or hand tools can perform bevel cutting. It is a key technique in metalworking.

Bevel cutting is important in many industries. In construction, it helps create strong joints. In the automotive industry, it shapes car parts. Shipbuilding also uses bevel cutting for strong hulls. Aerospace relies on it for precise parts. Even in art, bevel cuts add unique designs. This process improves the fit and strength of metal pieces. It is a versatile and essential technique.

Credit: ronixtools.com

Types Of Bevel Cuts

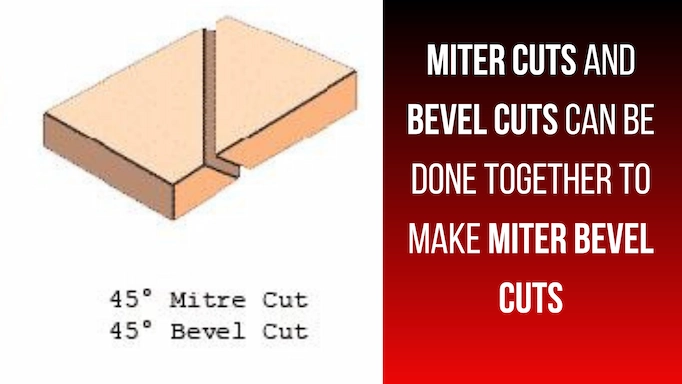

A standard bevel is a simple angle cut. This cut is at one angle on one edge. It is common in many projects. Easy to understand and use.

A compound bevel involves two angles. One angle is on the face. The other is on the edge. It is more complex than a standard bevel. Used in intricate work.

A double bevel has two angled cuts. Both angles are on opposite edges. It is useful for precise joints. This cut is often used in woodworking.

Tools For Bevel Cutting

Hand tools are simple but useful. Chisels and files can create smooth bevels. Saw blades with angled teeth help too. Manual saws are slow but precise.

Power tools make the job faster. Electric saws cut quickly. Angle grinders shape edges well. Rotary tools are versatile. Power sanders smooth the bevels.

Specialized machines are for big projects. Beveling machines cut at exact angles. CNC machines are very precise. Laser cutters offer clean cuts. Water jet cutters can cut thick materials.

Credit: www.instructables.com

Materials Suitable For Bevel Cutting

Bevel cutting on wood creates smooth edges. It is used in furniture and art. Many types of wood are suitable. Hardwoods like oak and softwoods like pine work well. The process is simple and quick.

Bevel cutting on metal is precise. It helps in creating strong joints. Metals like steel and aluminum are common. This method is used in construction and machinery. It ensures clean and accurate cuts.

Plastics are also ideal for bevel cutting. This is used in signs and models. Acrylic and PVC are popular choices. The process is easy and efficient. It offers a neat finish.

Techniques For Precision Bevel Cuts

Accurate angle measurement is vital for bevel cuts. Using a protractor helps you find the right angle. Digital angle finders provide more precision. Set the angle carefully before cutting. Always double-check to avoid mistakes.

Choose the right tool for the material. A miter saw works well for wood. For metal, a plasma cutter is better. Keep the blade sharp for clean cuts. Hold the material steady to prevent errors. Practice on scrap pieces first. It helps you get the feel of the cut.

Safety Precautions

Bevel cutting involves angling the blade to achieve a precise edge. Ensure safety by wearing protective gear and maintaining equipment properly.

Protective Gear

Wearing the right protective gear is very important. Always use goggles to protect your eyes from sparks. Wear gloves to keep your hands safe. Use ear protection to guard your ears from loud noises. A face shield offers extra protection for your face. Don’t forget to wear a dust mask to avoid inhaling small particles. Safety boots are a must to protect your feet. Long sleeves and pants keep your skin safe from burns.

Safe Handling Practices

Always keep your work area clean and well-lit. Make sure to secure the material you are cutting. Ensure the cutting tool is in good shape. Never use a damaged tool. Keep a steady hand while cutting. Never rush the process. Double-check your measurements before starting. Ensure you have a first aid kit nearby. Follow all safety instructions of the tool. Never cut near flammable materials. Always focus on the task. Do not get distracted.

Common Applications

Bevel cutting involves slicing materials at an angle, creating slanted edges. It is commonly used in welding, carpentry, and metal fabrication. This technique ensures precise fitting and enhances the strength of joints.

Furniture Making

Bevel cutting is popular in furniture making. It helps create smooth and neat edges. This technique is used for making chairs, tables, and cabinets. It makes the joints strong and durable. Bevel cuts add a professional touch to wood pieces. This method is loved by carpenters and DIY enthusiasts.

Metal Fabrication

Bevel cutting plays a big role in metal fabrication. It is used to prepare metal parts for welding. Bevel cuts make the welds stronger and more reliable. This technique is used in making pipes, beams, and other metal structures. It is crucial in industries like automotive and aerospace.

Construction

In construction, bevel cutting is essential. It is used for cutting materials like wood, metal, and stone. Bevel cuts help in fitting pieces together neatly. This technique is used in building frames, roofs, and other structures. It ensures a precise and clean finish. Builders rely on bevel cutting for quality work.

Credit: www.instructables.com

Troubleshooting Common Issues

Inaccurate cuts can cause big problems. Check the blade alignment. Ensure it is set correctly. Measure twice, cut once. This helps avoid mistakes. Use guides to keep the material steady. Slow down. Rushing can lead to errors.

Inspect your tools regularly. Look for wear and tear. Clean the blade. Dust and debris can affect performance. Replace dull blades. Sharp blades cut better. Check power connections. Loose wires can cause issues.

Future Trends In Bevel Cutting

New technology is changing bevel cutting. Laser cutters are more precise now. Automation makes the process faster. Software helps in designing better cuts. Robots are also used for cutting. These changes save time and reduce costs.

New materials are being used in bevel cutting. Composite materials are popular now. They are strong and light. Alloys are also being cut. They are very durable. These materials are used in many industries. This includes aerospace and automotive sectors.

Frequently Asked Questions

What Does Bevel Cut Mean?

A bevel cut is an angled cut made along the edge of a material, typically wood, for decorative or functional purposes.

What Is The Purpose Of A Bevel?

A bevel creates a sloped edge for aesthetics, safety, or functionality, often used in carpentry and machining.

What Does Bevel Look Like?

A bevel has an angled edge, typically sloping at 45 degrees, creating a smooth, finished look on materials.

How Do You Make A Bevel Cut?

To make a bevel cut, adjust the saw blade to the desired angle. Secure the material, then carefully cut along the marked line. Use safety gear.

Conclusion

Bevel cutting is a versatile and useful technique. It allows for precise and angled cuts. Many industries benefit from its application. Understanding bevel cutting can improve project outcomes. Remember to use the right tools and safety measures. This method enhances the quality of your work.

With practice, you can achieve clean and accurate bevel cuts. Keep experimenting and refining your skills. Soon, you will see improvements in your projects. Enjoy the process and keep learning. Bevel cutting is a valuable skill to have.