Which Way Do Saw Blades Go? Discover the Best Techniques for a Precision Cut!

Saw blades go in a specific direction, typically rotating clockwise when cutting through materials. Saw blades have a specific orientation when they are installed on a saw.

This orientation is determined by the direction in which the teeth on the blade are positioned. Most saw blades are designed to rotate in a clockwise direction when cutting through materials. This rotating motion allows the teeth to efficiently cut through the material being worked on.

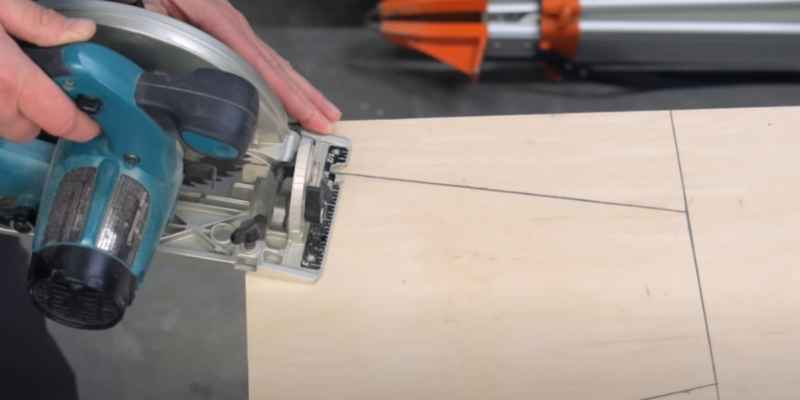

It’s important to ensure that the saw blade is securely installed and properly aligned in order to achieve accurate and effective cuts. Whether you’re using a circular saw, table saw, or any other type of saw, understanding the proper direction of the saw blade is essential for safe and efficient cutting.

The Basics Of Saw Blades

Saw blades have a preferred direction of motion. Knowing which way saw blades go helps ensure safe and efficient cutting. Get familiar with the correct orientation to optimize your saw’s performance.

A keen understanding of the basics of saw blades is essential for achieving precise and efficient cuts. Whether you’re a DIY enthusiast or a professional woodworker, knowing the type of saw blades and their anatomy can make all the difference in your projects.

Type of Saw Blades

There is a wide variety of saw blades available, each designed for specific cutting tasks. The following is a breakdown of the most common types of saw blades:

1. Circular Saw Blades: Ideal for making straight cuts in wood, metal, or plastic.

2. Band Saw Blades: Perfect for cutting irregular shapes and curved patterns.

3. Jigsaw Blades: Suitable for intricate and detailed cuts in wood, metal, and other materials.

4. Reciprocating Saw Blades: Designed for rough cuts and demolition work.

Anatomy of a Saw Blade

Understanding the components of a saw blade can help in selecting the right blade for your cutting needs. Here is a brief overview of the key parts of a saw blade:

– Teeth: The cutting edges of the blade that vary in size, shape, and distribution based on the blade type and cutting material.

– Gullet: The space between the teeth that allows for effective chip removal during cutting.

– Kerf: The slot created by the saw blade as it cuts through the material.

– Plate: The main body of the saw blade, which determines its thickness and rigidity.

– Arbor Hole: The center hole of the blade that fits onto the saw’s arbor.

Understanding the type of saw blades and their anatomy is crucial for achieving clean and precise cuts. By selecting the right blade for the job and being aware of its key components, you can enhance the efficiency and quality of your cutting tasks.

Understanding Saw Blade Direction

Understanding the correct direction of a saw blade is essential for any woodworking enthusiast or professional carpenter. Using the blade in the wrong direction can result in poor cutting efficiency, damage to the blade or workpiece, and even potential safety hazards. In this article, we will explore the importance of correct blade direction and the various options available.

Importance Of Correct Blade Direction

Using a saw blade in the correct direction is crucial to achieve precise and clean cuts. A saw blade is specifically designed to cut smoothly and effectively when it rotates in the intended direction. When used incorrectly, the blade can push wood fibers outwards, causing tear-out, splintering, or even kickback—posing a risk of injury to the operator.

To ensure optimal cutting performance and maintain safety, it is necessary to understand and follow the recommended blade direction for each type of saw. This knowledge will help woodworkers achieve better results with fewer complications.

Different Saw Blade Direction Options

Depending on the type of saw, there can be different options for blade direction. Let’s take a look at a few common types:

1. Circular Saws:

Circular saw blades generally rotate counterclockwise when viewed from above. Due to their design, they are more effective when cutting through materials with the teeth facing towards the front of the saw. This allows the blade to make a clean entry into the material, reducing the chances of splinters and tear-outs.

2. Table Saws:

Table saw blades are typically designed to rotate towards the operator, or clockwise when viewed from the top. The cutting edge of the teeth should be facing towards the operator as well. This design ensures that wood fibers are pushed down against the table, resulting in cleaner cuts and minimizing kickback.

3. Band Saws:

Band saw blades can have different direction options depending on whether they are used for resawing or general-purpose cutting. For resawing, the blade should typically rotate with the teeth facing downwards or towards the table. However, for general-purpose cutting, the blades usually rotate with the teeth facing upwards.

4. Jigsaws:

Unlike other saws, jigsaw blades move in an up-and-down motion rather than in a rotational manner. Therefore, the direction of the teeth is crucial for efficient cutting. The teeth, often pointed towards the front of the jigsaw, should be facing downwards to allow the blade to cut smoothly as it moves up and down.

Always refer to the manufacturer’s instructions and guidelines for the specific model of saw you are using. Ensuring correct blade direction not only helps maintain the longevity of the blade but also enhances cutting performance while prioritizing safety.

Techniques For A Precision Cut

When it comes to achieving a precise and clean cut using a saw, there are several important techniques to consider. From setting up the saw correctly to using the right blade for the material, each step plays a crucial role in ensuring a precision cut. Additionally, properly maintaining and replacing saw blades is vital to maintain cutting accuracy. In this article, we will explore these techniques in detail to help you achieve the best results with your sawing projects.

Setting Up The Saw Correctly

Before starting any cutting project, it is essential to set up your saw correctly. This involves checking and adjusting the blade alignment, ensuring the blade is securely fastened, and confirming that the fence or guide is positioned accurately. By taking the time to set up your saw properly, you can ensure that the blade will cut straight and true, minimizing any deviation from the desired cut line.

Using The Right Blade For The Material

Choosing the right blade for the material you are cutting is crucial for achieving a precision cut. Different types of saw blades are designed for specific materials, such as wood, metal, or plastic. It is important to select a blade that matches the material’s thickness and hardness to ensure clean and efficient cutting. Using the wrong blade can result in rough cuts, blade dullness, and potential damage to the material or the saw itself. Refer to the manufacturer’s recommendations or consult with a professional to determine the appropriate blade for your project.

Maintaining And Replacing Saw Blades

Proper maintenance of saw blades is essential for optimal cutting performance. Regularly check the blades for signs of wear, such as dullness or chipping, and clean them thoroughly after each use to remove any sawdust or debris. Sharpening dull blades or replacing worn-out blades will not only improve cutting precision but also extend the lifespan of the blade. Remember, a sharp and well-maintained saw blade will not only ensure clean cuts but also reduce the risk of overheating and kickback, making your cutting tasks safer and more efficient.

Common Mistakes And Troubleshooting

When it comes to using saw blades, it’s crucial to ensure that they are correctly installed and oriented for optimal performance. However, it’s not uncommon for DIY enthusiasts and even professionals to make mistakes when setting up their saw blades. Understanding the common mistakes and troubleshooting techniques can help you achieve accurate and high-quality cuts with your saw. In this section, we’ll explore some of the blade direction errors, cut quality issues, and solutions to fix saw blade problems.

Blade Direction Errors

Incorrect blade direction can lead to a multitude of issues when using a saw. Whether it’s a circular saw, table saw, or miter saw, ensuring that the saw blade is installed in the correct orientation is essential for safe and effective operation. One common mistake is installing the saw blade backwards, which can cause kickback and poor cutting performance.

Cut Quality Issues

When the saw blade direction is incorrect, it can result in subpar cut quality. Common issues include tear-out, burning, and rough edges, which can significantly impact the final outcome of your woodworking projects. It’s crucial to address these cut quality issues promptly to achieve precise and clean cuts.

How To Fix Saw Blade Problems

Fortunately, addressing saw blade problems is often straightforward. By ensuring the blade is correctly oriented and making adjustments to the saw settings, you can significantly improve the overall performance and cut quality. Proper troubleshooting techniques, such as blade inspection and adjustment, are crucial for resolving common saw blade issues.

Conclusion

In understanding saw blade direction, safety and efficiency are key. Correct installation ensures optimal cutting results and minimizes the risk of accidents. By following manufacturer guidelines, you can confidently use saw blades and achieve professional results in your woodworking projects.

Remember, a well-maintained saw blade ensures precise and safe cutting.