Can I Glue Pressure Treated Wood? Expert Tips Revealed

Yes, you can glue pressure treated wood. Pressure treated wood can be glued using specific types of adhesives that are designed to bond with this type of wood.

When working with pressure treated wood, it is important to choose the right adhesive to ensure a strong and durable bond. Epoxy adhesives are often recommended for gluing pressure treated wood, as they have excellent bonding properties and can withstand the moisture and chemicals present in the wood.

Before gluing, make sure to clean the surface of the wood and remove any dirt, dust, or debris. Apply the adhesive according to the manufacturer’s instructions, and clamp the pieces together until the glue is fully cured. This will ensure a secure bond between the pressure treated wood pieces.

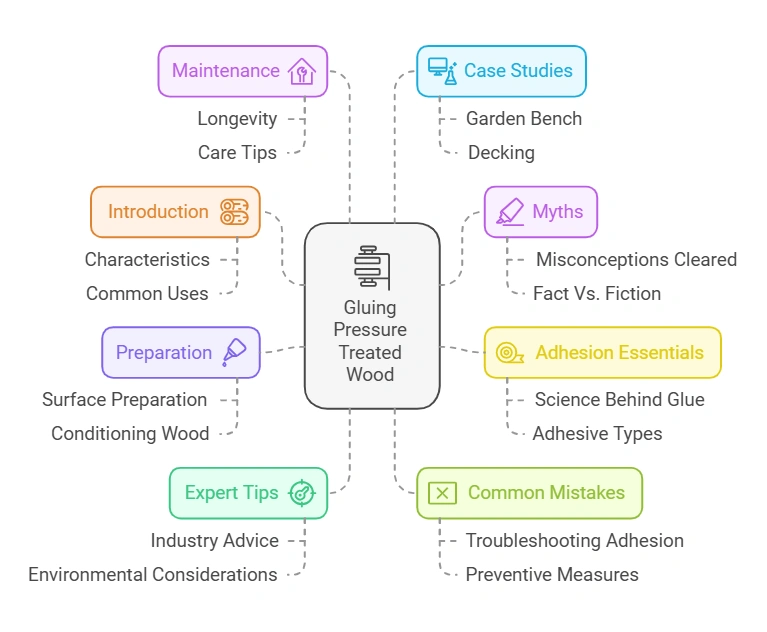

Introduction To Pressure Treated Wood

Pressure treated wood is a popular choice for outdoor construction and DIY projects due to its durability and resistance to decay. This type of lumber is treated with chemicals to enhance its ability to withstand the elements, making it ideal for applications where regular wood would quickly deteriorate. In this article, we will explore the characteristics of pressure treated lumber and its common uses in construction and DIY projects.

Characteristics Of Pressure Treated Lumber

Pressure treated lumber is infused with preservatives to protect it from rot, decay, and insect damage. The treatment process involves placing the wood in a pressurized chamber and forcing the preservatives deep into the wood fibers. This results in wood that is highly resistant to moisture and pests, making it suitable for outdoor and ground-contact applications.

Common Uses In Construction And Diy

Pressure treated wood is commonly used for outdoor structures such as decks, fences, and retaining walls. Its resistance to decay makes it well-suited for applications where the wood will be exposed to moisture and soil. Additionally, pressure treated lumber is a popular choice for DIY projects such as building garden beds, outdoor furniture, and playsets. Its durability and long lifespan make it an excellent option for outdoor projects that require weather-resistant materials.

Myths About Gluing Pressure Treated Wood

Myths about gluing pressure treated wood have circulated for years, causing confusion among DIY enthusiasts and professionals alike. In this section, we’ll debunk some common misconceptions and shed light on the facts surrounding this topic.

Misconceptions Cleared

One common misconception is that pressure treated wood cannot be glued due to its chemical treatment. Another myth is that gluing pressure treated wood will not hold up over time. These misunderstandings often lead to reluctance in using adhesives with pressure treated wood. Let’s explore the truth behind these myths.

Fact Vs. Fiction

Contrary to popular belief, gluing pressure treated wood is possible and can result in strong, durable bonds when done correctly. While it’s true that pressure treated wood contains chemicals that may hinder adhesion, with proper surface preparation and suitable adhesives, successful bonding can be achieved.

Essentials Of Pressure Treated Wood Adhesion

When working with pressure treated wood, it’s important to understand how to achieve proper adhesion when gluing pieces together. The unique properties of pressure treated wood can present challenges when it comes to adhesion, but with the right approach, successful bonding can be achieved.

The Science Behind Glue And Treated Lumber

Understanding the science behind the adhesion of glue to pressure treated wood is essential for achieving strong and durable bonds. Pressure treated wood contains chemical preservatives that can interfere with the adhesion process, making it crucial to select the right adhesive and application method.

Adhesive Types Suitable For Pressure Treated Wood

Several adhesive types are suitable for bonding pressure treated wood, each with its own advantages and considerations. It’s important to choose an adhesive that can effectively penetrate the surface of the wood and create a strong bond despite the presence of preservatives.

Preparation Steps For Effective Gluing

To effectively glue pressure treated wood, preparation is key. Start by sanding the surface and wiping it clean with a damp cloth. Apply the glue evenly and use clamps to hold the pieces together while the glue dries.

Surface Preparation Techniques

Before gluing pressure treated wood, ensure the surface is clean and dry.

- Sand the surfaces to remove any rough spots or imperfections.

- Wipe the surfaces with a damp cloth to remove dust and debris.

Conditioning Wood For Optimal Bonding

To optimize bonding, condition the pressure treated wood properly.

- Allow the wood to acclimate to the environment for a few days.

- Apply a wood conditioner to enhance adhesion.

Expert Tips For Gluing Pressure Treated Wood

Expert tips for gluing pressure treated wood include selecting the right adhesive and preparing the surface properly. While it is possible to glue pressure treated wood, using a polyurethane construction adhesive is recommended for better adhesion and durability over time.

If you’re working with pressure treated wood, you may be wondering if it’s possible to glue it. The good news is that it is possible, but there are some important considerations to keep in mind. In this section, we’ll share expert tips for gluing pressure treated wood that will help you achieve the best results.

Advice From Industry Professionals

When it comes to gluing pressure treated wood, it’s important to get advice from industry professionals. The experts recommend using a polyurethane-based adhesive, as it has the best bonding properties for this type of wood. Additionally, it’s essential to ensure that the wood is clean and free of any dirt or debris before you begin gluing.

Temperature And Humidity Considerations

Temperature and humidity can have a significant impact on the success of your glue job. When gluing pressure treated wood, it’s best to work in an environment that is between 60-80°F (15-27°C) with a relative humidity of 35-65%. If the temperature is too cold or too hot, the glue may not set correctly, and the bond may fail. Additionally, high humidity levels can cause the wood to absorb moisture, which can weaken the bond over time.

Best Practices For Gluing Pressure Treated Wood

To achieve the best results when gluing pressure treated wood, it’s essential to follow these best practices:

- Use a polyurethane-based adhesive for the best bonding properties

- Ensure the wood is clean and free of any dirt or debris before gluing

- Work in an environment that is between 60-80°F (15-27°C) with a relative humidity of 35-65%

- Apply the glue evenly and use clamps to hold the wood in place while the glue sets

- Allow the glue to dry completely before removing the clamps or applying any pressure to the wood

By following these expert tips and best practices, you’ll be able to glue pressure treated wood successfully and achieve a strong, long-lasting bond.

Common Gluing Mistakes To Avoid

Yes, you can glue pressure-treated wood, but there are some common mistakes to avoid. It’s important to use the right type of adhesive, as pressure-treated wood contains chemicals that can interfere with certain glues. Additionally, proper surface preparation, clamping, and drying time are crucial for a strong bond.

Troubleshooting Poor Adhesion

Preventive Measures For Strong Bonds

When gluing pressure-treated wood, avoiding common mistakes is crucial for a successful bond.

Troubleshooting Poor Adhesion

- Check for moisture content in the wood before applying glue.

- Ensure the surfaces are clean and free of any debris or dust.

- Use the right type of adhesive suitable for pressure-treated wood.

Preventive Measures For Strong Bonds

- Apply the adhesive evenly on both surfaces for maximum contact.

- Allow sufficient drying time as per the manufacturer’s instructions.

- Consider roughening the surface slightly for better adhesion.

Maintenance And Durability Of Glued Joints

Pressure treated wood can be effectively glued, but it’s essential to choose the right adhesive for long-lasting durability. Epoxy or polyurethane adhesives are recommended for strong and reliable glued joints. Proper surface preparation and application techniques are crucial for ensuring the maintenance of glued pressure treated wood joints.

Longevity Of Glued Pressure Treated Wood

Pressure treated wood is a popular choice for outdoor projects due to its resistance to rot and decay. However, when it comes to gluing pressure treated wood, it’s essential to consider the longevity of the glued joints. The adhesive used must be able to withstand the harsh outdoor elements and maintain its strength over time.

To ensure the longevity of glued pressure treated wood, it’s crucial to use an adhesive that is specifically designed for this type of wood. Epoxy or polyurethane adhesives are the best options for long-lasting results. These adhesives provide a strong bond and are resistant to water, weather, and insects.

Care Tips For Maintained Strength

While choosing the right adhesive is crucial, proper maintenance is equally important for maintaining the strength of glued pressure treated wood. Here are some care tips to ensure that the glued joints remain strong:

– Regularly clean the wood to remove dirt, debris, and other contaminants that can weaken the bond.

– Apply a water-resistant coating to the wood to protect it from moisture, which can cause the adhesive to break down over time.

– Avoid exposing the wood to extreme temperature changes, as this can cause the wood to expand or contract, leading to weakened joints.

– Inspect the glued joints periodically and repair any damage immediately to prevent further deterioration.

In conclusion, while it is possible to glue pressure treated wood, it’s important to choose the right adhesive and follow proper maintenance practices to ensure the longevity of the glued joints. With the right care, glued pressure treated wood can provide a long-lasting and durable solution for outdoor projects.

Case Studies: Successful Projects With Glued Pressure Treated Wood

Discover the success stories of using glued pressure treated wood in various projects. Learn about the effectiveness and advantages of using this method to achieve durable and secure structures. Explore the possibilities of using glued pressure treated wood for your next project.

Real-life Examples Of Applications

Gluing pressure treated wood can be challenging due to the chemicals used to preserve the wood. However, with the right adhesive and techniques, it can be done successfully. Let’s take a look at some real-life examples of applications where glued pressure treated wood was used.

Example 1: Garden Bench

A homeowner wanted to build a garden bench using pressure treated wood. They decided to glue the pieces together for added stability. They used a polyurethane-based adhesive and clamps to hold the pieces in place while the glue dried. The bench has held up well over time, even with exposure to the elements.

Example 2: Decking

A contractor was tasked with building a deck using pressure treated wood. They wanted to ensure the deck was as sturdy as possible, so they decided to glue the boards together. They used a waterproof adhesive and clamps to hold the boards in place while the glue dried. The deck has been in use for several years and is still in great condition.

Learning From Success Stories

These examples demonstrate that gluing pressure treated wood can be done successfully with the right adhesive and techniques. When considering gluing pressure treated wood, it’s important to choose an adhesive that is waterproof and designed for use with treated lumber. It’s also important to use clamps or other methods to hold the pieces in place while the glue dries.

Remember, not all adhesives are suitable for gluing pressure treated wood, and improper techniques can result in weak joints. By learning from these success stories and using the right adhesive and techniques, you can successfully glue pressure treated wood for your own projects.

Conclusion: Harnessing The Potential Of Glued Pressure Treated Wood

Discover the untapped potential of bonding pressure treated wood through effective gluing techniques. Unleash the durability and strength of pressure treated wood by utilizing proper adhesives for lasting structural integrity. Maximize the benefits of glued pressure treated wood for your projects with reliable bonding methods.

Summing Up The Do’s And Don’ts

Do’s and Don’ts to consider while gluing pressure treated wood:

- Do: Use adhesive rated for exterior use.

- Do: Sand the wood for better adhesion.

- Do: Apply pressure while the glue sets.

- Don’t: Expect glue to penetrate deeply into the wood.

- Don’t: Skip cleaning the wood surface.

- Don’t: Forget to clamp the pieces firmly.

Encouraging Innovation In Woodworking

Innovate your woodworking by exploring new techniques for gluing pressure treated wood:

- Experiment with different adhesives for best results.

- Explore creative ways to join wood pieces.

- Embrace modern tools and technologies.

Frequently Asked Questions

Can Pressure Treated Wood Be Glued Together Effectively?

Yes, pressure treated wood can be glued effectively using exterior grade construction adhesive for strong and durable bonds.

What Type Of Adhesive Is Best For Pressure Treated Wood?

For pressure treated wood, it is recommended to use polyurethane-based construction adhesive for its superior bonding strength and durability.

Is It Necessary To Prepare Pressure Treated Wood Before Gluing?

Yes, it is essential to prepare pressure treated wood by sanding the surfaces to be glued to remove any dirt, debris, or rough spots for optimal adhesion.

How Long Should Pressure Treated Wood Be Clamped After Gluing?

After gluing pressure treated wood, it is recommended to clamp the pieces together for at least 24 hours to ensure a secure and long-lasting bond.

Conclusion

Gluing pressure treated wood can be a challenging task due to the chemicals used in the treatment process. However, with the right adhesive and proper preparation, it is possible to achieve a strong bond. Remember to follow the manufacturer’s instructions and consider using mechanical fasteners for added strength.

By understanding the limitations and taking the necessary precautions, you can successfully glue pressure treated wood for your projects.