Drill Bit Between 3/8 and 1/2: Choosing the Right Option

Picking the right drill bit can feel tricky, especially when you’re just starting. The question of the best size option for a Drill Bit Between 3/8 and 1/2: Best Size Option is a common one. Don’t worry, it’s not as hard as it seems! We’ll walk through the important stuff in plain English, so you can pick the perfect bit for your project. We’ll explore the things to keep in mind, making sure you make the right choice.

Understanding Drill Bit Sizes and Materials

Before we pick the best size, let’s look at what makes drill bits work. Drill bits aren’t one-size-fits-all. They come in different sizes and are made of various materials. Choosing the right size and material depends on the job. Things like the type of material you’re drilling into (wood, metal, plastic), the size of the hole you need, and the type of drill you have all play a role. There’s more to it than just grabbing the first drill bit you see.

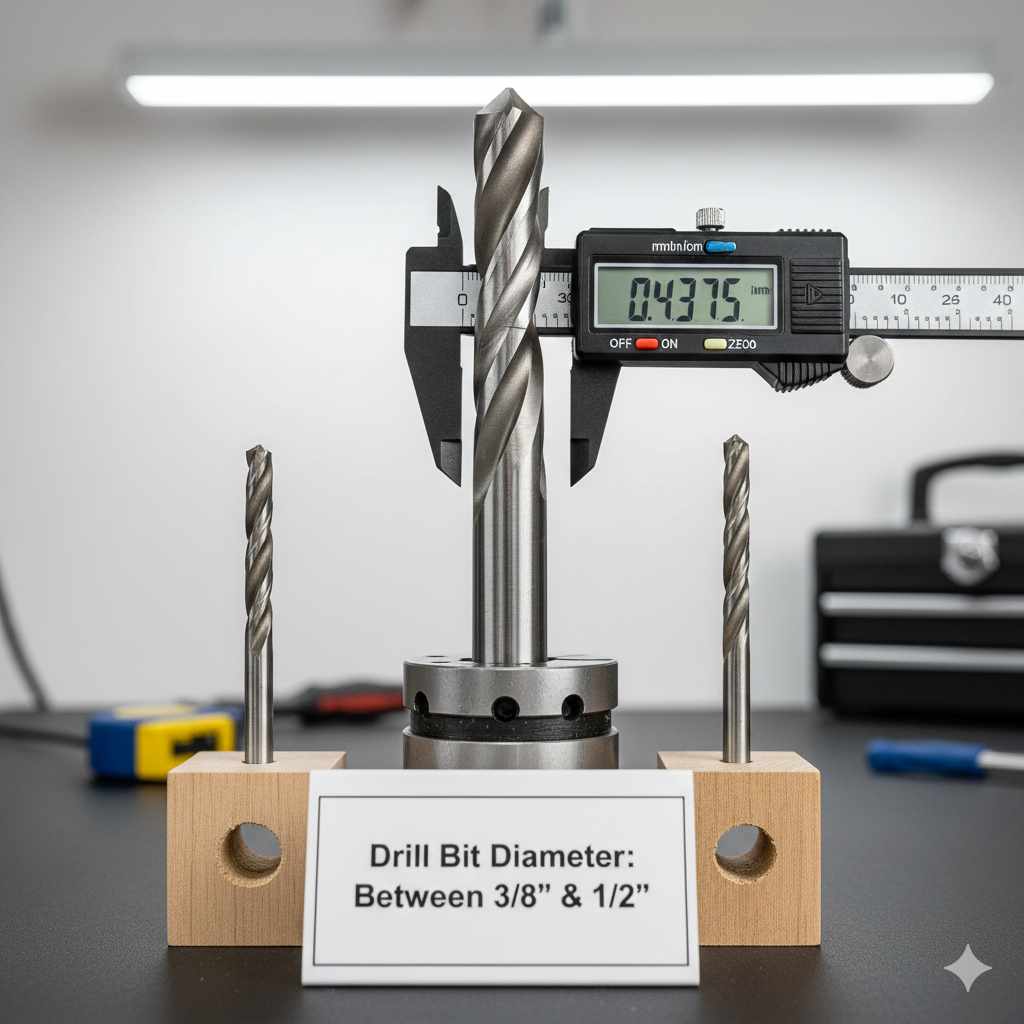

Decoding Drill Bit Measurements

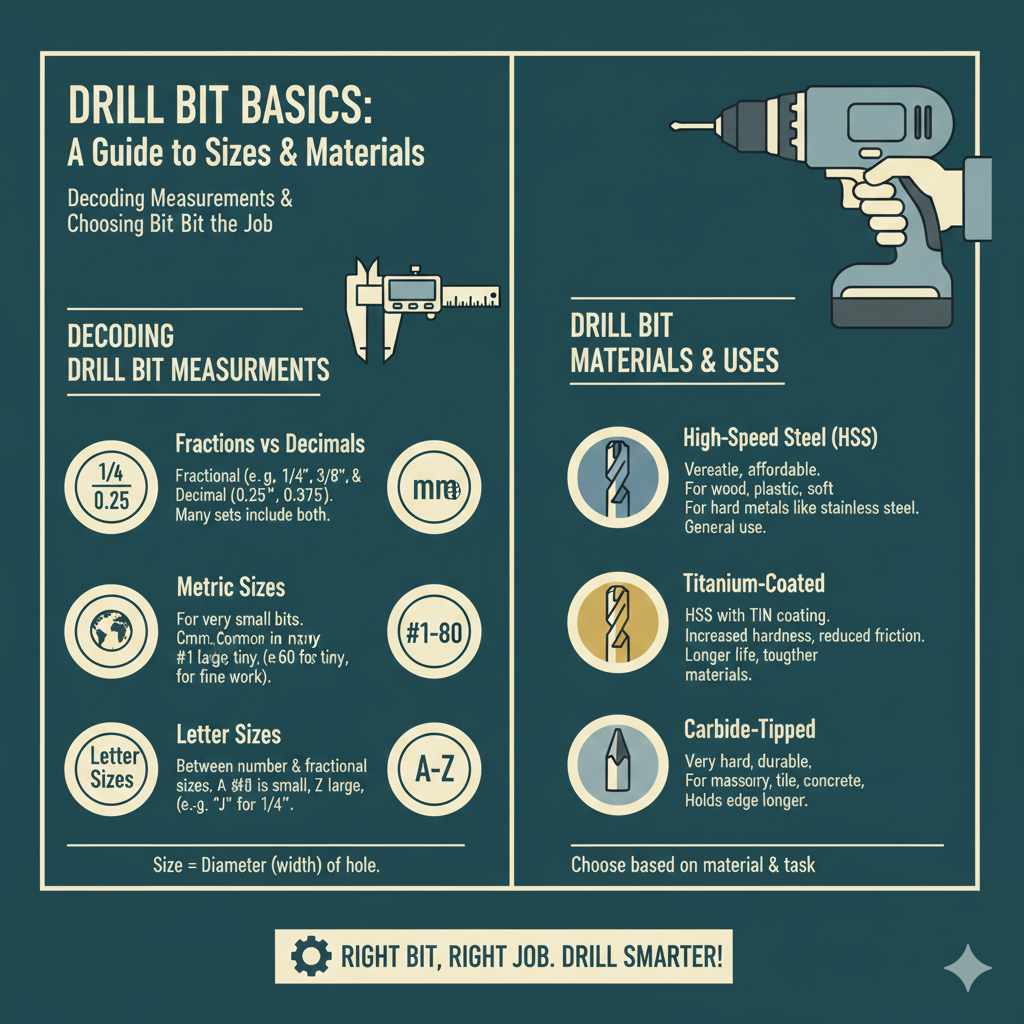

Drill bit sizes are usually given in fractions of an inch, like 3/8 or 1/2. However, you might also find drill bits measured in millimeters. The size refers to the diameter, or the width, of the hole the bit will make. Understanding these measurements helps you match the bit to your project requirements. A slightly larger or smaller hole could make a big difference.

- Fractions vs. Decimals: Drill bit sizes can be expressed as fractions (e.g., 1/4 inch) or decimals (e.g., 0.25 inch). Knowing both is useful. Many drill bit sets will include both fractional and metric sizes for convenience.

- Metric Sizes: In countries using the metric system, you’ll see drill bits measured in millimeters (mm). For example, a 6 mm drill bit is about 1/4 inch. Conversion charts are handy.

- Number Sizes: Some drill bits are identified by number sizes (e.g., #1 to #80). This system is often used for very small drill bits. Larger number = smaller bit.

- Letter Sizes: Like number sizes, letter sizes (A to Z) also refer to bit sizes. These typically fall between number and fractional sizes.

Drill Bit Materials and Their Uses

The material your drill bit is made of affects how it performs. Different materials are suited for different tasks. It’s like choosing the right tool for the job. You wouldn’t use a screwdriver to hammer a nail, would you? The same goes for drill bits. The ideal material depends on the material you’re drilling into.

- High-Speed Steel (HSS): A common, versatile choice, good for wood, plastic, and some metals. It’s a good starting point for general use. These bits are relatively inexpensive and widely available.

- Cobalt Steel: Stronger than HSS, ideal for harder metals like stainless steel. Cobalt bits can handle more heat and pressure.

- Titanium-Coated: HSS bits with a titanium coating. This coating increases hardness and reduces friction, extending the bit’s life and making it better for tougher materials.

- Carbide-Tipped: Very hard and durable, perfect for drilling through masonry, tile, and other abrasive materials. Carbide bits hold their edge longer than HSS or cobalt.

Selecting the Right Drill Bit for Your Project

Choosing the right size of a Drill Bit Between 3/8 and 1/2: Best Size Option hinges on your project. The best selection depends on what you’re working with. Getting it right is important for a good outcome. This section breaks down the factors you must think about to make a good choice.

Assessing the Material to Be Drilled

The type of material you’re drilling into is very important. Think about whether it’s wood, metal, plastic, or something else. Different materials need different approaches. For example, softwood and hardwood will each react differently to the same drill bit. Soft materials are usually easy to drill, but hard materials need special care.

- Wood: Wood is generally easier to drill than metal. You can use HSS bits, but be sure to choose the right size and type for the specific project. A brad-point bit is excellent for wood.

- Metal: Metal requires more care. Use HSS, cobalt, or titanium-coated bits. Lubrication (like cutting oil) can help reduce heat and wear.

- Plastic: Plastic can melt if drilled too fast. Use lower speeds and sharp bits. HSS is a good choice.

- Masonry: For brick or concrete, you’ll need a masonry bit or a carbide-tipped bit designed for this purpose.

Determining the Correct Hole Size

Know the size of the hole you need. Consider what will go into the hole. Will it be a screw, a bolt, or maybe a dowel rod? The drill bit needs to be the right size for that. A hole that’s too small will be hard to fit into and might damage the material. A hole that’s too big won’t hold the screw or whatever you are using it for properly.

- For Screws: The drill bit should be slightly smaller than the screw’s major diameter (the widest part of the threads). This ensures the screw grabs the material.

- For Bolts: The hole should be a little bigger than the bolt’s diameter to allow for easy fitting. A snug but not tight fit is best.

- Pilot Holes: When using screws, it is often wise to start with a smaller “pilot” hole. This helps the screw go in straight and prevents the wood from splitting.

- Countersinking: If you want the screw head to sit flush with the surface, you’ll need to use a countersink bit. This creates a cone-shaped opening.

Specific Applications: 3/8 to 1/2 Inch Drill Bit Uses

The size range of a Drill Bit Between 3/8 and 1/2: Best Size Option is useful for many different projects. From furniture building to home improvement, this range of sizes covers lots of typical needs. The choices you make within this range should depend on what you need to do, the materials you are working with, and the precision required for the job. This section explores several different applications.

Woodworking Applications

In woodworking, drill bits between 3/8 and 1/2 inches are frequently used. These sizes offer flexibility in crafting furniture, joining pieces, and creating openings for various purposes. Knowing how to use these bit sizes correctly is important to achieving good results.

- Furniture Construction: These sizes are used to create holes for dowels, connecting pieces, and inserting hardware like hinges or knobs.

- Shelf Supports: You can use these bits to make holes for shelf supports, ensuring your shelves stay in place.

- Routing: When you need to create a large hole, such as for a router bit, these sizes can create an edge or entry point.

- Creating Decorative Elements: These bit sizes enable you to shape edges, add designs, and perform detailed cuts on wooden surfaces, enhancing the visual appeal.

Metalworking Applications

Though less common than in woodworking, these bit sizes play their role in metalworking, too. They are ideal for creating holes for bolts, rivets, and other fasteners. You’ll need to use the right materials and techniques to be successful. Proper drilling speed, pressure, and lubrication are often vital.

- Bolt Holes: Create holes of various sizes for bolts. The correct size ensures a secure fit, important for structural integrity.

- Riveting: You can create holes for rivets, which are used to join metal pieces together permanently.

- Equipment Modification: These sizes can be used for changes to existing structures, such as adding accessories or making adjustments.

- Repair Projects: If you need to fix or restore metal objects, these drill bit sizes are perfect for tasks like removing and replacing old hardware.

Home Improvement Projects

Home improvement projects often involve a lot of drilling, and this size range is handy. These sizes work well for many common tasks. Being able to choose the correct size and type of bit helps you complete the project properly and safely. Planning ahead of time is vital for success.

- Installing Hardware: When you install doors, cabinets, and other fixtures, you’ll use these sizes to make holes for hinges, handles, and other hardware.

- Electrical Work: You can use these sizes to run wires through walls, ensuring safe and concealed electrical installations.

- Plumbing: These bit sizes help in creating passages for pipes, allowing for water supply and drainage systems.

- General Repairs: Whether hanging pictures, securing shelves, or repairing furniture, these drill bit sizes cover many repair situations.

Tools and Techniques for Drilling

Having the right tools and knowing the correct techniques are important to drilling accurately and safely. This section will walk you through the essential tools and methods needed for success. Whether you’re a beginner or an experienced DIYer, these tips will improve your results.

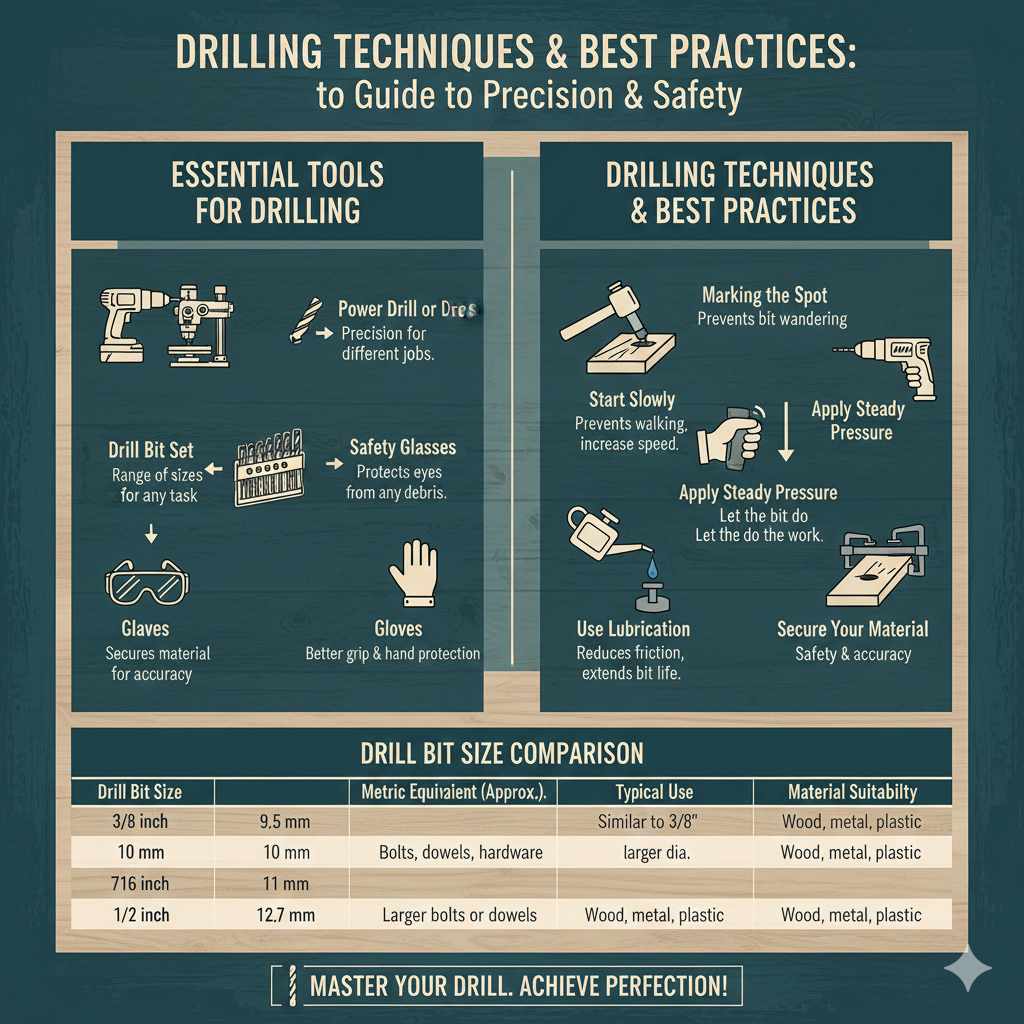

Essential Tools for Drilling

The right tools can make all the difference when you’re drilling. This is also true when deciding what Drill Bit Between 3/8 and 1/2: Best Size Option to choose. You’ll want to have the proper equipment. Quality tools will last longer and provide you with better results. Here’s what you will need.

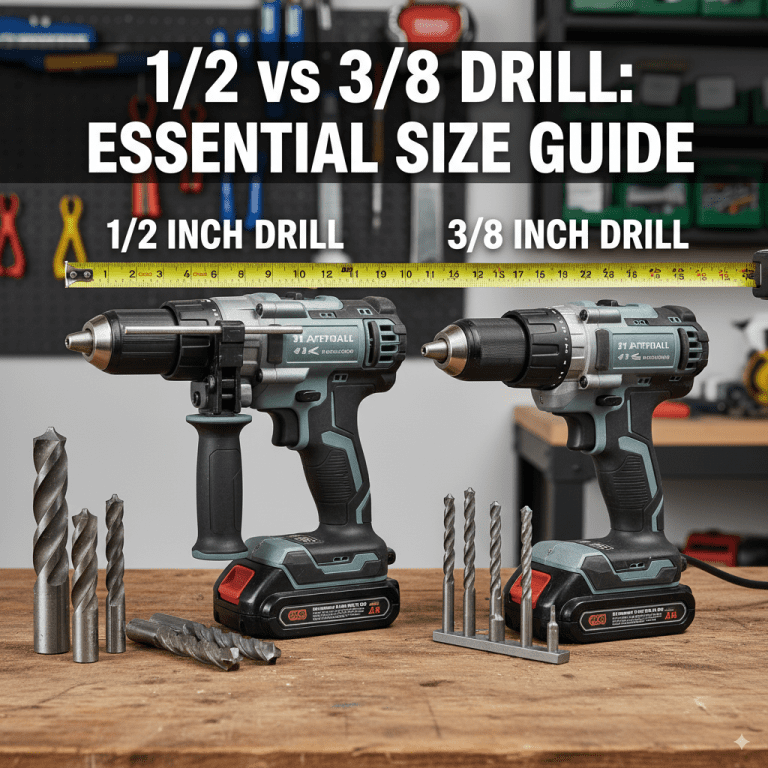

- Power Drill or Drill Press: A power drill is the basic tool for drilling. A drill press offers more precision and control, especially for larger holes.

- Drill Bit Set: A drill bit set is important, especially one that contains a range of sizes. Having different sizes makes sure you have the right drill bit for any task.

- Safety Glasses: Safety glasses protect your eyes from debris, which is very important. Always wear eye protection when drilling.

- Gloves: Gloves give you a better grip and protect your hands. This is most important when working with metal or materials that can cause splinters.

- Clamps: Clamps keep the material you’re drilling in place, giving you a safe and accurate workspace. This helps you avoid the material moving while drilling.

Drilling Techniques and Best Practices

Even with the correct tools, technique is important. Using the right drilling method helps you get accurate, clean holes. These best practices will improve your drilling skills and lead to better outcomes. This section covers basic safety practices for using a drill.

- Marking the Spot: Accurately mark where you want to drill. A center punch can help create a starting point for your drill bit, preventing it from wandering.

- Start Slowly: Begin drilling at a slow speed to prevent the bit from walking or wandering across the surface. Once you have a small pilot hole, you can increase the speed.

- Apply Steady Pressure: Apply consistent, even pressure, but don’t force it. Let the drill bit do the work. Too much pressure can break the bit or damage the material.

- Use Lubrication: When drilling metal, use cutting oil or another lubricant. This reduces friction, prevents heat buildup, and extends the life of the drill bit.

- Secure Your Material: Always clamp the material you’re drilling. This prevents it from moving and keeps you safe.

Table: Drill Bit Size Comparison

| Drill Bit Size | Metric Equivalent (Approx.) | Typical Use | Material Suitability |

|---|---|---|---|

| 3/8 inch | 9.5 mm | Creating holes for bolts, dowels, and various hardware. | Wood, metal, plastic |

| 10 mm | 10 mm | Similar uses as 3/8 inch, slightly larger diameter. | Wood, metal, plastic |

| 7/16 inch | 11 mm | Often for larger bolts or dowels. | Wood, metal, plastic |

| 1/2 inch | 12.7 mm | Making holes for larger hardware, shelf supports, or running wires. | Wood, metal, plastic |

This table demonstrates the relationship between drill bit sizes and common applications. Remember that the correct selection hinges on the specifics of your project.

Frequently Asked Questions

Question: What’s the best drill bit for drilling metal?

Answer: High-Speed Steel (HSS) bits with a cobalt or titanium coating are a good choice for metal, offering increased durability and heat resistance. Make sure to use cutting oil to lubricate the bit and the metal.

Question: How do I prevent a drill bit from wandering when I start drilling?

Answer: Use a center punch to make a small indentation at the spot you want to drill. Start drilling slowly, and apply consistent pressure.

Question: What type of drill bit is best for drilling through wood?

Answer: For wood, a general HSS drill bit works well. Brad-point bits are excellent for clean, accurate holes in wood, as they prevent splintering.

Question: Can I use the same drill bit for wood and metal?

Answer: Yes, you can use HSS bits for both wood and some metals. However, for harder metals, consider cobalt or titanium-coated bits for better performance.

Question: What is the purpose of a pilot hole?

Answer: A pilot hole is a small hole drilled before inserting a screw. It makes it easier for the screw to enter the material straight and prevents the wood from splitting.

Final Thoughts

Choosing the right Drill Bit Between 3/8 and 1/2: Best Size Option can seem like a lot, but it gets easier with practice. You now have a better idea of how to pick the perfect drill bit for your next project. It starts with knowing the size, the material, and what you’re trying to do. Keep in mind the type of material, what you’re trying to build, and the kind of screws or hardware you are using. Remember to start slow, and use the right tools for the job. Do some research, and consider what the professionals do. Then, you can make informed decisions. Go ahead and start your project with confidence, and enjoy the satisfaction of a job well done!