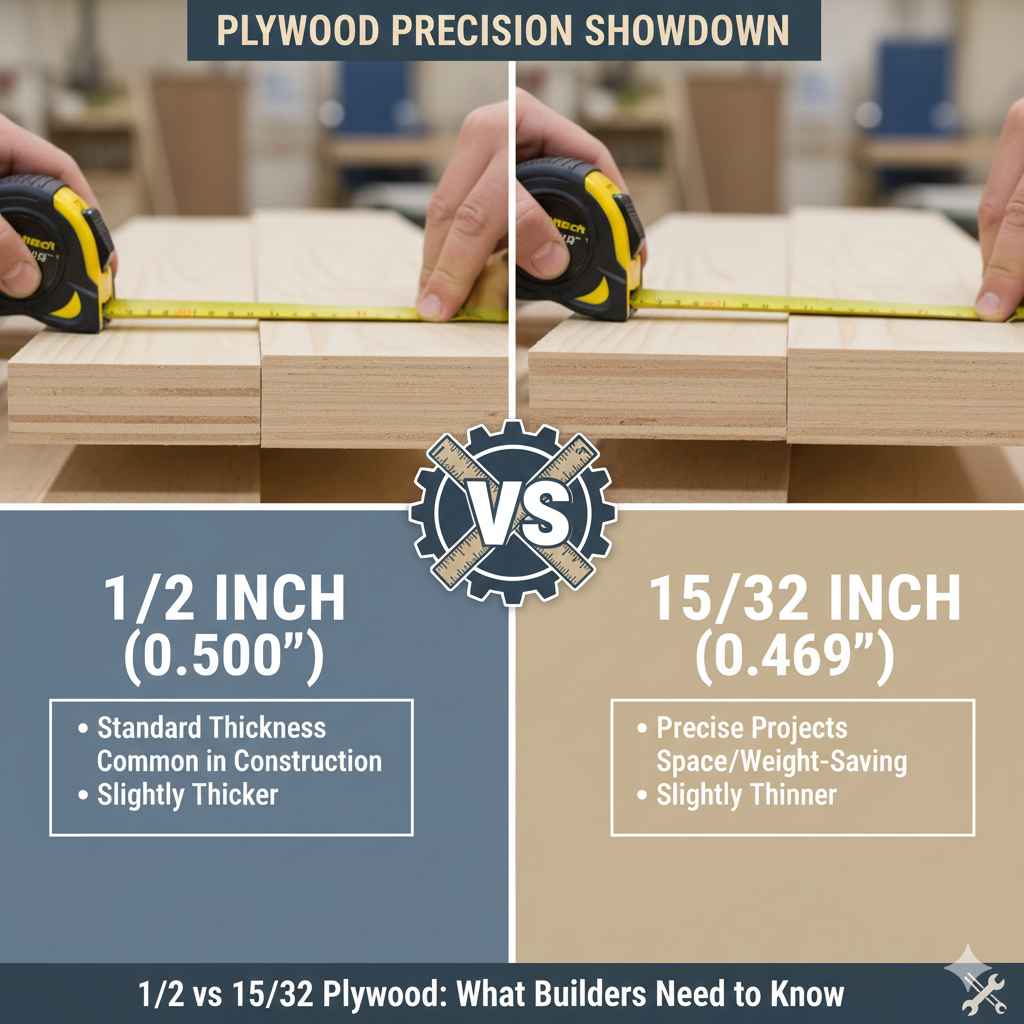

1/2 vs 15/32 Plywood: What Builders Need to Know

Figuring out the differences between 1/2 vs 15/32 Plywood: Key Differences Explained can seem tricky at first, especially if you’re new to building or woodworking. Don’t worry, many people find it confusing! This guide will break down everything in a simple way, step by step. We’ll explore the main differences and help you decide which type of plywood is best for your projects. Get ready to learn about plywood thickness and what it means for your next project.

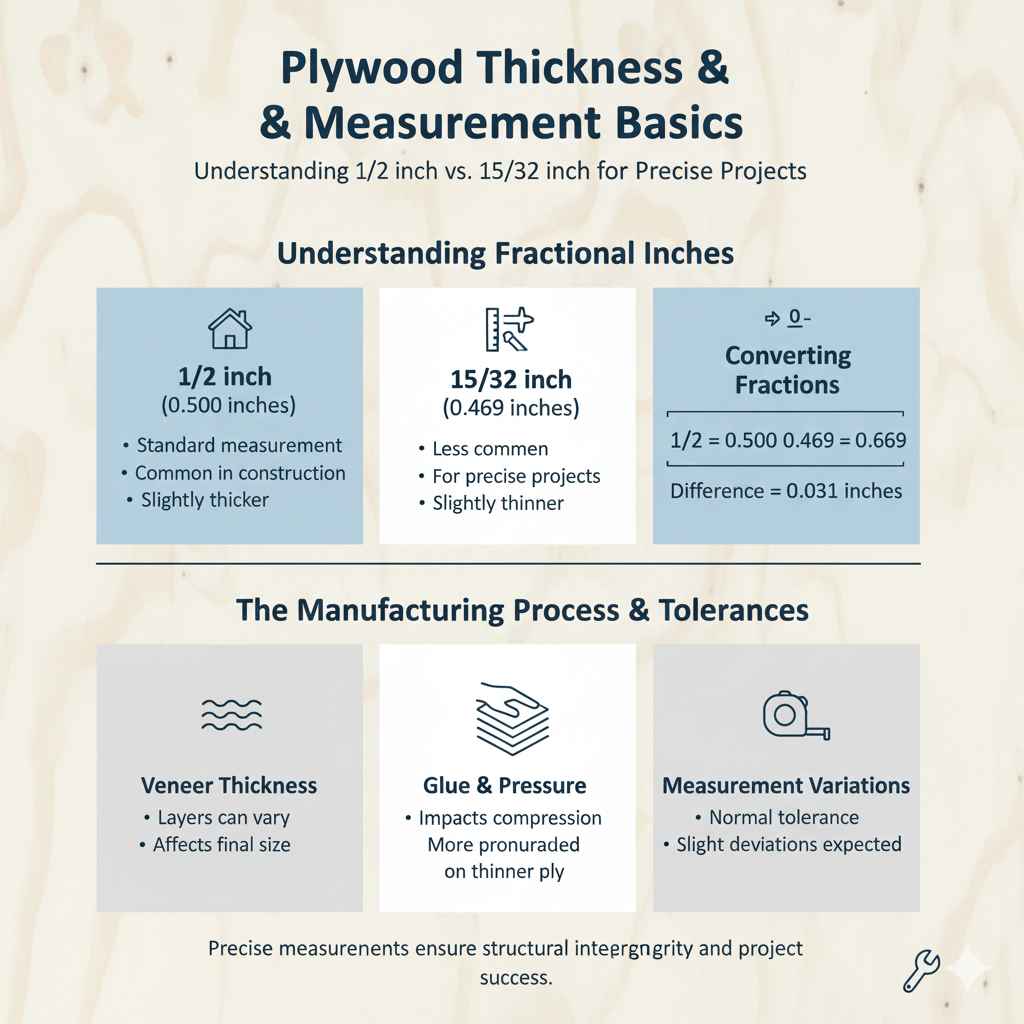

Thickness and Measurement Basics

When you’re shopping for plywood, one of the first things you’ll notice is the thickness. Plywood thickness is measured in inches, but there are some slight differences that can make a big impact on your project. The two thicknesses that often cause confusion are 1/2 inch and 15/32 inch. It’s important to know the precise differences because that will dictate structural integrity and your wood working.

Understanding Fractional Inches

The numbers 1/2 and 15/32 are both fractions of an inch, representing the thickness of the plywood sheets. Knowing how to convert them can make a huge difference in your project’s success. It can also help you choose the right materials the first time. The difference, while seemingly small, can be important when working with other materials or fitting into existing structures.

- 1/2 inch (0.500 inches): This is a standard measurement, often used in many common construction projects. Many builders are familiar with 1/2-inch plywood. It is typically a little thicker, and you might have to adjust your measurements for some building plans.

- 15/32 inch (0.469 inches): This measurement is a bit less common, but still important. It is usually slightly thinner, making it an option when you need to save space or weight. You might run into this size when working on projects that require precise measurements.

- Converting Fractions: To visualize the difference, convert both fractions to decimals. 1/2 is equal to 0.500 inches, and 15/32 is approximately 0.469 inches. This difference of about 0.031 inches can affect how things fit together.

The Manufacturing Process and Tolerances

Plywood is made by layering thin sheets of wood, called veneers, and then gluing them together under heat and pressure. The way these veneers are layered determines the plywood’s thickness and strength. This process is a part of manufacturing that sometimes creates slight variations. You might find that actual measurements are slightly different from what’s labeled.

- Veneer Thickness: The thickness of each veneer can affect the final measurement. Veneers might be slightly thicker or thinner.

- Glue and Pressure: The type of glue and the amount of pressure used also impact the final thickness. This can be more pronounced on thinner plywood options.

- Measurement Variations: Plywood thicknesses are usually given a tolerance, meaning they can vary slightly from the stated size. This is a normal part of the manufacturing process.

Structural and Practical Applications of Plywood Thickness

The choice between 1/2 and 15/32 plywood often comes down to what you’re building. Consider what kind of loads the structure will bear, the specific space available, and the overall look you’re trying to achieve. One choice might be better than the other, based on your criteria.

When to Use 1/2 Inch Plywood

1/2 inch plywood is commonly chosen for projects where extra strength is needed. The added thickness makes it a good option when you want to make sure your building is sturdy. It provides more resistance to bending and other stresses, which is especially important for certain applications. These advantages often help make the projects more durable and long-lasting.

- Wall Sheathing: Because it is thicker, 1/2 inch plywood is great for sheathing walls, especially in buildings where extra sturdiness is needed.

- Subflooring: It is also a good choice for subflooring because it creates a more solid base for flooring materials. It can help reduce bounce.

- Furniture: For building furniture, like shelves and cabinets, the extra thickness can help with weight and durability.

When to Use 15/32 Inch Plywood

15/32 inch plywood is a good choice for situations where you want something a bit thinner or when space is limited. This is often the case with projects where overall weight matters or when you are working with tight spaces. It can also be a more cost-effective option, particularly when the strength difference isn’t a problem.

- Roof Sheathing: 15/32 inch plywood can work for roof sheathing. You might use it in projects where weight is a primary concern.

- Light Cabinets: If you’re constructing lighter cabinets, you might find this thickness to be easier to work with.

- Projects Where Weight is Key: Because it’s lighter, this thickness can be a good choice for projects where the weight of the material matters.

Key Differences Explained: 1/2 vs 15/32 Plywood

The differences between 1/2 vs 15/32 Plywood: Key Differences Explained are small. Still, they can impact your building. It helps to understand the advantages and disadvantages. This information makes a difference when choosing the right plywood for your project.

Strength and Durability

The strength of plywood directly relates to its thickness. When choosing between these two options, it’s essential to consider the expected load and stresses on the structure. This is especially true for projects that have to withstand the elements.

- Strength of 1/2 Inch: 1/2 inch plywood is generally stronger and more resistant to bending than 15/32 inch. It’s better at bearing loads and maintaining its shape.

- Strength of 15/32 Inch: While still strong, 15/32 inch plywood is slightly less so. It may not be suitable for high-stress applications.

- Consider the Load: Always think about the weight and forces your project will face. Will it handle the pressure?

Weight and Space Considerations

The weight of the plywood can also be important, especially in construction or renovation. The choice between 1/2 and 15/32 plywood can affect things like shipping costs and structural needs. Understanding the impact of weight helps you make informed decisions.

- Weight Difference: 15/32 inch plywood is lighter than 1/2 inch, making it easier to handle.

- Space Savings: In tight spaces, 15/32 inch plywood might be better because it takes up less space.

- Transportation Costs: Lighter materials can also reduce shipping costs if you’re buying online.

Working With and Compatibility

The best plywood for your project is the one that fits your needs. This requires understanding how these two plywood options work with other materials and the construction process. This section explores several practical considerations, from cutting to fasteners.

Cutting and Fastening Techniques

You can cut and fasten both types of plywood with standard tools and techniques. Yet, because of the thickness difference, some adjustments might be necessary. It helps to know the best methods to ensure a professional result.

- Cutting: Both 1/2 and 15/32 inch plywood can be cut with a circular saw, jigsaw, or table saw. Always use a blade designed for plywood to minimize splintering.

- Fastening: Screws or nails work well for fastening plywood. Choose the correct length for the thickness you are using to avoid going all the way through the material.

- Edge Treatment: For a clean finish, you might want to edge-band the plywood, especially if the edges will be visible.

Compatibility With Other Materials

When you’re building, plywood often works together with other materials. The choice of plywood thickness can affect how well these materials fit and work together. You’ll need to know which products will go well with which plywood type.

- Framing: Plywood should fit well with standard framing lumber, like 2x4s or 2x6s. This helps create a solid base for your building project.

- Flooring: Plywood is often used as a base for flooring materials, like hardwood or tile. Always make sure the thickness is adequate for the flooring material.

- Adhesives: Using the correct adhesives can significantly improve the strength of your project. Select adhesives that are appropriate for the materials involved.

Cost and Availability

Both cost and how easy it is to find these plywoods can affect your project. Both types are widely available, but prices can change based on different factors. Understanding the costs helps you create a reasonable budget.

Price Comparisons

The prices of plywood change based on a variety of things, including the type of wood, where you live, and current market conditions. It pays to shop around to get the best prices possible. The price difference between 1/2 and 15/32 inch plywood might affect your decision.

- Cost Differences: 1/2 inch plywood is sometimes a little more expensive than 15/32 inch plywood. This can change based on the brand.

- Regional Variations: Prices might change based on what’s available in your area. Check local suppliers to get the most accurate prices.

- Quantity Discounts: Buying in bulk can sometimes save you money. Check with your local suppliers to see if they offer discounts.

Where to Buy

You can buy plywood at many locations, including local home improvement stores and online retailers. Knowing where to get the products you need will make your building project easier. Finding the best location for your needs helps ensure your project gets done on time.

- Home Improvement Stores: Home improvement stores, like Home Depot and Lowe’s, usually have a great selection of plywood.

- Lumberyards: Lumberyards often specialize in wood products and can provide professional advice.

- Online Retailers: Online retailers are good options. You can often see reviews and compare prices before you buy.

Real-Life Examples

These examples provide you with practical insights into how 1/2 and 15/32 inch plywood are used in different construction tasks. You’ll see how these types help create successful outcomes, by looking at real-world scenarios.

Building a Bookshelf

Building a bookshelf is a great project to show how the choice of plywood thickness matters. Here’s a look at how to choose based on your desired results.

- 1/2 Inch Plywood: If the bookshelf will hold many heavy books, 1/2 inch plywood might be the best choice. It will provide extra strength and prevent the shelves from bending over time. For example, if you build a bookshelf with 1/2-inch plywood, it will easily handle the weight of heavy reference books.

- 15/32 Inch Plywood: If the bookshelf is lighter and you want to save space, 15/32 inch plywood is an acceptable option. This will be adequate if you’re storing only novels.

Constructing a Shed

The choice of plywood matters a great deal when building a shed because sheds often face external stresses. Consider the overall structural needs when choosing between 1/2 and 15/32 inch plywood.

- Wall Sheathing: 1/2 inch plywood is often used for wall sheathing in sheds because it offers greater resistance to the elements, like wind and rain. For example, a shed built with 1/2-inch plywood sheathing is better able to withstand strong winds and heavy snow loads.

- Roofing: 15/32 inch plywood is sometimes an acceptable option for roofing, especially if weight is a concern. A shed built with 15/32-inch plywood would still hold up well.

Creating a DIY Desk

Building a desk shows the different applications. This project gives you a look at how the plywood choice can affect how your desk functions. Consider the use case when making a choice.

- 1/2 Inch Plywood: For a desk, 1/2 inch plywood creates a strong, stable work surface that can bear the weight of computers and other equipment. If your desk will support heavy equipment, choose this option.

- 15/32 Inch Plywood: 15/32 inch plywood is also used for a desk, particularly if space is limited. The thinner material is lighter and sometimes more cost effective.

Frequently Asked Questions

Question: What is the primary difference between 1/2 and 15/32 inch plywood?

Answer: The primary difference is the thickness. 1/2 inch plywood is a full 1/2 inch (0.500 inches) thick, while 15/32 inch plywood is slightly thinner, measuring around 0.469 inches.

Question: Which type of plywood is stronger?

Answer: 1/2 inch plywood is generally stronger and more resistant to bending compared to 15/32 inch plywood because it is thicker.

Question: Can I use 15/32 inch plywood as a substitute for 1/2 inch plywood?

Answer: Yes, in many cases, you can use 15/32 inch plywood as a substitute. Yet, it depends on the project’s requirements. Consider the load the material has to bear and the overall design.

Question: Are the costs of 1/2 inch and 15/32 inch plywood very different?

Answer: The price difference between the two plywoods is typically small. Costs can vary based on location, brand, and market conditions.

Question: Which type of plywood is best for wall sheathing?

Answer: 1/2 inch plywood is commonly used for wall sheathing because it’s strong and offers more resistance to the elements.

Final Thoughts

Now that you’ve finished reading, you know the main differences between 1/2 vs 15/32 Plywood: Key Differences Explained. You’ve also learned about measurements, how these plywood options are used, and how to select them. Remember that 1/2 inch plywood is usually sturdier, while 15/32 inch plywood is often thinner and lighter. Think about what you’re building. Make sure you know the expected loads, space restrictions, and budget when picking a plywood option. With these insights, you can go ahead with more confidence. Make sure you use the right materials and techniques to ensure your project’s success.