Cut-Off Saw Blades for Metal: Top Choices for Precision Cutting

Cut-off saw blades for metal are essential for precise and efficient metal cutting. These blades are designed for cutting through various types of metal with accuracy and speed.

They are a crucial tool for metal workers, whether professionals or DIY enthusiasts. Metal workers rely on cut-off saw blades to achieve clean and precise cuts in various metal materials. With the right blade, they can effectively cut through steel, aluminum, and other metals, ensuring smooth and accurate results.

These blades are indispensable for a wide range of metal fabrication projects, making them a valuable asset in any workshop or job site. The versatility and precision of cut-off saw blades make them an essential tool for anyone working with metal, providing the efficiency and accuracy needed for successful metal cutting tasks.

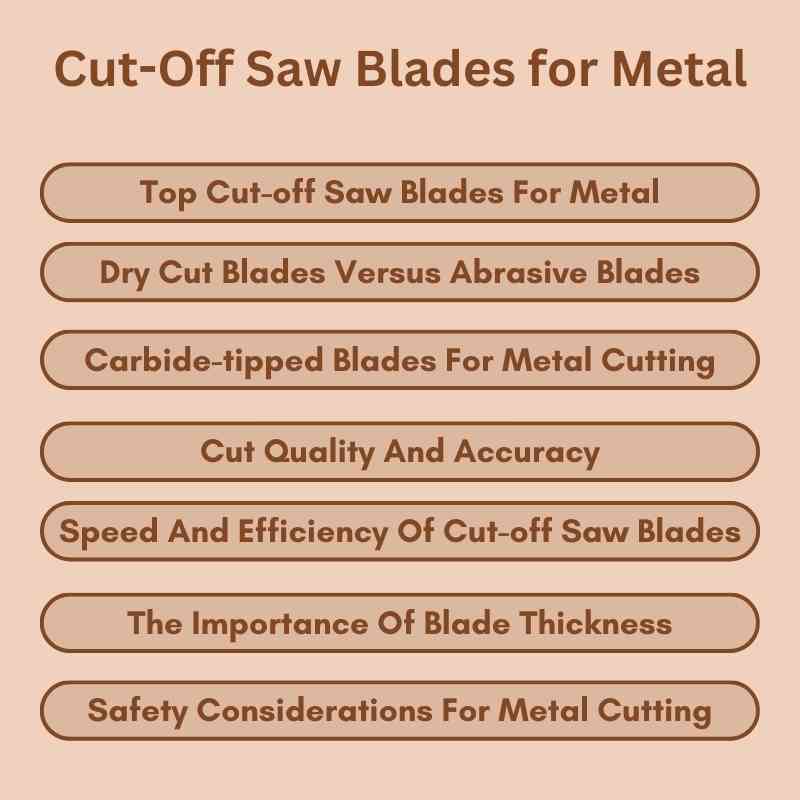

Top Cut-off Saw Blades For Metal

When it comes to cutting metal, having the right saw blade is crucial for achieving precise and clean cuts. Whether you’re working on a DIY project or a professional metalworking job, using the top cut-off saw blades for metal can make all the difference in the quality of your work. In this article, we will discuss the factors to consider when choosing blades and popular materials used for saw blades.

Factors To Consider When Choosing Blades

Choosing the right cut-off saw blade for your metal cutting needs requires careful consideration of several factors. Here are some key factors to keep in mind:

- Blade Material: The material the blade is made of determines its durability and cutting performance. Common materials include high-speed steel (HSS), carbide-tipped blades, and diamond blades.

- Tooth Configuration: The tooth configuration affects the cutting speed and the quality of the cut. Different tooth configurations are suitable for different types of metal.

- Blade Size: The size of the blade should match the size of your cut-off saw and the thickness of the metal you are cutting. Using the correct size blade ensures optimal cutting performance.

- Cutting Speed: The cutting speed of the blade determines how quickly and efficiently it can cut through metal. Higher cutting speeds are desirable for faster and smoother cuts.

Popular Materials For Saw Blades

There are various materials commonly used for manufacturing cut-off saw blades for metal. Each material offers different advantages and is suitable for specific applications. Here are some popular materials used for saw blades:

| Material | Advantages |

|---|---|

| High-Speed Steel (HSS) | Cost-effective, suitable for cutting softer metals |

| Carbide-Tipped Blades | Highly durable, suitable for cutting harder metals |

| Diamond Blades | Extreme durability, ideal for cutting through tough materials like concrete and stone with embedded metal |

Choosing the right material for your saw blade depends on the type of metal you are cutting, the desired cutting speed, and the level of precision required.

By considering these factors and understanding the different materials available, you can select the best cut-off saw blades for your metal cutting needs. Investing in high-quality blades will not only improve the efficiency and accuracy of your cuts but also ensure the longevity of your tools.

Dry Cut Blades Versus Abrasive Blades

When it comes to cut-off saw blades for metal, there is a choice between dry cut blades and abrasive blades. Dry cut blades offer cleaner cuts and faster cutting speeds, while abrasive blades are more affordable but tend to produce more sparks and require more frequent replacements.

Comparison Of Cutting Techniques

When it comes to cutting metal, two popular cutting techniques are commonly used: dry cut blades and abrasive blades. Each technique has its own set of advantages and disadvantages, making it important to understand the differences between the two. Let’s take a closer look at the pros and cons of each type.

Pros And Cons Of Each Type

Dry Cut Blades

Dry cut blades, also known as cold cut blades, are designed for clean and precise metal cutting. These blades are specifically engineered to operate at lower RPMs, reducing heat and friction during the cutting process. Here are the pros and cons of using dry cut blades:

| Pros | Cons |

|---|---|

|

|

Abrasive Blades

Abrasive blades, on the other hand, are commonly used for general metal cutting. These blades feature abrasive particles embedded in a resin matrix, allowing them to grind through metal surfaces. Here are the pros and cons of using abrasive blades:

| Pros | Cons |

|---|---|

|

|

In conclusion, when choosing between dry cut blades and abrasive blades for metal cutting, it’s important to consider the specific requirements of your project. Dry cut blades offer clean and precise cuts with minimal heat generation, but they come at a higher initial cost and may require a specialized saw. On the other hand, abrasive blades are more affordable and can be used with standard saws, but they generate more heat and produce sparks and debris. Ultimately, the choice depends on factors such as cutting speed, cut quality, and the materials being cut.

Carbide-tipped Blades For Metal Cutting

When it comes to precision metal cutting, carbide-tipped blades are highly regarded for their exceptional performance and durability. These blades are specifically designed to handle the rigors of metal cutting, offering superior cutting capabilities and extended lifespan.

Benefits Of Carbide For Precision

Carbide-tipped blades are renowned for their precision cutting abilities, allowing for clean and accurate cuts on various metal materials. The hardness and wear resistance of carbide make it ideal for maintaining sharpness and precision over prolonged use, ensuring consistent cutting quality.

Maintenance And Lifespan

Due to their exceptional durability, carbide-tipped blades require minimal maintenance and offer an extended lifespan compared to traditional metal cutting blades. This longevity translates to cost savings and reduced downtime, making them a valuable investment for metalworking professionals and hobbyists alike.

Cut Quality And Accuracy

When it comes to using a cut-off saw for metal, achieving high-quality cuts and accurate results is essential. The cut quality and accuracy of your metal cutting process can be influenced by various factors, and it’s important to understand how to optimize these aspects for superior performance.

What Affects Cut Quality?

Several factors can impact the cut quality when using cut-off saw blades for metal:

- Blade Type: Different blade types, such as abrasive or dry cut blades, can have varying effects on the quality of the cut.

- Blade Sharpness: A sharp blade is crucial for achieving clean and precise cuts in metal.

- Material Thickness: Thicker metal materials may require different blade specifications to maintain cut quality.

- Speed and Feed Rate: The cutting speed and the rate at which the blade engages with the metal can impact the quality of the cut.

- Workpiece Stability: Ensuring the metal workpiece is securely held in place can prevent vibrations and maintain cut quality.

Ensuring Accurate Cuts

For accurate cuts when using cut-off saw blades for metal, consider the following:

- Blade Alignment: Proper alignment of the blade is crucial for achieving accurate and straight cuts.

- Workpiece Clamping: Securely clamping the metal workpiece helps maintain stability and accuracy during the cutting process.

- Cutting Depth Control: Adjusting the cutting depth according to the material thickness is essential for precision.

- Operator Technique: The skill and technique of the operator play a significant role in achieving accurate cuts.

- Maintenance: Regular maintenance of the saw and blade ensures optimal performance and accuracy over time.

Speed And Efficiency Of Cut-off Saw Blades

Cut-off saw blades for metal are designed for speed and efficiency, allowing for quick and precise cuts through various types of metal. With options like dry cut and abrasive blades available, it’s important to consider factors such as cut speed and quality, as well as cost, when selecting the best blade for your needs.

Maximizing Cutting Speed

When it comes to metal cutting, speed and efficiency are critical. You don’t want to waste time and energy using a blade that can’t handle the job or takes too long to do it. That’s where cut-off saw blades come in. These blades are specifically designed to make quick, clean cuts through metal materials. But how can you maximize their cutting speed?

One key factor is the type of blade you choose. For example, carbide-tipped blades are known for their high cutting speeds and durability. They can handle tough materials like stainless steel, cast iron, and aluminum with ease. Other blades, like diamond blades, are also excellent for cutting through hard metals quickly.

Another factor to consider is the size and thickness of the blade. A thicker blade will generally be more durable and able to handle heavier loads, but it may also slow down the cutting process. A thinner blade, on the other hand, may be faster but not as long-lasting. It’s important to find the right balance for your specific cutting needs.

Reducing Workload With Efficient Blades

Efficiency is another important consideration when it comes to cut-off saw blades. You don’t want to waste time and energy using a blade that’s not efficient or wears out quickly. One way to improve efficiency is to choose a blade with the right tooth count. Blades with more teeth will generally produce smoother, cleaner cuts but may not be as fast. Blades with fewer teeth will be faster but may produce rougher cuts.

Another factor to consider is the blade’s coating. Many blades come with special coatings that help reduce friction and heat buildup, which can improve cutting speed and prolong the blade’s life. Some common coatings include titanium, carbide, and diamond.

Ultimately, the key to reducing your workload is to find a blade that’s tailored to your specific needs. Consider the type of metal you’ll be cutting, the thickness of the material, and the volume of work you’ll be doing. With the right blade, you can make quick, efficient cuts and get the job done in no time.

The Importance Of Blade Thickness

When it comes to cutting metal, choosing the right blade thickness is crucial. A cut-off saw blade with the appropriate thickness will not only make the job easier but also produce better results. In this article, we will discuss the importance of blade thickness and help you choose the right one for your job.

Thick Versus Thin Blades

Thick blades are typically used for heavy-duty cutting tasks, such as cutting through thick metal sheets or bars. They are more durable and can withstand higher levels of pressure and heat. However, thick blades are slower and produce rougher cuts compared to thin blades.

Thin blades, on the other hand, are ideal for cutting thinner metal sheets or tubes. They are faster and produce smoother cuts, but they are not as durable as thick blades. Thin blades can also warp or bend if subjected to excessive pressure or heat.

Choosing The Right Thickness For Your Job

Choosing the right blade thickness depends on the type and thickness of the metal you need to cut. As a general rule, thick blades are best for thicker metals, while thin blades are best for thinner metals.

If you are unsure about the appropriate blade thickness for your job, refer to the manufacturer’s recommendations or consult with a professional. Using the wrong blade thickness can not only produce poor results but also damage your cut-off saw or pose a safety hazard.

Choosing the right blade thickness for your cut-off saw is crucial for achieving optimal results and ensuring safety. Consider the type and thickness of the metal you need to cut and refer to manufacturer recommendations or seek professional advice if unsure. With the right blade thickness, you can make clean, precise cuts and get the job done efficiently.

Safety Considerations For Metal Cutting

Cut-off saw blades are essential tools for metal cutting, but it’s crucial to prioritize safety when operating these powerful machines. By following best practices and being mindful of common hazards, you can ensure a safe and efficient metal cutting experience.

Best Practices For Safe Operation

When using a cut-off saw for metal cutting, there are several best practices to adhere to:

- Wear appropriate personal protective equipment, including safety glasses, gloves, and ear protection.

- Ensure the workpiece is securely clamped or held in place to prevent movement during cutting.

- Regularly inspect the saw blade for any signs of damage or wear, and replace it if necessary.

- Follow the manufacturer’s guidelines for operating the cut-off saw and adhere to recommended safety precautions.

Avoiding Common Hazards

It’s important to be aware of and actively avoid common hazards associated with metal cutting using a cut-off saw. Some key points to consider include:

- Avoid cutting materials that are not suitable for the specific type of blade being used, as this can lead to kickback or blade damage.

- Keep the work area clear of clutter and debris to prevent tripping hazards and ensure a clear path for safe operation.

- Be cautious of sparks and hot metal shavings that may be produced during cutting, as they pose a fire hazard and can cause burns.

- Never force the blade through the metal; instead, allow the blade to cut at its own pace to prevent overheating and potential kickback.

Cost-effective Choices For Professionals And Diyers

When it comes to selecting cut-off saw blades for metal, finding a balance between cost and performance is crucial for both professionals and do-it-yourself enthusiasts. Whether you’re working on a commercial project or a weekend home improvement task, having top budget-friendly options can make a significant difference in the overall outcome.

Balancing Cost And Performance

When choosing cut-off saw blades for metal, it’s important to consider both the upfront cost and the long-term performance. Opting for a lower-priced blade that wears out quickly may end up costing more in the long run. Conversely, investing in a high-performance, durable blade may initially seem more expensive but can ultimately save money by lasting longer and delivering superior results.

Top Budget-friendly Blades

For those seeking cost-effective options, there are several top budget-friendly blades available in the market. These blades are designed to offer a balance between affordability and performance, making them ideal for professionals and DIYers looking to maximize value without compromising on quality.

- Diablo Cermet Blade

- DeWalt Metal Cutting Blade

- Evolution Cutting Blade Steel

- Diablo Steel Demon Circular Saw Blade

- Ridgid Metal Cut-Off Wheel Set

User Reviews And Recommendations

When it comes to finding the best cut-off saw blades for metal, user reviews and recommendations can be incredibly valuable. Hearing from other users who have firsthand experience with different blades can help you make an informed decision and choose the right blade for your specific needs. In this section, we will explore trusted brands in the market and share user experiences with various blades.

Trusted Brands In The Market

When it comes to cut-off saw blades for metal, there are several trusted brands in the market that consistently deliver high-quality and reliable products. Some of the top brands that users recommend include:

- Diablo

- DeWalt

- Ryobi

- Evolution

- Ridgid

These brands have built a reputation for producing blades that offer exceptional performance, durability, and precision. Users have found these brands to be reliable and trustworthy when it comes to metal cutting applications.

User Experiences With Various Blades

Now, let’s dive into user experiences with different cut-off saw blades for metal. Hearing from users who have used these blades in real-world scenarios can provide valuable insights into their performance and suitability for specific tasks. Here are some key takeaways from user reviews:

| Brand | Blade Type | User Feedback |

|---|---|---|

| Diablo | Cermet Blade | Users have praised the Diablo Cermet Blade for its cutting speed and minimal dust production. It is particularly effective when cutting steel tubes and angle iron. |

| DeWalt | Metal Cutting Blade | Users have found the DeWalt metal cutting blade to be versatile and reliable. It delivers clean and precise cuts on various metal materials, including rebar. |

| Ryobi | Abrasive Saw Blade | Users appreciate the affordability of Ryobi abrasive saw blades. They are a cost-effective option that still provides satisfactory cut quality and accuracy. |

| Evolution | Cutting Blade Steel | Although slightly more expensive, users have found the Evolution cutting blade steel to be worth the investment. It offers exceptional durability and longevity. |

| Ridgid | Metal Cut-Off Wheel Set | Users have praised the Ridgid metal cut-off wheel set for its versatility and performance. It is a reliable option for various metal cutting applications. |

These user experiences highlight the strengths and capabilities of different cut-off saw blades for metal. By considering the feedback from other users, you can make an informed decision and select the blade that best suits your specific needs and requirements.

Innovations In Metal Cut-off Saw Blades

When it comes to metal cutting, having the right blade for your cut-off saw is crucial. Innovations in metal cut-off saw blades have revolutionized the metal cutting industry, providing improved performance, durability, and precision. In this article, we will explore the latest technologies in blade design and discuss future trends in metal cutting.

Latest Technologies In Blade Design

The advancements in blade design have significantly enhanced the cutting efficiency and quality of metal cut-off saw blades. Manufacturers have introduced various technologies to optimize the performance of these blades:

- Carbide-tipped blades: These blades feature carbide teeth that are extremely durable and can cut through tough metals with ease.

- Cermet blades: Combining ceramic and metal, cermet blades offer a high level of heat resistance and wear resistance, resulting in extended blade life.

- Coated blades: Blades with specialized coatings, such as titanium nitride or carbide, provide reduced friction and heat buildup, resulting in smoother cuts and increased blade longevity.

- Variable tooth pitch: Blades with variable tooth pitch have teeth that are spaced differently, allowing for faster cuts in the beginning and smoother cuts towards the end of the blade.

Future Trends In Metal Cutting

The metal cutting industry is constantly evolving, and there are exciting trends on the horizon that will shape the future of metal cut-off saw blades:

- Laser technology: Laser-guided metal cutting blades are being developed to provide unparalleled precision and accuracy.

- Nanotechnology: Nanocoatings and nanomaterials are being explored to further enhance the durability and performance of metal cut-off saw blades.

- Smart blades: Integrated sensors and data analytics are being utilized to create “smart” blades that can adapt to different cutting conditions and provide real-time feedback on blade performance.

- Environmentally-friendly materials: With a focus on sustainability, manufacturers are researching and developing blades made from eco-friendly materials that still offer exceptional cutting performance.

As these innovations continue to emerge and evolve, metal cut-off saw blades will become even more efficient, precise, and durable, allowing for faster and cleaner cuts in various metal cutting applications.

Frequently Asked Questions

Can A Cut Off Saw Be Used For Metal?

Yes, a cut off saw can be used for metal cutting, making it versatile for various job sites and workshops.

What Type Of Saw Blade To Cut Metal?

For cutting metal, use steel-cutting saw blades designed for toughness and precision. These blades are essential for metal workers, whether professional or DIY.

What Is The Best Metal Cut-off Saw?

The best metal cut-off saw depends on various factors such as cut speed, cut quality, cut accuracy, cleanup, and cost. Dry cut saws and carbide chop saws are popular options. Steel-cutting saw blades are a must for any metal worker, whether a professional or DIY’er.

Several brands like Diablo, DeWalt, and Ridgid offer high-quality metal cutting blades.

Do You Need A Special Blade To Cut Metal?

No, you don’t need a special blade to cut metal. Steel-cutting saw blades are designed to cut metal accurately and efficiently. They are a must-have for metal workers, both professionals and DIY enthusiasts. These blades are tough and precise, making them suitable for various metal cutting tasks.

Conclusion

To conclude, choosing the right cut-off saw blade for metal is crucial for achieving accurate, clean cuts and maximizing efficiency. It’s important to consider the type of saw, the material being cut, the blade’s size and thickness, and the tooth count.

By following these guidelines and considering the options available, you can find the best cut-off saw blade for your specific needs. With the right blade, you can tackle any metal cutting project with ease and precision.