What is Polyurethane Dispersion: Unveiling Its Secrets

Polyurethane dispersion, also known as PUD, is a water-based polyurethane polymer resin that is dispersed in water instead of a solvent. It is commonly used in various applications, including coatings, adhesives, and sealants.

These dispersions offer the benefits of a two-component system without the need for additional crosslinkers, making them environmentally friendly and low in volatile organic compounds (VOCs). They are formed by finely dispersing urethane polymers in water, allowing for easy application and improved performance.

Waterborne polyurethane dispersions are gaining popularity due to their versatility and compatibility with different substrates. They provide excellent adhesion, durability, and resistance to chemicals and abrasion. Overall, polyurethane dispersions offer a water-based alternative to traditional solvent-based polyurethane products.

Introduction To Polyurethane Dispersion

Polyurethane dispersion, often abbreviated as PUD, is a type of polyurethane polymer resin that is dispersed in water, as opposed to being dissolved in a solvent. This dispersion may sometimes include a cosolvent, but the primary medium is water. The use of polyurethane dispersion has gained popularity due to its eco-friendly and sustainable nature, making it an attractive alternative to traditional solvent-based products. In this section, we will delve into the basics of PUD and explore its comparison with traditional solvents.

The Basics Of PUD

Polyurethane dispersion (PUD) is a polymer dispersion that contains polyurethane particles dispersed in water. These particles are typically on the nanoscale, resulting in a colloidal dispersion that can be used in various applications such as coatings, adhesives, and sealants. PUD offers several advantages, including low VOC emissions, excellent chemical resistance, and the ability to form durable and flexible films upon curing.

PUD Versus Traditional Solvents

When comparing PUD with traditional solvent-based systems, one of the key distinctions is the absence of volatile organic compounds (VOCs) in PUD formulations. This makes PUD environmentally friendly and compliant with stringent regulations regarding air quality and emissions. Additionally, PUD offers improved safety for workers due to the reduced risk of exposure to harmful solvents. Furthermore, the water-based nature of PUD facilitates easier cleanup and reduces the impact on the environment.

Chemical Composition

Polyurethane dispersion, known as PUD, is a polymer resin dispersed in water, rather than solvent, offering eco-friendly coatings. This innovative chemistry enhances various products with improved durability and performance.

Polyurethane Polymer Structure

Polyurethane dispersion (PUD) is a type of polymer made up of urethane linkages. The urethane linkages are formed by reacting isocyanates with polyols. The resulting polymer can have a wide range of properties depending on the types of isocyanates and polyols used in its synthesis. PUDs are often used in coatings, adhesives, and sealants due to their excellent mechanical properties, good chemical resistance, and high durability.

Role Of Water In PUDs

Water plays a crucial role in the production and use of polyurethane dispersions. In order to disperse the polyurethane polymer in water, the polymer must be modified to make it hydrophilic. This is typically done by incorporating ionic or non-ionic hydrophilic segments into the polymer structure. The water acts as a dispersant for the polymer, allowing it to be more easily mixed with other ingredients and applied to surfaces. Once the PUD is applied, the water evaporates, leaving behind a cured polymer coating, adhesive, or sealant.

In addition to their use in one-component formulations, PUDs are also used in two-component systems. In these systems, the PUD is combined with a crosslinker to create a more durable and chemically resistant coating or adhesive. The water acts as a carrier for the PUD and crosslinker, allowing them to be easily mixed and applied to surfaces.

Overall, the chemical composition of PUDs makes them a versatile and valuable material for a wide range of applications. Whether you need a coating, adhesive, or sealant, PUDs offer excellent mechanical properties, good chemical resistance, and high durability.

Manufacturing Process

Polyurethane dispersion, also known as PUD, is a type of polyurethane polymer resin that is dispersed in water instead of a solvent. These urethane polymers are finely dispersed in water and are used in both one-component and two-component systems for various applications such as coatings, adhesives, and sealants.

Steps To Creating PUD

Polyurethane dispersion, also known as PUD, is a type of polyurethane polymer resin that is dispersed in water rather than a solvent. The manufacturing process of PUD involves several steps to ensure the dispersion is of high quality and suitable for various applications.

- Polymerization: The first step in creating PUD is the polymerization of polyurethane. This process involves the reaction of polyols and diisocyanates to form the polyurethane polymer.

- Dispersing Agents: To disperse the polyurethane polymer in water, dispersing agents are added. These agents help to break down the polymer into smaller particles, allowing it to mix with water effectively.

- Hydrophilic Modification: Polyurethanes are typically hydrophobic and insoluble in water. To make them suitable for dispersion, hydrophilic elements are incorporated into the polymer structure. This modification can involve the addition of ionic groups or non-ionic hydrophilic segments.

- Emulsification: The next step is emulsification, where the polyurethane dispersion is formed. Emulsifiers are used to stabilize the mixture of water and polyurethane particles, preventing them from separating.

- Adjustment: Depending on the desired properties of the PUD, adjustments may be made at this stage. This can include modifying the particle size, viscosity, or solid content of the dispersion.

- Testing and Quality Control: Before the PUD is ready for use, it undergoes rigorous testing and quality control procedures. This ensures that the dispersion meets the required specifications and is suitable for its intended applications.

The manufacturing process of polyurethane dispersion involves these steps to create a stable and effective water-based dispersion. By incorporating hydrophilic elements and utilizing appropriate dispersing agents and emulsifiers, PUDs can be tailored to meet specific performance requirements in various industries such as coatings, adhesives, and sealants.

Overall, the process of creating PUDs is a complex and precise one, requiring careful control of parameters to achieve optimal dispersion properties. The resulting polyurethane dispersion offers a range of benefits, including environmental friendliness, improved safety, and excellent performance characteristics.

Properties And Characteristics

Polyurethane dispersion, also known as PUD, is a water-based polyurethane polymer resin. It is used as a solvent-free alternative and can be modified with cosolvents. PUDs are finely dispersed in water and commonly used in coatings, adhesives, and sealants.

Polyurethane dispersion, also known as PUD, is a polyurethane polymer resin that is dispersed in water instead of a solvent. This water-based dispersion offers several unique properties and characteristics that make it a popular choice in various industries. Let’s explore some of these properties in more detail.

Physical Properties

Polyurethane dispersion exhibits excellent film-forming properties, resulting in coatings that are smooth, durable, and resistant to abrasion. The dispersion particles are typically smaller in size, allowing for improved film uniformity and adhesion to various substrates.

Furthermore, PUD offers a wide range of hardness options, from soft and flexible to hard and rigid, making it suitable for diverse applications. Its ability to maintain flexibility even at low temperatures ensures that the coating remains intact and doesn’t crack or peel.

Chemical Stability

One of the key advantages of polyurethane dispersion is its exceptional chemical stability. It is resistant to various chemicals, including solvents, oils, and acids, making it ideal for applications that require protection against harsh environments.

Additionally, PUD coatings exhibit excellent resistance to UV radiation, ensuring long-lasting performance and color retention. This makes them suitable for outdoor applications where exposure to sunlight is a concern.

The waterborne nature of polyurethane dispersion also contributes to its environmental friendliness. It significantly reduces the emission of volatile organic compounds (VOCs), making it a greener alternative to solvent-based coatings.

In conclusion, polyurethane dispersion offers a range of properties and characteristics that make it a versatile and sustainable choice for various applications. Its excellent film-forming abilities, flexibility, chemical stability, and environmental friendliness make it a preferred option in industries such as coatings, adhesives, and sealants.

References:

– [Polyurethane Dispersion – an overview | ScienceDirect Topics](https://www.sciencedirect.com/topics/engineering/polyurethane-dispersion)

– [Polyurethane Dispersions – Coatings | The Lubrizol Corporation](https://www.lubrizol.com/Resins-and-Binders/Polyurethane-Dispersions)

– [Waterborne Polyurethane Dispersion (PUD) Adhesives | Sanyo Chemical America](https://www.sanyo-chemical.com/waterborne-polyurethane-dispersion-pud-adhesives)

– [Polyurethane Dispersion Market: Global Demand Surge and … | LinkedIn](https://www.linkedin.com/pulse/polyurethane-dispersion-market-global-demand-surge-insights-research)

– [Polyurethane dispersion – Wikipedia](https://en.wikipedia.org/wiki/Polyurethane_dispersion)

Applications In Industry

Polyurethane dispersion, also known as PUD, is a water-based polyurethane polymer resin. It is used as a coating, adhesive, and in the production of polyurethane foam. Polyurethane dispersions offer the performance of a two-component system without the need for additional crosslinkers.

Polyurethane dispersion (PUD) is a versatile material that finds a wide range of applications in various industrial sectors. The water-based dispersion has excellent film-forming properties and can be used as a substitute for traditional solvent-based coatings and adhesives. Here are some of the industries that rely on PUDs for their unique properties:

PUDs In Coatings

PUDs are widely used in the coatings industry due to their exceptional film-forming properties. They are used to create high-performance coatings for various substrates such as wood, metal, and plastic. The coatings offer excellent resistance to abrasion, chemicals, and UV radiation. PUDs can be used in applications such as automotive coatings, industrial coatings, and furniture coatings.

Adhesives And Sealants

PUDs are also used extensively in the adhesives and sealants industry. They offer excellent bonding properties and can be used to create adhesives for various substrates such as metals, plastics, and wood. PUD-based adhesives offer excellent resistance to water, chemicals, and UV radiation. They can be used in applications such as laminating adhesives, pressure-sensitive adhesives, and structural adhesives.

In conclusion, PUDs are a highly versatile material that finds a wide range of applications in various industrial sectors. They offer excellent film-forming and bonding properties, making them an ideal substitute for traditional solvent-based coatings and adhesives. With their exceptional properties, PUDs are sure to continue to be a popular choice among manufacturers and industrial users alike.

Environmental Impact

Polyurethane dispersion (PUD) offers several eco-friendly aspects and regulatory considerations that make it a sustainable choice in various applications.

Eco-friendly Aspects

- Low volatile organic compound (VOC) content

- Reduced carbon footprint

- Water-based formulation

- Biodegradable components

Regulatory Considerations

- Compliance with environmental regulations

- Safe disposal practices

- Health and safety standards

- Recyclable packaging materials

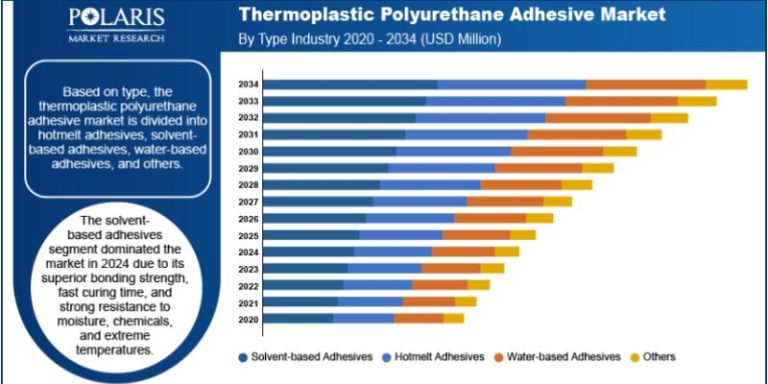

Market Trends

Polyurethane dispersion, or PUD, is a type of polyurethane polymer resin that is dispersed in water instead of a solvent. This dispersion process allows for the creation of waterborne one-component formulations and two-component systems without the need for additional crosslinkers.

Polyurethane dispersion, also known as PUD, is a polyurethane polymer resin dispersed in water, rather than a solvent. Let’s delve into the

Demand And Growth

Innovations And Future Prospects

in the market for polyurethane dispersions.

Demand And Growth

– Increasing demand for eco-friendly coatings boosts the market.

– Growing adoption in various industries like automotive, textiles, and construction.

– Rising awareness about sustainable solutions drives the market growth.

Innovations And Future Prospects

– Advancements in manufacturing processes lead to higher quality PUDs.

– Development of novel applications in electronics and medical sectors.

– Expansion of product portfolios by key players for enhanced performance.

In conclusion, the polyurethane dispersion market shows promising growth opportunities driven by sustainability and technological innovations.

Challenges And Solutions

Polyurethane dispersion, also known as PUD, involves dispersing polyurethane polymer resin in water rather than a solvent, offering a more eco-friendly solution for various applications. This innovative technology presents challenges in formulation and stability, but it also provides solutions for creating waterborne coatings, adhesives, and more.

Water Solubility Issues

Polyurethane dispersions (PUDs) are hydrophobic by nature and not soluble in water. To address this challenge, the polymer structure can be modified by introducing ionic or non-ionic hydrophilic segments.

Advancements In PUD Technology

Recent advancements in Polyurethane Dispersion (PUD) technology have led to improved water compatibility and stability. New formulations incorporate innovative additives to enhance dispersion properties.

Frequently Asked Questions

What Is A Polyurethane Dispersion?

Polyurethane dispersion, or PUD, is a water-dispersed polyurethane polymer resin, used in coatings and adhesives.

How To Make Pu Dispersion?

To make PU dispersion, disperse polyurethane polymer resin in water, using a cosolvent if needed.

What Is The Market For Polyurethane Dispersions?

The market for polyurethane dispersions is growing rapidly. Polyurethane dispersions are water-based polyurethane polymers that are used in various applications such as coatings, adhesives, sealants, and more. These dispersions offer excellent performance and environmental benefits compared to solvent-based alternatives. As the demand for sustainable and eco-friendly solutions increases, the market for polyurethane dispersions is expected to expand further.

Does Polyurethane Dissolve In Water?

Polyurethane does not dissolve in water because it is hydrophobic and insoluble. To disperse polyurethane in water, it needs to be modified by incorporating ionic groups or non-ionic hydrophilic segments into the polymer structure. This allows for waterborne polyurethane dispersions to be created, which are used in various applications.

Conclusion

Polyurethane dispersion (PUD) is a water-based polyurethane polymer resin used in coatings and adhesives. Its eco-friendly nature and low VOC content make it an ideal choice for various applications. Understanding its chemistry and market demand is crucial for utilizing its benefits effectively in different industries.