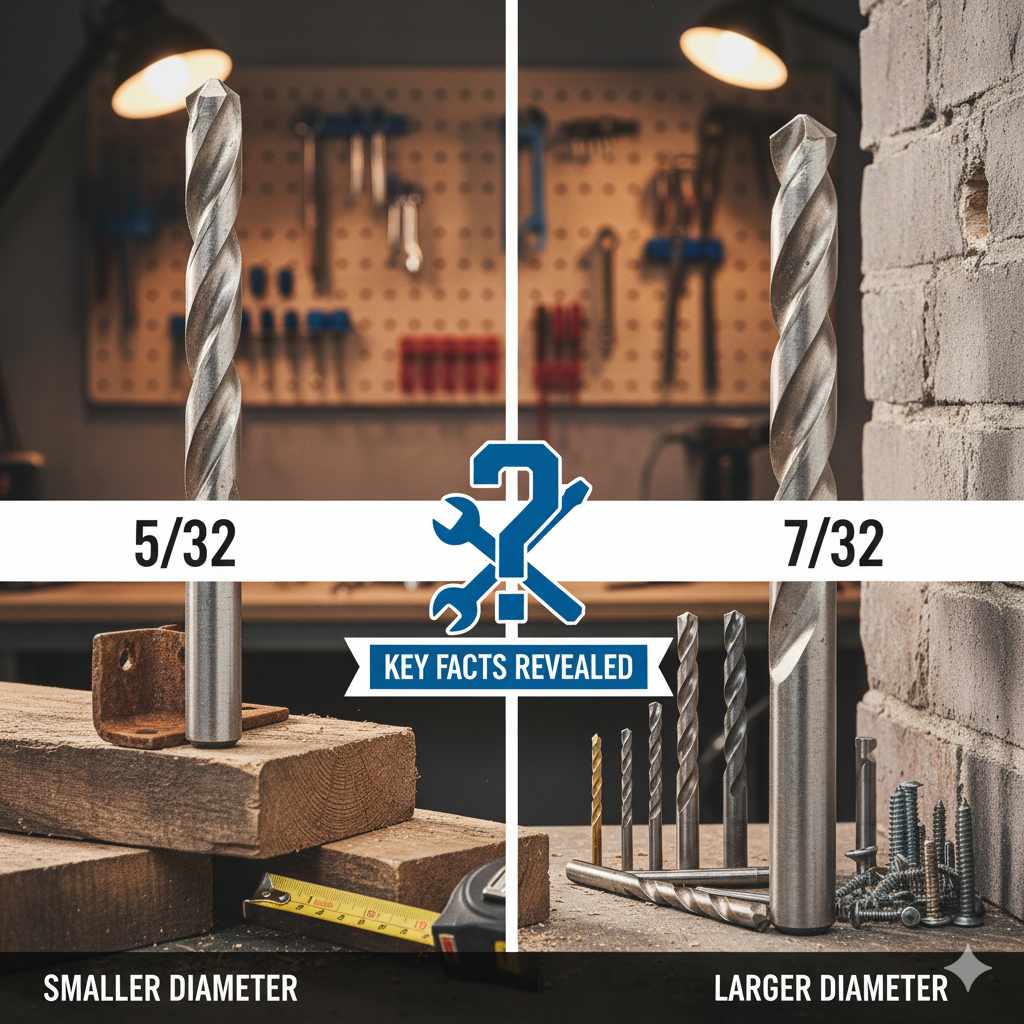

Difference between 5 32 And 7 32 Drill Bit: Key Facts Revealed

When you’re working on a project that needs drilling, choosing the right drill bit can make all the difference. You might have come across the sizes 5/32 and 7/32 but aren’t sure which one to pick.

Understanding the difference between these two drill bits isn’t just about numbers—it can affect the quality of your work and how smoothly the job goes. You’ll discover exactly what sets the 5/32 and 7/32 drill bits apart, so you can make the best choice for your tools and materials.

Keep reading to find out how a small change in size can have a big impact on your project’s success.

Size Comparison

Understanding the size difference between 5/32 and 7/32 drill bits helps you choose the right tool. Each size fits specific drilling needs. Knowing their exact measurements avoids mistakes and saves time. Below, we compare their diameters and metric equivalents for clarity.

Diameter Measurements

The 5/32 drill bit has a diameter of 0.156 inches. The 7/32 drill bit measures larger at 0.219 inches. This means the 7/32 bit is about 0.063 inches bigger. This size difference affects the hole width and the material removed. Choosing the right diameter ensures proper fit for screws or fasteners.

Metric Equivalents

The 5/32 inch drill bit converts to approximately 3.97 millimeters. The 7/32 inch drill bit equals about 5.56 millimeters. These metric values help users who work with millimeter-based tools or plans. Knowing both units makes it easier to match drill bits worldwide.

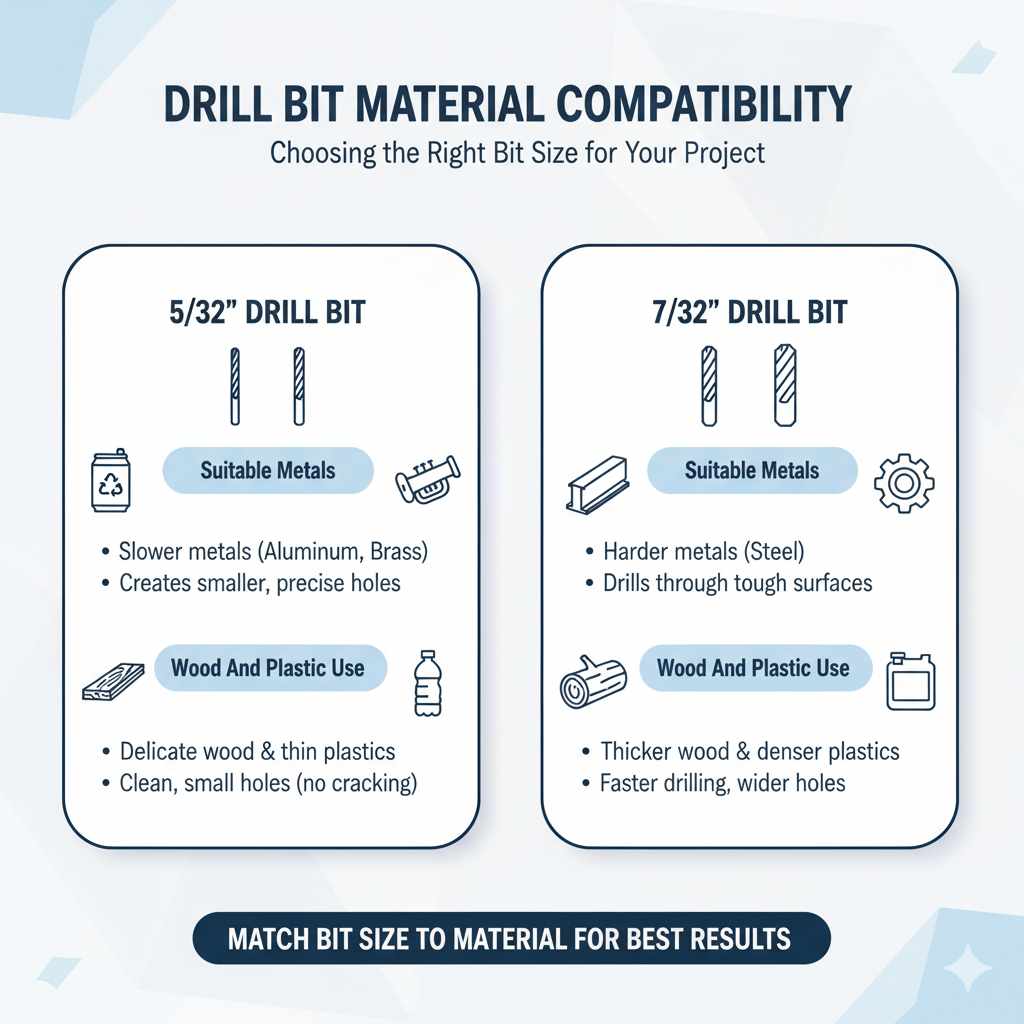

Material Compatibility

Choosing the right drill bit size depends on the material you plan to work with. The 5/32 and 7/32 drill bits serve different purposes based on their size and strength. Material compatibility is key to getting clean holes and avoiding damage to your workpiece or tool.

Suitable Metals

The 5/32 drill bit works well with softer metals like aluminum and brass. It creates smaller holes with precision. The 7/32 drill bit handles harder metals such as steel better. Its larger size helps drill through tough surfaces without bending.

Using the correct size prevents bit wear and metal damage. Both bits need steady pressure and the right speed to avoid overheating. Choose the bit size based on metal thickness and hole size needed.

Wood And Plastic Use

The 5/32 bit is ideal for delicate wood projects and thin plastics. It makes clean, small holes without cracking the material. The 7/32 bit suits thicker wood and denser plastics. It drills faster and creates wider holes for screws or anchors.

Both bits require sharp edges to avoid splintering wood or melting plastic. Use slower drill speeds for plastics to keep holes neat. Match bit size to material thickness and hole purpose for best results.

Application Uses

Drill bits come in many sizes, each fit for different tasks. The 5/32 and 7/32 drill bits serve unique purposes in various applications. Understanding their uses helps choose the right bit for your project. Size affects the hole diameter and the work you can do.

Common Projects

The 5/32 drill bit works well for smaller holes. It suits tasks like making pilot holes for screws or light woodworking. This size is common in furniture assembly and crafts. It also fits well for metal or plastic drilling where precision is less critical.

The 7/32 drill bit makes larger holes. It is useful for drilling through thicker wood or metal. This size often appears in plumbing, electrical work, or construction projects. It helps create holes for bolts, anchors, or larger fasteners.

Precision Requirements

The 5/32 drill bit offers more control for delicate tasks. Its smaller size reduces the risk of splitting wood or damaging thin materials. It works best when precise, clean holes matter.

The 7/32 drill bit suits jobs needing bigger holes with less precision. It may cause more material removal and rougher edges. This bit is good for rougher work where exact size is less vital.

Drill Bit Types

Drill bits come in different types for various jobs. Choosing the right drill bit makes drilling easier and more precise. Two common types are twist drill bits and specialty bits. Each has unique features and uses.

Twist Drill Bits

Twist drill bits are the most common type. They have a spiral shape that helps remove material while drilling. These bits work well on wood, metal, and plastic. The 5/32 and 7/32 sizes are popular for small to medium holes. Twist bits provide clean and accurate holes. They are easy to use and widely available.

Specialty Bits

Specialty bits serve specific purposes. Examples include spade bits, masonry bits, and hole saws. These bits are designed for tough materials like concrete or large holes. They come in various shapes and sizes. Specialty bits are not interchangeable with twist bits. Choosing the right specialty bit depends on the material and hole size needed.

Choosing The Right Bit

Choosing the right drill bit is important for your project success. The size difference between 5/32 and 7/32 drill bits may seem small. Yet, it affects the hole size and the tool you use. Picking the correct bit helps you avoid mistakes and saves time.

Understanding how to select the right bit depends on your project needs and tool compatibility. These two factors guide you to the best choice.

Project Needs

Consider the material you will drill into. Soft wood needs smaller bits like 5/32 for precise holes. Hard materials like metal may require the larger 7/32 bit for stronger holes.

Think about the hole size needed for screws or bolts. Smaller screws match the 5/32 bit well. Larger screws or bolts often need the 7/32 bit.

Drilling holes for anchors or fittings may also affect your choice. Choose the bit size that fits the hardware snugly. This ensures a secure hold.

Tool Compatibility

Check your drill’s chuck size before picking a bit. Most drills accept both 5/32 and 7/32 bits easily. Some smaller drills may not fit the larger 7/32 bit.

Using the correct bit size ensures better control and less wear on your tools. A loose fit can cause the bit to slip or break. A tight fit improves accuracy and safety.

Also, consider your drill speed and power. Larger bits like 7/32 need slower speeds for metal. Smaller bits work well at higher speeds for wood or plastic.

Cost And Availability

Cost and availability are key factors when choosing between a 5/32 and 7/32 drill bit. Both sizes serve different purposes, which affects their price and where you can find them. Understanding these differences helps you pick the right tool without overspending.

Price Differences

Generally, 5/32 drill bits cost less than 7/32 bits. The smaller size uses less material, lowering production costs. Prices for both sizes vary depending on brand and quality. Higher quality bits last longer but may cost more upfront. Buying in sets often reduces the cost per bit.

Where To Buy

Both 5/32 and 7/32 drill bits are widely available. Hardware stores and home improvement centers carry them. Online marketplaces offer a bigger selection and competitive prices. Specialty tool shops may have premium options. Checking multiple sources helps you find the best deal and availability.

Frequently Asked Questions

What Is The Size Difference Between 5/32 And 7/32 Drill Bits?

5/32 drill bit measures 0. 156 inches, while 7/32 measures 0. 219 inches. The 7/32 is larger by 0. 063 inches, ideal for bigger holes.

When Should I Use A 5/32 Drill Bit?

Use a 5/32 drill bit for smaller holes in wood, metal, or plastic. It’s perfect for pilot holes and light-duty tasks.

What Materials Are Suitable For 7/32 Drill Bits?

7/32 drill bits are good for drilling medium-sized holes in wood, metal, and plastic. They suit projects needing larger, stronger holes.

How Do 5/32 And 7/32 Drill Bits Affect Hole Precision?

Smaller 5/32 bits offer higher precision for detailed work. Larger 7/32 bits create bigger holes but may reduce fine accuracy.

Conclusion

Choosing between a 5/32 and 7/32 drill bit depends on your task. The 5/32 bit creates smaller holes, useful for light jobs. The 7/32 bit makes bigger holes, better for tougher materials. Knowing their size difference helps you pick the right tool.

Use the correct drill bit for clean, precise holes. This avoids damage and saves time. Remember, matching the bit size to your project is key. Simple steps lead to better results and less frustration.