Can You Put Epoxy Resin Over Polyurethane? Quick Tips!

Yes, you can put epoxy resin over polyurethane, but proper preparation is essential for adhesion. Clean and lightly sand the polyurethane surface before applying epoxy.

Epoxy resin is a popular choice for various projects, from woodworking to art. Its durability and glossy finish make it appealing. Many people wonder about layering epoxy over polyurethane finishes, especially for added protection or aesthetics. Understanding how these materials interact is crucial for achieving the best results.

Proper preparation ensures strong adhesion and prevents issues like peeling or bubbling. This guide will explore the compatibility of epoxy resin with polyurethane and provide tips for successful application. Whether you’re a DIY enthusiast or a professional, knowing how to use these materials together will enhance your projects.

Introduction To Epoxy Resin And Polyurethane

Understanding the differences between epoxy resin and polyurethane is essential for various projects. Both materials have unique properties and applications. Knowing how they interact can help you make better choices.

The Basics Of Epoxy Resin

Epoxy resin is a versatile material. It is popular in crafts and industrial applications. Here are some key features:

- Durability: Epoxy is strong and resistant to chemicals.

- Adhesion: It bonds well to many surfaces.

- Clear Finish: It can provide a glossy, clear look.

Common uses include:

- Coating wooden surfaces.

- Creating art pieces.

- Repairing damaged items.

Understanding Polyurethane

Polyurethane is another durable material. It comes in various forms, such as coatings, foams, and adhesives. Key features include:

- Flexibility: Polyurethane is more flexible than epoxy.

- Weather Resistance: It withstands outdoor conditions well.

- Variety: Available in both water-based and oil-based forms.

Common applications are:

- Finishing wooden floors.

- Sealing surfaces.

- Creating insulation materials.

Understanding both materials helps in choosing the right one for your projects.

Comparing Epoxy Resin And Polyurethane

Understanding the differences between epoxy resin and polyurethane is essential. Each material has unique properties and uses. This knowledge helps in choosing the right one for your project.

Key Properties

| Property | Epoxy Resin | Polyurethane |

|---|---|---|

| Composition | Two-part system (resin and hardener) | Single or multi-component |

| Finish | Hard and glossy | Soft and flexible |

| Drying Time | Varies (usually longer) | Usually quicker |

| UV Resistance | Low (can yellow) | Higher (more resistant) |

Durability And Usage

Both materials are durable but serve different purposes.

- Epoxy Resin: Ideal for heavy-duty applications.

- Polyurethane: Great for flexible surfaces.

- Common Uses of Epoxy Resin:

- Coatings for floors

- Adhesives in construction

- Art and crafts

- Common Uses of Polyurethane:

- Furniture finishes

- Sealants for wood

- Foams for insulation

Choose wisely based on your project’s needs. Understanding these differences guides better results.

The Compatibility Question

Understanding the compatibility between epoxy resin and polyurethane is essential. Both materials have unique properties. Knowing how they interact can help you make the right choice for your project.

Chemical Interactions

Epoxy resin and polyurethane have different chemical structures. Here are key points about their interactions:

- Epoxy resin cures through a chemical reaction.

- Polyurethane cures through evaporation of solvents.

- Mixing these two can lead to unpredictable results.

- Compatibility varies based on specific formulations.

Some epoxy resins may bond with polyurethane. Others may not adhere well. Always test a small area first.

Surface Adhesion Considerations

Surface preparation plays a crucial role in adhesion. Consider these steps:

- Clean the polyurethane surface thoroughly.

- Sand the surface to create a rough texture.

- Apply a primer designed for epoxy resin.

Using a primer improves bonding. Check for manufacturer recommendations. This will ensure the best results.

| Material | Adhesion Potential | Recommended Action |

|---|---|---|

| Epoxy Resin | Good if properly prepared | Use primer and sand |

| Polyurethane | Variable | Test adhesion first |

Proper preparation boosts adhesion. Always prioritize surface treatment for the best bond.

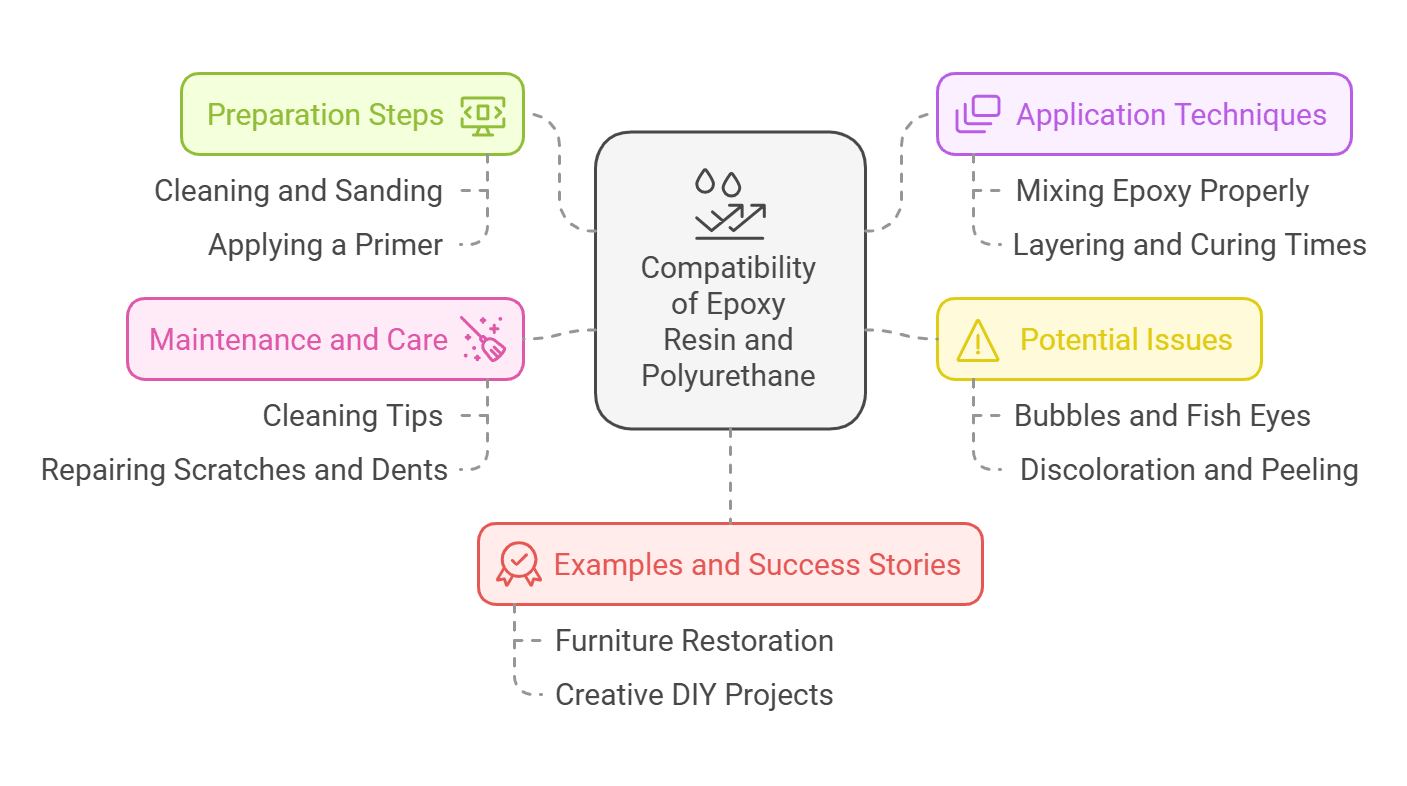

Preparing Surfaces For Epoxy Over Polyurethane

Preparing surfaces correctly is crucial for a successful epoxy application. This process ensures strong adhesion and a smooth finish. Proper preparation prevents peeling and bubbling in the final layer.

Cleaning And Sanding

Cleaning and sanding the surface is the first step. Follow these steps for best results:

- Remove Debris: Use a vacuum to clear dust and dirt.

- Wash the Surface: Clean with soap and water. Rinse thoroughly.

- Dry Completely: Allow the surface to dry fully before proceeding.

- Sanding: Use medium-grit sandpaper (around 120-grit). Sand the entire area to create a rough texture.

Rough surfaces help the epoxy bond better. After sanding, wipe the surface with a clean cloth. This removes any dust particles.

Applying A Primer

Applying a primer is an important step. It enhances adhesion between the epoxy and polyurethane. Use the following steps:

- Choose the Right Primer: Select a primer designed for epoxy applications.

- Apply Evenly: Use a brush or roller to apply the primer. Ensure it covers the entire surface.

- Follow Drying Instructions: Allow the primer to dry as per the manufacturer’s guidelines.

Once the primer is dry, the surface is ready for epoxy application. A well-prepared surface ensures a durable and long-lasting finish.

Application Techniques

Applying epoxy resin over polyurethane requires careful techniques. Proper methods ensure strong adhesion and a smooth finish. Let’s explore essential steps for successful application.

Mixing Epoxy Properly

Mixing epoxy resin correctly is crucial for successful application. Follow these steps:

- Gather Materials: Use gloves, a mixing cup, and a stir stick.

- Measure Components: Follow the manufacturer’s ratio of resin to hardener.

- Mix Thoroughly: Stir for at least 3 minutes, scraping the sides.

- Avoid Air Bubbles: Mix gently to minimize bubbles.

Using the right tools ensures an even mixture. A well-mixed epoxy will cure properly.

Layering And Curing Times

Layering and curing times are vital in the application process. Here’s how to manage them:

| Layer Type | Curing Time | Notes |

|---|---|---|

| First Layer | 4-6 hours | Ensure it’s tacky but not fully cured. |

| Subsequent Layers | 24 hours | Apply within 72 hours for best adhesion. |

| Final Cure | 5-7 days | Full strength achieved after this period. |

Apply the next layer when the previous one is still tacky. This ensures strong bonding. Always check the manufacturer’s instructions for specific curing times.

Potential Issues And Solutions

Applying epoxy resin over polyurethane can lead to specific challenges. Understanding these issues helps in creating a smooth finish. Below are common problems and effective solutions.

Bubbles And Fish Eyes

Bubbles and fish eyes can ruin the appearance of your project. Here are some common causes and solutions:

- Trapped Air: Air can get trapped between layers.

- Surface Contamination: Dust or oils can cause fish eyes.

To avoid these issues:

- Ensure the polyurethane surface is clean and dry.

- Use a heat gun to pop bubbles.

- Apply thin layers of epoxy.

Discoloration And Peeling

Discoloration and peeling can occur due to improper application. Here are the main causes:

- Moisture: Excess moisture can lead to peeling.

- Incompatible Products: Not all polyurethane works with epoxy.

To prevent these problems:

- Choose compatible products.

- Wait for the polyurethane to cure completely.

- Apply epoxy in a controlled environment.

Following these tips can lead to a successful finish.

Maintenance And Care

Proper maintenance keeps your epoxy resin surface looking great. Care routines help preserve its beauty and durability. Regular attention prevents damage and ensures longevity.

Cleaning Tips

Keeping your epoxy resin surface clean is easy. Follow these simple steps:

- Use a soft cloth or sponge.

- Mix warm water with a mild soap.

- Wipe the surface gently.

- Rinse with clean water.

- Dry with a soft towel.

Avoid harsh chemicals. They can damage the finish. Regular cleaning helps maintain shine and luster.

Repairing Scratches And Dents

Scratches and dents can happen. Repair them quickly to keep your surface flawless. Here’s how:

- Identify the damaged area.

- Sand the scratch lightly with fine-grit sandpaper.

- Clean the area to remove dust.

- Mix a small amount of epoxy resin.

- Apply it carefully to the scratch.

- Let it cure as per instructions.

- Buff the area gently for a smooth finish.

This method restores the surface. It keeps your epoxy looking new.

Examples And Success Stories

Many people have successfully used epoxy resin over polyurethane. Their projects show great results. Here are two inspiring examples: furniture restoration and creative DIY projects.

Furniture Restoration

Restoring old furniture can breathe new life into worn pieces. Many enthusiasts use epoxy resin over polyurethane finishes. This method creates a strong, beautiful surface. Here are some success stories:

- Wooden Tables: A family restored a scratched dining table. They applied epoxy resin over the existing polyurethane. The table now shines and looks brand new.

- Chairs: Vintage chairs received a makeover. The owners added a layer of epoxy resin. The result? A glossy finish that attracts attention.

- Dressers: A worn dresser transformed into a stunning focal point. The epoxy filled in scratches and made it durable.

Creative Diy Projects

DIY enthusiasts have taken epoxy resin to new heights. They combine it with polyurethane for unique creations. Here are some project ideas:

- Coasters: Epoxy resin coasters are trendy. Adding a polyurethane base makes them sturdy.

- Wall Art: Artists use epoxy over polyurethane to create stunning pieces. The glossy finish enhances colors.

- Jewelry: DIY jewelry makers layer epoxy resin on polyurethane. This results in beautiful, durable accessories.

| Project Type | Material Used | Result |

|---|---|---|

| Furniture Restoration | Epoxy over Polyurethane | Durable and glossy finish |

| DIY Coasters | Polyurethane base with Epoxy | Stylish and sturdy coasters |

| Wall Art | Epoxy over Polyurethane | Vibrant and eye-catching art |

Frequently Asked Questions

Can Epoxy Resin Adhere To Polyurethane Surfaces?

Yes, epoxy resin can adhere to polyurethane surfaces. However, proper surface preparation is crucial for a strong bond. Make sure the polyurethane is clean, dry, and free of contaminants. Lightly sanding the surface can also help improve adhesion.

Is Polyurethane A Barrier For Epoxy Resin?

Polyurethane can act as a barrier to epoxy resin. If the polyurethane layer is fully cured, it may prevent proper bonding. This can lead to peeling or delamination over time. Ensure compatibility by testing small areas before applying the full coat.

How To Prepare Polyurethane For Epoxy Application?

To prepare polyurethane for epoxy application, start by cleaning the surface thoroughly. Use a mild detergent and water to remove dirt and grease. Once dry, lightly sand the surface to create a rough texture. This will enhance the bond between the two materials.

Can You Apply Epoxy Resin Over Old Polyurethane?

Yes, you can apply epoxy resin over old polyurethane. Ensure the polyurethane is fully cured and clean. Light sanding helps create a better surface for adhesion. Always conduct a small test patch to confirm compatibility and adhesion before proceeding with the entire project.

Conclusion

Applying epoxy resin over polyurethane is possible, but caution is key. Ensure the surface is clean and well-prepared for optimal adhesion. Always perform a test patch to avoid any surprises. With proper techniques, you can achieve a stunning finish that enhances your project’s durability and aesthetics.

Happy crafting!