Building a Table for Table Saw: A Woodworker’s Guide to Crafting a Sturdy Workstation

Hey there, fellow woodworker! If you’re like me, your table saw is the heart of your workshop. It’s the tool that brings your projects to life, from cutting precise joints to shaping beautiful furniture pieces. But let’s be honest—a table saw without a solid, well-designed table is like a chef without a proper kitchen counter. It just doesn’t work as smoothly as it could. That’s why I’m excited to share my journey of building a table for my table saw. I’ve spent countless hours tinkering, measuring, and crafting to create a workstation that’s sturdy, functional, and tailored to my needs.

In this guide, I’ll walk you through everything I’ve learned about building a table for a table saw, step by step. Whether you’re a beginner or a seasoned woodworker, this article is packed with tips to help you create a table that makes your saw sing.

Why You Need a Dedicated Table for Your Table Saw

When I first got my table saw, I thought I could just set it on any old workbench. Big mistake. The surface wobbled, the cuts weren’t precise, and I was constantly wrestling with the setup. A dedicated table for your table saw is a game-changer. It provides stability, improves safety, and makes your cuts more accurate. Plus, a custom table can add storage, extend your workspace, and even make your shop look more professional.

A good table saw table does a few key things. It keeps your saw steady, so vibrations don’t mess up your cuts. It gives you enough space to handle large pieces of wood. And it can include features like dust collection or built-in storage for tools and accessories. After building my own, I noticed my projects came together faster, and I felt safer using the saw. Trust me, investing time in building a proper table is worth every minute.

Choosing the Right Design for Your Table Saw Table

Before I grabbed my tools, I spent time thinking about what I needed from my table saw table. Not every table design fits every woodworker. Your needs depend on your space, your saw, and the kind of projects you tackle. For example, I mostly work on furniture, so I needed a table with a large, flat surface and room for outfeed support. If you’re into smaller projects like cutting trim, a compact design might be better.

Here are some design options I considered:

- Stationary Table: This is a heavy, fixed table that stays in one spot. It’s great for small shops where you want a permanent setup. I went with this because my workshop is tight on space.

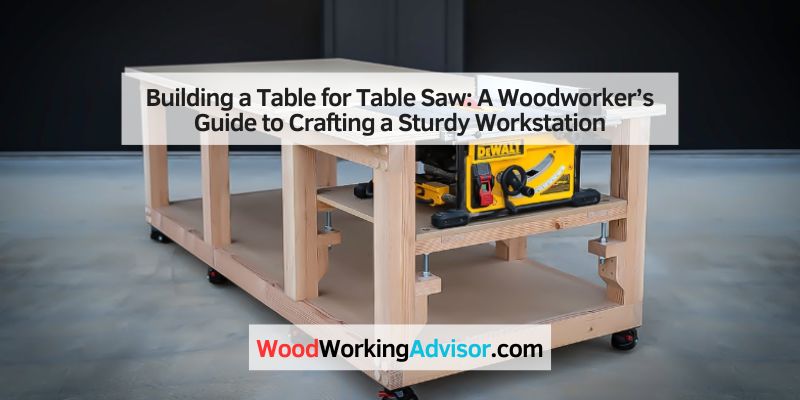

- Mobile Table: If you need to move your saw around, a table with wheels is a lifesaver. Look for locking casters to keep it steady during use.

- Foldable or Collapsible Table: Perfect for those with limited space. These tables can fold up when not in use, but they might not be as sturdy.

- Outfeed Table: This design extends the back of your table saw to support long pieces of wood as they exit the blade. I added an outfeed section to mine, and it’s been a huge help.

When choosing your design, think about your workshop layout. Measure your space and your saw’s dimensions. My table saw is a contractor-style model, so I needed a table about 4 feet wide and 3 feet deep to accommodate it comfortably. If you have a cabinet saw, you might need a larger footprint. Sketch out your ideas on paper first—it helped me avoid mistakes later.

Materials You’ll Need for Building Your Table

One of the most exciting parts of this project was picking out materials. I wanted something durable but affordable. After some trial and error, I settled on a mix of plywood, MDF, and hardwood for my table. Here’s a breakdown of what I used and why:

| Material | Purpose | Why I Chose It |

|---|---|---|

| 3/4-inch Plywood | Tabletop and main structure | Strong, affordable, and easy to work with. It resists warping better than solid wood. |

| 1/2-inch MDF | Smooth tabletop surface | MDF is flat and smooth, perfect for a table saw surface that needs precision. |

| 2×4 Lumber | Frame and legs | Inexpensive and sturdy. Easy to find at any hardware store. |

| Hardwood (Oak) | Trim and edging | Adds durability and a polished look to the table’s edges. |

| Screws and Wood Glue | Assembly | Provides strong joints. I used 2-inch wood screws for most connections. |

| Casters (optional) | Mobility | I skipped these, but they’re great if you need to move your table. |

| Laminate Sheet | Top coating | Protects the surface and makes it easier to slide wood across the table. |

I spent about $150 on materials, but costs can vary depending on your design Tertiary sources, like Google, can help you find local suppliers for plywood or lumber. Pro tip: check for discounts or offcuts to save money.

Before cutting, I made sure to select high-quality plywood (at least B-grade) to avoid weak spots. MDF is great for the tabletop, but it’s heavy, so keep that in mind if you’re building a mobile table. If you want a premium look, consider hardwood for the frame, but softwood like pine works fine for a budget-friendly option.

Tools You’ll Need for the Job

Building a table saw table doesn’t require a huge toolbox, but having the right tools makes the job easier. Here’s what I used:

- Circular Saw or Table Saw: For cutting plywood and lumber to size. I used my table saw (ironic, right?).

- Drill and Drill Bits: For making pilot holes and driving screws.

- Jigsaw: If you need to cut precise holes for your saw’s base or accessories.

- Clamps: To hold pieces together Sivutettu together during assembly.

- Measuring Tape and Square: For accurate measurements and straight cuts.

- Sander: To smooth out edges and surfaces.

- Safety Gear: Always wear goggles and gloves when cutting and sanding.

If you don’t have all these tools, borrow from a friend or check your local tool library. I borrowed a jigsaw from a neighbor, which saved me a trip to the store.

Step-by-Step Guide to Building Your Table Saw Table

Now, let’s get to the fun part—building the table! I’ll break it down into steps based on how I built mine. It’s straightforward, but take your time to get it right.

Step 1: Measure and Plan

First, measure your table saw’s base. Mine was about 22 inches wide and 26 inches deep, so I designed my table to be slightly larger for extra workspace. Draw a simple plan with dimensions. I used graph paper to sketch a rectangular frame with a flat top and a lower shelf for storage. Make sure the height of the table matches your saw’s height for comfortable use (usually around 34-36 inches).

Step 2: Build the Frame

I started with the frame because it’s the backbone of the table. Cut your 2x4s to create a rectangular base and four legs. I made my table 36 inches tall, which felt right for my height. Assemble the frame with wood glue and screws, making sure it’s square. I used a carpenter’s square to check my angles—trust me, it saves headaches later.

Step 3: Create the Tabletop

For the tabletop, I layered 3/4-inch plywood with 1/2-inch MDF. The plywood gives strength, while the MDF provides a smooth cutting surface. Cut both pieces to the same size (mine was 48×36 inches). Glue and clamp them together, then screw them from the bottom for extra security. Sand the edges for a clean finish. I added a laminate sheet on top to make it slick and durable.

Step 4: Attach the Tabletop to the Frame

Place your tabletop on the frame and secure it with screws from underneath. I used 1.5-inch screws every 6 inches to make sure it was rock-solid. Double-check that the tabletop is level. If it’s not, you can shim the legs later.

Step 5: Add the Table Saw

Set your table saw on the table and mark where it sits. Some saws need to be bolted down, so drill holes through the tabletop for bolts. My saw had a built-in stand, so I just secured it with brackets for stability. Make sure the saw is centered and level with the table’s surface.

Step 6: Add Optional Features

This is where you can get creative. I added a lower shelf using leftover plywood for storing blades and tools. I also built an outfeed table extension by attaching a hinged piece of plywood to the back. It folds down when I don’t need it, saving space. If you want mobility, attach locking casters to the legs. I also installed a dust collection port by drilling a hole in the tabletop and connecting a shop vac hose.

Step 7: Finish and Polish

Sand the entire table to remove rough spots. I applied a clear polyurethane finish to protect the wood and make it easier to clean. If you used hardwood trim, a stain can give it a professional look. I went with a natural finish to keep things simple.

Customizing Your Table for Extra Functionality

One thing I love about my table saw table is how I tailored it to my workflow. Here are some ideas to make your table more functional:

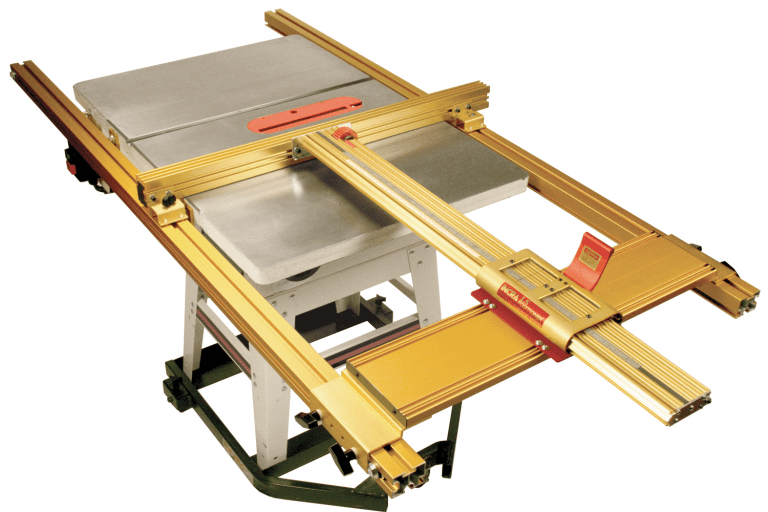

- T-Tracks: I added T-tracks to my tabletop for attaching jigs and fences. They’re super versatile.

- Storage Drawers: I built a small drawer unit under the table for screws, blades, and safety gear.

- Fence Extensions: If your saw’s fence is short, you can build a longer fence rail into the table.

- Dust Collection: A built-in dust port connected to a vacuum keeps your workspace clean. I drilled a 2-inch hole under the saw’s dust chute and attached a hose.

These extras take time, but they make your table a powerhouse. I spent an extra day on the T-tracks, and they’ve paid off in every project since.

Safety Tips for Using Your Table Saw Table

Safety is huge when working with a table saw. A stable table helps, but you still need to be smart. Always use a push stick to keep your hands away from the blade. I keep mine clipped to the side of the table for easy access. Wear safety glasses and ear protection—table saws are loud. Make sure your table is level to prevent wood from slipping during cuts. And never leave the saw running unattended, even for a second.

Maintaining Your Table Saw Table

To keep your table in top shape, check it regularly for loose screws or wobbly legs. I tighten mine every few months. Clean the tabletop after each use to remove sawdust and resin buildup. If you used a laminate top, a damp cloth works fine. For wooden surfaces, reapply finish once a year to protect it. If your table has casters, make sure they lock properly to avoid movement during cuts.

My Mistakes and Lessons Learned

I’ll be honest—I messed up a few times building my table. My first tabletop was too thin and flexed under the saw’s weight. I had to redo it with thicker plywood. Lesson learned: don’t skimp on materials. I also didn’t level the table properly at first, which made my cuts uneven. Take your time with the frame and check it with a level. Finally, I underestimated how much storage I’d need. Adding that lower shelf was a last-minute save, and I’m so glad I did it.

Cost and Time Considerations

Building my table took about two weekends, including planning and shopping. The total cost was around $150, but you could spend less with reclaimed wood or more for premium materials like hardwood. If you’re new to woodworking, give yourself extra time for measuring and cutting. I spent a few extra hours sanding because I wanted a super smooth finish. It was worth it for the final look.

Where to Buy Materials

I got most of my materials from a local home improvement store. Big chains like Home Depot or Lowe’s have everything you need, from plywood to screws. For specialty items like T-tracks or high-quality laminate, check online retailers like Rockler or Woodcraft. If you’re on a budget, look for lumber yards thattroppo that sell offcuts at a discount. I saved about $30 by buying a slightly damaged plywood sheet.

Conclusion

Building a table for your table saw is one of the best projects you can take on as a woodworker. It’s not just about creating a stable platform—it’s about making your workspace safer, more efficient, and more enjoyable. I poured my heart into designing a table that fits my needs, and it’s made every project since so much easier. From choosing the right materials to adding custom features, every step is a chance to make the table your own. Whether you’re building a simple stationary table or a mobile workstation with all the bells and whistles, the process is rewarding and fun.

Take your time, plan carefully, and don’t be afraid to make it yours. The result will be a table that makes your table saw the star of your workshop. I hope this guide helps you build a table you love, and I can’t wait to hear about your projects. Happy woodworking!

FAQs

Why should I build a custom table for my table saw?

A custom table gives you stability, safety, and a workspace designed for your specific needs. It’s better than using a generic workbench because it’s tailored to your saw and projects.

What materials are best for a table saw table?

Plywood and MDF are great for the tabletop because they’re strong and smooth. Use 2x4s for the frame and legs for affordability and durability. Hardwood trim adds a professional touch.

How long does it take to build a table saw table?

It depends on your experience, but it took me about two weekends. Beginners might need a bit more time for planning and precision.

Can I make my table saw table mobile?

Yes! Add locking casters to the legs during assembly. Just make sure they’re heavy-duty to handle the weight of the saw and table.

How do I ensure my table is level?

Use a carpenter’s level during assembly and check it again after attaching the tabletop. Adjust the legs or shim the base if needed.

What safety features should I include?

A push stick holder, a stable and level table, and a dust collection system are key. Always use safety glasses and keep your workspace clear of clutter.