Cedar Vs Redwood Deck: Proven Essential Choice

Cedar vs Redwood Deck: The expert verdict is that for maximizing visible aesthetic appeal and rich color naturally, Redwood often edges out Cedar in high-moisture or coastal areas, while Cedar often wins on initial cost and wider initial availability; evaluate your region and budget for the best fit.

Cedar Vs Redwood Deck: Deciding Your Proven Essential Choice

Picking the right wood for your new deck can feel like the biggest puzzle piece in your DIY project. You want a deck built to last, beautiful to look at, yet one that doesn’t completely empty your wallet at the lumberyard. Two superstars in natural decking frequently rise to the top but confuse us: Cedar and Redwood.

Many folks online make quick judgments on Cedar versus Redwood, but the actual best choice for you depends on a few simple things happening right outside your door. Maybe you thought they were the same or interchangeable—they are definitely not twins!

Don’t worry; we are going to take the intimidation factor right out of this. By digging into how each wood grows, what resistances they naturally have, and what they cost, you will walk away confident. Next, we cover grades, real money value, and how to install them safely—no guessing required once we are done.

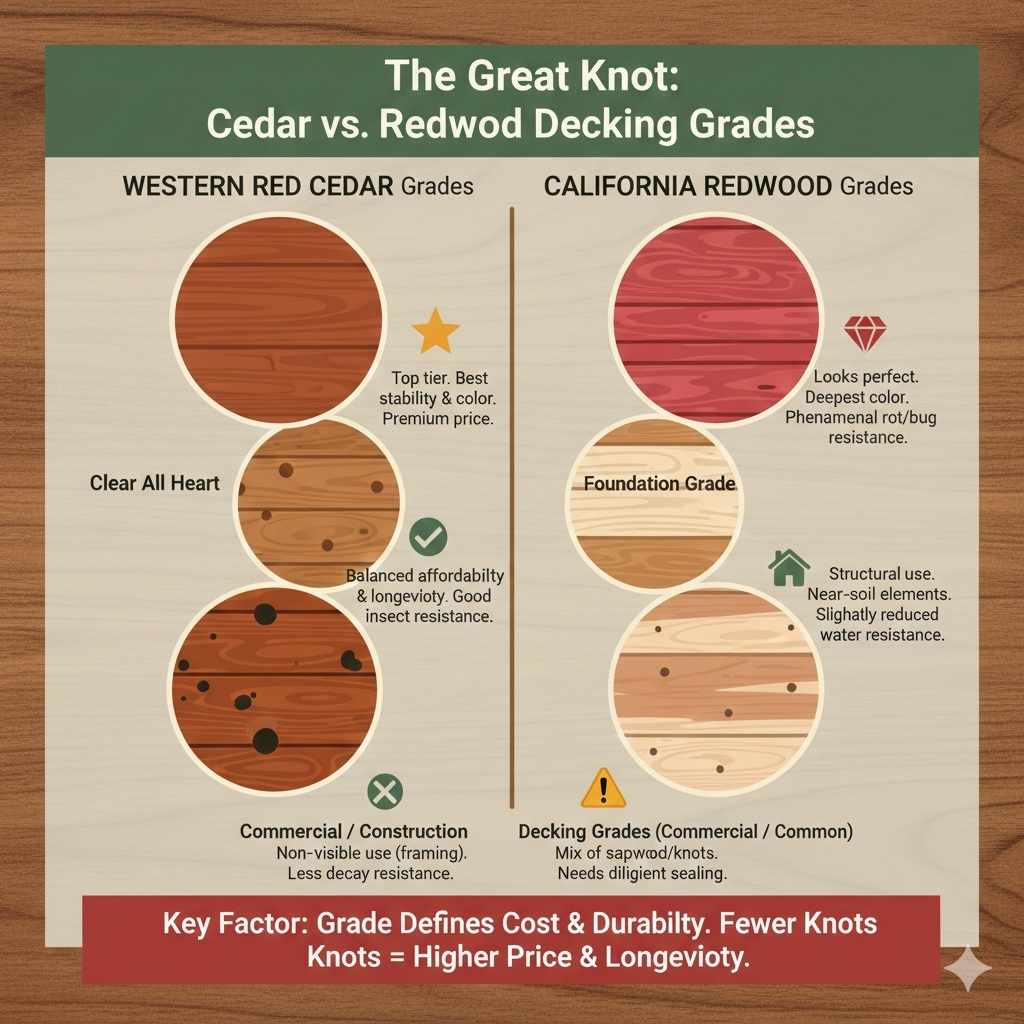

Understanding the Great Knot: Cedar vs Redwood Decking Grades

To compare Cedar and Redwood accurately, we must speak the same language regarding the wood grades you see stacked at the builder’s supply store or homeowner center. The grade defines how much of the wood contains knots, stains, or small blemishes. Lower grades mean lower cost, but faster wear. Fewer knots usually mean fewer worries down the line!

Western Red Cedar Grades Explained

When you hear “Western Red Cedar” (Thuja plicata), think rich aroma and beautiful grain patterning. It’s popular across the country because it handles wide temperature swings well.

The common professional ordering grades involve Clear and Shop grades:

- Cedar Clear All Heart: This is the top tier. It means all the wood is taken almost exclusively from the center (heartwood) of the tree. No knots escape. This offers the very best stability and color, holding up incredibly long against bug incursions and rot. It carries a near-premium price tag.

- Cedar Standard or Select Knotty: This grade has an accepted amount of knots but the clearest “face” grading. It’s a great balance between affordability and longevity for an average backyard deck. It’s naturally good at repelling insects, though perhaps not as intensely protective as the Clear Heart grade’s heavy oils.

- Cedar Commercial / Construction Grade: Mostly used secretly under surface decking structure, or in non-visible applications where looks do not matter. Knots are plentiful, and decay resistance is lessened overall.

California Redwood Grades Explained

Coming primarily from our western neighbor states, Redwood (Sequoia sempervirens) often boasts a deeper, richer reddish-pink hue that many builders argue is unmatched. Like Cedar, resistance centers in the dark-colored ‘heartwood.’

- Redwood Clear All Heart: Simply put, this looks perfect. It holds the deepest color and possesses phenomenal resistance to our biggest woody enemies—rot and termites—because these areas of the wood naturally produce strong resistant chemicals (tannins). Excellent but pricey.

- Redwood Foundation Grade: Generally sound woods, often used for structural framing beneath the home or low-to-the-ground elements nearest the soil. They might include a few darker portions that slightly reduce water resistance compared to the Clear grades.

- Redwood Decking Grades (Commercial / Common): Similar to Cedar’s lower grades, these usually mix sapwood (lighter color, less resistant) and have knots present. Good lookers, but be diligent about post-seaing care or placement far from ground moisture exposure, especially for beginners.

Durability Deep Dive: Rot Resistance and Stability

This is arguably the most important comparison for a deck owner: How long will my investment stay sound? Wood durability relies on its heartwood containing natural extracts that resist fungus (rot) and creepy crawlies (termites and borers).

Insect and Decay Resistance Comparison

Both woods star in environments treated lumber struggles (like coastal salt air or heavy shade). Here’s a surprising fact: many high-quality Redwood species come chemically equipped a bit better straight outta the forest in terms of raw resistance because of the heavy natural tannins they contain.

One established guide, the US Forest Products Laboratory classification system often referenced heavily within construction codes suggests specific groupings. While both are naturally classed highly, the absolute best Heart Grades of redwood are often slightly superior naturally against widespread rot conditions than the best Cedar. However, for hobbyist upkeep, applying quality seals to both significantly equalizes this difference.

Cedar’s Toughness Score

Native Western Red Cedar is a champion, especially against widespread fungus. It sheds water reasonably well using that tight grain structure. Due to extensive commercial plantings, it dries flatter and can be found stabilized faster than some high-moisture Redwood logs.

Redwood’s Superior Deep Color Resistance

If you live right on the coast, where wood sucks in atmospheric moisture continually, high-grade Redwood really shines due to the deep extractives sealing that wood from within—preventing rapid degradation beneath the surface finish.

Dimensional Movement and Stability

Deck boards swell when they get wet and shrink as they dry in the sun. We call this “dimensional movement.” Excessive rocking creates popped Fasteners and cracks on a beginner build.

Generally speaking across standard grades, Cedar tends to be slightly superior and dimensionally stables than Redwood in environments with great changes in moisture levels—think desert climates or sharply contrasting spring floods versus harsh winter dryness.

- Cedar Pros: Incredible resistance to cupping (warping sideways) after sealing treatments.

- Redwood Cons: Can exhibit mild cupping or checking if wide boards are poorly installed across narrow joist spacing. Tip: Ensure ample airflow when building the subframe for dense wood types.

| Feature | Cedar Standard Grade | Redwood Standard to Select Grade |

|---|---|---|

| Natural Rot Resistance | High | Naturally Higher (Thicker Heartwood Content) |

| Stability (Resistance to Warping) | Very Good | Good (Check job side humidity) |

| Softness to Impact Tool & Saw Blade | Moderate Shock Absorption | Slightly softer / easier to dent with sharp impact shock. |

| Preferred Placement | General Exposure decks everywhere. | Slight wetness exposure (coastal framing due to best rot proofing). |

The Cost Calculation: Budget Versus Premium Beauty

Now let’s talk about what every DIYer considers first: emptying the budget. While initial lumber prices fluctuate constantly based on geography, transport costs, and supplier stock levels, one almost always comes with a higher shelf tag than the other in most major US markets.

Cedar Price Point Reality

In standard nationwide comparison studies, milled Cedar lumber usually carries an initial price tag that is frequently 15% to 25% lower than comparable high-grade Redwood products before sealants or additives.

How Cedar Saves You Money:

- Wider geographic availability means less transportation inflation built into every footing you order.

- Lower premium grades (Select Knotty decking board) offer amazing quality far cheaper than Redwood’s baseline Clear grade.

Redwood Price Point Reality

Redwood faces stiff regulation regarding harvesting due to long growth cycles and conservation efforts, mainly in its pristine growing habitats of California. This scarcity drives cost up.

For true comparative quality (Heartwood, low expansion factor), Redwood might cost upwards of 30% more volume-for-volume than Mid and upper-range Cedar products. You are paying partly for exceptional natural pedigree!

If budget is your single largest concern and superior color is just “something nice to have,” easily select Cedar from competitive suppliers near you!

Tool Talk: Which One Punches Up Your Tools More?

As hobby builders, we need to know how the project will treat our power tools. Softer woods wear blades slower and leave wood splintering easier if using dull blades. Very hard (dense) woods destroy blades faster. Happily, BOTH Cedar Cedar versus Redwood deck lumber generally fit into the easy milling category.

Cutting Cedar

Cedar rarely resists a saw path once you accept its tendency for surface tearing:

- Benefit: Cuts stack up very fast; consumes less blade carbide for fine details or ripping/cross cuts. (Less power needed)

- Challenge: Due to resin channels, boards can shatter right on the cut line (“burnout”) if using old, dull, combination-toothed blades. For sharp, straight, long cuts, use a smooth-action carbide-grit finish blade suitable for softwood projects.

Cutting Redwood

Redwoods generally feel slightly softer in the hand when testing (less dense sapwood sections aside). They are a joyful material to work with speed wise but need great care.

- Benefit: Truly effortless milling; sands quickly using minimal physical effort.

- Caveat: Due to deep surface tannins staining the wood, you MUST utilize dedicated fresh material blades (avoid re-using that heavily dirty edging blade from old PT pine projects!) or these materials can get smeared with contaminants.

Pro Mentor Tip on Dust Safety: Both woods emit finely scented oils which can be mildly irritating similar to dust from certain hardwoods based on how your body reacts. Always treat exposure to redwood and cedar sawdust exactly like any wood dust.

[For safety standards regarding respiratory exposure, reference construction safety organizations to familiarize yourself with appropriate PPE before starting major milling.]

The Crucial Finishing Step: Stain, Seal, or Allow Gray Patina?

This choice is entirely aesthetics, as both woods achieve amazing long-term performance via regular maintenance oil/sealer applications around the nation.

Cedar Finishing Pathways

Cedar’s porous grain readily accepts oil-based or water-based sealers evenly across its surface area. Its overall native tone warms any color stain applied.

Cedar Color Outcomes

- Natural Grain Stain: Leaves deep gold tones that develop a beautiful, soft pearl-gray patina over decades if left completely untouched naturally.

- Tinted Sealers: Stains absorb incredibly evenly due to density variations, making over-application mistakes less common for a beginner installer painting or slightly sun-screening the wood later.<.}

Redwood Finishing Pathways

Due to Redwood’s deep iron-red heartwood saturation, it “wants” to look rich right away. Many owners apply clear waterproofing sealant only to showcase that natural inherent beauty.

- Natural Depth Maximized: Sealing with Ultra-UV blocking clears seems to make the red fibers deepen almost permanently, an aesthetic unparalleled by Cedar.

- Staining Challenge: High-quality, pigmented stains applied to Cedar look clear and refined. If you stain Redwood to look like Cedar territory (like dark brown), you waste a lot of money inherently spent on beautiful primary color layers. Keep it clear or amber to highlight depth naturally!

Putting the Boards Down: Essential Construction Considerations

How do you physically build things with these variations in wood density and expected wear life behind the face boards?

Fastener Selection 101

This is an area where Redwood truly demands precision over Cedar—primarily because surface oils in Redwood are very reactive with basic steel.

DO NOT USE COMMON BRIGHT ALUMINUM NAILS IN REDWOOD !

Bright aluminum nail alloys, commonly cheap choices for framing, tend to corrode slightly faster underneath the harsh environments promoted by native Redwood’s protective inner structure. Over years, corrosion stress degrades fasteners. You might end up with an awful situation caused by basic fastener reaction.

- Cedar Fastener Recommendation: Stainless Steel (304 or coated screws); Hot-Dip Galvanized provides adequate (but not premium) longevity.

- Redwood Fastener Mandate: Spend the minor amount extra for coated exterior deck screws or straight-316 grade stainless steel for phenomenal, long-term piece of mind connection in any residential structure. Follow established fastener guidelines here: [Resource on exterior fastener best practices].

Support Span Guidelines

Because Redwood usually has a slightly better strength rating compared to Cedar for structural integrity in standard framing thicknesses (think common 2x10s or beams), your acceptable distance between structural piers (joist span or ledger supports) can sometimes stretch a minuscule amount further for Redwood using lower grades.

For a standard 2×6 or 5/4 decking thickness: ALWAYS follow official decking code tables and manufacturer spans for safety regardless of species performance scores. Beginners should keep joists tighter—I firmly suggest maxing load support—go tighter on deck joists for any deck build, just ensuring a solid-feeling underside.

Quick Project Recap: Cedar vs Redwood Quick Comparison Table

| Factor | Cedar (Western Red) | Redwood (California) |

|---|---|---|

| Average Cost Basis | ($ / 2/8 board foot equivalent, lower-intermediate baseline) | ($$ / Costly premium baseline) |

| Best Aesthetic Perk (Beginner Focus) / Appearance | Finely textured, excellent UV fading control over clear sealer. | Rich, legendary permanent color depth enhancement with clear coat. |

| Maintenance Schedule Required | Annual light washing/sealing every 18 – 24 months. | Annual light washing/sealing every 12 – 18 months for ideal color locking. |

| Ease of Working (Mistake Tolerance) | Higher tolerance forgiveness with stains and slightly less sensitive fastening. | Needs more care around fasteners (Use SS or coated). |

Working Ahead: Building Safety and Care Checklist for Both Woods

No matter if Cedar or Redwood moves to the top, safety and prep work dominate successful project completion. Forgetfulness spoils results!

- Stock Acclimation: Allow the wood package to sit on clean blocks (not directly on soil!) for 3–7 sunny days just covered on top. This releases surface expansion tension before fastening starts.

- Pre-Drill Everything Critical: Remember, end-grain screws go in harder than those buried deep. Always pre-drill any area close to an error risk (at board edges particularly). This dramatically elevates joint safety upon sealing.

- Secure Offcuts for Future Patching: This is something beginners often skip until a tool drops onto the new deck a few months later! Dedicate a labeled box for matching wood cut-offs, especially premium grades or heartwood pieces you can’t cut again safely across joists.

- Sealing Time: Once the deck is assembled, do not stain it immediately. Wait 4–8 glorious warm weeks minimum—allowing any natural ground moisture vapor transfer (if laid close to ground) to exhale—unless instructions specifically advise quick application for mildew removal purposes.

Frequently Asked Questions (FAQ) for Deck Beginners

Q1. Can I mix Redwood and Cedar wood on the same deck structure?

Absolutely—but use caution. If you use cheaper Red or Cedar grades for underlying sleepers built close to the ground (“wet” area), then utilize premium KD (Kiln Dried) Cedar or Redwood for ONLY visible decking surface boards, consistency is maintained. However, NEVER mix Cedar deck boards in a pure Redwood structure unless you are 100% sure the sealant treatment plan accounts for differing oil/tanain ratios of the two woods.

Q2. If both are naturally resilient, can I completely leave a Cedar or Redwood deck unfinished?

Yes. If located under a solid roof eave, less UV exposure limits change. Complete exposure: yes—the wood will eventually oxidize, turn a soft silver-gray—BUT exposure leads to checking (nail like splits) and surface softness faster than constantly sealed woods. To keep woodworking happy long, sealer is almost universally mandatory.

Q3. Which deck material tends to last longer in Northern US Winters’ freeze-thaw cycling?

Technically, premium grades of Cedar often outperform slightly due to historically slightly better cellular uniformity and control over swelling mechanics. However, if you rigorously adhere to high-UV resistant oil sealants over both materials yearly, the difference becomes truly negligible throughout a homeowner’s lifetime ownership timeframe.

Q4. Which one prevents splintering better after five years exposed to foot traffic?

Both splinter when surface cellular structure degrades through extreme dryness or overly aggressive pressure washing. Both perform vastly better resisting those shallow fuzz splinters than composites, provided sealants bridge surface gaps correctly and sealers/oils are reapplied, refreshing the wooden fiber integration.

Q5. I inherited a home with one redwood area and one Cedar treated frame underneath. Should I reinforce parts with modern PT lumbar?

NO! Do not mix new, high-retention-rate Pressure Treated (PT) lumber with historic/organic, non-treated heartwood framing timber unless separated by extensive waterproof barrier tape. The chemical reactions differ enough to risk increased corrosion (especially in steel ties/brackets connecting the structures) and the pressure application of preservative chemicals on old framing can complicate repairs enormously. Keep original structure material consistent!

Q6. Is Cedar always available everywhere, making it ‘easier’ for homeowners to source during peak deck season?

Historically, across the vast Midwestern and Eastern US distribution channels, Yes, readily available grades of Western Red Cedar have an easier, more consistent supply chain presence versus the sometimes seasonal, geographically locked supply required for specific grades of premium Redwood.

Conclusion: Bringing Confidence to Your Cedar vs Rediswood Takeaway

Pat yourself on the back! You now possess practical, hard-won insight most first-time builders are missing completely simply by stopping at Google search results. You understand that deck selection is seldom a one-size-fits-all verdict.

If your primary driver is immediate budget preservation, geographic access simplicity, and slightly flatter board mapping post-job without excessive moisture concern across decades, Cedar holds fantastic reign year after year. It allows flexibility in mid-range options.

However—and this is crucial knowledge to apply specific to your location—if your area sees unusually high groundwater intrusion scenarios, coastal salt spray impact, or perhaps you are chasing that iconic deep architectural red hue above your fireplace—spending that necessary extra sum for high Redwood heartwood investments yields truly rewarding longevity payback and unmatched visual drama. Both promise enduring natural beauty fit for welcoming guests into your lovingly built outdoor space. Arm yourself with the stainless steel fasteners, seal it well when the trees tell you to (wait an appropriate off-site drying waiting period!), and enjoy the craft!”