Can a Dremel Cut Wood? Tips for Best Results

Lots of people wonder, Can a Dremel Cut Wood? Tips for Best Results? It might seem a bit tricky at first, especially if you’re new to using these handy tools for woodworking projects.

You might think a Dremel is too small or not powerful enough for wood. But don’t worry! It’s totally possible, and with a few simple tricks, you can get great results.

We’ll walk you through exactly what you need to know to make your Dremel work wonders on wood. Get ready to learn how to turn your Dremel into a wood-cutting machine.

Yes, a Dremel absolutely can cut wood. While they are often thought of for smaller, detailed tasks like engraving or polishing, many Dremel tools and accessories are perfectly capable of cutting through various types of wood. The key to success lies in choosing the right Dremel attachment, setting the correct speed, and using proper technique.

For beginners, the initial hesitation often comes from the perceived limitations of a rotary tool compared to larger saws. However, for many crafting and DIY projects, the precision and control offered by a Dremel make it an excellent choice for wood cutting.

Choosing the Right Dremel Accessories for Wood

The type of cutting accessory you use is the most important factor when cutting wood with a Dremel. Different bits are designed for different tasks and materials. For wood, you’ll want to focus on specific types of cutting wheels and bits.

Cutting Wheels

Dremel offers a variety of cutting wheels. For wood, the reinforced cut-off wheels are generally the best choice. These are typically made from materials like fiberglass-reinforced aluminum oxide, which makes them stronger and less likely to break during use.

- Heavy Duty Cut-Off Wheels: These are good for general wood cutting and can handle thicker materials.

- Thin Cut-Off Wheels: Excellent for making very thin, precise cuts or slots.

Always ensure the cut-off wheel is rated for the material you are cutting. Wood dust can also be a factor, so consider using a dust collection system or wearing a mask.

Router Bits and Engraving Bits

While not strictly for “cutting through” wood in the same way as a cut-off wheel, Dremel also has router bits and engraving bits that can shape and carve wood. These are fantastic for adding decorative elements, creating grooves, or doing inlays.

- Router Bits: These are designed to hollow out material or create decorative edges.

- Engraving Bits: Used for fine detail work, lettering, or creating patterns on the wood surface.

Drill Bits

Before making a cut, especially a straight cut, you might want to drill a small pilot hole. This can help you start your cut cleanly and prevent the wood from splitting.

Dremel Tool Selection for Wood Cutting

While many Dremel rotary tools can cut wood, some models are better suited for it than others. The power and speed of the tool play a significant role.

Corded vs. Cordless Dremels

Corded Dremels generally offer more consistent power, which can be beneficial when cutting through tougher wood. Cordless models offer portability and freedom of movement, but their power can sometimes fluctuate depending on battery life.

Variable Speed Control

This is a key feature. Cutting wood effectively with a Dremel often requires adjusting the speed. Generally, a slower speed is better for control and to prevent overheating, while a faster speed might be needed for smoother cuts in softer woods.

Setting Up Your Dremel for Wood Cutting

Proper setup is essential for safety and for achieving the best results. This includes selecting the right speed, chuck, and any necessary attachments.

Speed Settings

The ideal speed depends on the type of wood and the cutting bit you are using. As a general guideline:

- Hardwoods: Start with a lower speed, around 10,000-15,000 RPM. This allows for more control and reduces the risk of burning the wood.

- Softwoods: You can often use a slightly higher speed, perhaps 15,000-20,000 RPM, for faster and smoother cuts.

It’s always a good idea to test your speed on a scrap piece of wood first. Listen to the tool and observe the cut. If you’re getting a lot of smoke or the wood is burning, reduce the speed.

Chuck and Collet Selection

Make sure you are using the correct chuck or collet for your Dremel accessory. Most Dremel cutting wheels and bits will fit standard Dremel collets. Ensure the accessory is securely fastened in the chuck.

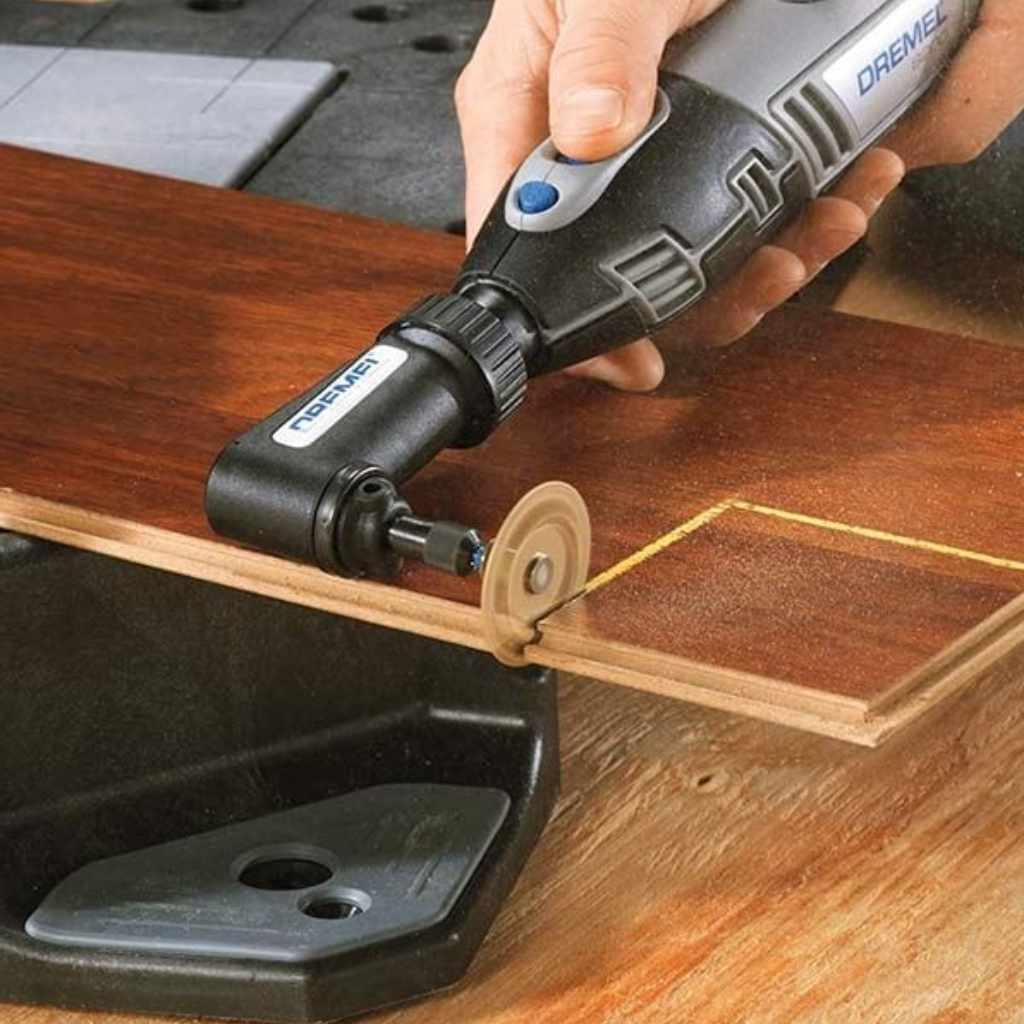

Using Cutting Guides and Attachments

For straighter cuts, consider using a Dremel guide attachment. Some kits come with a circle cutter or a straight edge guide that can help you maintain a steady line.

Techniques for Cutting Wood with a Dremel

Once you have your Dremel set up, how you actually make the cut is just as important as the tools you use.

Stance and Grip

Maintain a firm, stable grip on your Dremel. Brace your hand or the tool against a stable surface if possible. This helps prevent jerky movements that can lead to inaccurate cuts or accidents.

Applying Pressure

Do not force the Dremel. Let the tool do the work. Apply light, steady pressure and guide the cutting wheel smoothly through the wood.

Forcing the tool can cause it to overheat, break the accessory, or result in a rough, uneven cut.

Cutting Direction

When using a cutting wheel, it’s generally best to cut in the direction that pushes the debris away from you. This helps with visibility and can create a cleaner cut.

Multiple Passes

For thicker wood, it’s often better to make multiple shallow passes rather than trying to cut all the way through in one go. This reduces strain on the tool and the cutting accessory, and it leads to a cleaner finish.

Cooling the Bit and Wood

Wood dust and friction can generate heat. If you notice the cutting bit or the wood getting excessively hot, stop and let them cool down. You can also dip the bit in water briefly, but be careful not to get water into the tool itself.

Types of Wood and Dremel Suitability

Not all woods are created equal when it comes to cutting with a Dremel. The hardness and density of the wood will impact the ease of cutting and the results you get.

Softwoods

Woods like pine, cedar, and fir are generally easier to cut with a Dremel. They are less dense and require less force. You can usually achieve smoother cuts in softwoods with higher speeds.

Hardwoods

Woods such as oak, maple, and cherry are denser and tougher. Cutting these will require more patience, lower speeds, and potentially multiple passes. Be prepared for slower progress and possibly more wear on your cutting bits.

Plywood and MDF

Plywood can be cut with a Dremel, but be mindful of the glue layers, which can cause some gumming. MDF (Medium-Density Fiberboard) can also be cut, but it produces a lot of fine dust, so dust protection is crucial. The edges of MDF can sometimes fray if not cut carefully.

Safety First When Cutting Wood with a Dremel

Safety is paramount when working with any power tool, including a Dremel. Always follow these precautions:

Eye Protection

Always wear safety glasses or goggles to protect your eyes from flying wood dust and debris. Wood chips can be sharp.

Dust Mask

Wood dust can be harmful to inhale. Wear a dust mask or respirator, especially when cutting MDF or prolonged periods.

Hearing Protection

While Dremels aren’t as loud as some power tools, prolonged use can still affect your hearing. Earplugs or earmuffs are recommended.

Gloves

Wearing gloves can improve your grip and protect your hands from splinters or minor abrasions. Avoid loose-fitting gloves that could get caught in the spinning accessory.

Work Area

Ensure your work area is well-lit, clean, and free of clutter. Secure the wood you are cutting so it doesn’t move during the process.

Accessory Inspection

Before each use, inspect your cutting accessory for any signs of damage, such as cracks or chips. Do not use damaged accessories.

Unplug When Changing Accessories

Always unplug your Dremel from the power source before changing or adjusting accessories to prevent accidental starts.

Troubleshooting Common Issues

Even with the best preparation, you might encounter a few issues. Here’s how to address them:

Burning Wood

If the wood is burning, you are likely moving too slowly, applying too much pressure, or your speed is too high. Reduce speed, increase the pace of your cut, or make shallower passes. Ensure your cutting bit is sharp and not dull.

Rough Cuts

Rough cuts can result from a wobbly tool, inconsistent pressure, or using the wrong type of cutting accessory. Ensure the accessory is securely in the chuck, maintain a steady hand, and try a different cutting wheel if needed.

Accessory Breaking

Cutting wheels can break if too much side pressure is applied, if they overheat, or if they strike a knot or obstruction unexpectedly. Be gentle, don’t force the cut, and use reinforced wheels for tougher jobs.

Dremel Overheating

If your Dremel tool itself is overheating, you might be asking too much of it. Allow it to cool down, take breaks, and ensure you are using an appropriate speed and pressure for the material and task.

Comparison of Dremel Cutting vs. Other Tools

It’s helpful to see how a Dremel stacks up against other common woodworking tools for cutting.

| Tool | Pros | Cons | Best For |

|---|---|---|---|

| Dremel Rotary Tool | Precision, detail work, small cuts, portability, versatility | Limited depth of cut, slower for large jobs, accessory wear | Crafting, detail trimming, small projects, repair work |

| Jigsaw | Curved cuts, versatile for different materials, good depth of cut | Can be less precise for very fine details, blade can wander | Rough cuts, curved shapes, general woodworking |

| Circular Saw | Fast, straight cuts, good for sheet goods and long boards | Limited for intricate shapes, requires more space | Sheet goods, rip cuts, crosscuts on larger pieces |

| Scroll Saw | Extremely precise, intricate curves and detailed cuts | Slow, limited material thickness, requires skill | Fine woodworking, inlay work, detailed decorative pieces |

As you can see, the Dremel excels in situations where precision and control are more important than speed or depth. It fills a niche for detailed wood modification.

Frequently Asked Questions

Question: What is the best Dremel bit for cutting wood?

Answer: For general wood cutting, reinforced cut-off wheels are your best bet. Dremel offers specific wood cutting bits and router bits that are also excellent for shaping and carving.

Question: Can I cut 3/4 inch wood with a Dremel?

Answer: You can cut through 3/4 inch wood with a Dremel, but it will require multiple shallow passes and patience. Use reinforced cut-off wheels and a lower speed setting for best results and to avoid breaking the bit.

Question: How do I prevent burning when cutting wood with a Dremel?

Answer: To prevent burning, use a lower speed setting, apply light pressure, and make multiple shallow passes instead of trying to cut all the way through at once. Ensure your cutting wheel is sharp and not dull.

Question: Is it safe to cut wood with a Dremel?

Answer: Yes, it is safe to cut wood with a Dremel when you follow proper safety precautions. Always wear eye protection, a dust mask, and secure your workpiece. Inspect your cutting accessories before use and unplug the tool when changing bits.

Question: What kind of wood is easiest to cut with a Dremel?

Answer: Softer woods like pine, cedar, or fir are generally the easiest to cut with a Dremel because they are less dense and require less effort. Hardwoods will take more time and effort.

Final Thoughts

So, Can a Dremel Cut Wood? Tips for Best Results? The answer is a resounding yes, and it’s an incredibly useful tool for detailed woodworking.

By selecting the right accessories like reinforced cut-off wheels or specialized wood bits, and by adjusting your Dremel’s speed appropriately, you can achieve clean and precise cuts. Remember to take your time, apply gentle pressure, and make multiple passes for thicker materials. Safety should always be your top priority, so always use eye protection and a dust mask.

Experimenting on scrap wood will help you find the perfect settings and techniques for different types of wood. With these tips, your Dremel can become a go-to tool for all sorts of creative wood projects, from small crafts to intricate details on larger pieces.