Circular Saw Blade Cut Aluminum: Smooth & Precise!

Yes, you can cut aluminum with a regular circular saw blade. However, it is recommended to use a non-ferrous circular saw blade or a wood blade with a carbide tip to achieve clean and accurate cuts.

Carbide-tipped cold saw blades are also suitable for cutting aluminum materials. Using a circular saw or jigsaw with metal cutting blades is the appropriate tool for this task.

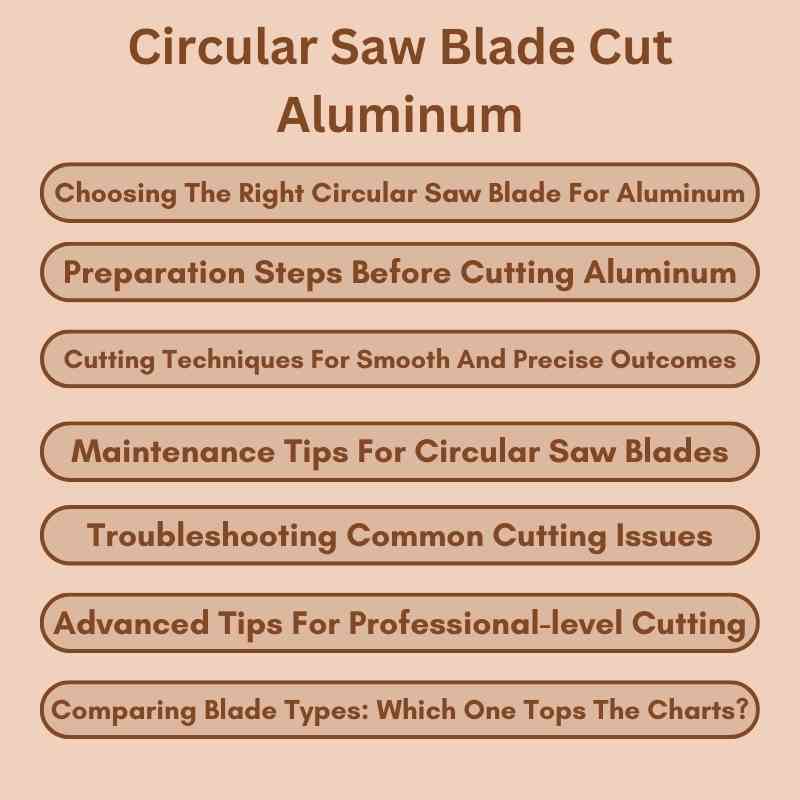

Choosing The Right Circular Saw Blade For Aluminum

When it comes to cutting aluminum with a circular saw, choosing the right blade is essential for achieving clean and precise cuts. The right blade can make all the difference in terms of efficiency and quality of the cut. In this guide, we will discuss the key factors to consider when selecting a circular saw blade for cutting aluminum.

Material Compatibility: Matching Blade To Aluminum

One of the first things to consider when choosing a circular saw blade for cutting aluminum is the material compatibility. Not all blades are designed to cut through aluminum effectively. You need to ensure that the blade you choose is specifically designed and labeled for cutting aluminum. Using the wrong blade can lead to poor performance, excessive heat, and potential damage to both the blade and the workpiece.

When selecting a blade, look for those that are specifically labeled as “aluminum cutting” or “non-ferrous metal cutting.” These blades are typically made from carbide or carbide-tipped, which provides the necessary hardness and durability to cut through aluminum effectively.

Tooth Count And Design For Optimal Cutting

The tooth count and design of the circular saw blade are crucial for achieving optimal cutting results on aluminum. The tooth count refers to the number of teeth on the blade, and it plays a significant role in the speed and quality of the cut.

For cutting aluminum, blades with a higher tooth count are generally recommended. Higher tooth count blades, such as those with 80 to 100 teeth, provide a smoother and cleaner cut. They create smaller chips and reduce the risk of material deformation or burrs. These blades are particularly suitable for cutting thin aluminum sheets or delicate materials.

In addition to the tooth count, consider the tooth design of the blade. Look for blades with alternate top bevel (ATB) or triple-chip grind (TCG) tooth configurations. These tooth designs are specifically engineered to cut through non-ferrous metals like aluminum efficiently. They help to minimize heat buildup, reduce blade vibrations, and ensure clean and precise cuts.

Choosing the right circular saw blade for cutting aluminum is crucial for achieving clean, precise, and efficient cuts. Make sure to select a blade that is compatible with aluminum, and consider the tooth count and design to optimize cutting performance. By using the right blade, you can enhance the quality of your work and prolong the life of your tools.

Preparation Steps Before Cutting Aluminum

To prepare for cutting aluminum with a circular saw blade, make sure to use a non-ferrous blade or a wood blade with carbide tips for best results. Secure the aluminum firmly and wear appropriate safety gear to protect yourself from metal shavings during the cutting process.

Safety Measures: Protecting Yourself And Your Equipment

Before cutting aluminum with a circular saw blade, it’s crucial to prioritize safety measures to protect both yourself and your equipment. Always wear protective eyewear to shield your eyes from potential metal fragments. Additionally, use hearing protection to safeguard against the loud noise generated by the saw. Wear gloves to ensure a secure grip while handling the material and to protect your hands from sharp edges. Lastly, make sure the work area is well-ventilated to minimize exposure to aluminum dust and fumes.

Setting Up The Saw: Ensuring Precision And Stability

Setting up the circular saw for cutting aluminum requires attention to detail to ensure precision and stability. Secure the aluminum securely to prevent any movement during the cutting process. Use clamps or a vise to hold the material firmly in place, reducing the risk of accidents. Before starting the saw, adjust the cutting depth to match the thickness of the aluminum. This helps in achieving clean and precise cuts while minimizing the risk of kickbacks. Ensure that the blade is sharp and suitable for cutting aluminum to maintain the efficiency of the cutting process. Lastly, position the aluminum carefully to avoid any potential hazards during the cutting process.

Cutting Techniques For Smooth And Precise Outcomes

When it comes to cutting aluminum with a circular saw blade, employing the right techniques is crucial for achieving smooth and precise results. By balancing speed with control and minimizing vibration and warp, you can optimize the cutting process to ensure a high-quality finish.

Feed Rate: Balancing Speed With Control

Adjusting the feed rate when cutting aluminum is essential for achieving a clean and precise outcome. By finding the right balance between speed and control, you can prevent the blade from binding and ensure a smooth cutting action. Maintaining a consistent feed rate throughout the cutting process is key to achieving a uniform and accurate result.

Supporting The Aluminum: Minimizing Vibration And Warp

Minimizing vibration and warp during the cutting process is essential for preventing damage to the aluminum and achieving a precise cut. Properly supporting the aluminum workpiece with a stable and secure platform can help minimize vibration and reduce the risk of warping, resulting in a high-quality finish.

Maintenance Tips For Circular Saw Blades

Circular saw blades are an essential tool for cutting aluminum, but like any cutting tool, they require regular maintenance to ensure their sharpness and performance. By following these maintenance tips, you can prolong the lifespan of your circular saw blades and achieve clean and precise cuts every time.

Cleaning The Blade: Prolonging Sharpness And Performance

Regularly cleaning your circular saw blade is crucial for maintaining its sharpness and performance. Over time, the blade can accumulate pitch, resin, and other debris that can affect its cutting ability. Here are some tips for cleaning your circular saw blade:

- Remove the Blade: Before cleaning the blade, always make sure the saw is unplugged or the battery is removed. Safely remove the blade from the saw by following the manufacturer’s instructions.

- Inspect for Damage: Take a close look at the blade to check for any signs of damage or wear. If you notice any missing or damaged teeth, it’s best to replace the blade.

- Use a Blade Cleaning Solution: There are specialized blade cleaning solutions available that can effectively remove built-up pitch and resin. Follow the instructions on the cleaning solution and apply it to the blade.

- Scrub with a Brush: Use a soft-bristle brush or an old toothbrush to scrub the blade gently. Make sure to clean both sides of the blade and remove any remaining debris.

- Rinse and Dry: Rinse the blade with clean water to remove any residue from the cleaning solution. Dry the blade thoroughly using a clean cloth or air compressor.

Storage Solutions: Keeping Blades In Top Condition

Proper storage of your circular saw blades is essential for keeping them in top condition. Here are some storage tips to consider:

- Use Blade Covers: When the blade is not in use, it’s a good idea to protect it with a blade cover. This will prevent the blade from getting damaged or causing accidental injuries.

- Store in a Dry Area: Moisture can cause rust and corrosion on the blade, so it’s important to store it in a dry area. Avoid storing the blade in humid or damp environments.

- Organize and Label: If you have multiple blades, keep them organized and labeled to easily identify the one you need. This will also prevent accidental damage when searching for a specific blade.

- Avoid Contact with Hard Surfaces: When storing the blade, make sure it doesn’t come into contact with hard surfaces or other tools that could potentially damage its teeth.

- Regularly Inspect: Periodically inspect your stored blades for any signs of damage or wear. If you notice any issues, it’s best to replace the blade before using it.

By following these maintenance tips, you can keep your circular saw blades in optimal condition, ensuring they deliver clean and precise cuts every time you work with aluminum.

Troubleshooting Common Cutting Issues

When it comes to cutting aluminum with a circular saw blade, it is important to use a non-ferrous blade or a wood blade with a carbide tip. These specialized blades are designed to handle the unique properties of aluminum and ensure a clean and precise cut.

Dealing With Blade Bind And Kickback

When cutting aluminum with a circular saw blade, one of the most common problems is blade bind and kickback. Blade bind occurs when the blade gets pinched between the material being cut, causing it to stop spinning. Kickback happens when the blade suddenly jumps back towards the user, which could be dangerous. To prevent blade bind and kickback, make sure the blade is properly installed and tightened. Also, avoid forcing the blade through the material being cut and keep the speed of the saw at a manageable level.

Addressing Rough Edges And Burrs

Rough edges and burrs are another common issue when cutting aluminum with a circular saw blade. This is often caused by using a blade with dull teeth or by cutting at a speed that’s too fast. To address rough edges and burrs, use a blade with sharp teeth and make sure the saw is operating at an appropriate speed. Additionally, consider using a deburring tool to remove any burrs that appear after the cut.

By following these tips, you can troubleshoot common cutting issues when cutting aluminum with a circular saw blade. Remember to always use the appropriate blade for the job and to keep safety in mind while operating the saw. With the right technique and equipment, you can achieve clean and precise cuts every time.

Advanced Tips For Professional-level Cutting

To achieve professional-level cutting with a circular saw blade on aluminum, use a non-ferrous circular saw blade or a fine wood blade with a carbide tip. These specialized blades are suitable for cutting aluminum with precision and efficiency, providing clean and accurate results.

Lubrication Techniques For Enhanced Cutting

Lubrication plays a vital role in enhancing the cutting performance of a circular saw blade. Without proper lubrication, the blade can become overheated, which can lead to warping or even breakage. One effective lubrication technique is to apply a lubricant directly to the blade while cutting. This can be done using a specialized lubricant spray or by coating the blade in a thin layer of oil or wax. Another technique is to use a lubricant-coated saw blade, which comes pre-coated with a lubricant that helps reduce friction and heat buildup during cutting.

Cooling Methods To Extend Blade Life

In addition to lubrication, cooling is another important factor in extending the life of a circular saw blade when cutting aluminum. One effective cooling method is to use a coolant system that delivers a stream of water or oil to the blade during cutting. This helps keep the blade cool and reduces the risk of overheating and warping. Another cooling technique is to use a saw blade with laser-cut heat expansion slots, which allow heat to escape from the blade and prevent warping or bending.

By using these advanced tips for professional-level cutting, you can achieve precise and efficient cuts when using a circular saw blade to cut aluminum. Remember to always lubricate and cool the blade properly to ensure its longevity and performance.

Comparing Blade Types: Which One Tops The Charts?

Cutting aluminum with a circular saw blade requires a non-ferrous blade or a wood blade with carbide tip. There are a variety of options available, ranging from affordable to high-end, that offer durability and precision for cutting through aluminum. Some of the top options include Diablo Cutting Saw Blade and Saw Blade Aluminum Cutting Metal, Plastic.

Carbide-tipped Blades Versus Standard Steel

When it comes to cutting aluminum with a circular saw, choosing the right blade is crucial for achieving clean and precise cuts. Two popular options to consider are carbide-tipped blades and standard steel blades. Let’s take a closer look at the characteristics of each to determine which one comes out on top.

Carbide-Tipped Blades

Carbide-tipped blades are known for their exceptional durability and longevity. These blades are made with carbide-tipped teeth, which are harder and more resistant to wear compared to standard steel teeth. The carbide tips allow for a more precise and smoother cut through aluminum, reducing the chances of chipping or splintering.

One of the key advantages of carbide-tipped blades is their ability to maintain their sharpness for a longer period. This means fewer blade changes and increased efficiency in your cutting projects. However, it’s important to note that carbide-tipped blades tend to be more expensive than standard steel blades.

Standard Steel Blades

Standard steel blades, on the other hand, are a more cost-effective option for cutting aluminum. These blades are typically made from high-speed steel (HSS), which is known for its durability and ability to withstand high cutting speeds. While standard steel blades may not last as long as carbide-tipped blades, they still offer decent performance when cutting aluminum.

When using standard steel blades, it’s important to select a blade with a high tooth count. Blades with more teeth provide a smoother cut and reduce the chances of chipping or rough edges. Additionally, it’s recommended to use cutting lubricants or wax to minimize friction and heat buildup while cutting aluminum with standard steel blades.

Assessing Blade Quality: Price Vs Performance

Now that we’ve compared carbide-tipped blades and standard steel blades, it’s important to assess the quality of the blades based on their price and performance. While carbide-tipped blades may have a higher upfront cost, their extended lifespan and superior cutting performance justify the investment for those who frequently work with aluminum. On the other hand, standard steel blades offer a more budget-friendly option for occasional aluminum cutting projects.

Ultimately, the choice between carbide-tipped blades and standard steel blades depends on your specific needs and budget. If precision and durability are of utmost importance, investing in a carbide-tipped blade is recommended. However, if you have occasional aluminum cutting needs and are working within a limited budget, a standard steel blade with a high tooth count can still deliver satisfactory results.

In conclusion, when it comes to cutting aluminum with a circular saw, selecting the right blade type is essential for achieving clean and precise cuts. Carbide-tipped blades offer superior durability and cutting performance, while standard steel blades provide a more cost-effective option. Assessing the blade quality based on price and performance will help you make an informed decision that suits your specific requirements.

Final Thoughts On Cutting Aluminum With Circular Saws

When it comes to cutting aluminum with circular saw blades, it is important to use the appropriate tool like a circular saw or jigsaw with metal cutting blades. Using non-ferrous circular saw blades or delicate wood blades with carbide tips can ensure a precise and efficient cut on aluminum materials.

Recap Of Best Practices

When cutting aluminum with circular saws, it’s crucial to follow best practices to ensure safety and efficiency. Use a carbide-tipped saw blade specifically designed for cutting aluminum to achieve precise and clean cuts. Secure the aluminum workpiece firmly in place using clamps or a vise to prevent any movement during the cutting process. Additionally, wearing appropriate safety gear such as gloves, safety goggles, and a face mask is essential to protect yourself from metal shavings and potential hazards.

It’s also important to set the appropriate cutting speed and feed rate based on the thickness of the aluminum material. Using the correct blade rotation speed and applying a consistent and controlled feed force will result in smoother cuts and minimize the risk of blade binding. Furthermore, lubricating the blade with a suitable cutting fluid or lubricant can help dissipate heat and reduce friction, extending the lifespan of the blade and enhancing cutting performance.

Future Innovations In Aluminum Cutting Technology

The future of aluminum cutting technology holds promising advancements that aim to enhance precision, efficiency, and safety in the cutting process. Innovations such as advanced coatings and materials for saw blades are being developed to improve wear resistance, heat dissipation, and overall cutting performance when working with aluminum materials.

Furthermore, the integration of smart technologies and digital solutions in circular saws may enable real-time monitoring of cutting parameters, blade condition, and material behavior, leading to optimized cutting processes and predictive maintenance. These innovations could revolutionize the way aluminum is cut, providing greater accuracy, productivity, and cost-effectiveness for various industries and applications.

Frequently Asked Questions

Can You Cut Aluminum With A Regular Circular Saw Blade?

Yes, you can cut aluminum with a regular circular saw blade. Use a non-ferrous circular saw blade or a wood blade with a carbide tip for best results. Make sure to use appropriate safety measures when cutting aluminum.

What Blade Do I Use To Cut Aluminum?

To cut aluminum, it’s best to use a circular saw or jigsaw with a metal cutting blade. Non-ferrous circular saw blades or carbide-tipped wood blades can also work. Cold saw blades with carbide tips are great for precise and clean cuts.

Avoid using regular wood blades as they may not be strong enough for the job.

What Speed Circular Saw For Cutting Aluminum?

For cutting aluminum, use a circular saw with a non-ferrous blade or a wood blade with carbide tips. These blades are suitable for cutting aluminum.

What Type Of Tooth Set Is Good For Cutting Aluminum?

A carbide-tipped circular saw blade or a delicate wood blade with a carbide tip is recommended for cutting aluminum. Using a regular circular saw blade is not recommended. Carbide-tipped cold saw blades are also suitable for accurate and clean cuts in aluminum materials.

Conclusion

To summarize, cutting aluminum with a circular saw blade is possible with the right blade. It’s important to use a non-ferrous blade or a wood blade with carbide tips to ensure a clean and accurate cut. By following the proper safety precautions and using the appropriate blade, you can successfully cut aluminum with a circular saw.

With the variety of options available in the market, it’s important to choose a durable and well-made blade that fits your needs and budget.