What is the Difference between Mdf And Chipboard: Expert Insights

Have you ever found yourself standing in the aisles of a hardware store, staring at the rows of wooden boards, and wondering which one is right for your project? You’re not alone.

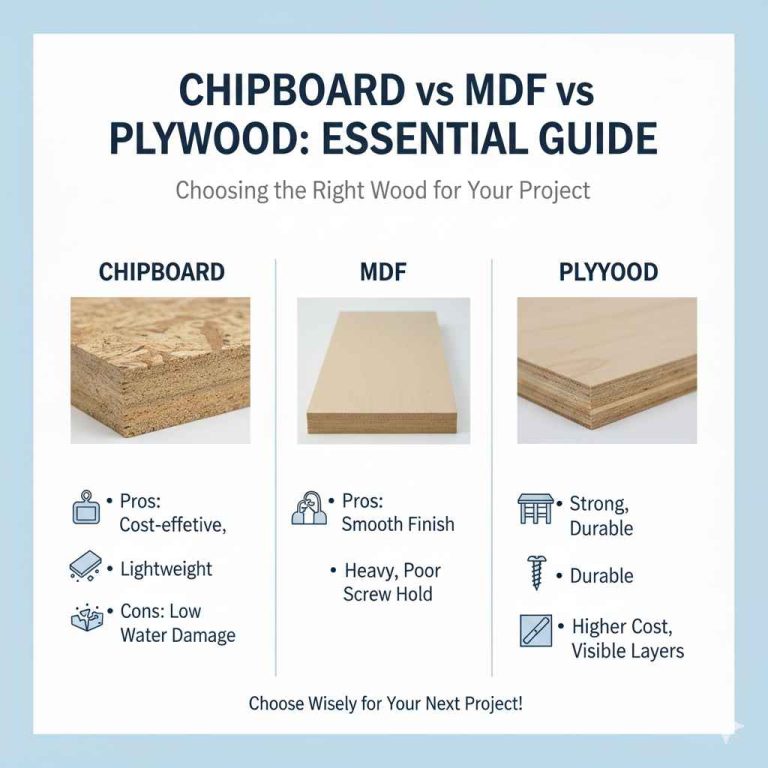

When it comes to choosing between MDF (Medium Density Fiberboard) and chipboard, the decision can be quite puzzling. Each has its own strengths and weaknesses, and making the wrong choice could affect the durability and appearance of your project. This guide will unravel the mysteries of MDF and chipboard, helping you make an informed decision that ensures your finished piece stands the test of time.

By the end, you’ll know exactly which material suits your needs, saving you time, money, and effort. Ready to unlock the secrets of wood materials? Let’s dive in!

Material Composition

MDF stands for Medium-Density Fiberboard. It is made from wood fibers mixed with wax and resin. These fibers are pressed into sheets. The sheets are smooth and uniform. MDF is dense and heavy. It is often used for furniture. It is strong but can be hard to cut.

Chipboard is made from wood chips or shavings. It uses glue to stick the chips together. The board is lighter than MDF. It is not as strong as MDF. Chipboard is often used for flooring and cheap furniture. It is easy to cut and shape.

Manufacturing Process

MDF stands for Medium Density Fiberboard. It is made from wood fibers. These fibers come from both softwood and hardwood. They are mixed with wax and resin. High pressure and heat are used to form sheets. The result is a smooth, dense board. It is easy to cut and shape.

Chipboard is also called particle board. It is made from wood chips and sawdust. These are by-products from other woodwork processes. They are mixed with a strong adhesive. Then, they are pressed into sheets. The surface is rougher than MDF. It is less dense and is more affordable.

Physical Properties

MDF and chipboard differ in density and strength. MDF is denser, smoother, and easier to paint. Chipboard is lighter and often used for affordable furniture.

Density And Weight

MDF is denser than chipboard. It feels heavier when you lift it. This is because MDF has more wood fibers packed tightly. It is smooth and has a fine texture. Chipboard is lighter and less dense. It has large wood particles. This makes it rougher and less smooth. MDF is often preferred for smooth finishes. Chipboard is used where weight matters less.

Strength And Durability

MDF is strong but not as tough as plywood. It can handle some weight but can break if bent. Chipboard is less strong. It might chip or crack easily. MDF lasts longer if kept dry. It can swell if wet. Chipboard is more prone to damage from water. Both are used in furniture. MDF is better for detailed work. Chipboard is cheaper but less durable.

Credit: kristinlia.ca

Applications And Uses

MDF is used in making furniture like tables and shelves. It is great for indoor use. MDF is easy to paint and decorate. Builders use it in kitchen cabinets and wardrobes. It is also used in making doors and moldings. MDF is smooth and looks neat. It is used in crafts and art projects. It is strong and lasts long indoors. MDF is a favorite for custom designs.

Chipboard is used in making economical furniture. It is common in flat-pack items. Chipboard is often used in flooring. It gives a smooth surface. It is also used in making cabinets. Chipboard is good for temporary structures. It is used in packaging and boxes. It is lighter than MDF. It is easy to cut and use. Chipboard is a popular choice in construction.

Cost Comparison

MDF is often more expensive than chipboard. It is made from wood fibers and resin. This gives it a smooth surface. Many people use MDF for furniture. It is strong and lasts longer. Prices can vary, but MDF is usually a bit pricey. It might cost more than $30 for a large sheet.

Chipboard is less costly. It is made from wood chips and glue. This makes it cheaper. People often use chipboard for temporary projects. It is not as strong as MDF. Prices are usually lower. You might pay less than $20 for a large sheet. Chipboard is a budget-friendly choice.

Environmental Impact

MDF is made from wood fibers. These fibers come from small trees. Recycled wood is also used in MDF. This reduces waste. Formaldehyde is sometimes used in MDF. It can harm the air. Some MDF uses low-formaldehyde glue. This makes it safer. MDF can be reused or recycled. It is strong and lasts long.

Chipboard is made from wood chips. It uses waste wood. This makes it eco-friendly. It needs less energy to make than other wood. Non-toxic glue is often used. Chipboard is cheap and easy to find. It can be recycled. But it is not as strong. It can break if wet. Using it saves trees.

Advantages And Disadvantages

MDF stands for Medium Density Fiberboard. It’s a type of wood product. One advantage of MDF is its smooth surface. This makes it easy to paint. It is also very strong and dense. MDF is perfect for creating furniture. But, MDF can absorb water. This makes it weak in wet places. It may also be heavy to carry. Dust from MDF can be harmful to health. Always wear a mask when cutting it.

Chipboard is made from wood chips. It’s cheaper than real wood. You can use chipboard for simple projects. It’s also light and easy to move. But, chipboard is not very strong. It can break easily. Water can damage it quickly. It is not good for outdoor use. Chipboard is best for temporary items. Always handle it with care.

Credit: www.kombiniranimasi.com

Expert Recommendations

MDF is denser and smoother, making it ideal for painting and detailed work. Chipboard, also known as particle board, is cheaper and made from wood chips, offering a rougher finish suitable for basic furniture. Both are popular in furniture making, but differ in strength and appearance.

Choosing Between MDF And Chipboard

MDF is made from wood fibers. It is denser and smoother. Chipboard is made from wood chips. It is rougher and lighter. People use MDF for furniture. It paints well and looks nice. Chipboard is cheaper. It is good for shelves and basic furniture. MDF is strong but heavy. It is good for detailed work. Chipboard is weak but easy to cut.

Experts suggest MDF for fancy projects. Use it for cabinets and decorative pieces. Chipboard works well for simple items. Choose it for budget-friendly options. Consider the finish you want. Think about the weight and cost. MDF lasts longer. Chipboard saves money. Both have good uses. Pick the one that fits your needs.

Frequently Asked Questions

What Is Better, MDF Or Chipboard?

MDF offers a smoother finish and greater strength compared to chipboard. It is ideal for detailed furniture work. Chipboard is more affordable and lightweight, suitable for basic construction. Choose MDF for durability and chipboard for budget-friendly projects.

When Should You Not Use MDF?

Avoid using MDF in high moisture areas like bathrooms or kitchens. It swells and deteriorates when wet. MDF is unsuitable for structural applications due to its low strength. It can’t hold screws well, making it unreliable for heavy loads. Opt for solid wood or plywood for durability.

What Is Chipboard Called Now?

Chipboard is now commonly called particle board. It’s made from compressed wood chips, sawdust, and resin. Used in furniture and construction, it offers affordability and versatility. It’s ideal for projects requiring a smooth finish. Particle board remains a popular choice for budget-friendly and durable applications.

What Are The Disadvantages Of Chipboard?

Chipboard lacks durability and is prone to moisture damage. It often swells and warps when wet. Its low strength makes it unsuitable for heavy loads. The material can emit formaldehyde, impacting indoor air quality. Its appearance is less attractive compared to natural wood.

Conclusion

Choosing between MDF and chipboard depends on your project needs. MDF offers smooth surfaces for painting and detailed work. Chipboard provides a cost-effective option, ideal for basic furniture. Both materials have their strengths and weaknesses. MDF excels in strength and versatility.

Chipboard shines in affordability and lightweight construction. Consider the environment and budget when deciding. Each material serves specific purposes well. Understanding their differences helps make informed choices. Always assess the requirements of your project. This ensures you select the right material for the job.