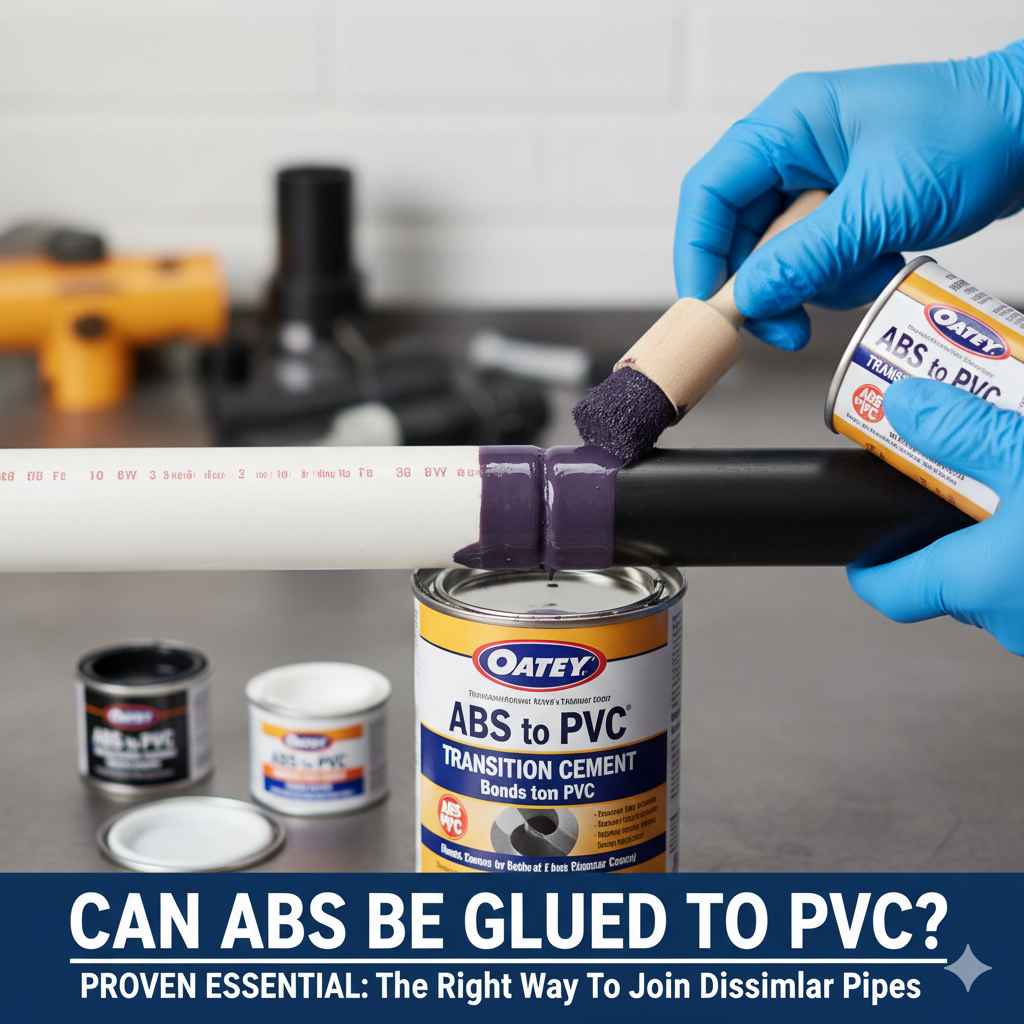

Can ABS Be Glued To PVC: Proven Essential

Yes, ABS can be reliably glued to PVC using the right type of adhesive and proper preparation. This guide will show you the proven essential steps to achieve a strong, durable bond for your projects.

Hey there, fellow creators! Ever found yourself with a project that needs a piece of ABS plastic connected to a piece of PVC? Maybe it’s a custom rack for your workshop, a unique piece of home decor, or even a repair for something around the house. It’s a common situation, and figuring out how to make these two popular plastics stick together can feel like a real head-scratcher. You want a bond that’s not going to come apart when you need it most, and you don’t want to waste time or money on the wrong glue.

Don’t worry, I’ve got your back! We’re going to break down exactly how to get a strong, lasting connection between ABS and PVC, step by simple step. Get ready to tackle your next project with confidence!

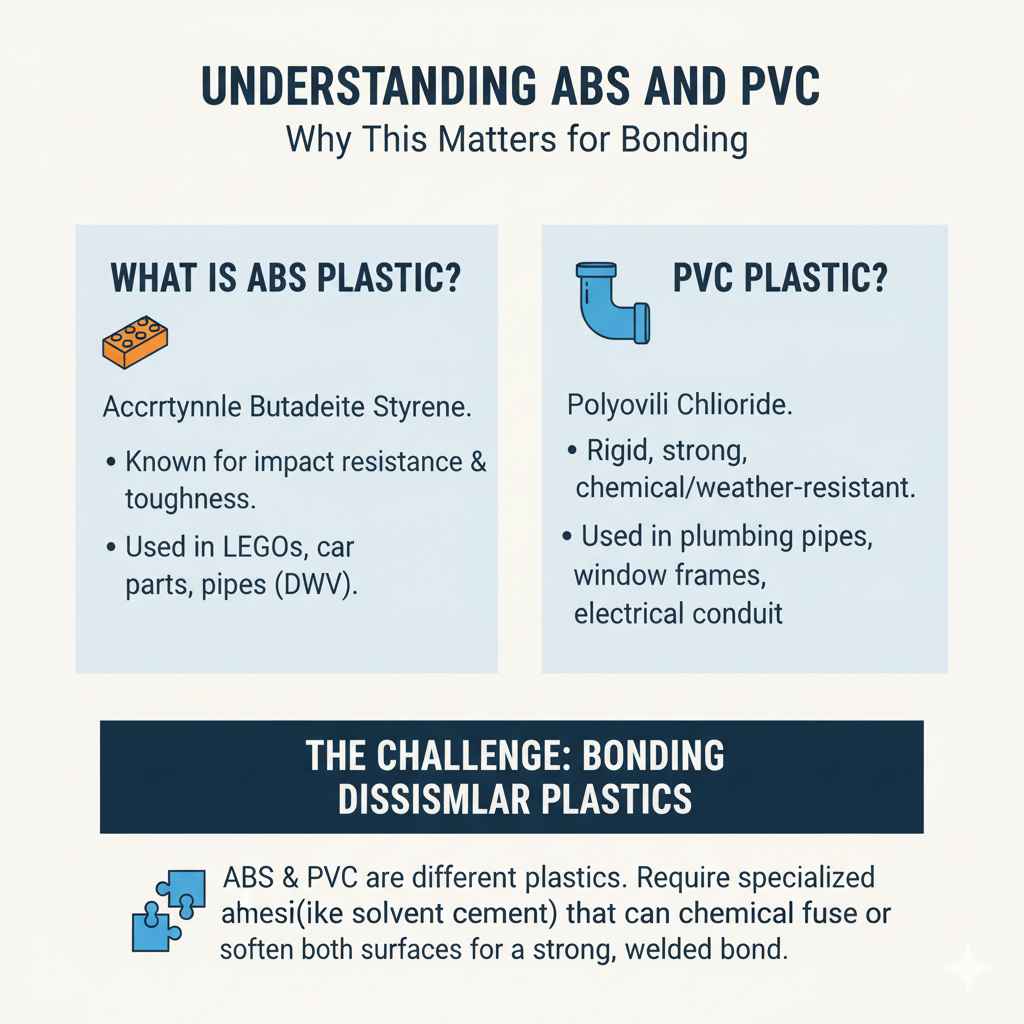

Understanding ABS and PVC: Why This Matters

Before we grab any glue, it’s super helpful to understand a little bit about ABS and PVC. Knowing what we’re working with helps us pick the right tools – and in this case, the right adhesive!

What is ABS Plastic?

ABS stands for Acrylonitrile Butadiene Styrene. It’s that tough, glossy plastic you find in everything from LEGO bricks and car parts to electronics casings and luggage. ABS is known for its impact resistance, which means it can take a beating without cracking. It’s also relatively easy to work with, which is why it’s a favorite among DIYers and manufacturers alike.

What is PVC Plastic?

PVC, or Polyvinyl Chloride, is another incredibly common and versatile plastic. You probably know it best from plumbing pipes, window frames, and electrical insulation. PVC is strong, rigid, and resistant to chemicals and weather. It’s also very affordable and widely available, making it a go-to for many construction and home improvement projects. There are two main types: rigid (like pipes) and flexible (like vinyl flooring or shower curtains), but for gluing projects, we’re usually talking about the rigid kind.

The Challenge of Bonding Dissimilar Plastics

Here’s the tricky part: ABS and PVC are different types of plastics, and they don’t always play nicely together. Standard glues that work wonders on one might not even budge the other. This is because plastics have different chemical makeups. To get a strong bond, the adhesive needs to either mechanically grip the surface or, even better, chemically fuse or soften the surfaces of both materials so they effectively become one. A good analogy is trying to glue wood to metal – you need a specialized adhesive that can bond both types of material.

The Proven Solution: What Glue Works for ABS to PVC?

So, can ABS be glued to PVC? The answer is a resounding YES, but you need the right adhesive. The key is using a special plastic cement designed to work with both ABS and PVC, or a strong solvent cement. Let’s dive into the options:

1. All-Purpose Plastic Cements or specific ABS/PVC Cements

These are your best bet for a strong, professional-grade bond. These cements are specifically formulated to soften the surface of both ABS and PVC plastics. When the solvent evaporates, the softened plastic surfaces fuse together as they harden, creating an incredibly strong, almost seamless connection. Think of it like solvent welding – it’s not just sticking them together; it’s actually partially melting and reforming them into a single piece.

- How they work: These cements contain solvents that temporarily dissolve the outer layer of the plastic. When the two pieces are pressed together, these dissolved surfaces intermingle. As the solvents evaporate, the plastics re-harden, forming a permanent, welded bond.

- Look for: Products labeled specifically for “ABS and PVC” or “General Purpose Plastic Cement.” Brands like Weld-On often have specific formulations that work well, but many hardware store brands carry effective all-purpose plastic adhesives. Always read the product label to ensure it states compatibility with both ABS and PVC.

- Application: Typically applied with a brush or a dauber tip included in the lid. You’ll apply it to one or both surfaces, join them, and hold them in place for a short period.

2. Epoxy (Use with Caution)

While not ideal for a solvent-weld type bond, a high-quality structural epoxy can sometimes work for bonding ABS to PVC, especially if the surfaces are meticulously prepped. Epoxy creates a very strong mechanical bond by adhering to the surface of both materials.

- How they work: Epoxy is a two-part adhesive that cures chemically. It doesn’t dissolve the plastic but creates a very strong physical bond to its surface.

- When to consider: If you can’t find a specific plastic cement or if the project doesn’t require the absolute strongest, welded bond that a solvent cement provides. Epoxies are good for filling small gaps too.

- Downsides: The bond may not be as seamless or as inherently strong as a solvent weld. Surface preparation is absolutely critical for epoxy to adhere well.

- Type to use: Look for a two-part epoxy specifically designed for plastics or a general-purpose structural epoxy.

3. Cyanoacrylate (Super Glue) – Limited Use

Cyanoacrylate glues, commonly known as super glues, can offer a quick bond for ABS and PVC but are generally not recommended for structural applications. They work best for small repairs or when you need to hold pieces together temporarily while another adhesive cures.

- How they work: Cyanoacrylates polymerize rapidly when exposed to moisture (even the trace amounts in the air and on surfaces).

- Limitations: The bond with plastics like ABS and PVC can be brittle. They are prone to snapping under stress or vibration. They also don’t fill gaps well.

- When to use: Very small, non-critical joints or for tacking pieces in place.

Essential Tools and Materials

Before you start gluing, gather everything you need. Having your tools and materials ready will make the process smoother and ensure a better result. Following the motto of “measure twice, cut once” also applies to preparation!

- The ABS and PVC pieces: Make sure they are clean and dry.

- The Right Adhesive: As discussed, a quality All-Purpose Plastic Cement or specific ABS/PVC Cement is highly recommended.

- Sandpaper: Medium-grit (around 120-180) for scuffing surfaces, and fine-grit (around 220-320) for smoothing.

- Cleaning Supplies: Denatured alcohol or a specialized plastic cleaner. Avoid acetone on ABS, as it can be too harsh and melt it excessively. Isopropyl alcohol is a safer bet for both.

- Clean Rags or Paper Towels: Lint-free is best.

- Gloves: To protect your hands from the adhesive and maintain surface cleanliness.

- Safety Glasses: Always protect your eyes, especially when working with solvents.

- Clamps or Tape: To hold pieces together while the adhesive cures.

- Razor Knife or Saw (if cutting/trimming needed): For trimming edges.

- Primer (Optional, but recommended for some cements): Some plastic cements require a primer to be applied to one or both surfaces first, especially for PVC. Always check your adhesive’s instructions.

Step-by-Step Guide: Gluing ABS to PVC

Here’s how to get that strong, reliable bond. Follow these steps carefully, and your parts will be fused together securely.

Step 1: Preparation is Key – Surface Cleaning

This is arguably the MOST important step for any strong bond. Dirt, grease, oil, or even dust can prevent the adhesive from making proper contact with the plastic.

To make sure you’re starting with properly clean surfaces, follow these steps:

- Gently wipe down both the ABS and PVC pieces with a clean rag dampened with denatured alcohol or isopropyl alcohol.

- Ensure the areas where you’ll be applying the glue are completely dry and free of any residue before proceeding.

Step 2: Surface Preparation – Mechanical Bonding (Scuffing)

While solvent cements fuse the plastics chemically, giving the surfaces a slight “tooth” can improve the overall bond strength, especially for areas that might experience stress.

Do this gently:

- Using 120-180 grit sandpaper, lightly scuff up the surfaces of both the ABS and PVC pieces where they will join.

- Don’t sand too deeply; you just want to create a slightly rough texture.

- After scuffing, wipe away any dust with a clean, dry cloth or a tack cloth. Repeating Step 1 (cleaning with alcohol) after scuffing is also a good idea to remove any fine plastic dust.

Step 3: Apply Primer (If Required)

Some plastic cements might suggest or require a primer, particularly for certain types of PVC or for maximum strength.

Check your adhesive bottle:

- If your chosen adhesive recommends a primer, apply a thin, even coat to one or both surfaces as instructed.

- Allow the primer to dry completely according to the product directions. This usually only takes a minute or two.

Step 4: Apply the Adhesive

Now for the glue! This is where the magic happens. Whether you’re using a dedicated ABS/PVC cement or an all-purpose plastic cement, the application is usually similar.

Get ready to join:

- If the adhesive has a brush or applicator, give it a good stir or shake as per the manufacturer’s instructions.

- Apply a liberal, but not excessive, coating of the cement to one or both surfaces. Some manufacturers recommend applying to both surfaces, while others suggest only one. ALWAYS refer to the specific product instructions for the best results. A good rule of thumb for solvent cements is to apply to both mating surfaces, or at least the surface that is more absorbent, and then quickly bring the parts together.

- Ensure the entire joint area is covered with a thin, even layer of cement.

Step 5: Assemble and Hold

This step requires speed and a steady hand, especially with solvent cements, as they start to set quickly.

Time to bring them together:

- Immediately after applying the cement, firmly press the ABS and PVC pieces together.

- For solvent cements, you’ll want to give the joint a slight twist (about a quarter turn) as you bring them together. This helps spread the solvent evenly across both surfaces and ensures a strong weld.

- Hold the pieces firmly in place for the amount of time specified on the adhesive packaging. This is often referred to as “set time” or “handling time” and can range from 30 seconds to a few minutes.

- Use clamps, tape, or even your hands (with gloves on!) to maintain this pressure. If using clamps, be careful not to over-tighten, which could crack the plastic or squeeze out too much adhesive.

Step 6: Curing Time

The joint might feel solid after a few minutes, but it takes time for the adhesive to fully cure and reach its maximum strength.

Be patient:

- Allow the joint to cure for the recommended time. This “cure time” is usually much longer than the “set time” and can range from several hours to 24 hours or more.

- Avoid putting any stress on the joint during the curing period. If you need to use the piece, it’s best to wait the full recommended cure time for maximum durability. You can find detailed cure times and strength development charts on many reputable product websites, like Interplastic’s technical data sheets.

Troubleshooting Common Issues

Even with the best intentions, sometimes things don’t go perfectly. Here are a few common issues and how to fix them:

- Weak Bond: This is almost always due to poor surface preparation (dirt, grease) or not using the correct type of adhesive. If possible, try to disassemble, re-clean, re-scuff, and re-glue. If it’s a permanent joint that failed, you might need to reinforce it with an external bracket or consider starting over.

- Excessive Glue Squeeze-Out: This happens when too much glue is applied or when pieces aren’t held together firmly enough initially. For solvent cements, some minor squeeze-out is often a sign of a good weld. You can carefully trim away any hardened, excess material with a sharp knife or sandpaper once fully cured. Be careful not to cut into the main joint.

- Joint Cracking: This can occur if the plastic is stressed during assembly or curing, or if the wrong type of adhesive was used (e.g., a brittle glue where flexibility is needed). For solvent cements, ensure you’re not forcing pieces that aren’t aligned correctly.

- Adhesive Not Setting: Ensure you used the correct adhesive for both plastics. Also, check that you haven’t accidentally used a type of glue that requires a catalyst or specific conditions not met. Some adhesives have a shelf life; an old glue might not cure properly.

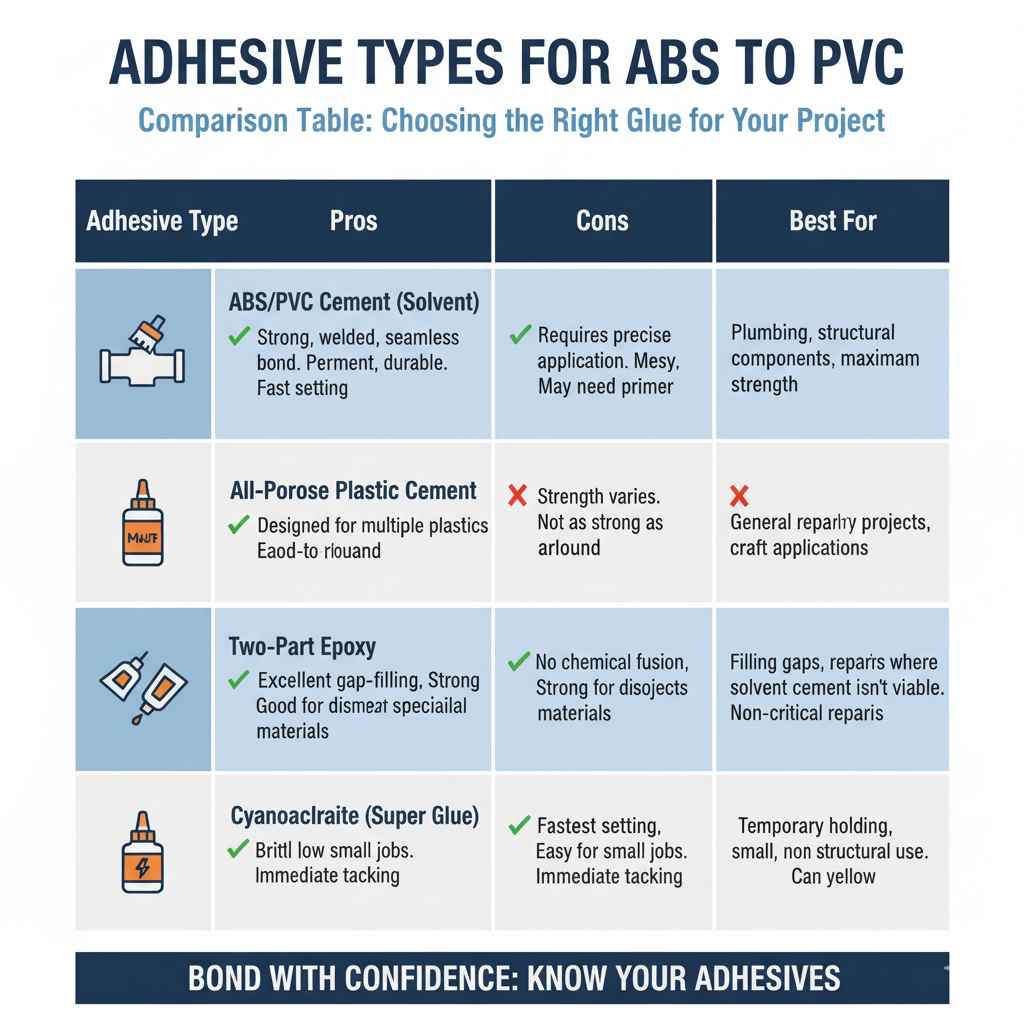

Comparison Table: Adhesive Types for ABS to PVC

Here’s a quick overview to help you decide which adhesive might be best for your specific needs.

| Adhesive Type | Pros | Cons | Best For |

|---|---|---|---|

| ABS/PVC Cement (Solvent) | Creates a strong, welded, seamless bond. Permanent and durable. Relatively fast setting for holding. | Requires precise application and quick assembly. Can be messy if not careful. May require primer. | Plumbing, structural components, projects requiring maximum strength and a seamless look. |

| All-Purpose Plastic Cement | Designed for multiple plastic types. Often easier to find. Good all-around performance. | Bond strength can vary by brand and specific plastic combination. May not be as strong as specialized cement. | General repairs, hobby projects, craft applications where extreme structural integrity isn’t paramount. |

| Two-Part Epoxy | Excellent gap-filling properties. Strong mechanical bond. Good for dissimilar materials. | Does not chemically fuse plastics. Bond may be brittle. Requires careful mixing and longer cure time. Surface prep is critical. | When a welded bond isn’t possible or available, or for filling slight irregularities. Repairs where slight flexibility is not critical. |

| Cyanoacrylate (Super Glue) | Fastest setting time for immediate tacking. Easy to use for small jobs. | Brittle bond, low impact resistance. Not suitable for structural applications. Can yellow over time. | Temporary holding, very small, non-critical repairs. |

Safety First: Working with Plastic Adhesives

When working with solvents and adhesives, safety should always be your top priority. These products often contain volatile organic compounds (VOCs) that can be harmful if inhaled or come into contact with skin. Always follow these guidelines:

- Ventilation: Work in a well-ventilated area. Open windows and doors, or use a fan to move air away from your workspace. This is crucial to prevent inhaling fumes.

- Eye Protection: Wear safety glasses or goggles at all times. Splashes can happen unexpectedly.

- Gloves: Use chemical-resistant gloves (like nitrile) to protect your skin from irritation and chemical absorption.

- Read the Can: ALWAYS read and follow the specific safety instructions and handling recommendations on the adhesive product’s label.

- Keep Away from Flames: Many adhesives and their fumes are flammable. Keep them away from sparks, open flames, and extreme heat.

- Storage: Store adhesives properly in a cool, dry place, away from direct sunlight and out of reach of children and pets.

If you’re ever unsure about a product, check the manufacturer’s website for a Safety Data Sheet (SDS), which provides detailed information on hazards and safe handling. You can often find these on the websites of major chemical suppliers like Dow Chemical.

Frequently Asked Questions (FAQ)

Q1: Can I use regular super glue for ABS to PVC?

A1: While super glue (cyanoacrylate) might hold pieces together temporarily, it’s generally not recommended for a strong, durable bond between ABS and PVC. The bond can be brittle and may fail under stress.

Q2: What is the strongest way to glue ABS to PVC?

A2: The strongest bond is typically achieved using a specialized ABS/PVC cement or a high-quality all-purpose plastic cement. These adhesives chemically fuse the plastics together, creating a true weld.

Q3: Do I need to prime ABS and PVC before gluing?

A3: Some plastic cements require a primer, especially for PVC. Always check the instructions on your specific adhesive product.