Drill Vs Impact Drill: Your Essential & Genius Choice

A standard drill is best for precision drilling and tasks requiring fine control, like making holes for dowels or furniture assembly. An impact drill (or impact driver) excels at driving long screws and large fasteners into tough materials with powerful, rapid rotational bursts, making it ideal for deck building or framing.

Hello, friends! Md Meraj here, from my workshop to yours. Step into the world of power tools, and you’ll quickly face a common question: “Should I get a drill or an impact drill?” It’s a bit confusing at first. They look similar, they both spin, and they both help you build amazing things. But trust me, they are very different tools designed for very different jobs.

Feeling stuck choosing between them? You’re not alone. Many new woodworkers and homeowners buy the wrong tool and end up with stripped screws or cracked wood. It can be so frustrating! But don’t worry. We’re going to clear this up together, nice and simple. In this guide, I’ll walk you through exactly what each tool does best, so you can pick the perfect one for your project with confidence. Let’s make a genius choice, shall we?

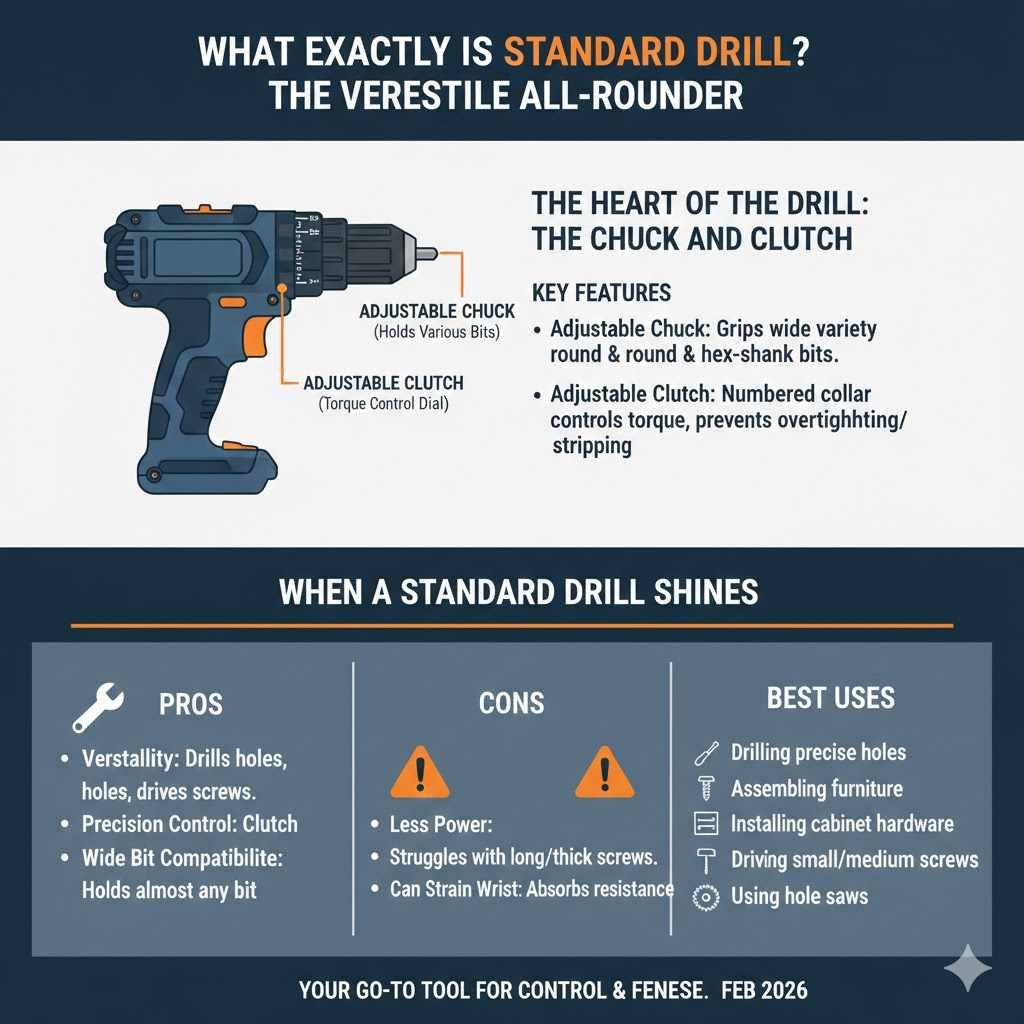

What Exactly Is a Standard Drill?

Let’s start with the tool everyone recognizes: the standard drill, often called a drill-driver. Think of it as the versatile all-rounder of your toolkit. Its main job is to spin a bit with consistent, smooth force. This steady rotation is what makes it so good at two key things: drilling clean holes and driving smaller screws with precision.

The Heart of the Drill: The Chuck and Clutch

The magic of a standard drill lies in two main parts: the adjustable chuck and the clutch.

- The Adjustable Chuck: This is the “mouth” at the front of the drill. You twist it to open and close three small jaws that grip the drill bit. Because it’s adjustable, it can hold a huge variety of round and hex-shank bits. This is what makes it perfect for drilling holes of all sizes.

- The Adjustable Clutch: The clutch is the ring with numbers on it, right behind the chuck. This is your control dial for torque (twisting power). A low number means less power, and the drill will “clutch out” or slip once the screw is tight. This feature is a lifesaver! It stops you from driving a screw too deep or stripping the screw head, which is essential for delicate projects like assembling furniture or cabinetry.

When a Standard Drill Shines

Your trusty drill-driver is the go-to tool for tasks that demand control and finesse. It’s not about brute force; it’s about getting the job done right.

Pros of a Standard Drill:

- Versatility: It drills holes and drives screws. It can also be used with accessories like wire wheels or sanding attachments.

- Precision Control: The adjustable clutch gives you complete control over the driving depth, preventing damage to your materials and fasteners.

- Wide Bit Compatibility: The adjustable chuck can hold almost any type of bit you can find, from tiny drill bits for pilot holes to larger hole saws.

- Lower Cost: Generally, a good quality drill-driver is more affordable than its impact counterpart.

Cons of a Standard Drill:

- Less Power for Tough Jobs: When driving long, thick screws into dense wood, a standard drill can struggle and may require you to apply a lot of physical force.

- Can Strain Your Wrist: Because the force is applied directly and consistently, your wrist and arm absorb the resistance. This can be tiring during repetitive, heavy-duty tasks.

Best Uses for a Standard Drill-Driver:

- Drilling precise holes in wood, metal, drywall, and plastics.

- Assembling flat-pack furniture without overtightening screws.

- Installing cabinet hardware.

- Driving small to medium-sized screws where precision is key.

- Using hole saws to cut large-diameter holes.

What Is an Impact Drill (Impact Driver)?

Now, let’s talk about the standard drill’s powerful cousin: the impact drill, more commonly known as an impact driver. This tool is a specialist. While it looks like a drill, it works in a completely different way. Its primary mission is to drive fasteners, especially long screws and lag bolts, with incredible speed and power.

The Power Inside: Hammers and Anvils

An impact driver doesn’t just spin; it also punches. Inside the tool is a spring, a hammer, and an anvil. As you drive a screw and the tool feels resistance, the internal mechanism kicks in. The hammer rapidly strikes the anvil thousands of times per minute. These quick, powerful rotational blows (the “impacts”) create immense torque.

Think of it like trying to loosen a stubborn bolt on a car wheel. You could pull on a wrench with all your might (like a drill), or you could hit the end of the wrench with a hammer (like an impact driver). The sharp taps deliver more effective power. This mechanism means the tool does the hard work, not your wrist.

The Chuck of an Impact Driver

You’ll immediately notice one big difference: the chuck. An impact driver has a quick-release collet that only accepts 1/4-inch hex-shank bits. You simply push the bit in to lock it. This design is built for high-torque applications and ensures bits won’t slip.

When an Impact Driver is the Champion

Bring out the impact driver when you need serious driving power without the wrist strain. It makes demanding jobs feel almost effortless.

Pros of an Impact Driver:

- Massive Torque: It can drive the longest screws and bolts into the densest materials with ease.

- Less User Fatigue: The impact action transfers the force to the screw, not your arm. You can drive hundreds of screws with minimal strain.

- Faster Driving Speed: The combination of high speed and high torque drives fasteners much quicker than a standard drill.

- Compact and Lightweight: They are typically smaller and lighter than drills of similar power, making them great for tight spaces.

Cons of an Impact Driver:

- Lack of Precision: It has no adjustable clutch. It’s all power, all the time, which can easily overtighten screws, strip heads, or crack delicate wood.

- Not for Drilling: While you can use special hex-shank drill bits, it’s not ideal. The percussive action can lead to messy, imprecise holes.

- Loud: The hammering mechanism is very loud. Hearing protection is an absolute must!

- Limited Bit Compatibility: It only accepts 1/4-inch hex-shank bits.

Best Uses for an Impact Driver:

- Building a deck or fence.

- Driving long screws for framing or subfloors.

- Working with large fasteners like lag screws or lag bolts.

- Any high-volume screw-driving job where speed and power are more important than delicate precision.

Drill vs Impact Drill: A Side-by-Side Showdown

Sometimes the easiest way to see the difference is to put them head-to-head. Here’s a simple table to help you compare their core features at a glance.

| Feature | Standard Drill-Driver | Impact Driver |

|---|---|---|

| Primary Function | Drilling precise holes & controlled screw driving | Driving long screws & large fasteners with high torque |

| Mechanism | Consistent rotational force | Rotational force + rapid concussive blows (impacts) |

| Chuck Type | Adjustable 3-jaw chuck | 1/4″ hex quick-release collet |

| Torque Control | Yes (Adjustable clutch) | No (Variable speed trigger only) |

| User Fatigue | Higher wrist strain on tough jobs | Very low wrist strain |

| Noise Level | Relatively quiet | Very loud |

| Best For… | Fine woodworking, furniture assembly, drilling clean holes | Deck building, framing, driving lag bolts, repetitive driving |

Choosing the Right Tool for Your Project

Understanding the “what” is great, but the “when” is what really matters in your workshop. Let’s make this super practical. Here’s a quick guide on which tool to grab for common DIY and woodworking tasks.

Grab Your Standard Drill-Driver When…

- You are Assembling Furniture: The adjustable clutch is your best friend. Set it to a low number to drive screws perfectly snug without damaging the particleboard or stripping the hardware.

- You Need to Drill a Clean Hole: Whether it’s a pilot hole for a screw or a larger hole for a dowel, the smooth, steady action of a drill gives you a clean entry and exit, preventing tear-out.

- You Are Working with Softwoods: Pine and other softwoods can split easily under too much power. A drill gives you the gentle touch needed to secure fasteners without cracking the wood.

- You are Installing Hardware: For hinges, knobs, and drawer pulls, precision is everything. A drill lets you place small screws exactly where you want them.

Grab Your Impact Driver When…

- You are Building a Deck: Driving hundreds of 3-inch deck screws is the perfect job for an impact driver. It will save your arm and get the job done in a fraction of the time.

- You are Driving Lag Screws: Securing a ledger board to a house or assembling a playset with big lag screws requires immense torque. The impact driver handles this with ease.

- You are Working in a Tight Space: Because they are often more compact, impact drivers can be easier to maneuver between studs or inside cabinets.

- You Need to Remove a Stubborn, Rusted Screw: The jarring impacts can often break a rusted fastener free when a standard drill would just spin and strip the head.

This simple table can serve as your quick-reference cheat sheet in the workshop.

| Task | Recommended Tool | Why? |

|---|---|---|

| Building a deck frame | Impact Driver | High power is needed for driving long structural screws quickly. |

| Assembling an IKEA bookshelf | Standard Drill | The adjustable clutch prevents over-tightening and damaging the material. |

| Drilling holes for shelf pins | Standard Drill | Provides the precision and clean-cut hole needed for a snug fit. |

| Installing drywall | Standard Drill (with a drywall dimpler bit) | Offers better control to set screws to the perfect depth without tearing paper. |

| Driving concrete anchor screws | Impact Driver | Requires high torque to drive fasteners into masonry. |

Safety First: A Word of Caution

No matter which tool you choose, safety is always the most important project. These are powerful tools, and treating them with respect is key to a lifetime of happy building. Here are a few essential safety tips.

- Wear Safety Glasses: This is non-negotiable. Sawdust, metal shards, or a broken bit can cause serious eye injury. Always protect your eyes.

- Use Hearing Protection with Impact Drivers: An impact driver can be as loud as 100 decibels or more. Consistent exposure can damage your hearing. Wear earplugs or earmuffs.

- Use the Right Bit for the Job: Use impact-rated (often black oxide) bits in your impact driver. Standard bits can shatter under the intense force.

- Secure Your Workpiece: Use clamps to hold your material firmly in place. This prevents it from spinning or flying off while you are working.

- Maintain a Firm Grip: Always use two hands when possible, especially when drilling large holes, as the tool can bind and twist unexpectedly. For more in-depth guidance on power tool safety, resources like the U.S. Occupational Safety and Health Administration (OSHA) offer excellent, authoritative information.

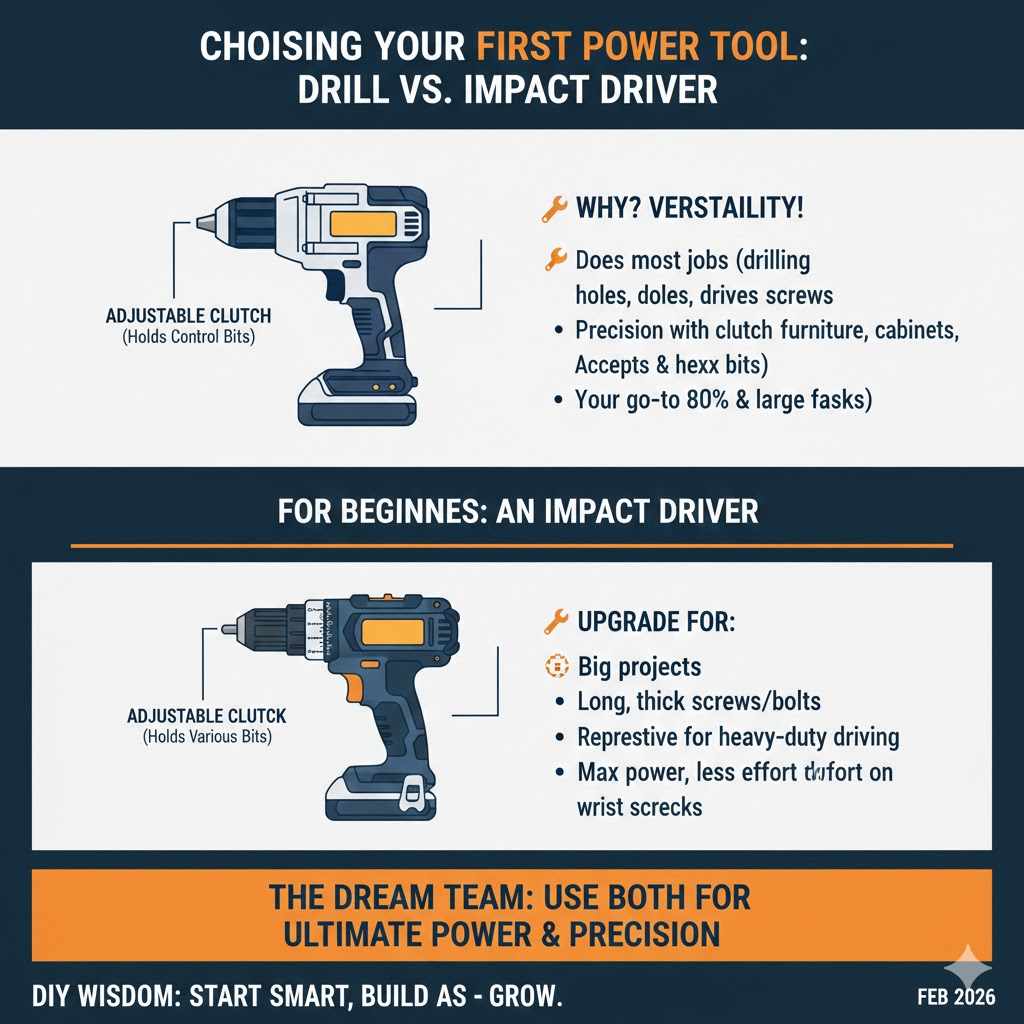

So, Which One Should You Buy First?

This is the ultimate question for a beginner building their toolkit. My advice is almost always the same: Start with a good quality cordless drill-driver.

Why? Because of its versatility. A standard drill can do most of what an impact driver can do (just slower and with more effort), but an impact driver cannot do what a drill does well (like drilling clean holes or delicate driving). The drill-driver is the jack-of-all-trades that will see you through the vast majority of your initial home repair and DIY projects.

You can build furniture, hang pictures, repair a fence post, and drill countless holes with just one tool. Once your projects get bigger and you find yourself driving a lot of long screws—like building a deck or a workshop bench—that’s the perfect time to add an impact driver to your collection. Having both is the dream setup for any serious DIYer, as they truly are a perfect team.

Conclusion: The Right Tool for a Job Well Done

So, the great debate of “drill vs impact drill” isn’t about which tool is better overall, but which tool is brilliantly designed for the specific task in front of you. They are not rivals; they are teammates. The drill-driver is your precision artist, focused on control and finesse. The impact driver is your powerhouse, ready for heavy lifting and speed.

By understanding their unique strengths, you can move past the confusion and start making confident, smart choices in your workshop. You’ll work faster, get better results, and most importantly, feel that incredible satisfaction of a job done right. Now go ahead, pick up the right tool, and build something wonderful!

Frequently Asked Questions (FAQ)

1. Can I use a drill as an impact driver?

You can use a standard drill to drive screws, but it will struggle with long or large fasteners in hard materials. It lacks the rotational impacts that make an impact driver so effective and will put more strain on your wrist and the tool’s motor.

2. Can I drill holes with an impact driver?

Yes, but it’s not ideal. You need to use special hex-shank drill bits. The percussive action of the impact driver can make it difficult to start a hole accurately and often results in a less clean, slightly triangular hole. For precise, round holes, a standard drill is always better.

3. Do I need both a drill and an impact driver?

For a beginner or casual homeowner, a good quality drill-driver is usually enough to handle most tasks. However, if you plan on doing a lot of building projects like decks, framing, or furniture from scratch, owning both will save you a huge amount of time and effort. They complement each other perfectly.

4. Why is my impact driver so loud?

The loud noise is a normal part of its operation. It comes from the internal hammer striking the anvil at high speed to create torque. This is why wearing hearing protection is absolutely essential when using an impact driver.

5. What does the clutch on my drill do?

The clutch is a torque-limiting feature. The numbers on the collar behind the chuck correspond to different torque settings. A low number delivers less twisting force and is good for small screws in soft materials. A high number delivers more force for larger screws. When the set torque is reached, the clutch disengages the motor with a clicking sound to prevent you from over-driving the screw.

6. What are impact-rated bits and why do I need them?

Impact-rated bits are made from a more ductile type of steel that can withstand the sudden, high-torque forces of an impact driver. Standard screwdriver bits are more brittle and can easily shatter under that stress, which can be dangerous. Always match the bit to the tool.

7. Corded or cordless for my first drill?

For a beginner, a cordless drill offers incredible convenience and is powerful enough for almost all home and DIY tasks. Modern battery technology is excellent. Corded drills offer consistent power without worrying about charging, but the cord can be cumbersome. I recommend a quality 18V or 20V cordless drill as the best first choice.