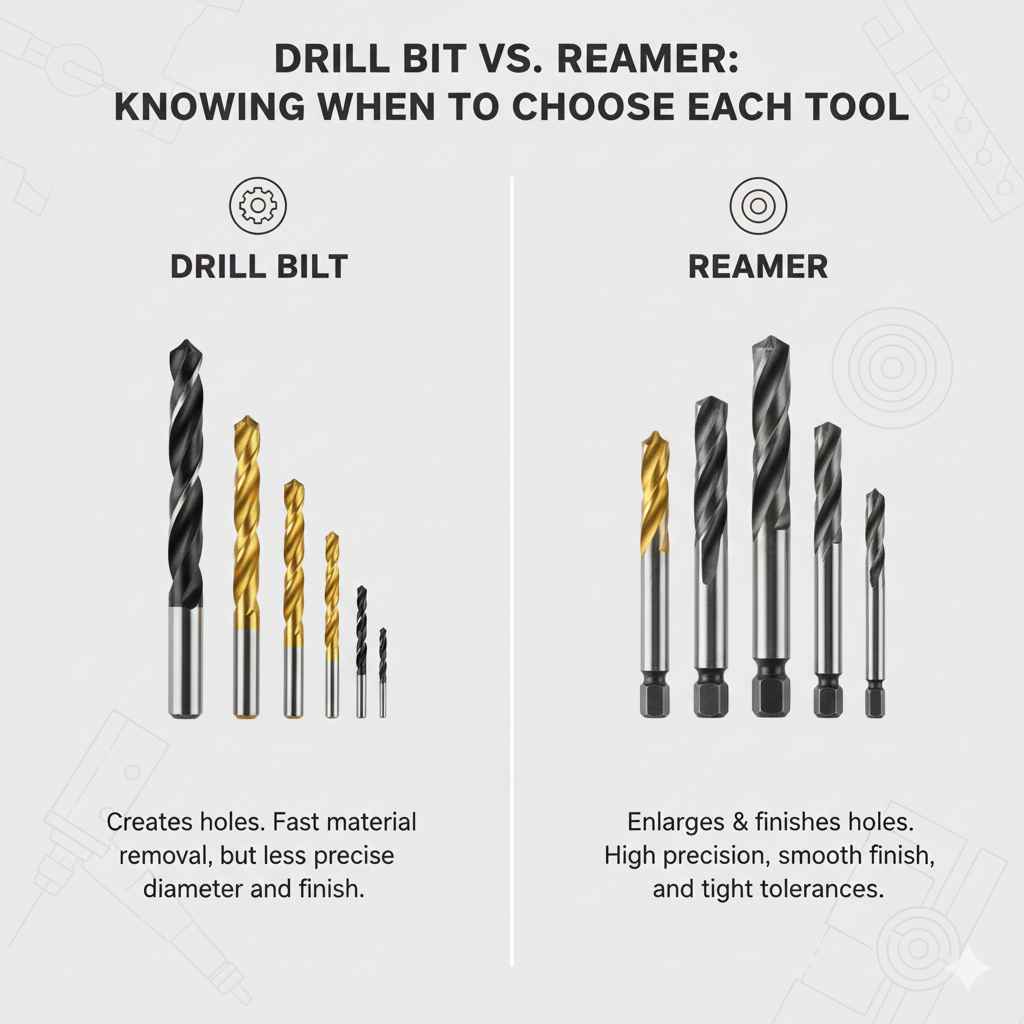

Drill Bit vs Reamer: Knowing When to Choose Each Tool

Choosing between a Drill Bit vs Reamer: When to Use Each Tool can be tricky when you’re just starting. Many people find it tough to know which tool to grab for a specific job, and it’s easy to make mistakes that mess up your project. Don’t worry, though! This guide will break down everything in simple steps, so you can easily tell the difference. We’ll explore what each tool does and when to use them. Get ready to learn about these tools and boost your skills!

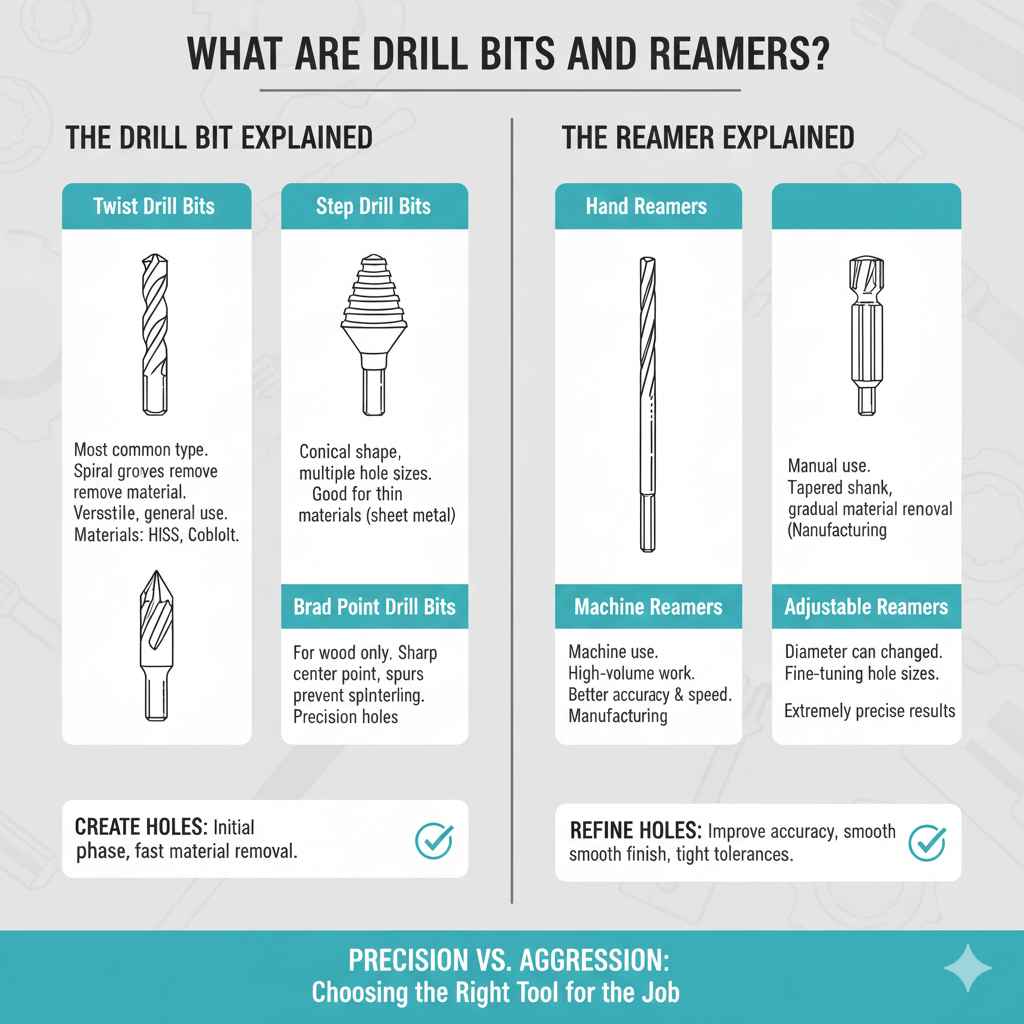

What Are Drill Bits and Reamers?

The first step is knowing what each tool is. Drill bits and reamers are both tools used to create or refine holes, but they do very different things. A drill bit is primarily used to make the initial hole, while a reamer is used to improve the hole’s precision and finish. Knowing the key differences in their uses, design, and outcome is critical for any project that involves holes. This section will get you started.

The Drill Bit Explained

A drill bit is a rotary cutting tool. Its job is to make a new hole or to enlarge an existing one in a solid material. They come in many sizes and styles, each designed for a specific task or material. From simple twist bits to specialized step bits, the right drill bit can drastically improve the efficiency of your project. They are generally used to create a starting hole, and are crucial for the initial phase of any project.

Twist Drill Bits: These are the most common type. They have spiral grooves that help remove material as the bit spins. The angle of the twist (helix angle) affects how quickly the bit cuts and how well it removes the waste. These are a jack of all trades and used for many applications.

Twist drill bits are used in various materials like wood, metal, and plastic. The drill bits are made from materials like high-speed steel (HSS) or cobalt, which makes them durable. Their design helps them cut cleanly and efficiently. The spiral flutes clear away chips, preventing the bit from getting stuck or overheating. This makes them good for a general use tool in many situations.

Step Drill Bits: Also known as unibits, these bits have a conical shape with different steps. Each step creates a hole of a specific size, eliminating the need to change bits.

Step drill bits are great for drilling different-sized holes without switching bits. They are good for thin materials like sheet metal. Their design helps them create clean, round holes. This makes them a great tool for electrical work and automotive repair. They are an efficient option, and this is a great reason to add them to your collection.

Brad Point Drill Bits: Specifically designed for wood, these bits have a sharp center point that helps position the bit. The spurs on the sides ensure a clean entry and prevent splintering.

Brad point bits are designed for clean holes in wood, and they are essential for woodworking. The center point keeps the bit from wandering, while the spurs cut cleanly. They reduce the chance of chipping or splintering. If you’re working with wood, using a brad point drill bit is a smart choice to ensure precision.

The Reamer Explained

A reamer is a precision tool used to enlarge a hole and improve its accuracy and surface finish. Reamers remove a small amount of material, ensuring the final hole is the desired size and shape. Unlike drill bits, which cut aggressively, reamers work more slowly to achieve a smooth, precise finish. They are a must-have tool for projects that require exact measurements and tight tolerances.

Hand Reamers: These reamers are designed for use by hand. They have a tapered shank and a long cutting edge, allowing for gradual material removal.

Hand reamers let you adjust the reaming process as you go. They offer excellent control and are useful for finishing holes where precision is a must. These are used in low-volume work where each hole matters. They are an accessible and easy-to-use tool.

Machine Reamers: Intended for use in a machine, these reamers are designed for high-volume work. They come in various styles, including chucking reamers and taper-shank reamers.

Machine reamers are designed for precision and efficiency in a high-volume work setting. They offer better accuracy and speed. This is an excellent option for manufacturing environments. They are great for ensuring consistent hole sizes.

Adjustable Reamers: Adjustable reamers allow you to change their diameter slightly, providing flexibility. This makes them useful for fine-tuning hole sizes.

These adjustable reamers offer the ability to make small adjustments to the hole size. This helps in achieving extremely precise results. They are perfect for projects where you need very accurate hole dimensions. The ability to fine-tune the size helps avoid mistakes.

Choosing the Right Tool: Drill Bit vs Reamer

Deciding which tool to use, a Drill Bit vs Reamer: When to Use Each Tool, is about knowing your goal. A drill bit creates the initial hole, while a reamer perfects it. Choosing the right tool from the start ensures your project succeeds. This helps you select the correct tool for your project.

When to Use a Drill Bit

Drill bits are for making the first hole in a material, or to enlarge an existing one. They are your go-to tool when you’re starting. The choice of drill bit depends on the material. Different types are designed for wood, metal, or plastic. They also come in various sizes, so matching the bit to the size of the desired hole is important. Using the correct drill bit is a must.

Initial Hole Creation: Drill bits are for starting a new hole.

Drill bits remove material and create a pilot hole to get started. It’s the first step in most projects. This includes everything from home repairs to building projects. This helps to make sure you start with the correct size.

Enlarging Existing Holes: You can enlarge a hole to a bigger size.

If a hole is too small, a drill bit can make it larger. This is helpful when you need to change the size of a screw or bolt. A bit with the correct size will make the hole bigger for your needs.

General Purpose Drilling: They are great for most drilling tasks.

Drill bits are versatile and can be used in many situations. They are suitable for tasks like installing shelves or assembling furniture. This makes them a useful tool.

When to Use a Reamer

Reamers are used to finish a hole that’s already been drilled. They enlarge the hole slightly while improving the accuracy and surface finish. This is especially important when tight tolerances are needed. You will have a smoother hole. This improves the performance of the final product.

Precision Hole Sizing: If accuracy is key, reach for a reamer.

Reamers give you extremely accurate hole sizes. They’re ideal for applications where parts need to fit together perfectly. If you are doing machinery work, they can improve the product.

Surface Finish Improvement: Reamers make a smooth hole.

Reaming leaves a clean, smooth surface inside the hole. This can be important for sliding parts or tight fits. The smooth surface ensures a better fit.

Achieving Tight Tolerances: Reamers create accurate dimensions.

Reaming is useful when working with measurements that must be exact. This is common in manufacturing. Using a reamer helps to avoid errors and ensure that parts fit as they should.

Materials and Applications

Both drill bits and reamers work on various materials, but their designs and applications vary. Understanding which tool is suitable for different materials is important. Knowing their use can help make a successful project. This will help you select the right tool for each job.

Drilling Materials

Drill bits are used across a wide range of materials. Their choice depends on the material’s properties. Steel, for example, needs a bit designed to withstand high temperatures and abrasion. Wood requires bits to prevent splintering and create clean holes. The drill bit has to suit the material. This ensures good results.

Wood: Use bits with a brad point.

Wood requires brad point bits to prevent splintering. These bits have a sharp center point to guide the cut. They also have side spurs for a clean edge. Choose a brad point bit for your woodworking projects.

Metal: Choose bits made of high-speed steel.

Metal requires a durable drill bit to withstand heat and pressure. High-speed steel (HSS) is a great choice. These bits can handle the wear. They can also cut different types of metal. Use a cutting fluid to keep things cool.

Plastic: Specialized bits avoid cracking.

Plastics can crack or melt. Use bits made for plastic with a sharp cutting edge. Apply slow speeds. This makes clean and accurate holes. This helps you get better results.

Reaming Applications

Reamers are used in high-precision situations. They are important in areas where precise holes are necessary for performance. They help ensure the accuracy of the final product. Reaming improves the quality of the finish and dimensions.

Manufacturing: Reamers are important in this industry.

Manufacturing often needs close tolerances. Reamers are used to create holes for pins, bearings, and other parts. Precise sizing is important in assembly.

Automotive: Used for various applications, reamers are useful.

Automotive work requires accurate holes. Reamers are used for engine parts, like connecting rods. They ensure parts fit snugly and work as intended. Proper hole sizes improve performance.

Aerospace: Accuracy is critical in aerospace.

Aerospace components demand the highest levels of accuracy. Reamers create holes for rivets and fasteners. The precise fit is essential for safety and reliability. This is vital in the sky.

Drill Bit vs Reamer: Tool Characteristics

Choosing between a Drill Bit vs Reamer: When to Use Each Tool means exploring their characteristics. The shape, design, and function of each tool is important. The way they work helps to determine the best choice for the job. Here are some of the design elements to consider.

Drill Bit Design and Features

Drill bits come in various shapes and designs, each suited to different tasks. Their features affect how they cut and the type of hole they make. The angles, flutes, and materials used all determine their effectiveness. Knowing these aspects helps you choose the right bit.

Helix Angle: This affects the cutting speed.

The helix angle refers to the angle of the spiral grooves on the drill bit. A steeper angle removes chips faster, while a shallow angle provides more strength. This can change how the bit works.

Flute Design: Flutes remove debris.

The flutes are the spiral grooves. They remove material as the drill bit rotates. Proper flute design keeps the bit from getting stuck. The design helps the cutting process.

Point Angle: Point angle affects cutting.

The point angle affects the drill bit’s ability to center itself. Different point angles are best for various materials. Selecting the right angle is essential for a clean hole.

Reamer Design and Features

Reamers are designed for precision and finishing, and they have unique features. Their designs are focused on making very accurate and smooth holes. Different elements help make this happen. Understanding these features can improve your results.

Number of Flutes: Impacts surface finish.

Reamers can have different numbers of flutes. More flutes often result in a smoother surface finish. The number of flutes affects cutting performance.

Taper: Improves cutting efficiency.

Reamers can have a slight taper, allowing for gradual material removal. This can improve cutting efficiency. Tapered reamers also help in aligning the tool.

Material: Impacts durability.

Reamers are made from high-quality materials to ensure durability and precision. High-speed steel (HSS) and carbide are commonly used. These materials can withstand wear. They provide excellent accuracy.

Drill Bit vs Reamer: Making the Right Choice

Choosing between a Drill Bit vs Reamer: When to Use Each Tool depends on the project. You need to know what you want to achieve. Each tool has its own strengths and is most suitable for different tasks. This will help improve your projects.

Factors for Drill Bit Selection

When selecting a drill bit, consider several factors to ensure you select the correct tool. The material you are working with, the size of the hole required, and the desired finish all play a role. These things will improve the success of your project.

Material Type: Match the bit to the material.

The material type determines the right type of drill bit. For metal, you need bits designed for hard materials. For wood, you will need a brad point bit. Using the right bit is essential.

Hole Size: Choose the right size for the job.

Drill bits come in a variety of sizes. You need to find the correct size to make the hole you want. Drill bits help you do the job.

Finish Requirements: Choose a good finish.

If the finish is important, select a bit that provides a clean hole. Twist drill bits are good for general use. Consider your finishing needs.

Factors for Reamer Selection

Selecting a reamer also requires careful consideration of the job. You’ll need to know the hole’s final size, required accuracy, and desired surface finish. This will improve the outcome of your project. If you plan carefully, you can produce the results you want.

Hole Size and Tolerance: Measure with precision.

Reamers are best when precise sizing is needed. Make sure you use the right reamer size. Your parts will fit and work well.

Surface Finish: Consider the surface finish.

If you need a very smooth surface, reaming is the way to go. Reamers create a fine finish. This can improve the function of the parts.

Material and Application: Match the tool to the task.

Consider the material and what the hole will be used for. Ensure the reamer material is suited to the job. This will help make sure you have the outcome you want.

Common Mistakes and How to Avoid Them

It’s easy to make mistakes when using drill bits and reamers. These can lead to problems like incorrect hole sizes, poor finishes, or even damage to the materials. This will help you avoid common mistakes. This can prevent damage to your materials.

Mistakes with Drill Bits

Several errors can occur when using drill bits. Using the wrong bit, applying too much pressure, and not using the right speed can ruin a project. This ensures a more successful experience.

Using the Wrong Bit Type: Match the bit to the material.

Using a drill bit not designed for the material can lead to problems. Always use the right drill bit for wood, metal, or plastic. This will improve results.

Applying Too Much Pressure: Let the drill do the work.

Pushing too hard can cause the bit to break or create inaccurate holes. Allow the drill bit to cut at its own pace. This ensures a clean hole.

Using the Wrong Speed: Adjust speed to the material.

Drilling at the wrong speed can cause the bit to overheat or damage the material. For hard materials, use a lower speed. Adjust speed to the material.

Mistakes with Reamers

Using reamers incorrectly can also lead to mistakes. Applying excessive force, not using cutting fluid, and using a reamer in a hole that’s too small can ruin the process. By avoiding these common errors, you can ensure a successful outcome.

Forcing the Reamer: Let the reamer cut slowly.

Forcing the reamer can damage the tool or the hole. Ream slowly and steadily. This helps the reamer to work properly.

Not Using Cutting Fluid: Keep the process cool.

Cutting fluid can reduce heat. It also helps with the smoothness of the process. Always use cutting fluid with your reamer.

Reaming a Hole That is Too Small: Start with the right size.

Trying to ream a hole that is too small can break the reamer or damage the hole. Always drill a pilot hole. This is the correct size before reaming.

Frequently Asked Questions

Question: What’s the main difference between a drill bit and a reamer?

Answer: A drill bit creates a new hole or enlarges an existing one, while a reamer refines a pre-drilled hole for precise sizing and finish.

Question: Can I use a drill bit to make a hole very accurate?

Answer: Drill bits are good for general holes, but for high accuracy, use a reamer after drilling the initial hole.

Question: What’s the best drill bit for metal?

Answer: High-speed steel (HSS) drill bits are commonly recommended for metal due to their durability and ability to withstand heat.

Question: Do I always need to use cutting fluid when reaming?

Answer: It’s generally a good idea. Cutting fluid reduces friction and heat, leading to a better surface finish and longer tool life.

Question: What do I do if my drill bit gets stuck in the material?

Answer: Stop the drill immediately, reverse the rotation to remove the bit, and try again with less pressure or a slower speed. If the problem continues, consider a different bit type.

Final Thoughts

Mastering the use of a Drill Bit vs Reamer: When to Use Each Tool is a key skill for any maker, mechanic, or hobbyist. You have a solid grasp of how to choose the right tool for the job. Now you can create a starting hole or perfect an existing one. Remember to consider the material and the goal of your project when choosing between a drill bit and a reamer. Practice using the right techniques to improve. With practice, you’ll become a pro at drilling and reaming.